Patents

Literature

32results about How to "Moving linear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

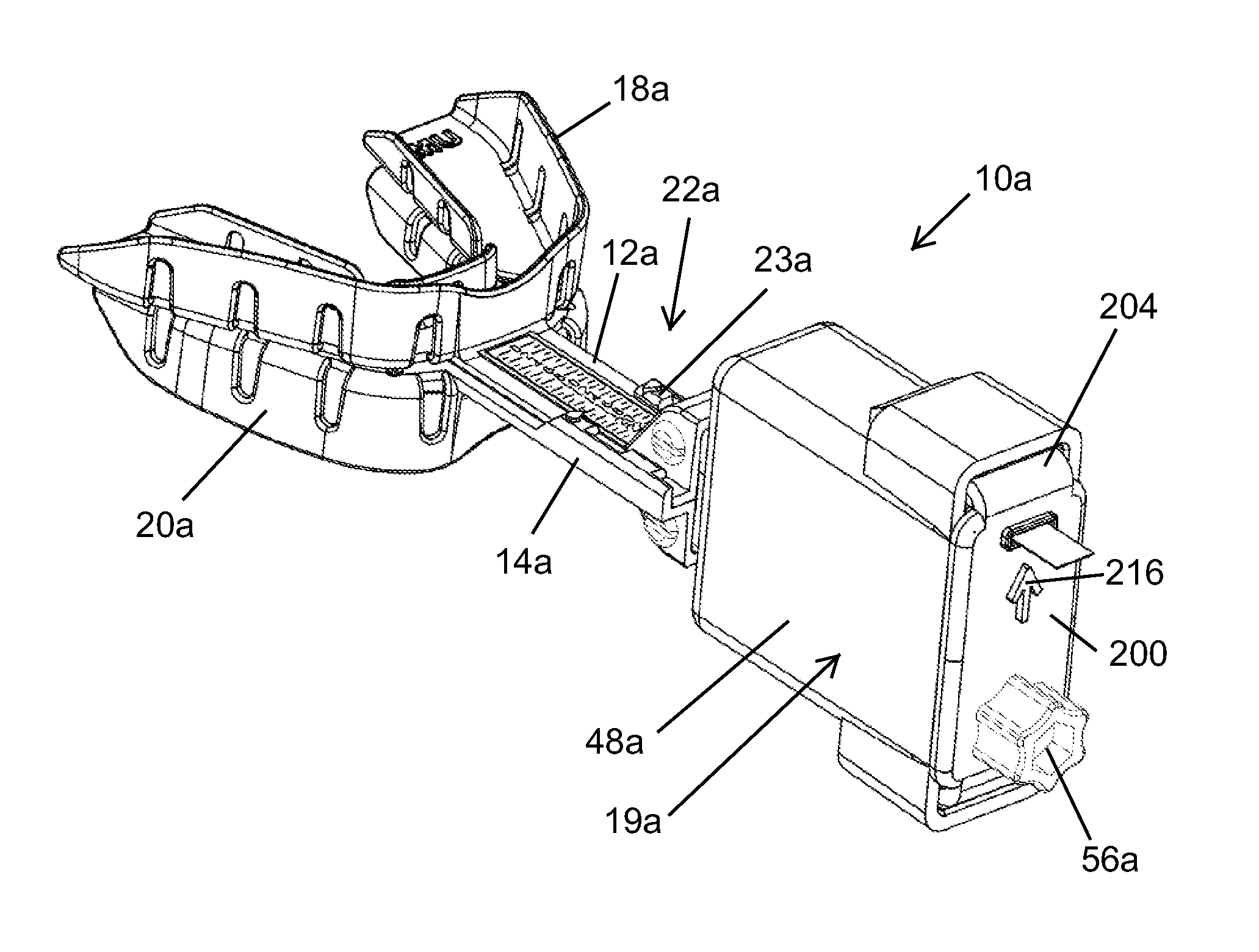

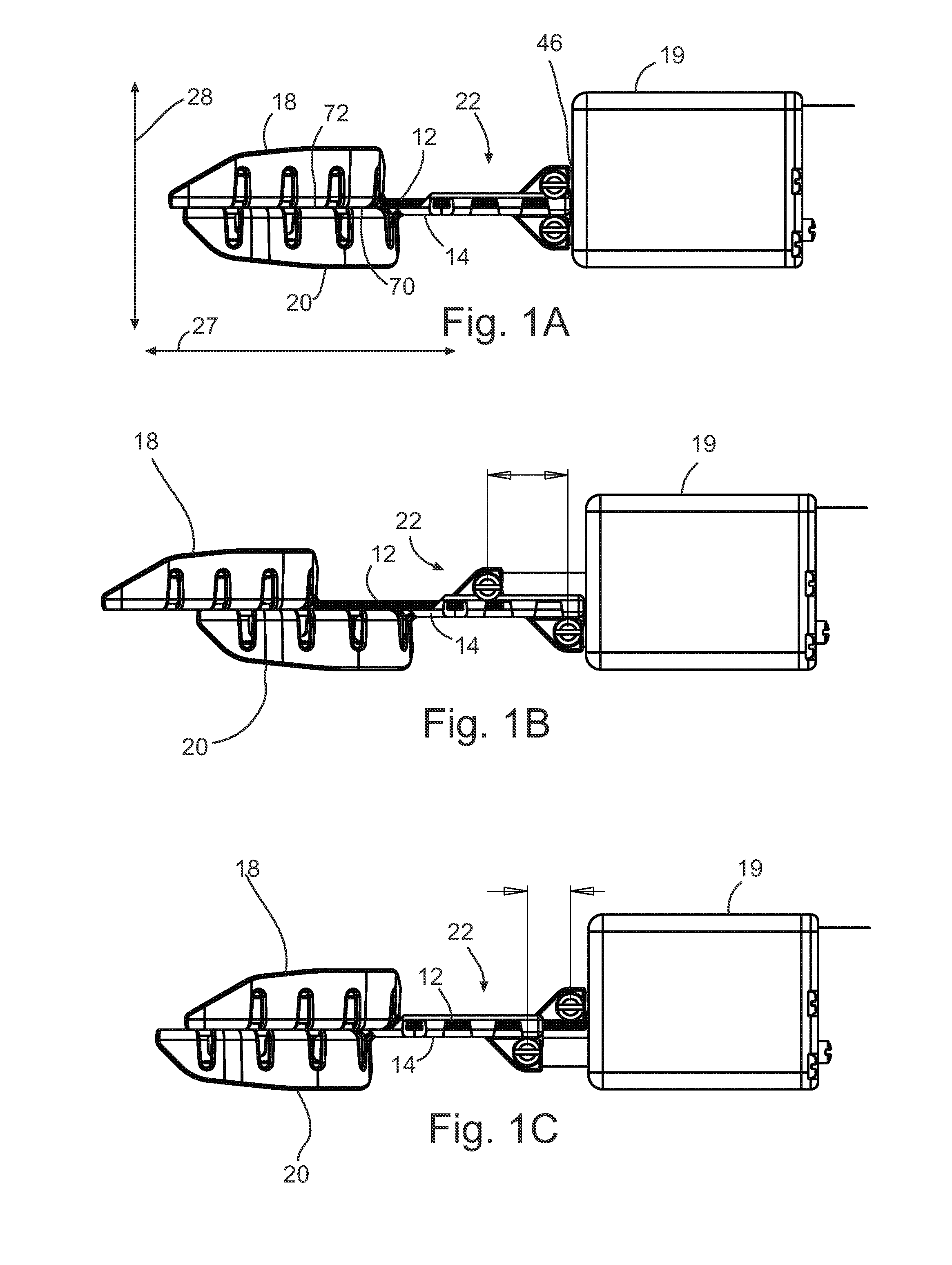

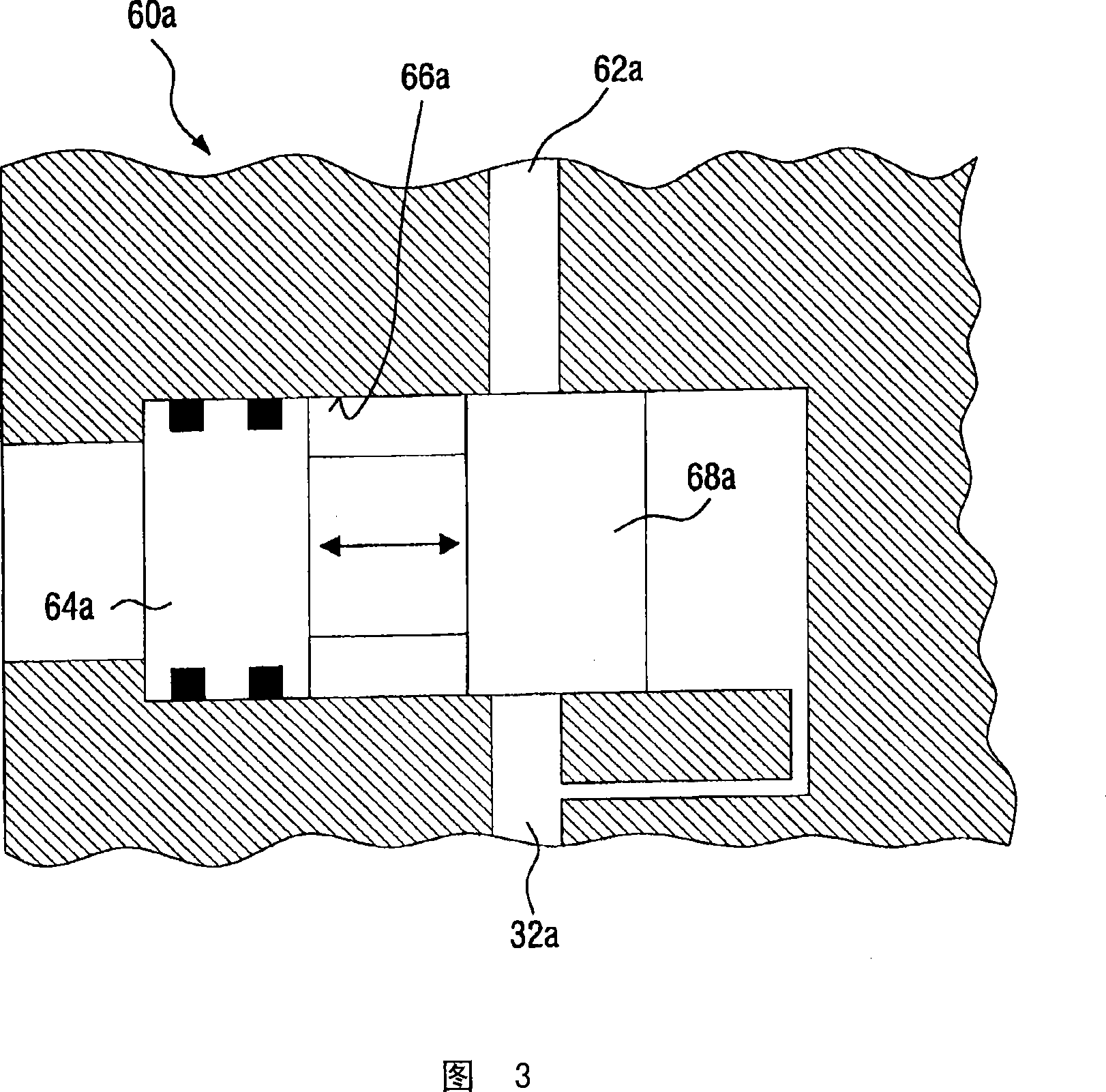

Apparatuses and Methods for Mandibular Protrusion

InactiveUS20100316973A1Moving linearImpression capsPerson identificationProminent mandibleDrive motor

Embodiments of methods and mandibular protruders and positioning devices, comprising, for example: an upper mounting bracket having an upper dental appliance; a lower mounting bracket having a lower dental appliance; and a rail system configured to couple the upper mounting bracket to the lower mounting bracket. Some embodiments comprise a drive motor and / or an initial position adjustment mechanism.

