Automotive leather cutting station

A technology of cutting table and turntable, which is applied in leather punching/punching/cutting, raw hide/leather/fur manufacturing equipment, small raw hide/large raw hide/leather/fur treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

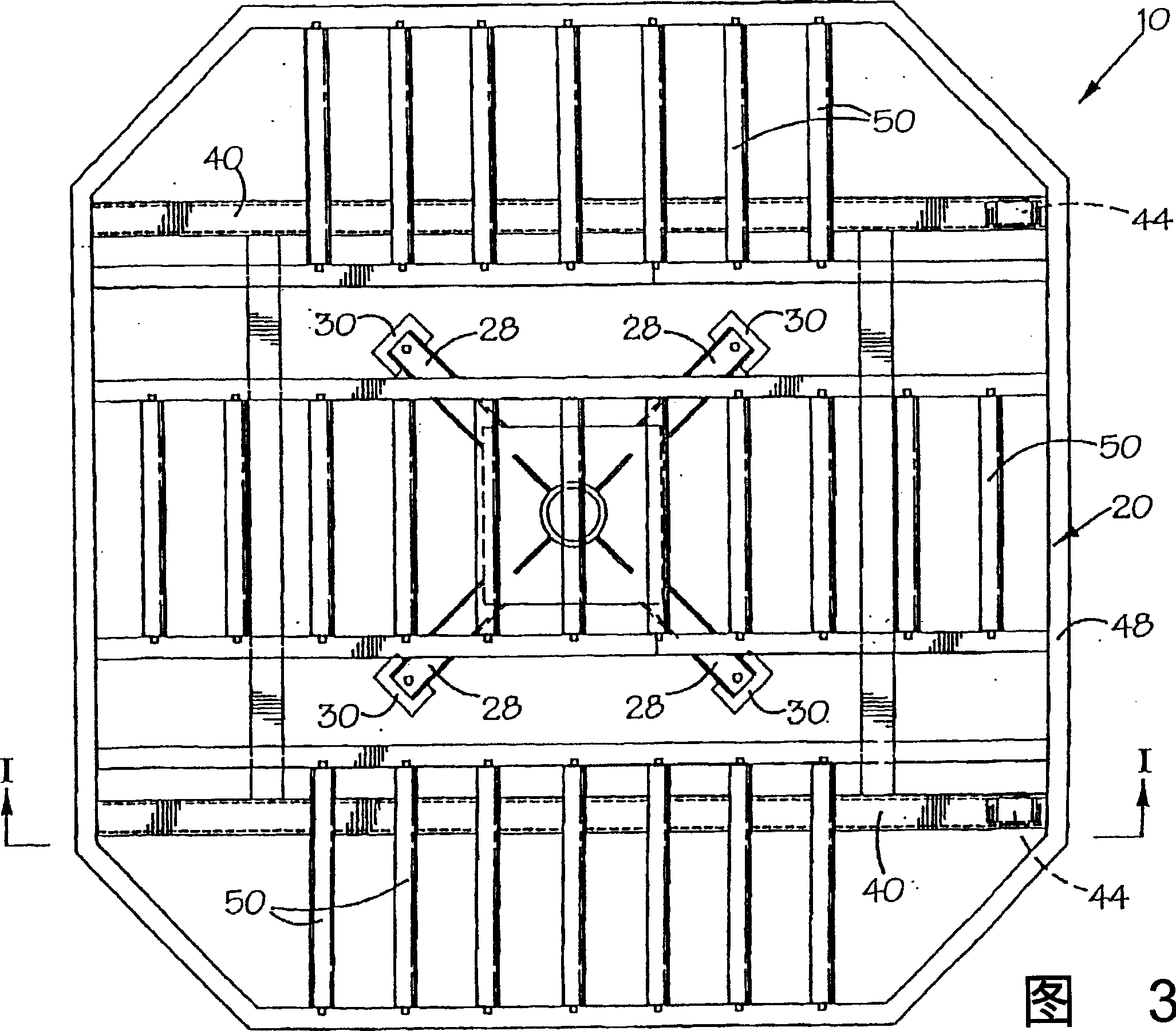

[0019] For purposes of the ensuing description, the terms "upper", "lower", "right", "left", "vertical", "horizontal", "top", "bottom", "lateral", "horizontal" and derivatives thereof , all relevant to the present invention, are oriented in the drawings. It should be understood, however, that the invention is capable of various alternative variations unless otherwise specified elsewhere. It should also be understood that the particular devices depicted in the drawings, hereinafter, are merely exemplary of the invention. Therefore, specific dimensions and other physical characteristics related to the embodiments disclosed herein are not limitations of the present invention.