Owner:ZST HLDG

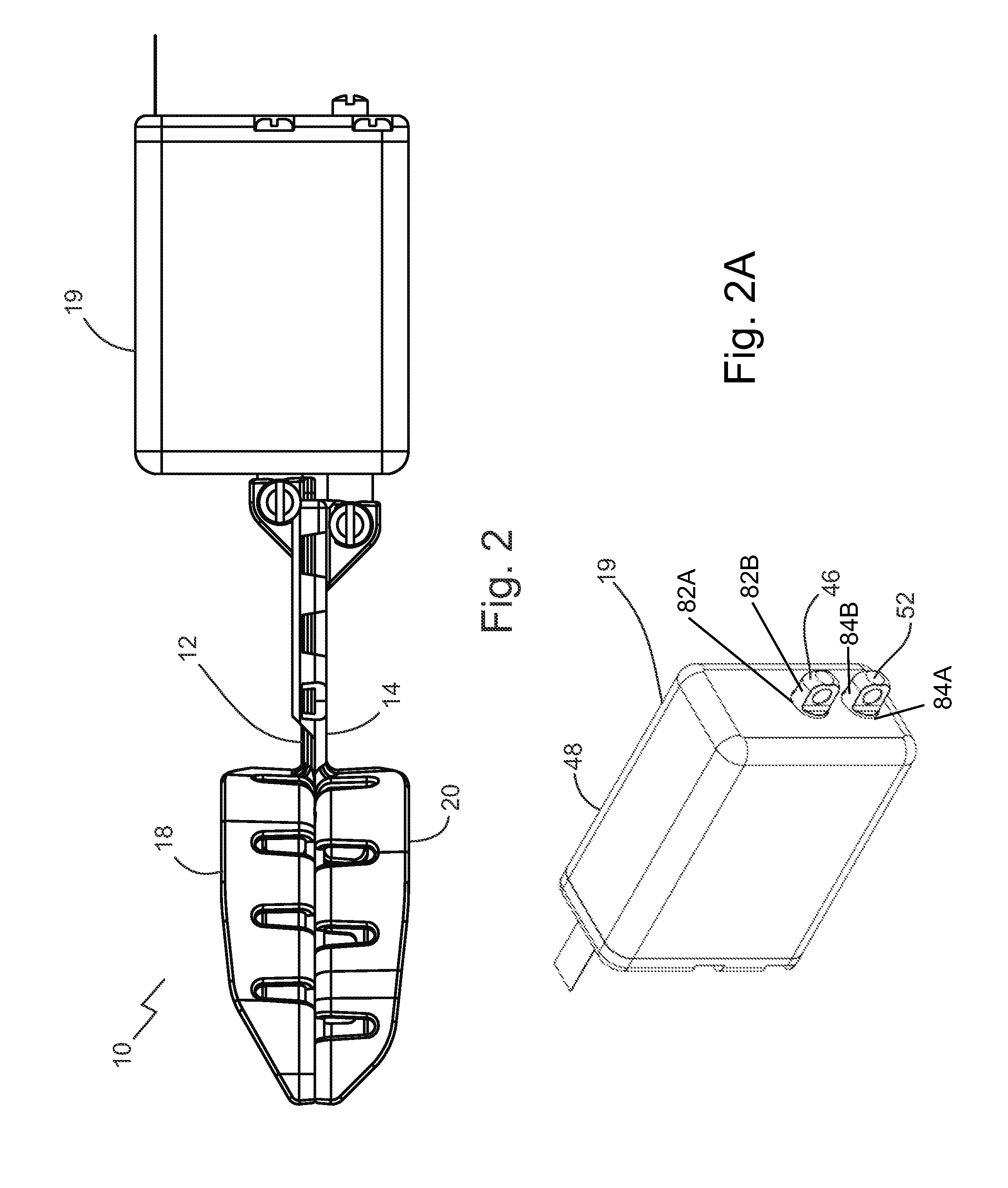

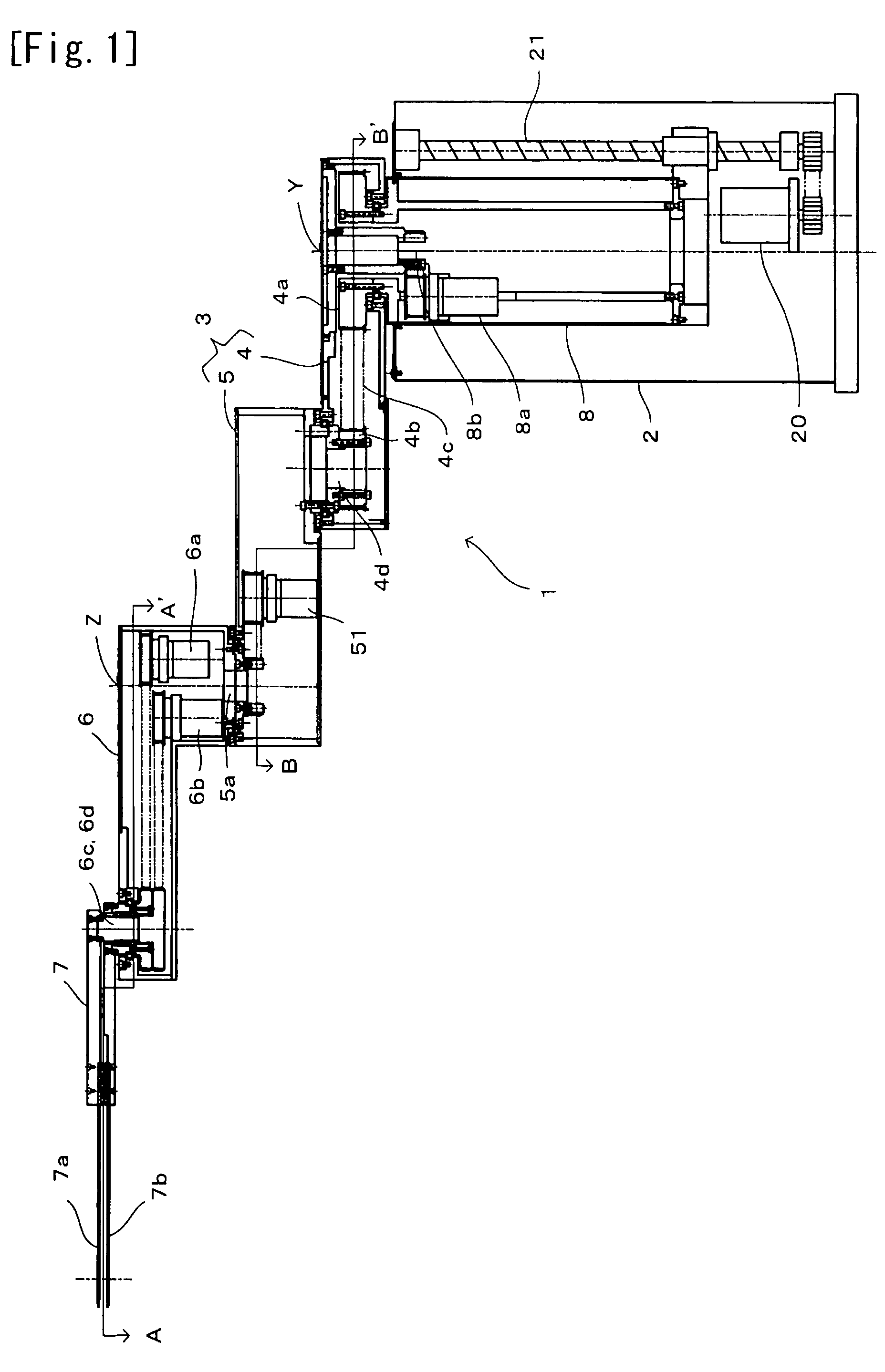

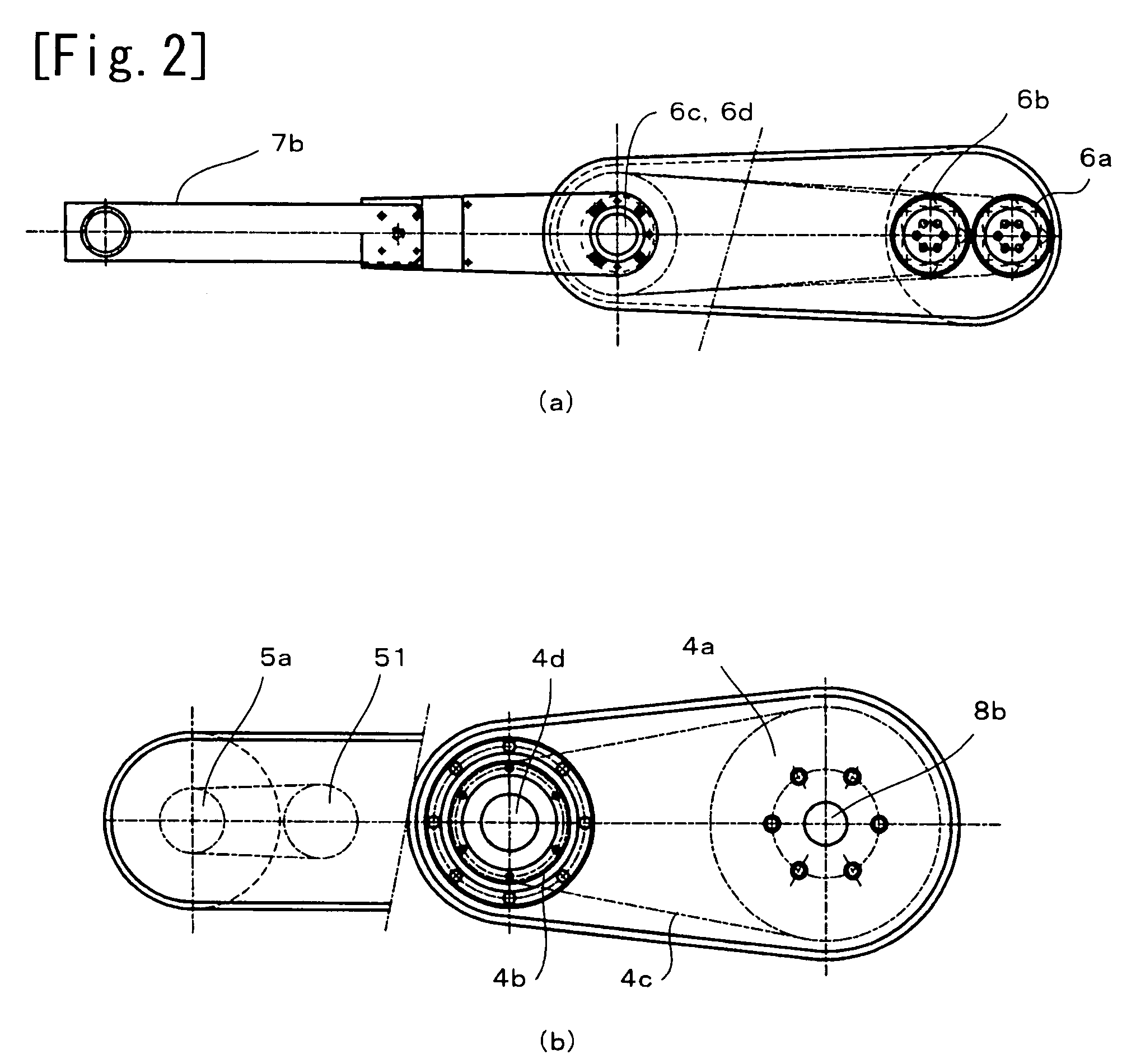

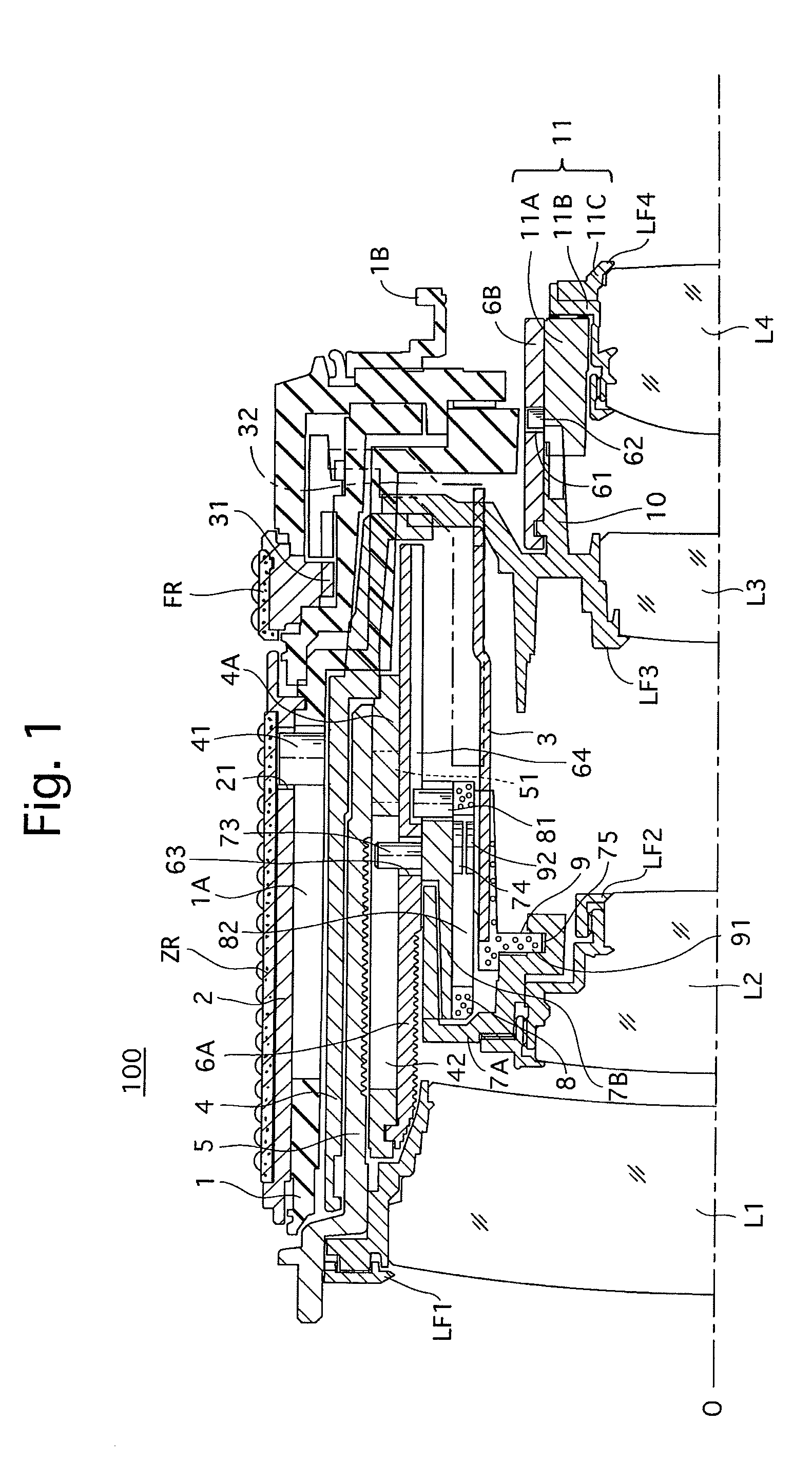

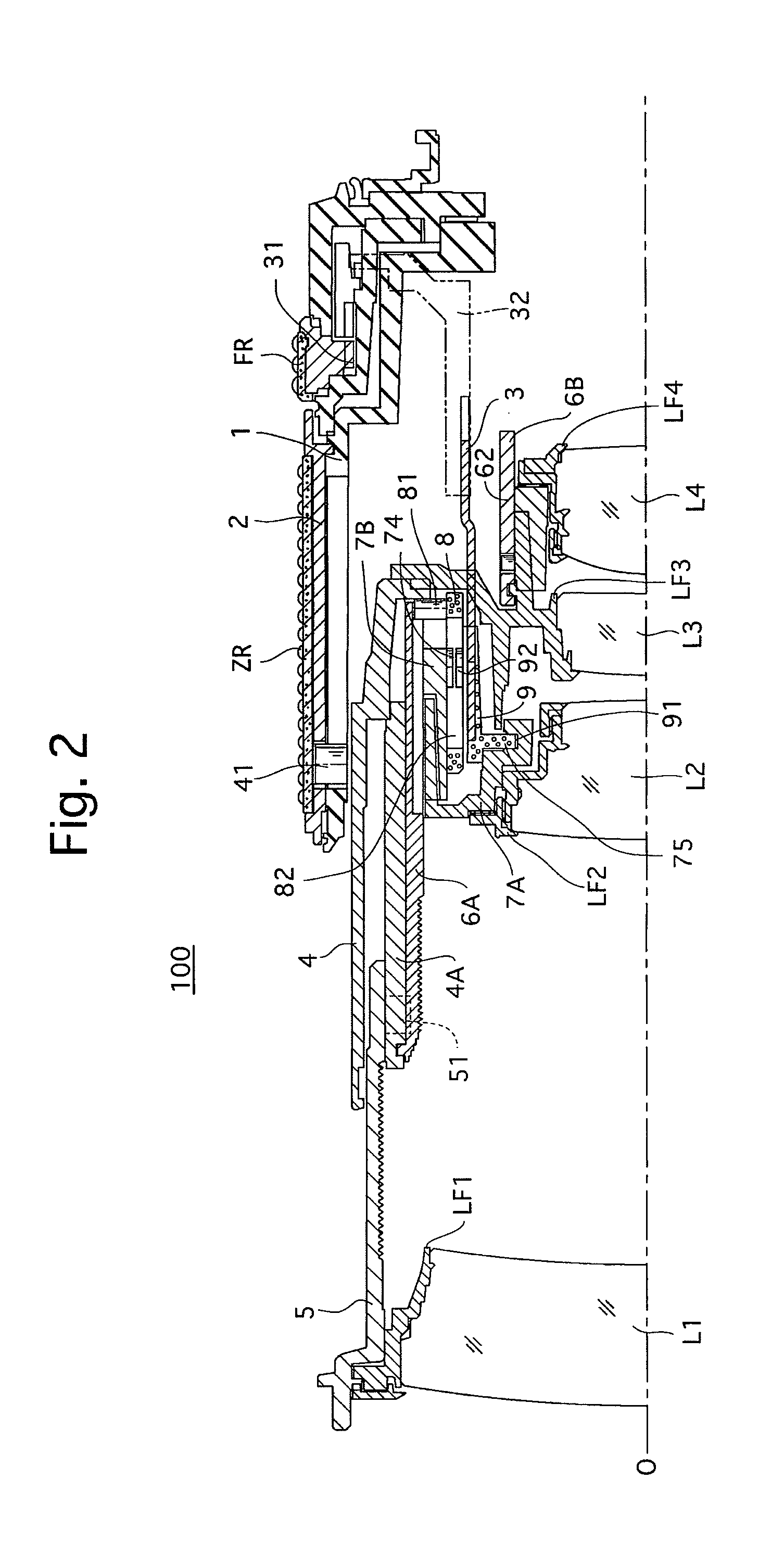

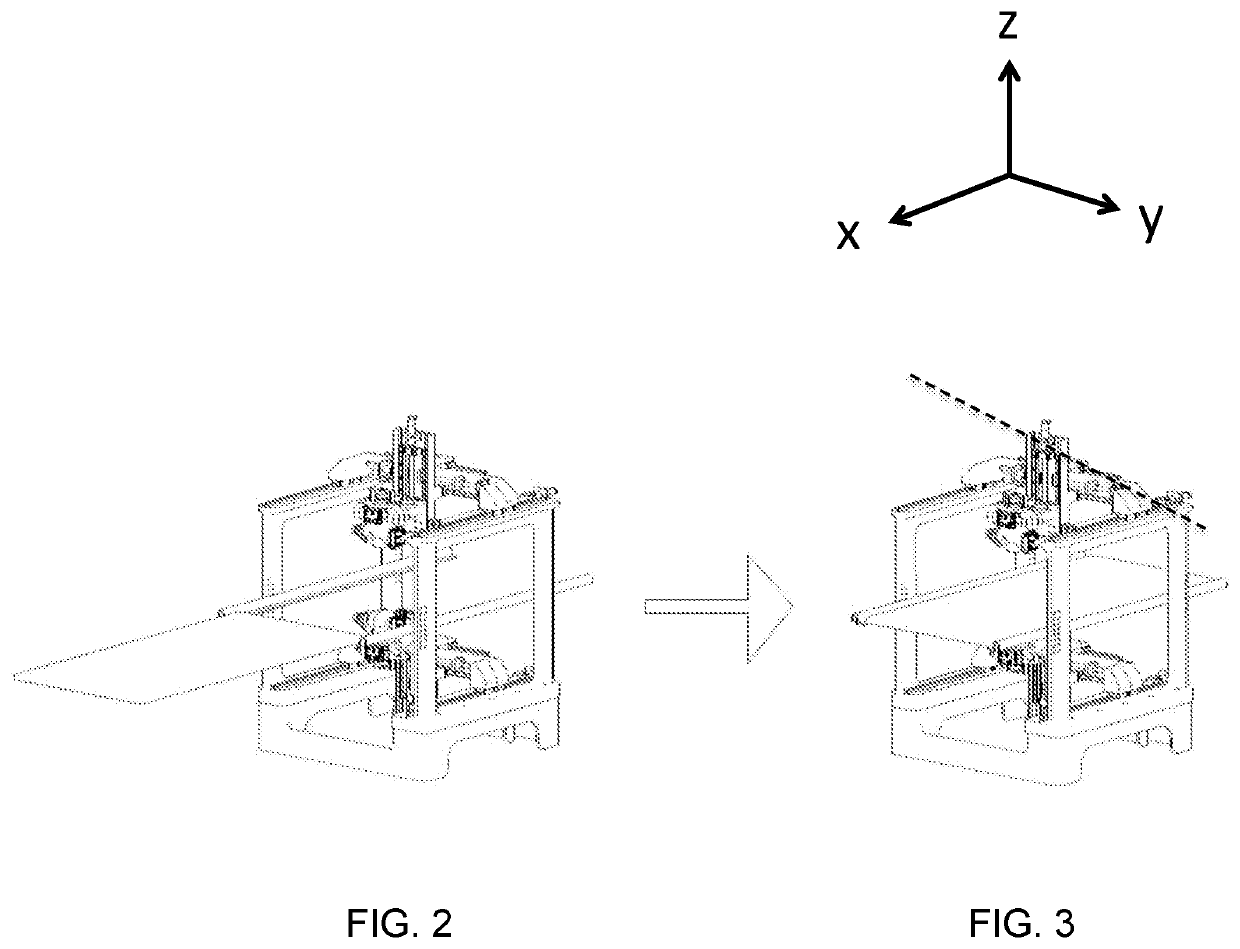

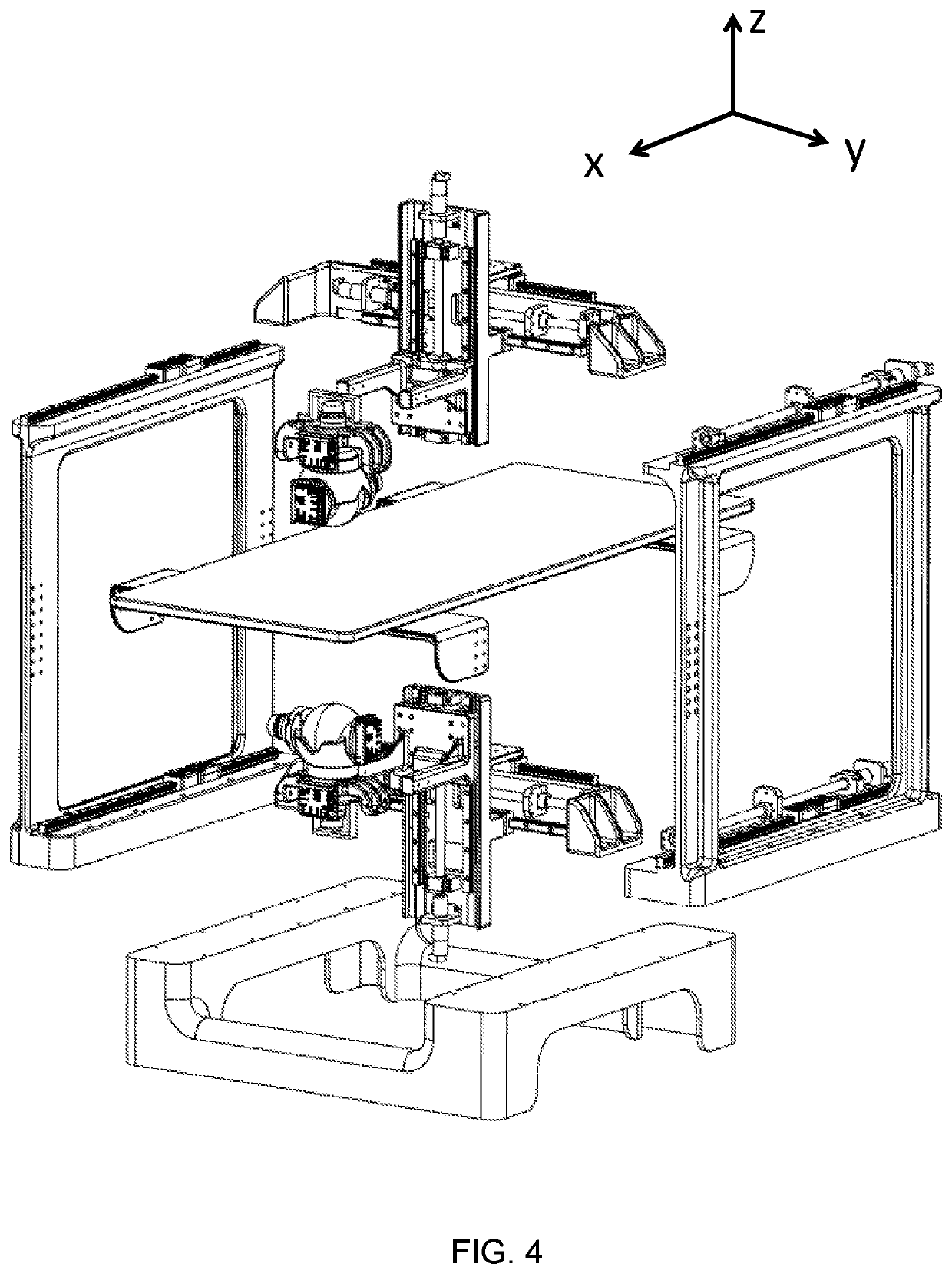

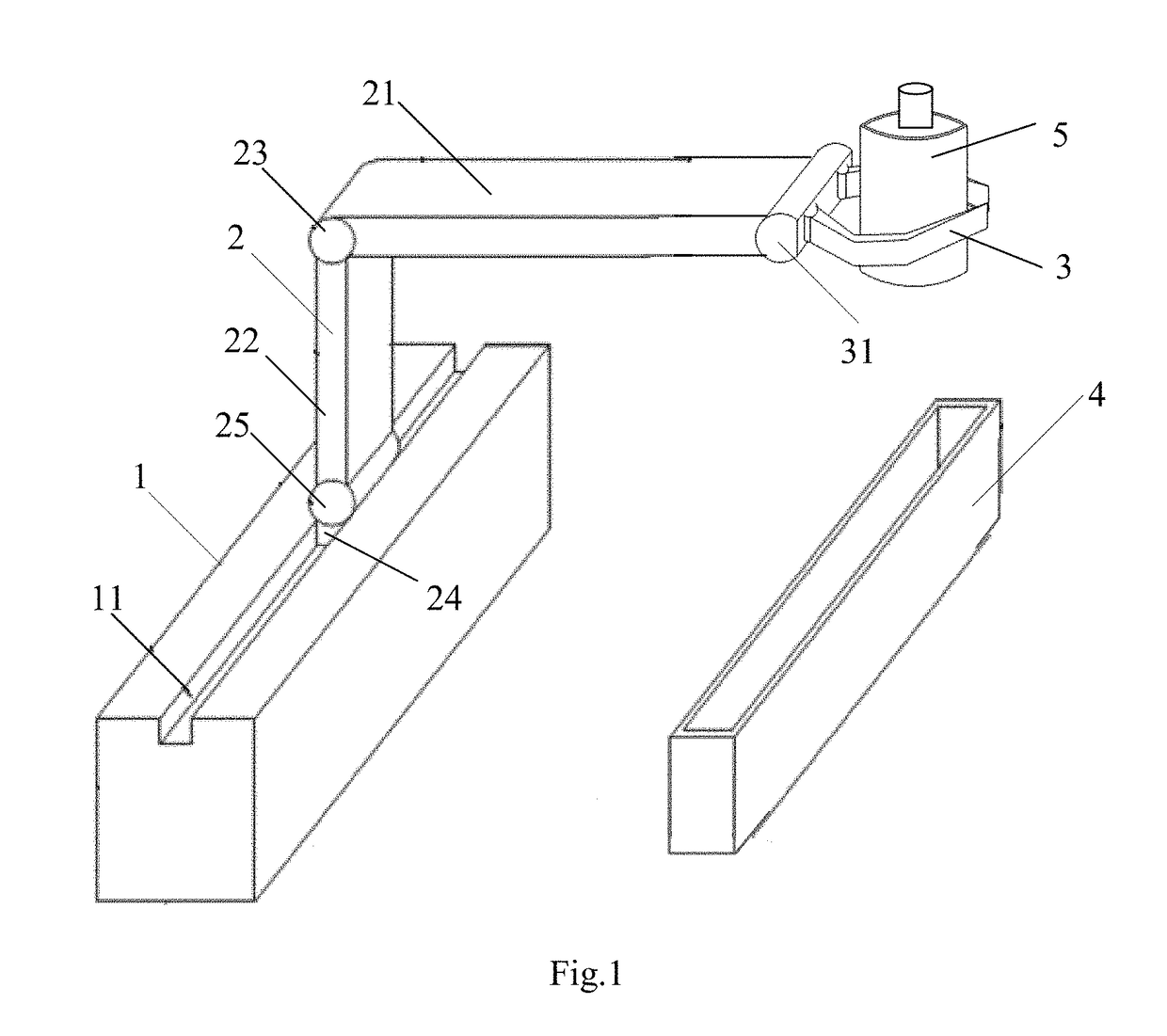

Articulated robot

ActiveUS8136422B2Stable to carryReduce distanceProgramme-controlled manipulatorMechanical apparatusEngineeringMechanical engineering

A multi-joint robot for loading / unloading a work into / from a cassette, which includes a hand part holding the work, an arm part rotatably holding the hand part, a link mechanism rotatably holding the base end side of the arm part and moving so that the moving route of the base end side of the arm part becomes linear in a direction roughly orthogonal to a direction for loading / unloading the work, and a driving device for moving the tip side of the arm part so as to linearly interpolate it in a direction for loading / unloading the work according to the movement of the link mechanism.

Owner:SANKYO SEIKI MFG CO LTD

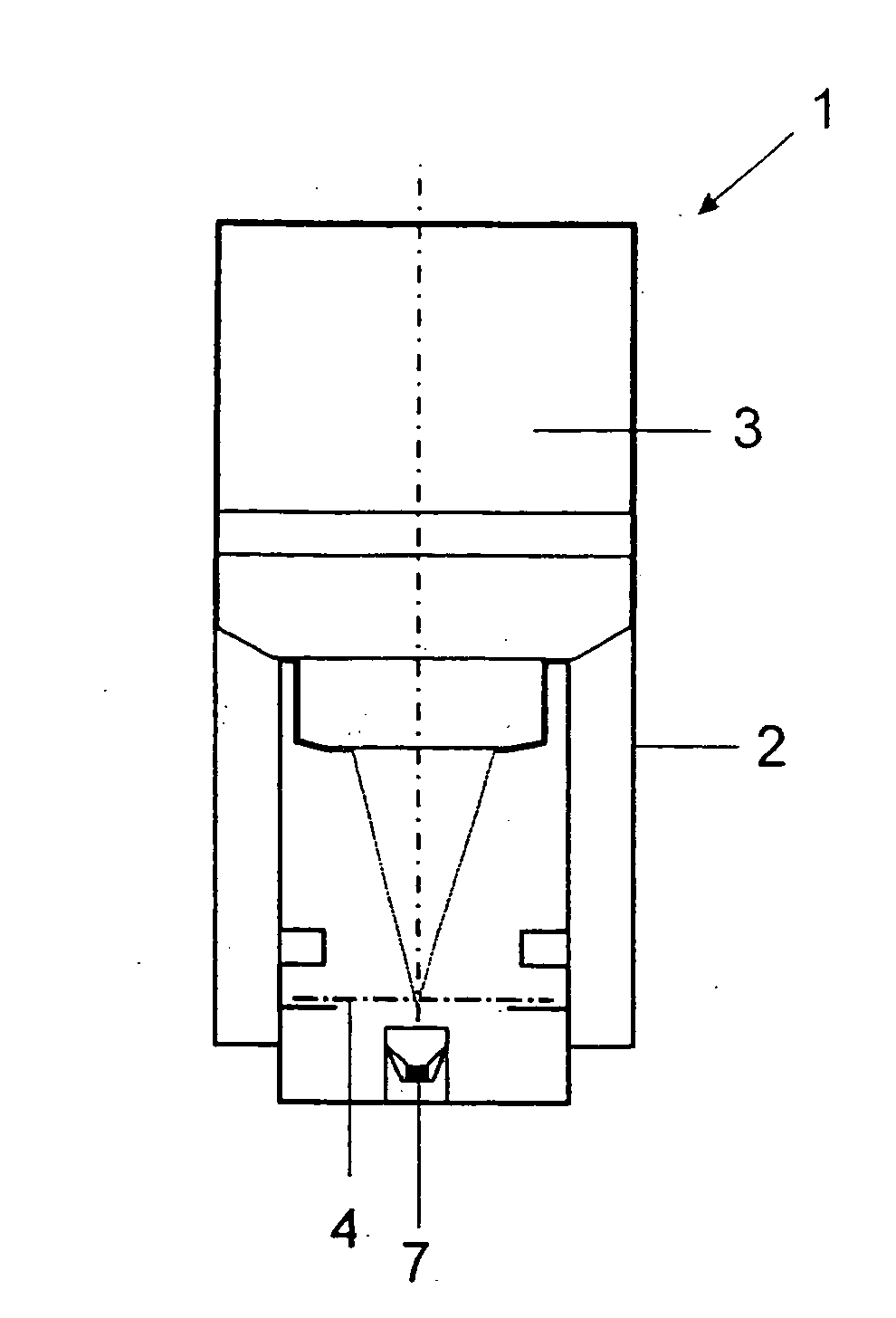

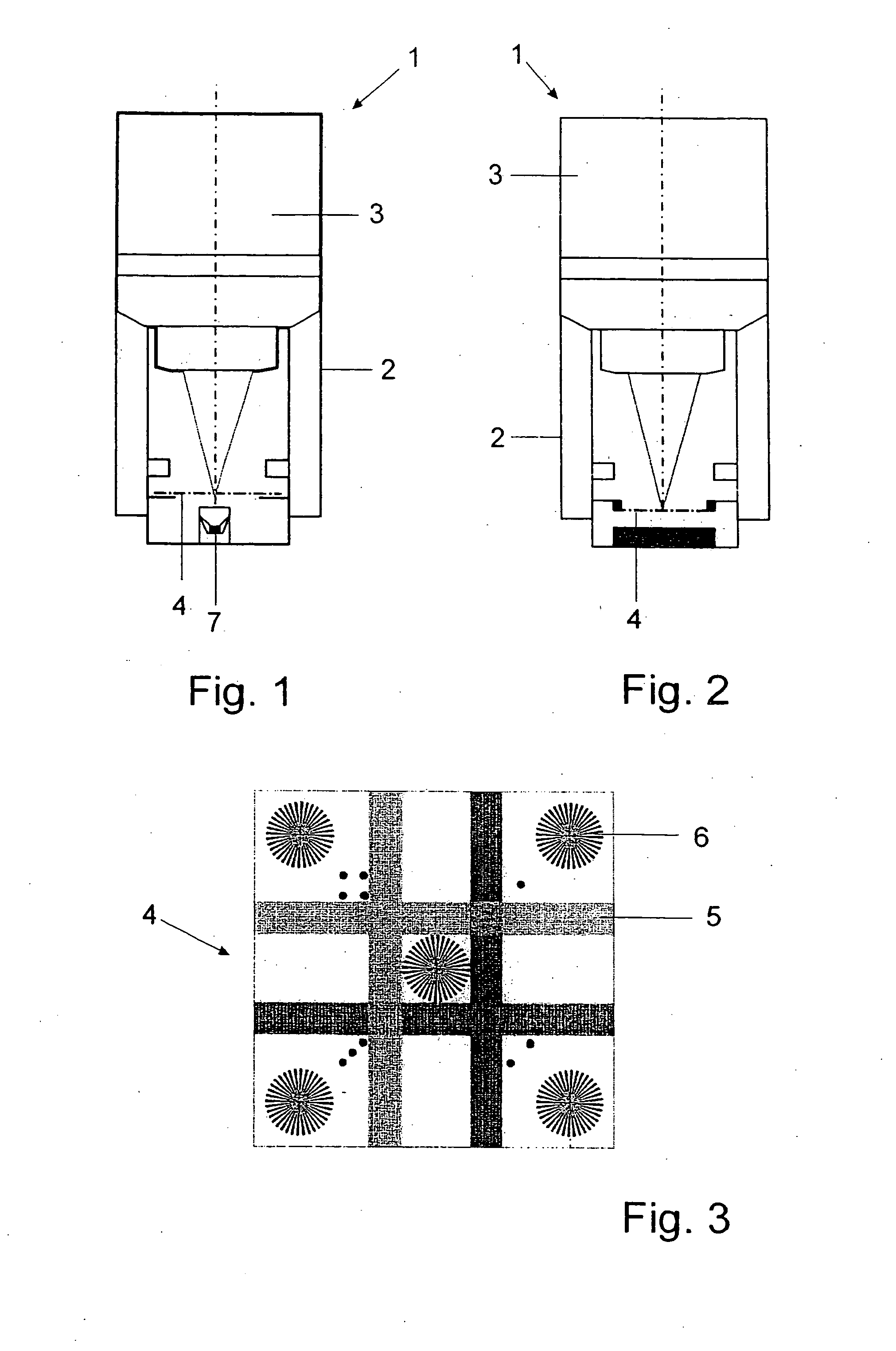

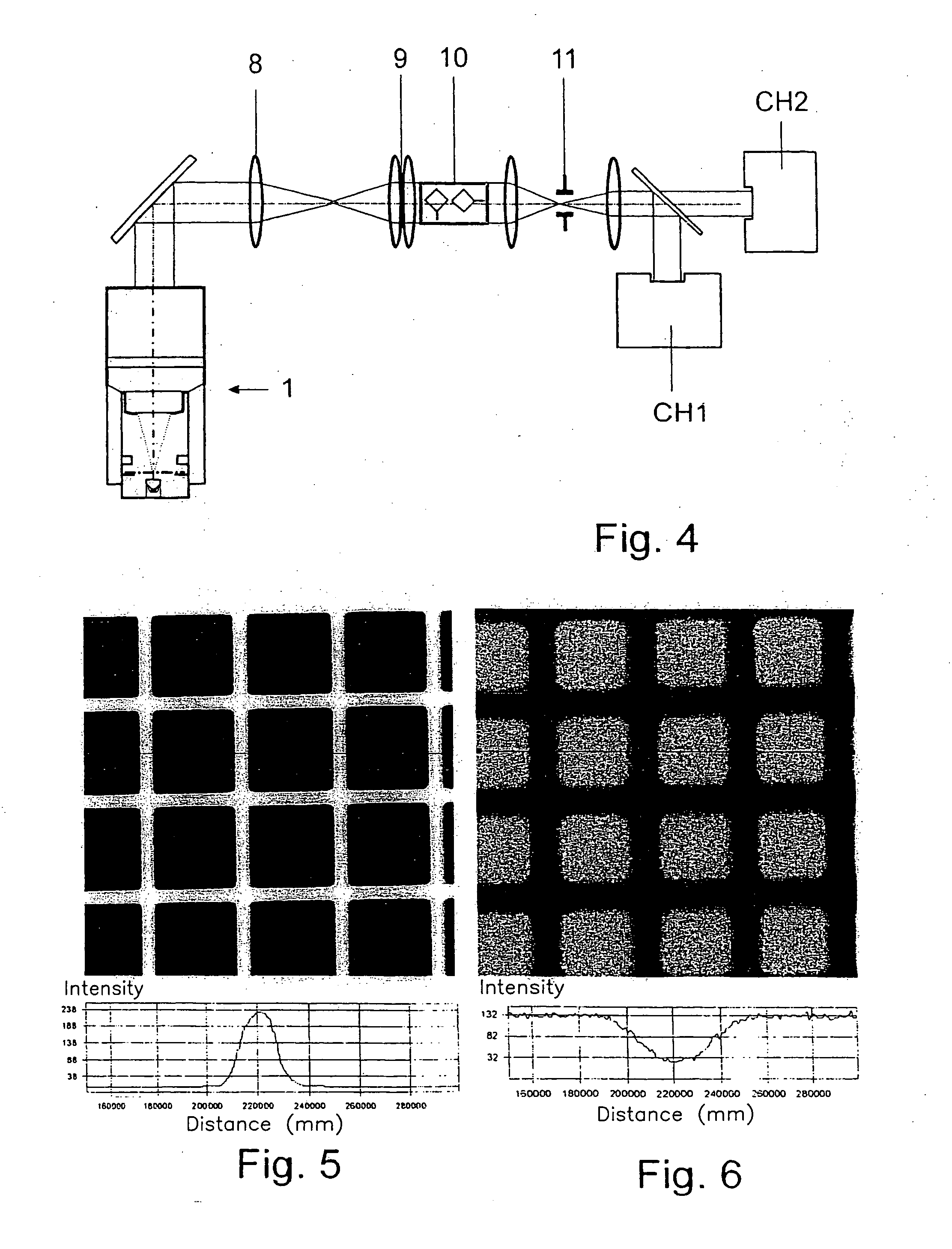

Calibration device and laser scanning microscope with such a calibration device

ActiveUS20090224174A1Moving linearEasy to replacePhotometryLuminescent dosimetersLaser scanning microscopeLight beam

A calibration device for managing a variety of performance tests and / or calibration tasks in a laser scanning microscope. The calibration device, which has focusing optics and a test structure arranged in the focal plane of the focusing optics, with structural elements detectable in reflected and / or transmitted light aligned to each other in a common mounting, can be switched into the microscope beam path in a laser scanning microscope, so that the pupil of the focusing optics coincides with the objective pupil of the laser scanning microscope or lies in a plane conjugated to it.