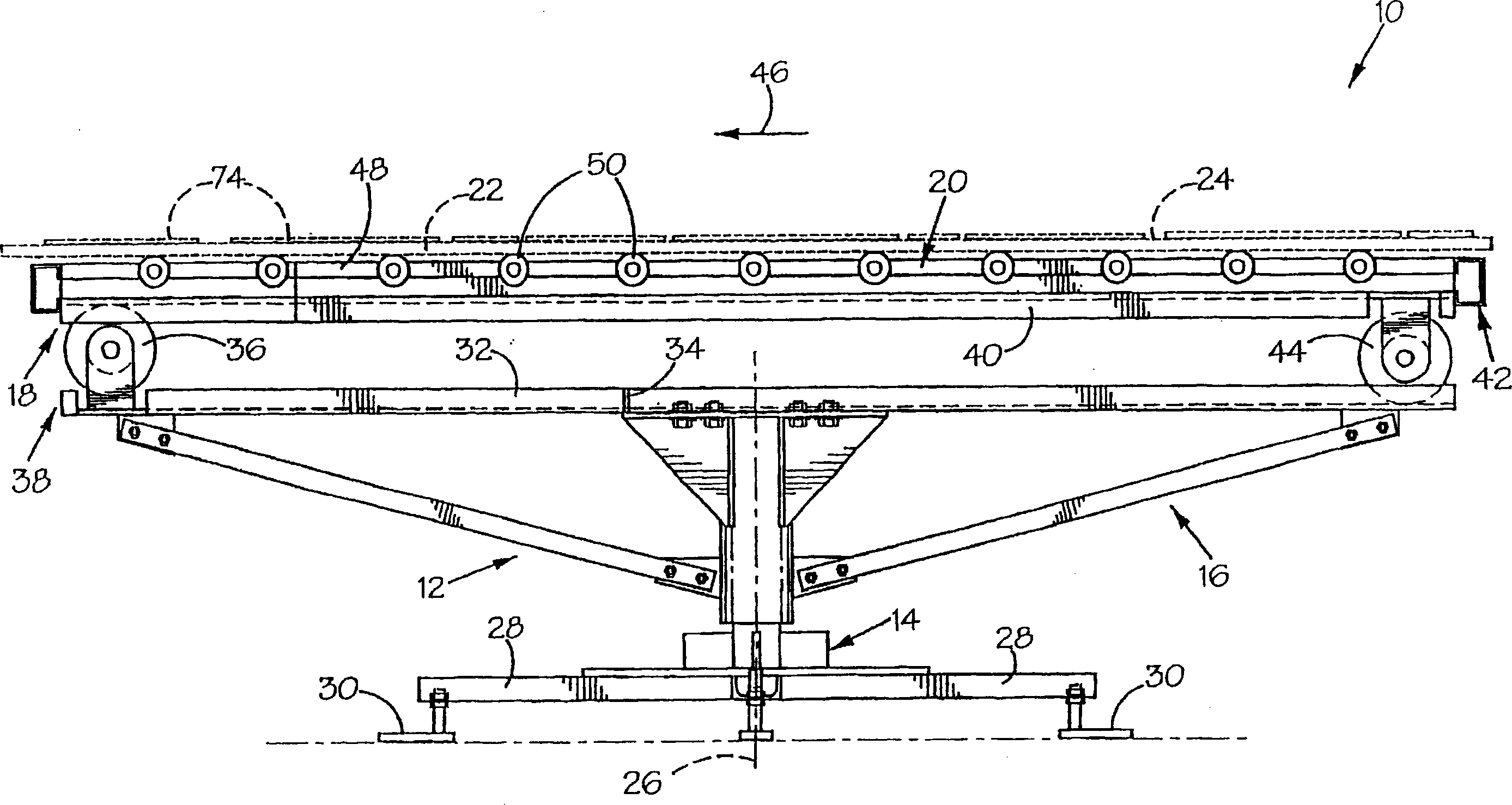

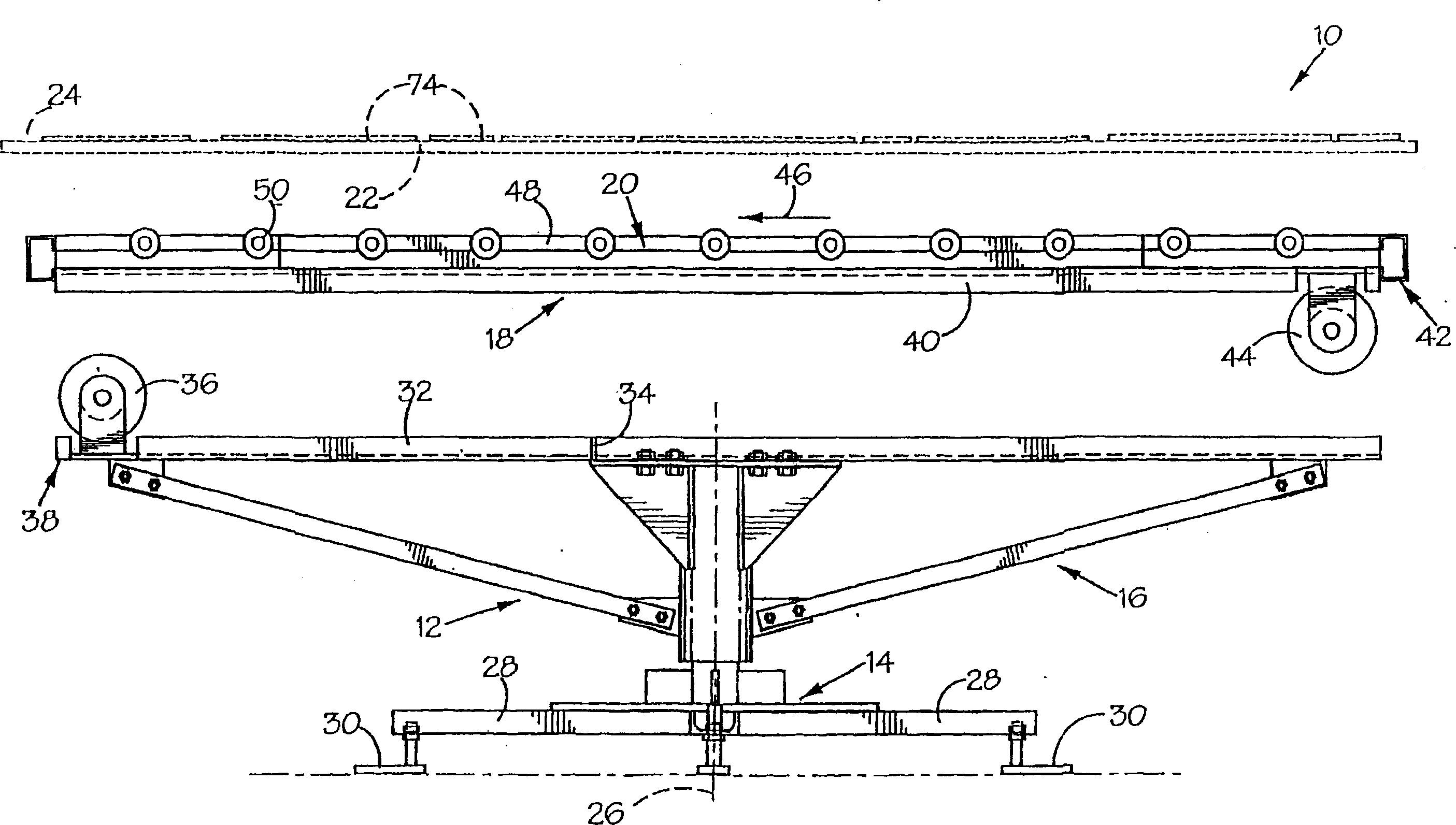

[0020] see figure 1 with 2 , the sheet cutting table 10 includes: a base 12 having a foot member 14 and a turntable member 16 . Cutting table 10 also includes a work surface 18 having supports 20 . The turntable member 16 is rotatably mounted on the base 12 for rotation about a generally vertical axis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com