Owner:CARL ZEISS MICROSCOPY GMBH

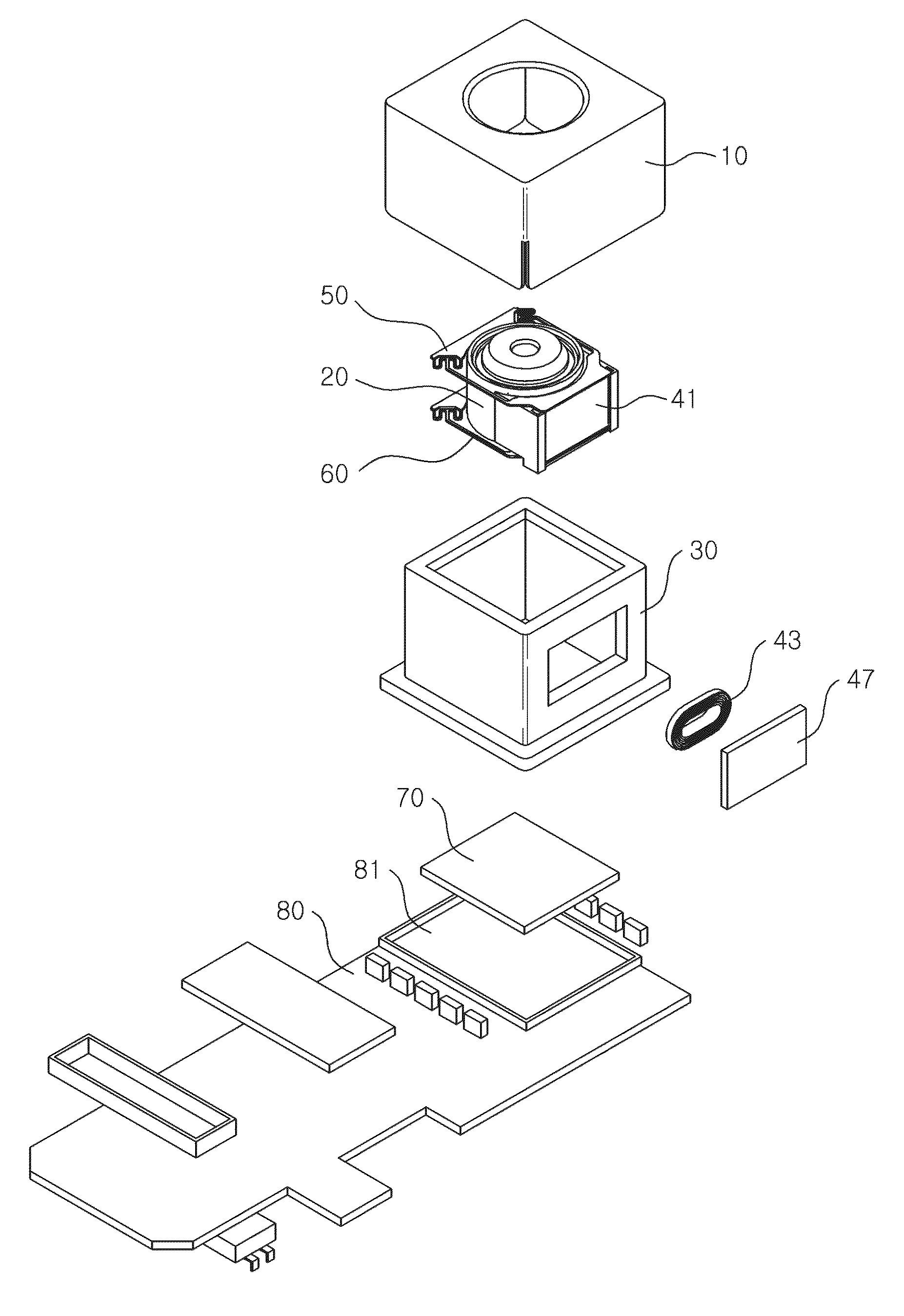

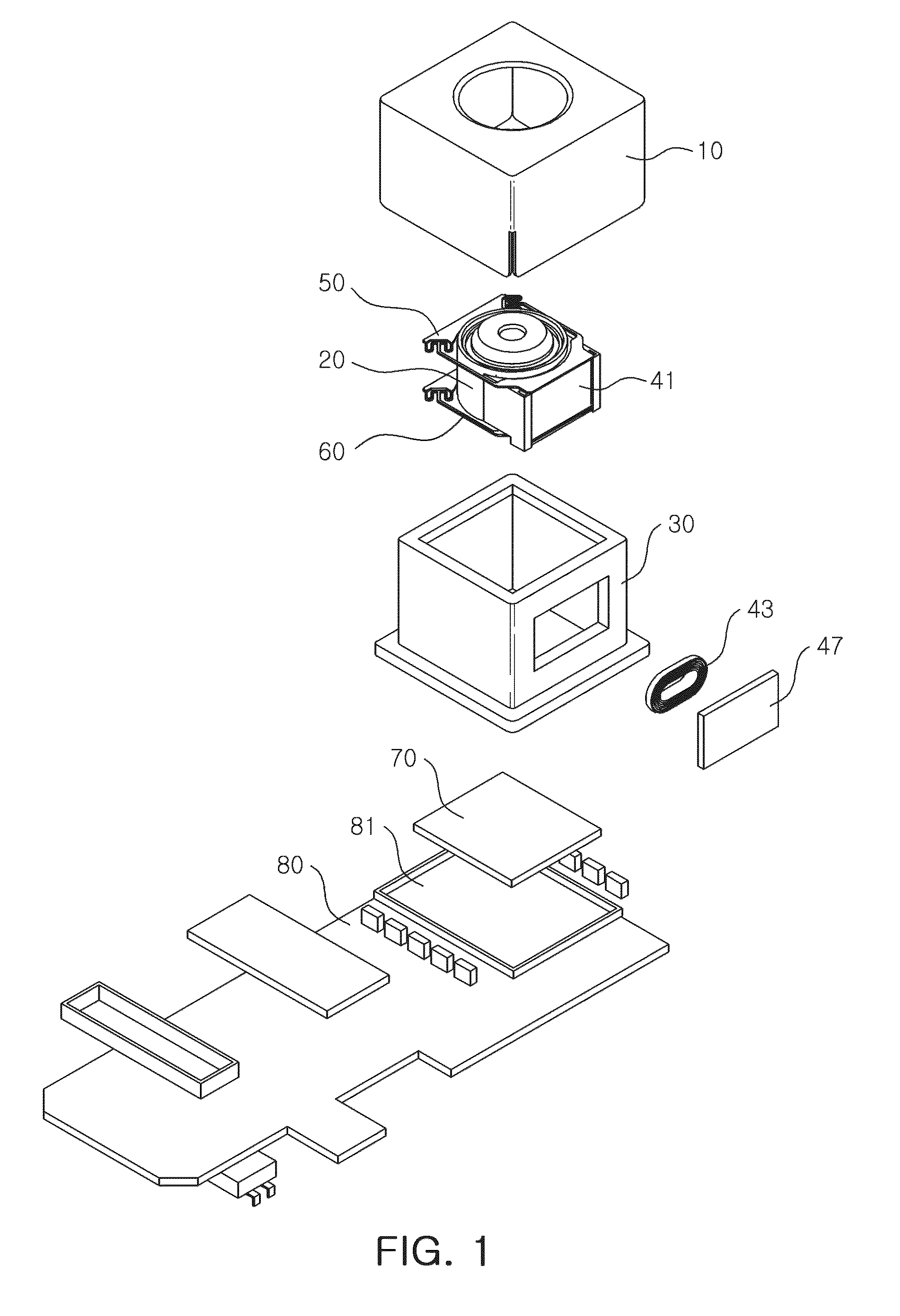

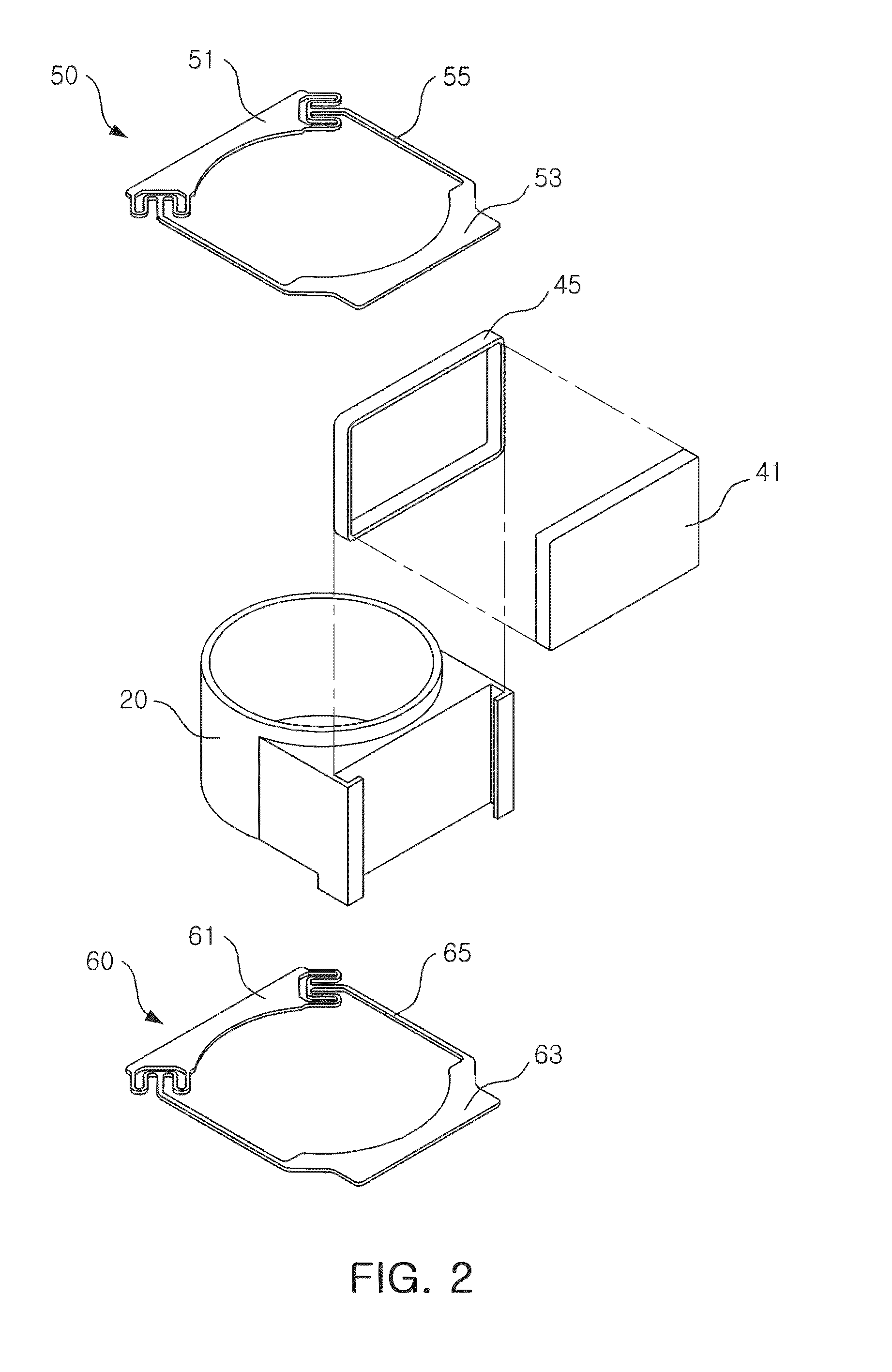

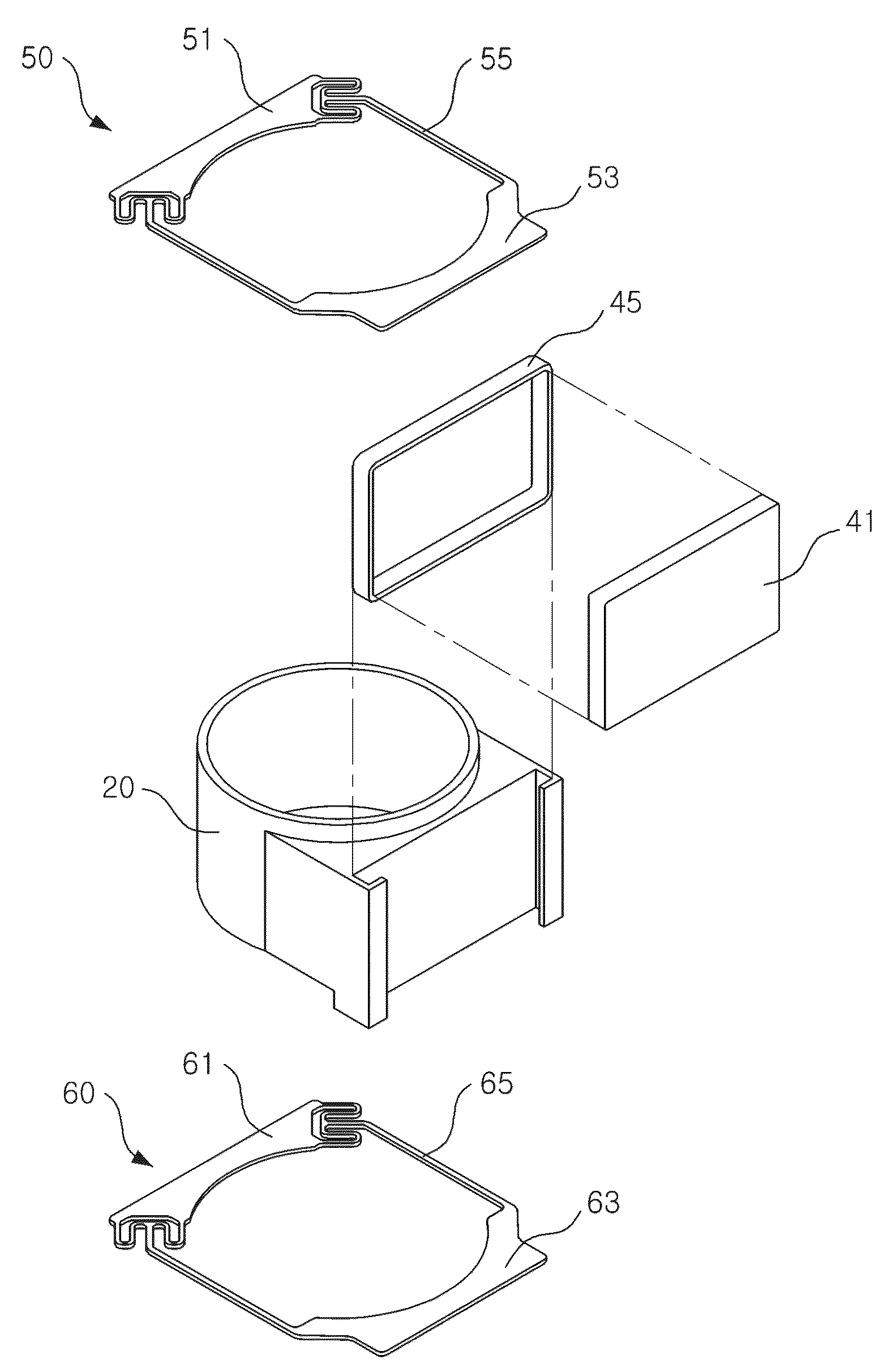

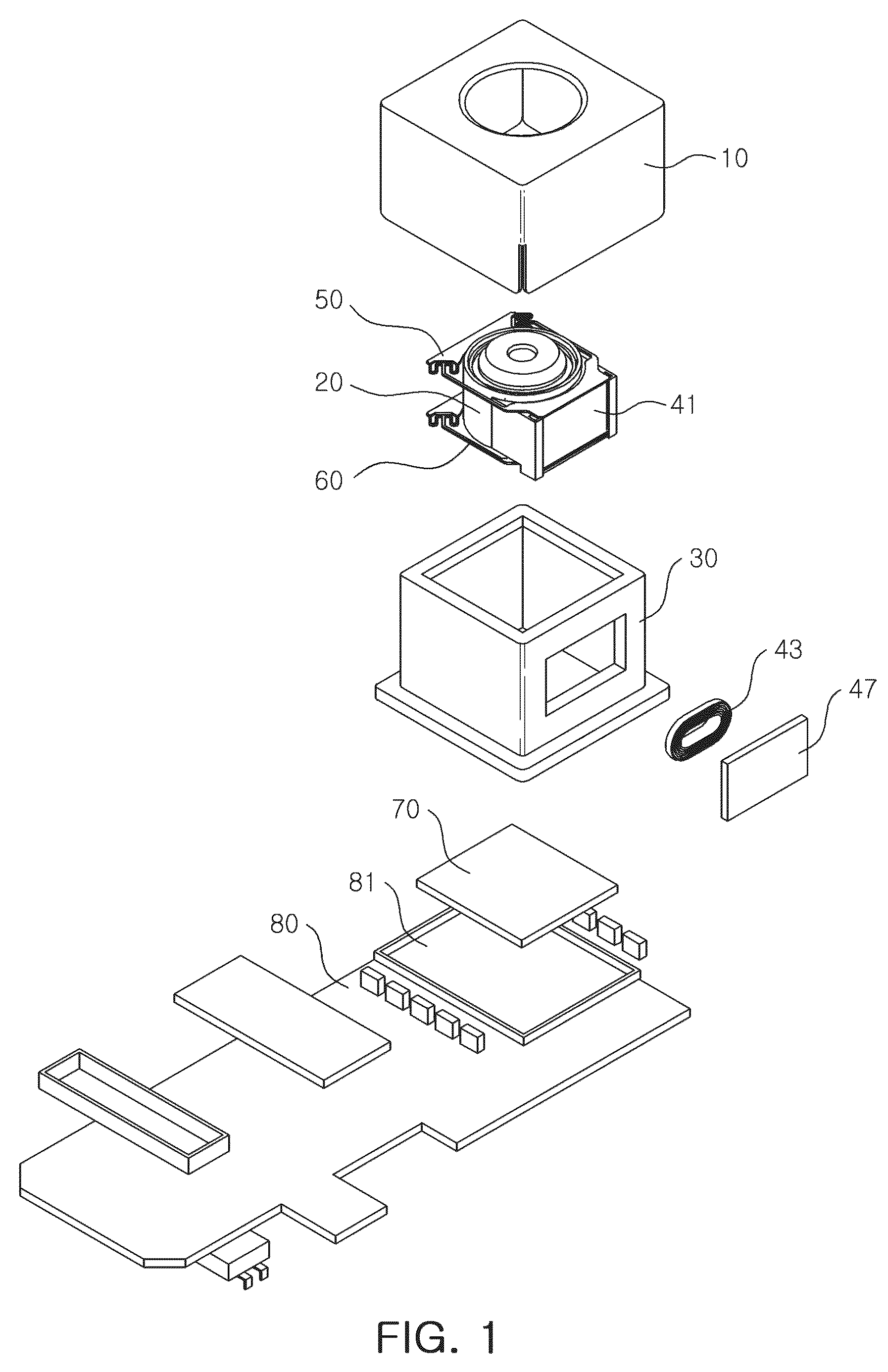

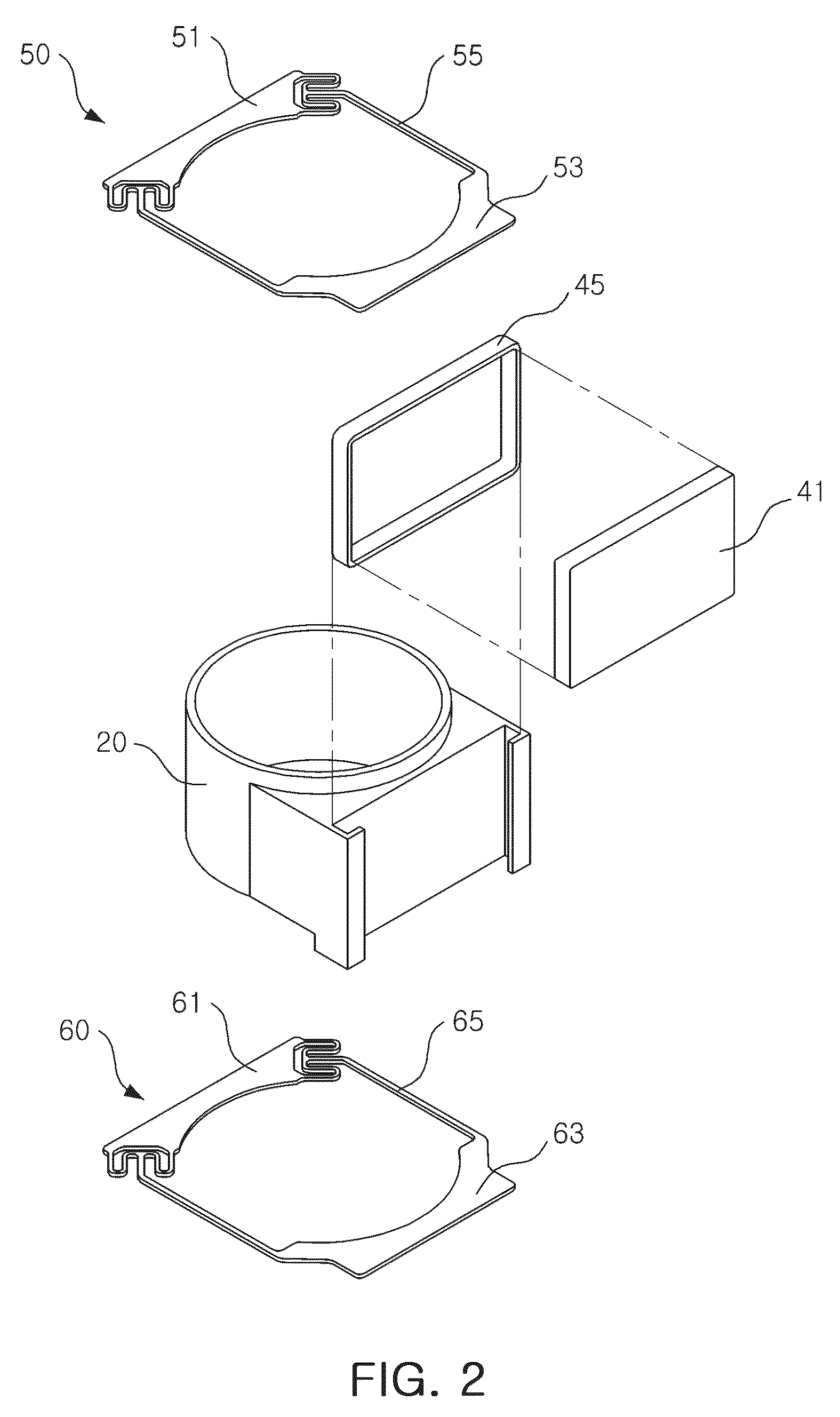

Camera module

ActiveUS20150062421A1Minimization requirementsAvoid it happening againTelevision system detailsColor television detailsOptical axisCamera module

There is provided a camera module including: a lens barrel including at least one lens disposed on an optical axis; a housing having the lens barrel disposed therein; and first and second elastic members elastically supporting upper and lower portions of the lens barrel, respectively, wherein the first and second elastic members include a fixed side coupled to the housing and a driving side coupled to the lens barrel, respectively, the fixed side and the driving side being disposed to face each other based on the optical axis.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

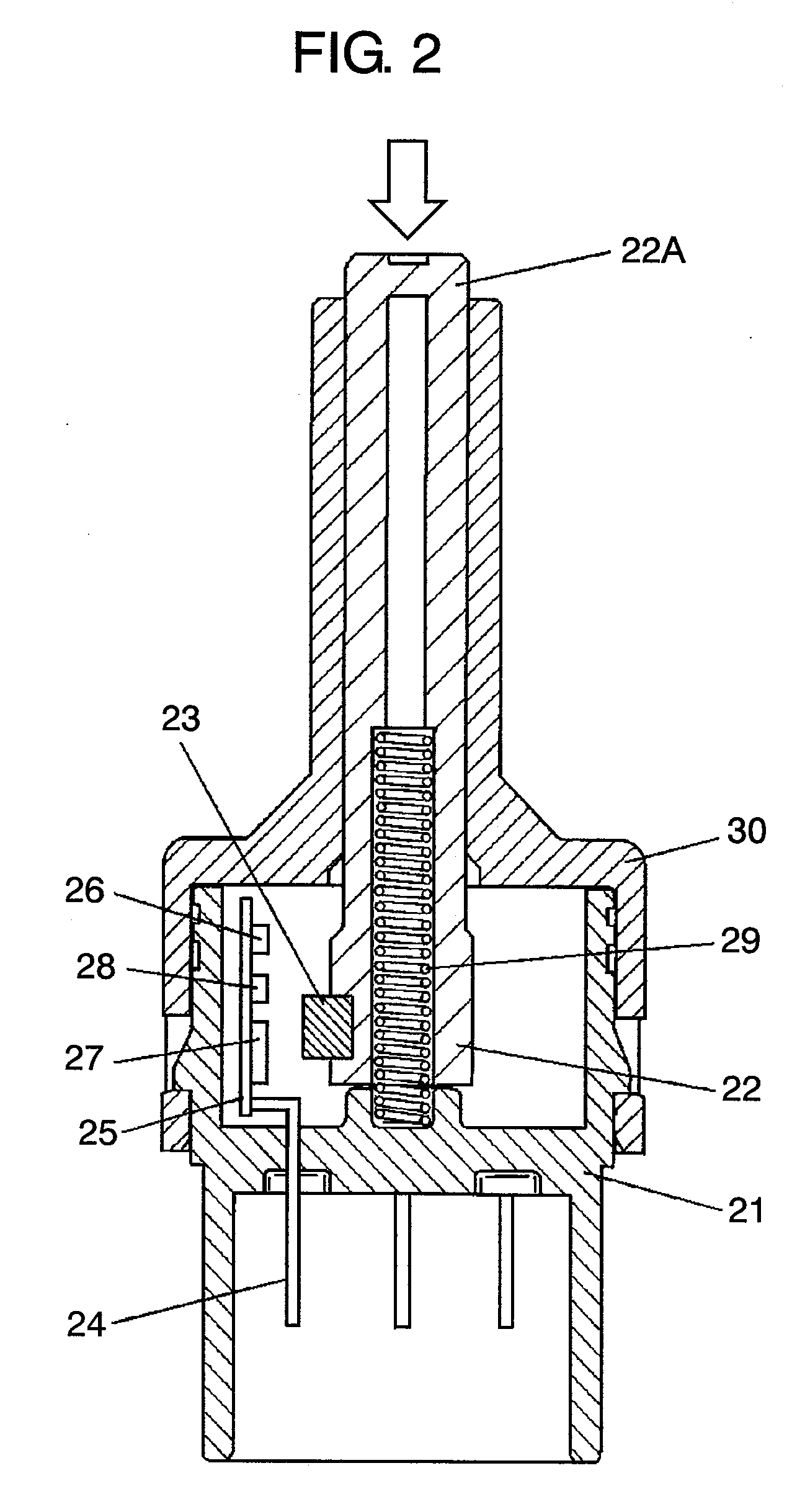

Vehicle switch

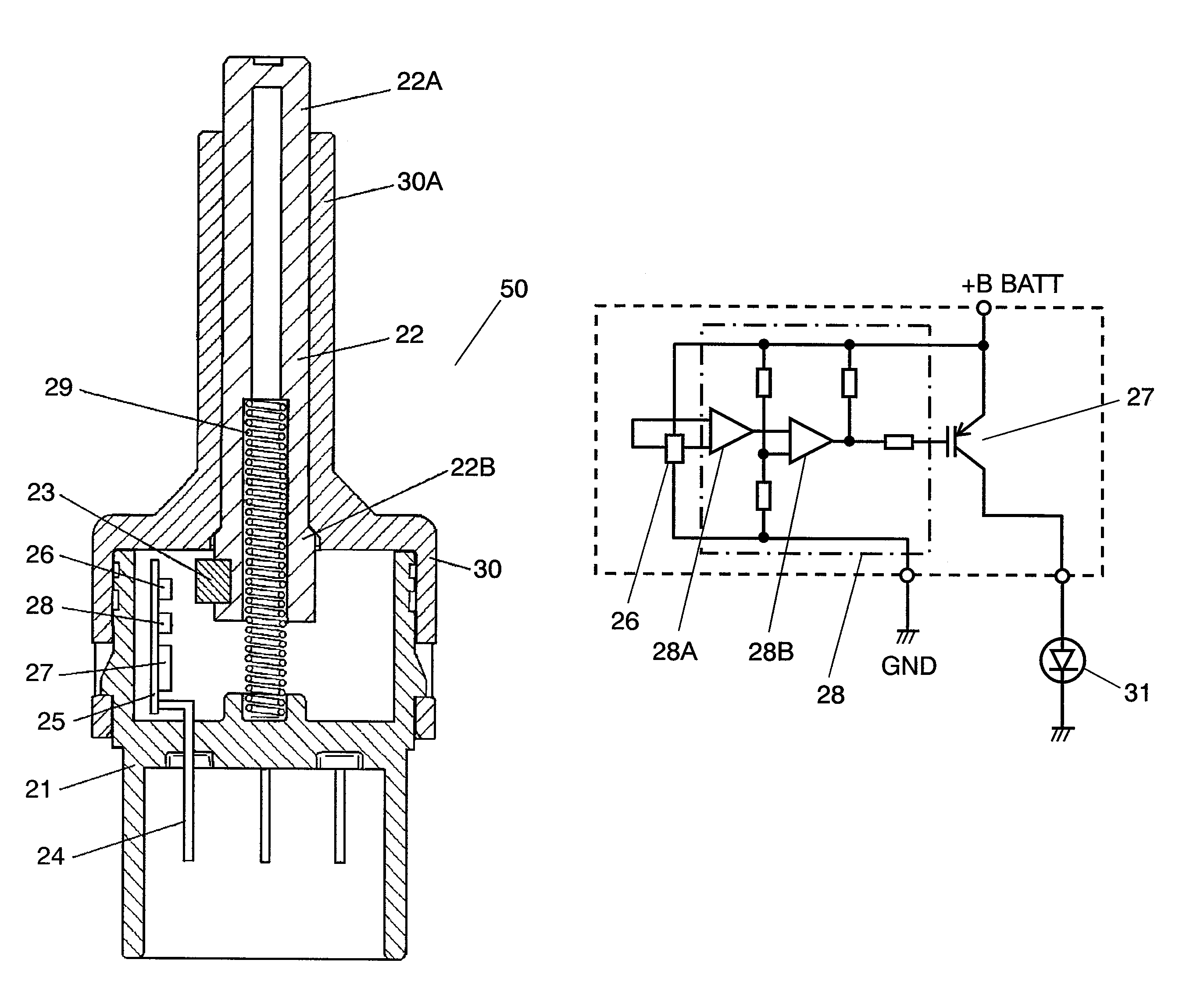

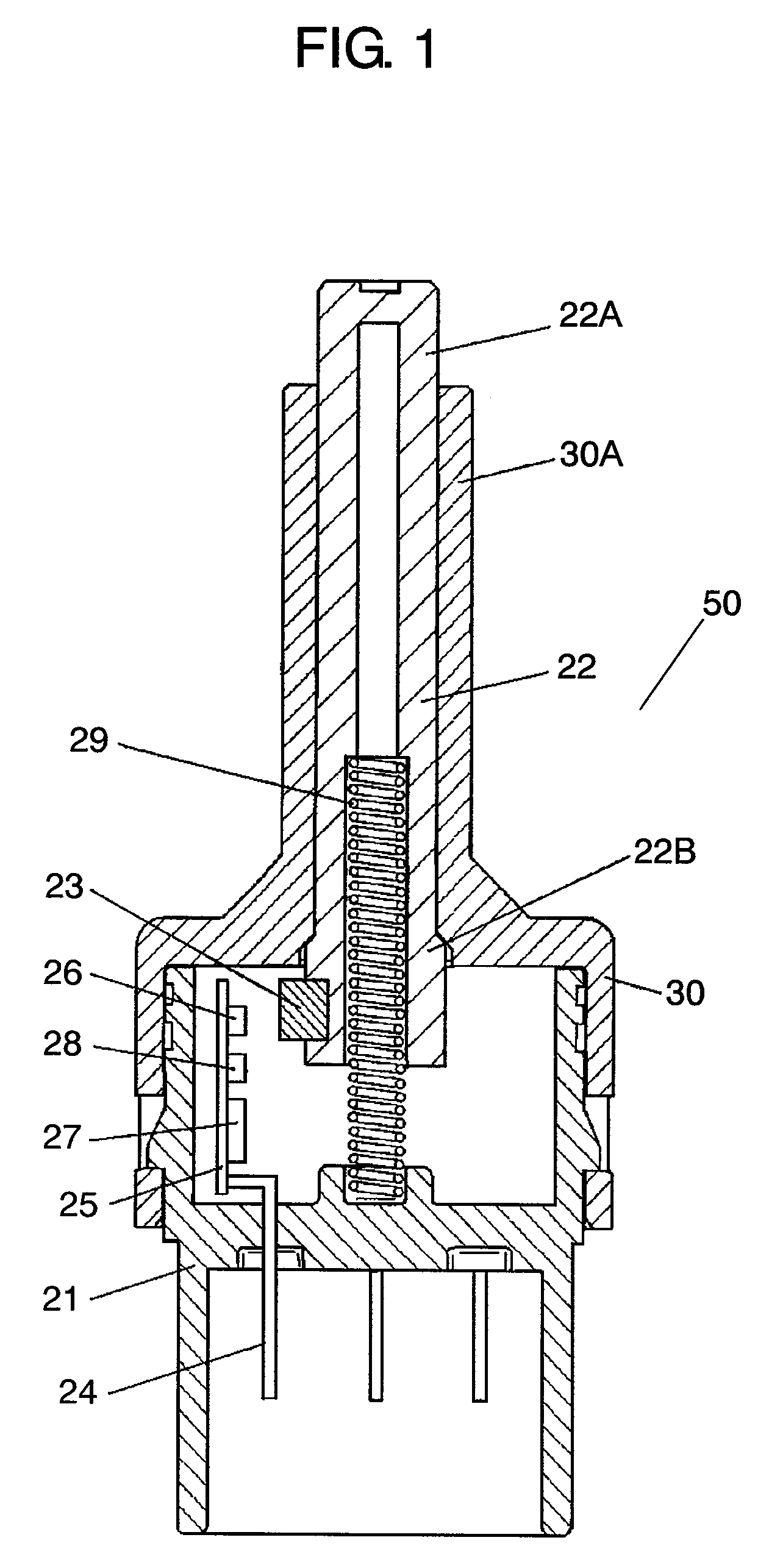

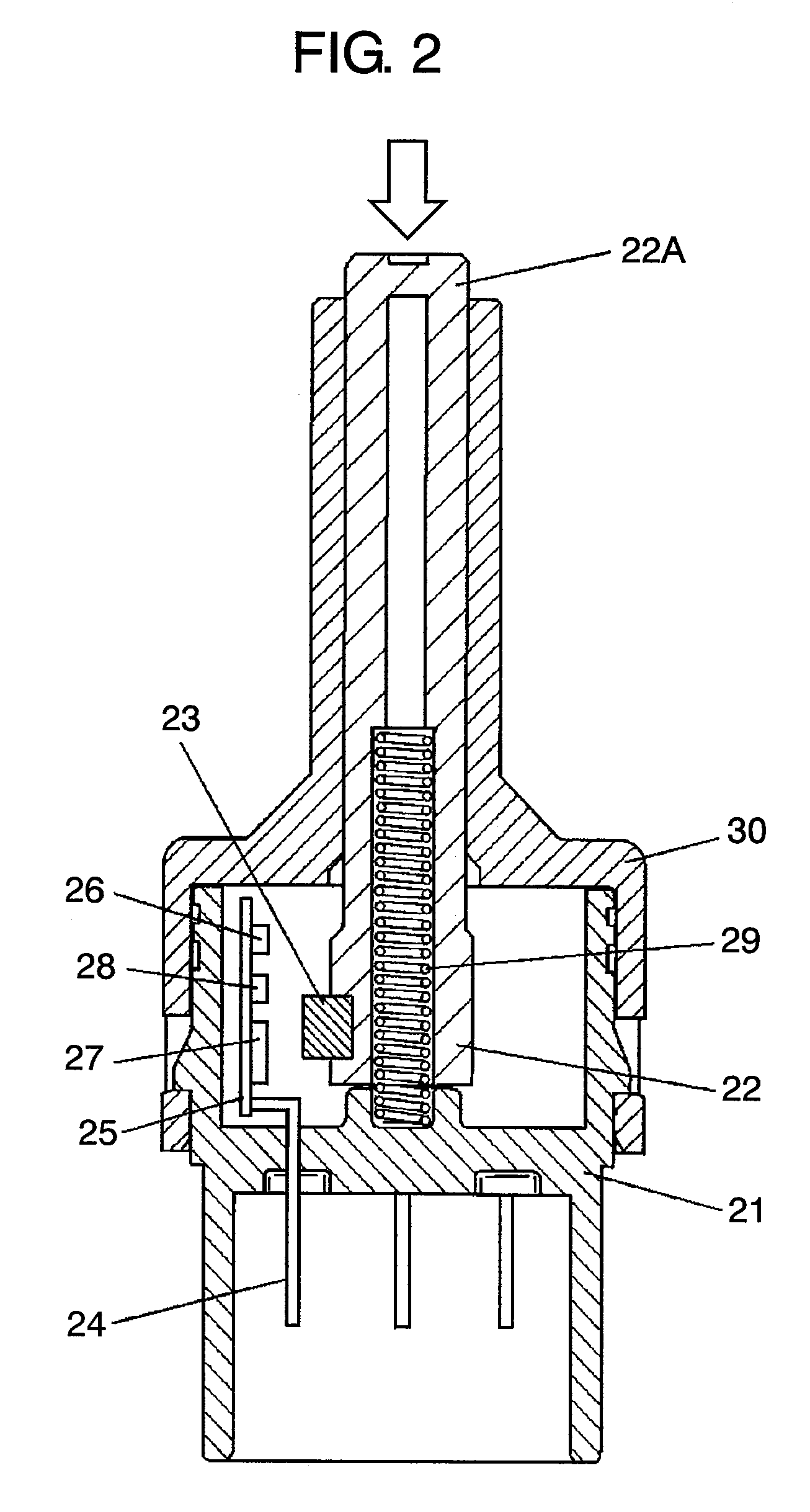

ActiveUS20070290642A1Reduce troubleDifferent strengthDC motor speed/torque controlContact operating partsLower limitMagnetic detector

A vehicle switch includes a magnet mounted to an operating unit accommodated in an external packaging such that the operating unit can move linearly. A magnetic detector is placed so as to receive different strength of the magnetism from the magnet in the two cases that the operating unit is at the upper limit position and at the lower limit position. A control circuit coupled to the magnetic detector opens and closes a switching device in response to strength of the detected magnetism.

Owner:PANASONIC CORP

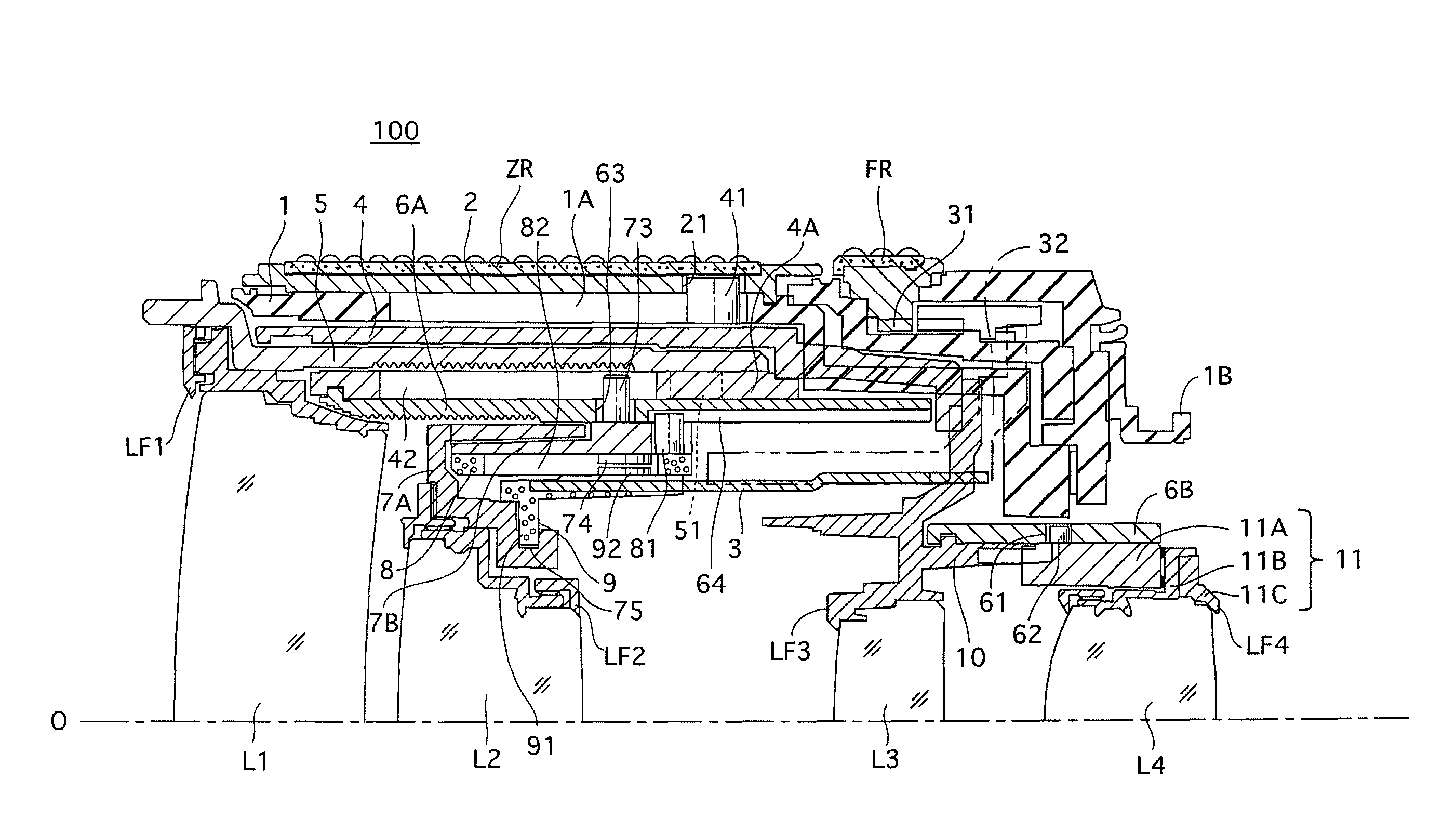

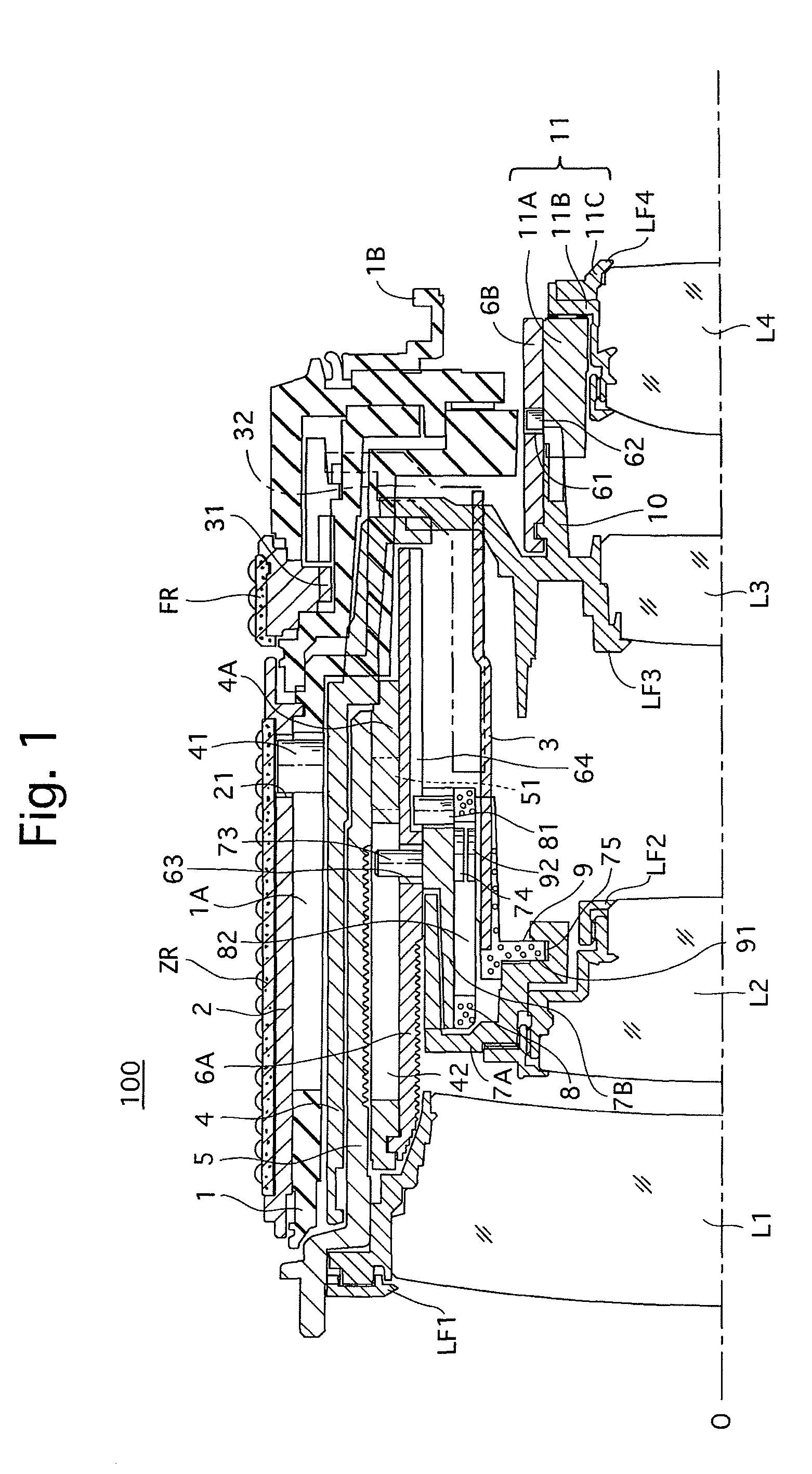

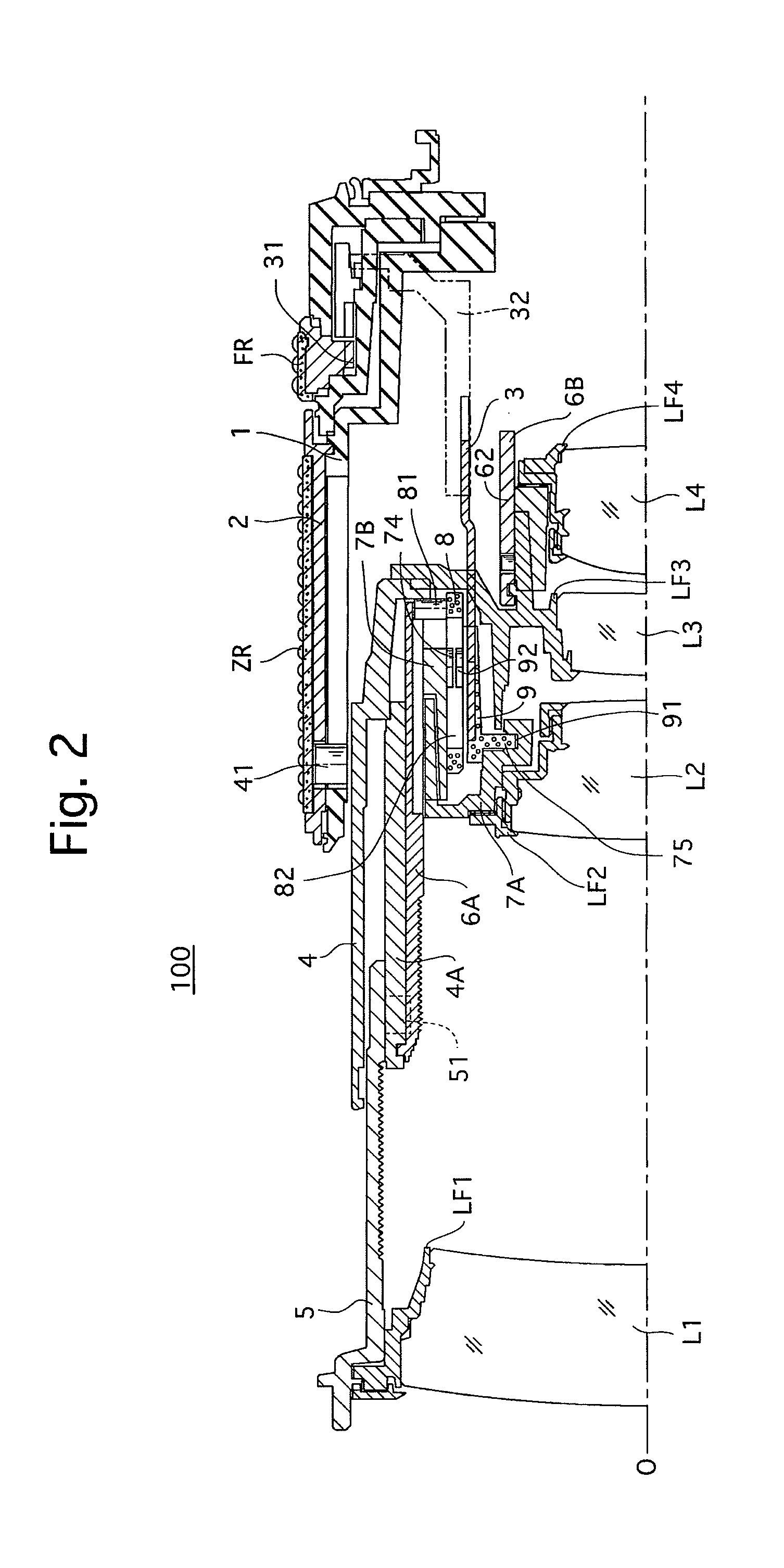

Varifocal lens barrel

InactiveUS20120075720A1Reduced lens assembly errorImprove imaging effectMountingsOptical axisOptoelectronics

A varifocal lens barrel includes a plurality of lens groups, each of which are linearly movable in the optical axis direction thereof without rotating about the optical axis during a zooming operation and during a focusing operation, including a base barrel which is linearly movable in the optical axis direction by rotation of a zoom operational ring, wherein lens frames of the respective lens groups are each supported by the base barrel.

Owner:RICOH IMAGING COMPANY

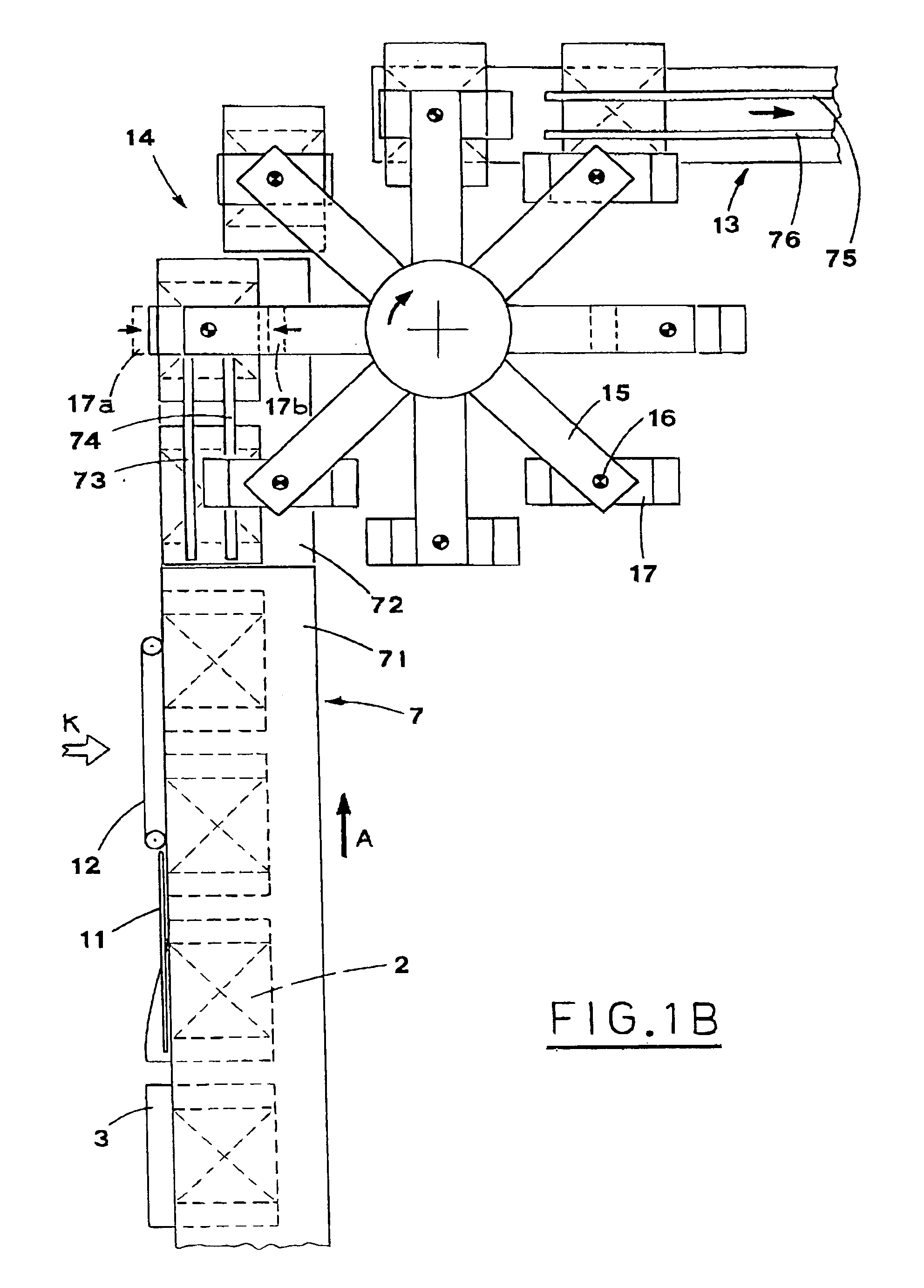

Method and apparatus for wrapping articles with a packaging sheet

InactiveUS6935091B2Moving linearEasy constructionPaper article packagingConveyor wrappingEngineeringMechanical engineering

The method envisages that groups of articles (2,22) to be packaged, arranged orderly with a lateral narrowed dimension oriented in the forward movement direction (A), are fed along a feeding line (1). Single packaging sheets (3) are carried beside the feeding line (1), in suitable phase relation with the forward movement of the articles (2,22). The groups of articles (2,22) are transferred crosswise to the feeding line (1), so as to hit the sheets (3) with the lateral narrow extension of the groups of articles (2,22) in order to fold the sheets (3). The folded edges of the sheets (3) are joined along the opposite side of the groups of articles (2,22), presenting a corresponding lateral narrow extension.

Owner:TISSUE MACHINERY

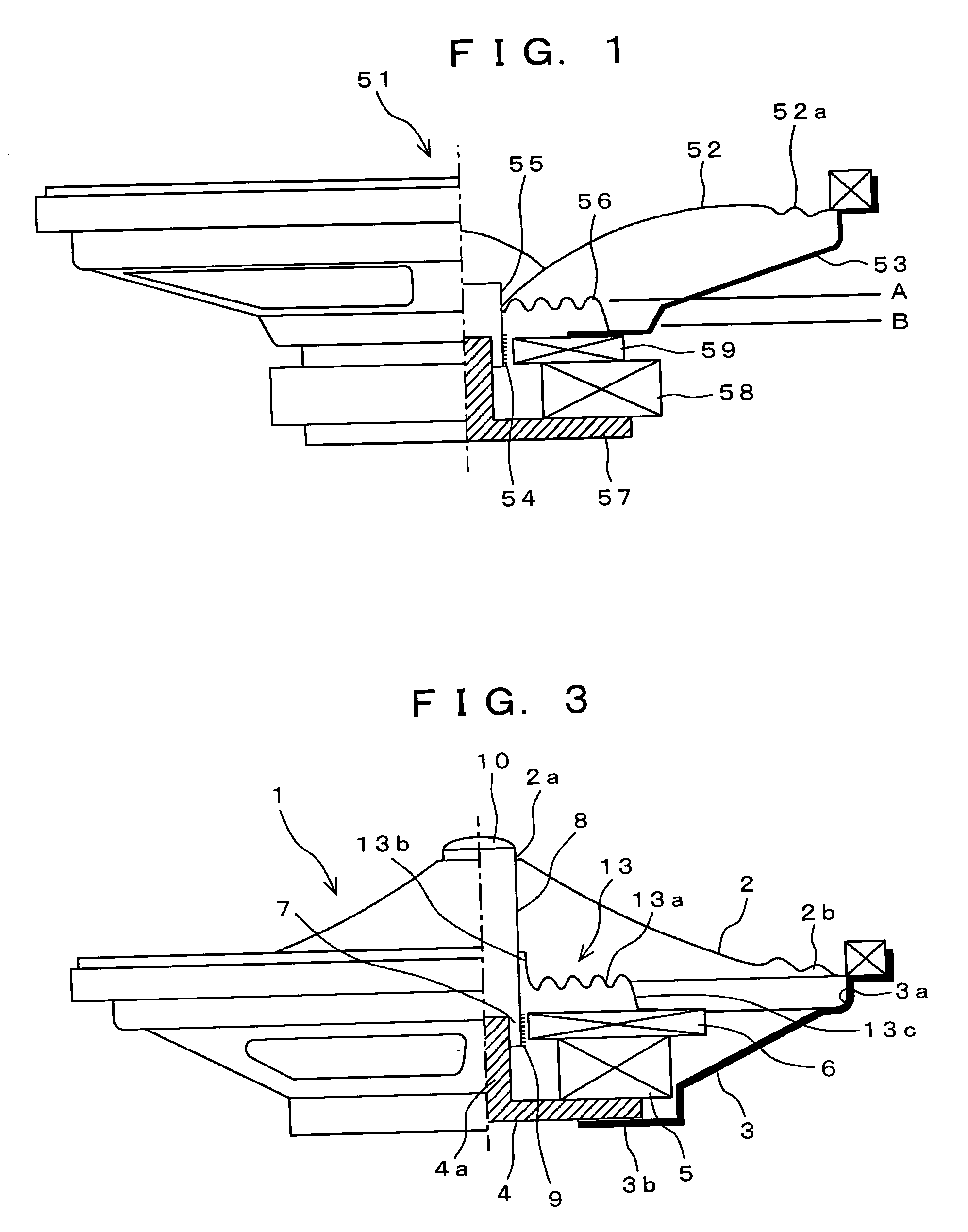

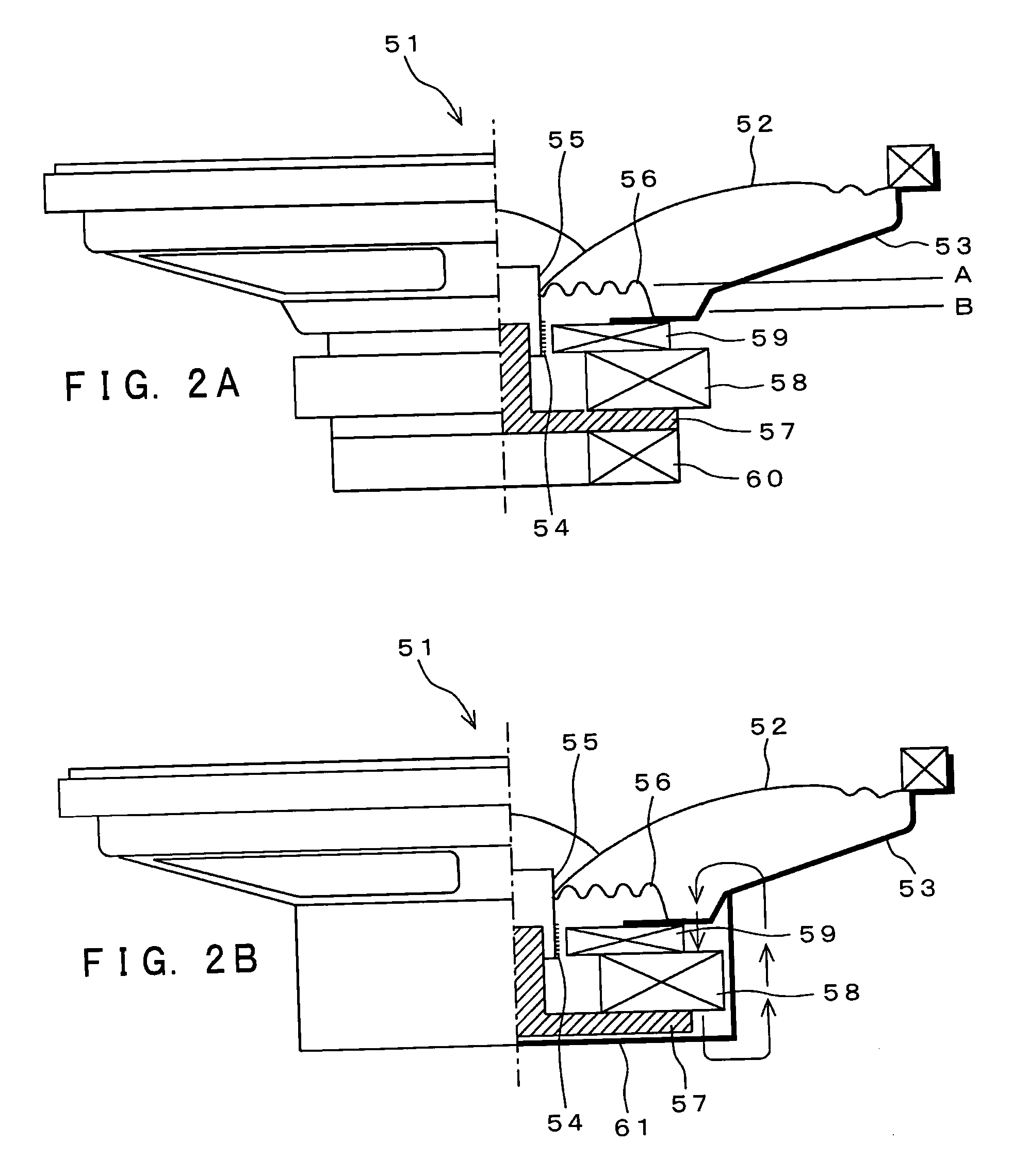

Speaker apparatus

InactiveUS20050175212A1Preventing the bobbin from vibrating laterallyMoving linearTransducer detailsNon-planar diaphragms/conesBobbinEngineering

A speaker apparatus has a frame to which a convex paper is attached. A bobbin with a voice coil is attached to the paper cone. A magnetic circuit is formed inside the frame. A damper suspending the bobbin is composed of a corrugation portion, which is positioned orthogonal to the bobbin in an inactivity of the speaker apparatus. The damper also includes a first leg portion extending forward along a vibration direction of the bobbin from an inner periphery end of the corrugation portion, and a second leg portion extending backward along the vibration direction of the bobbin from an outer periphery end of the corrugation portion. The first and second leg portions have substantially the same length.

Owner:SONY CORP

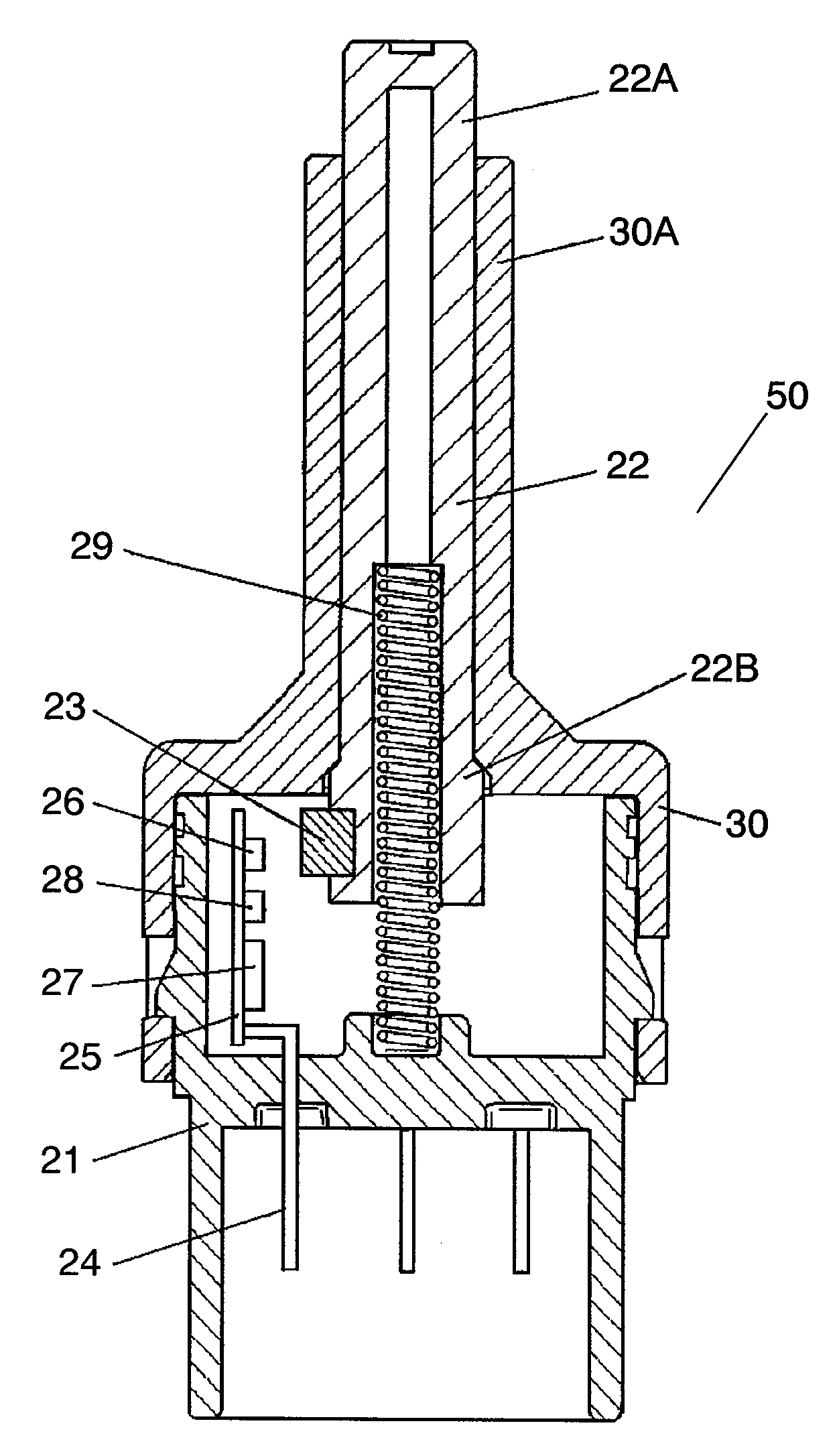

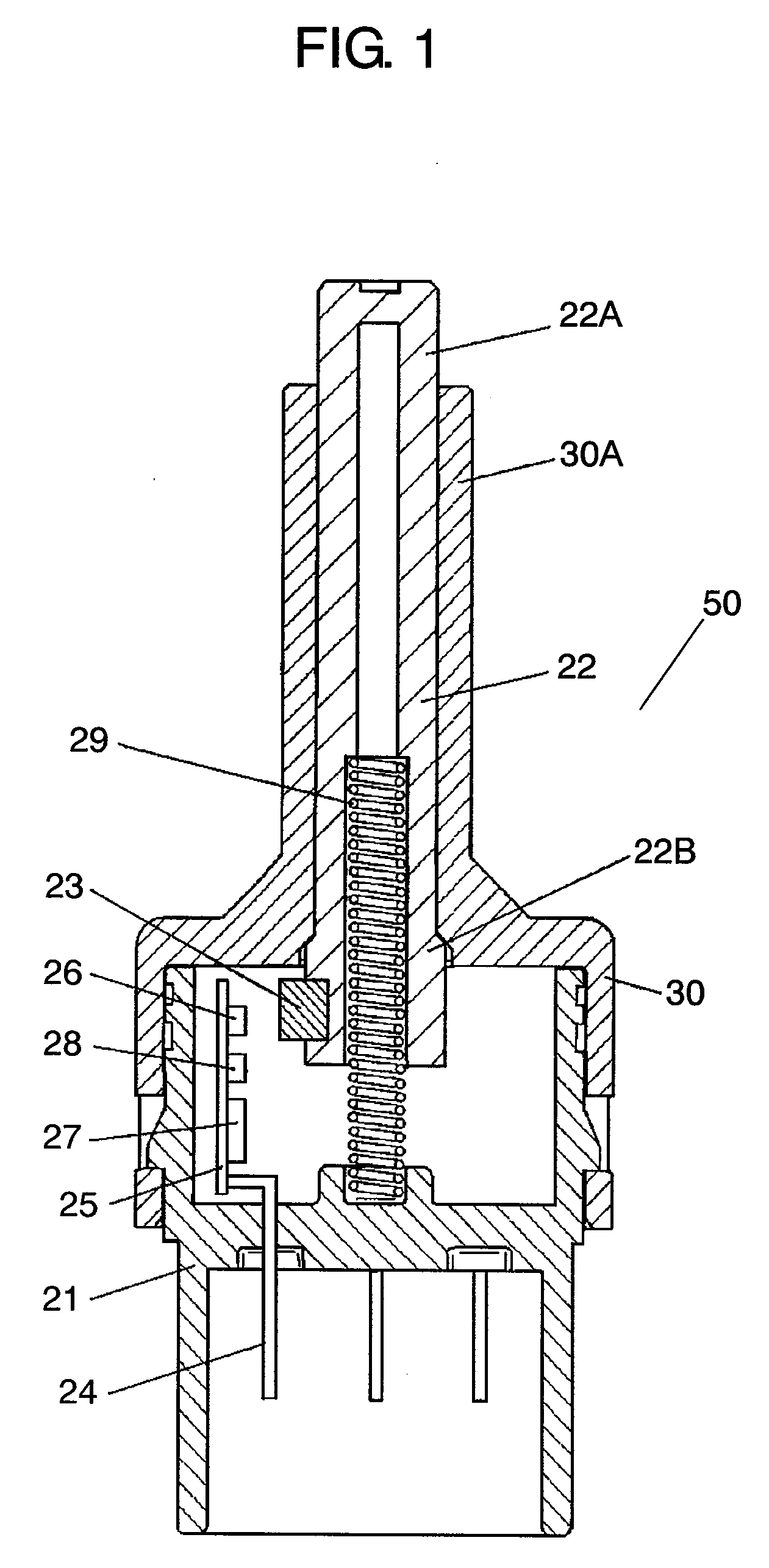

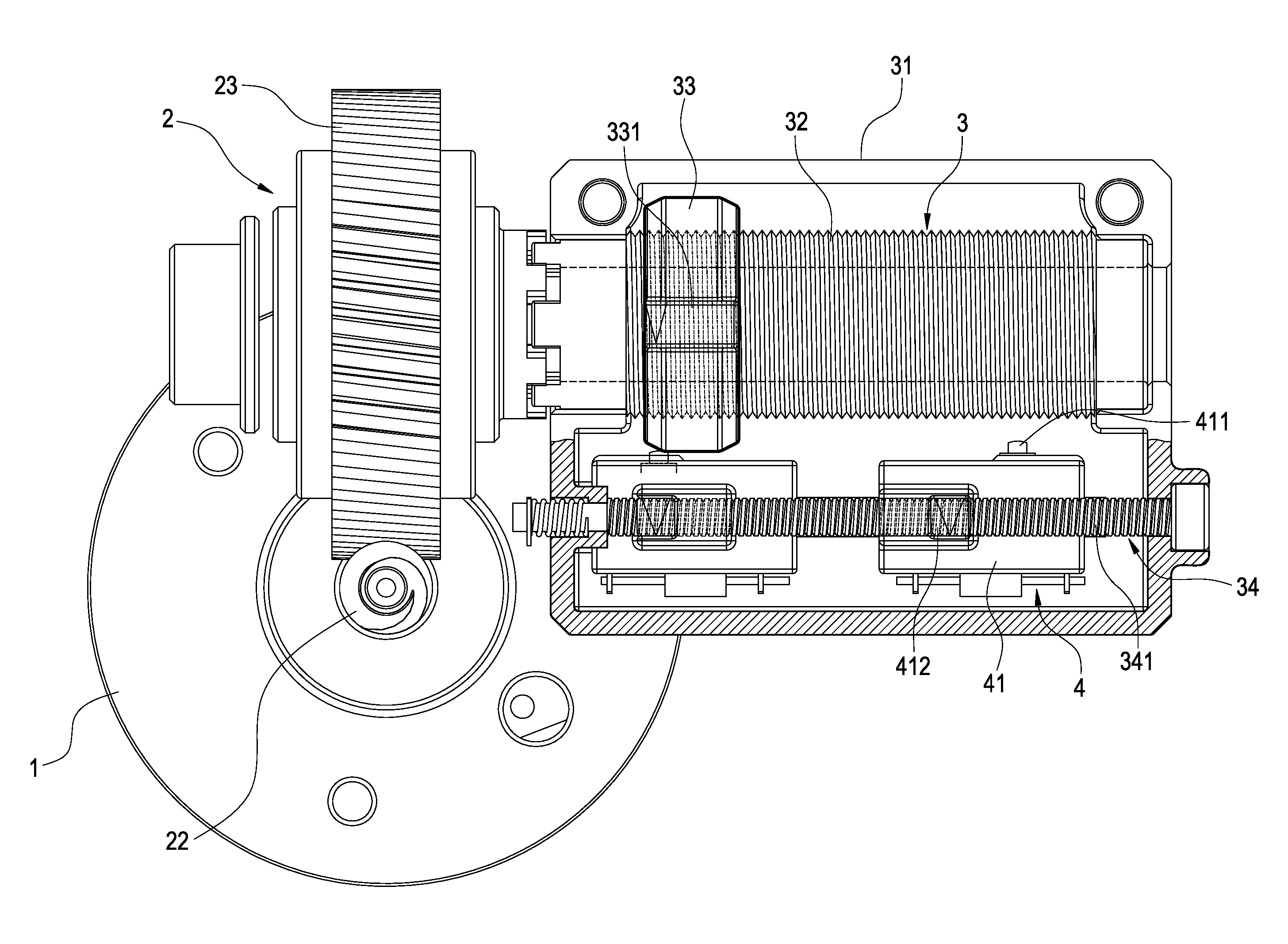

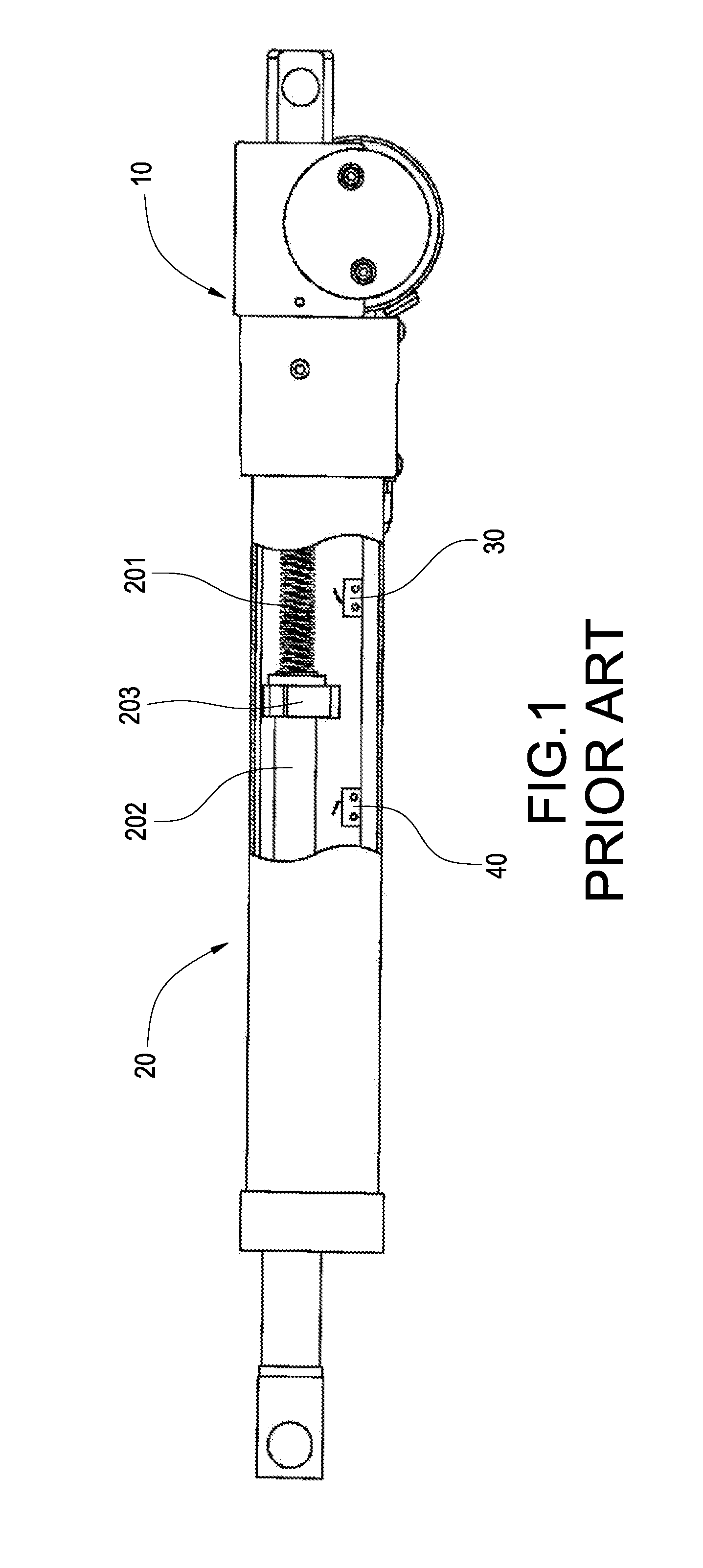

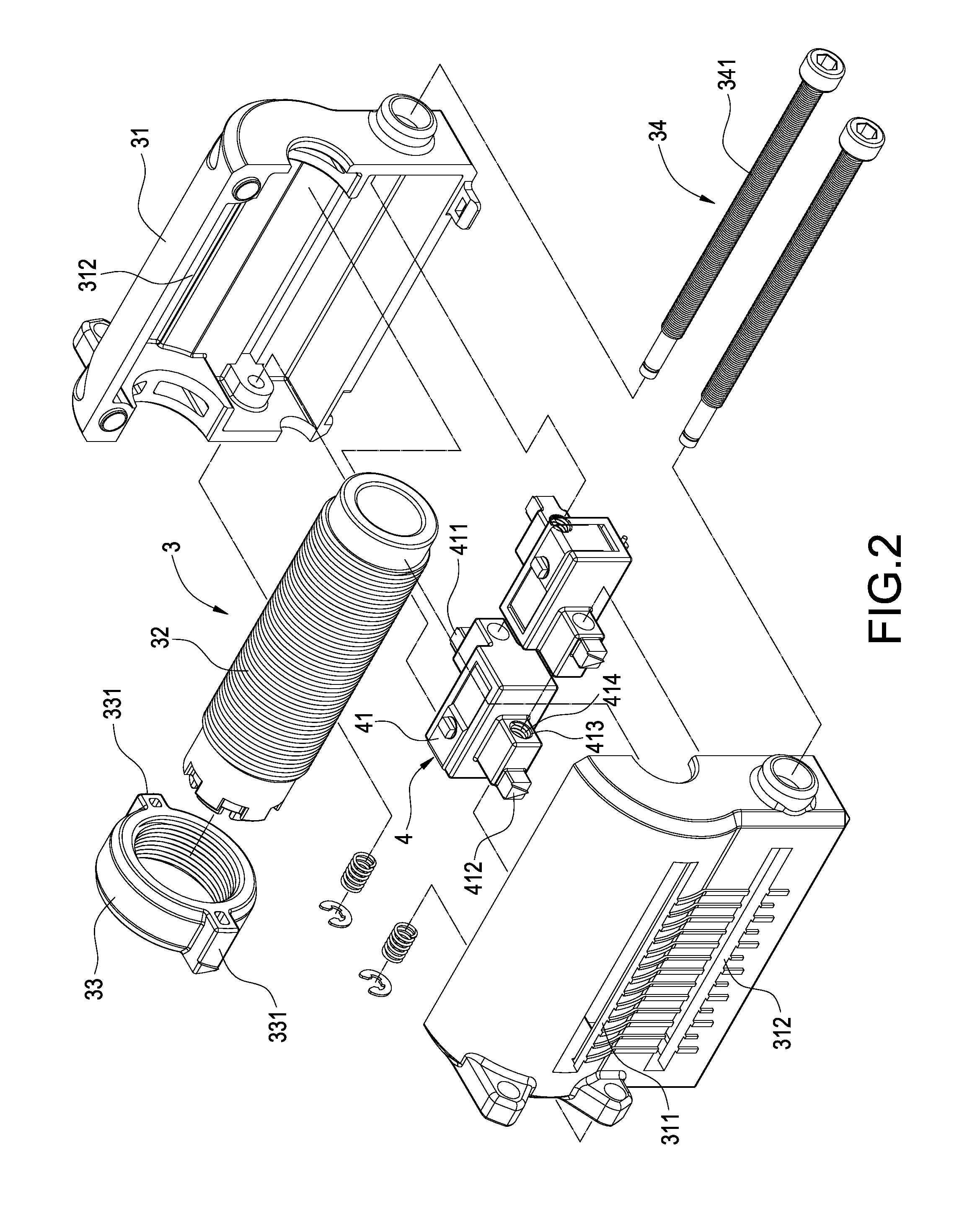

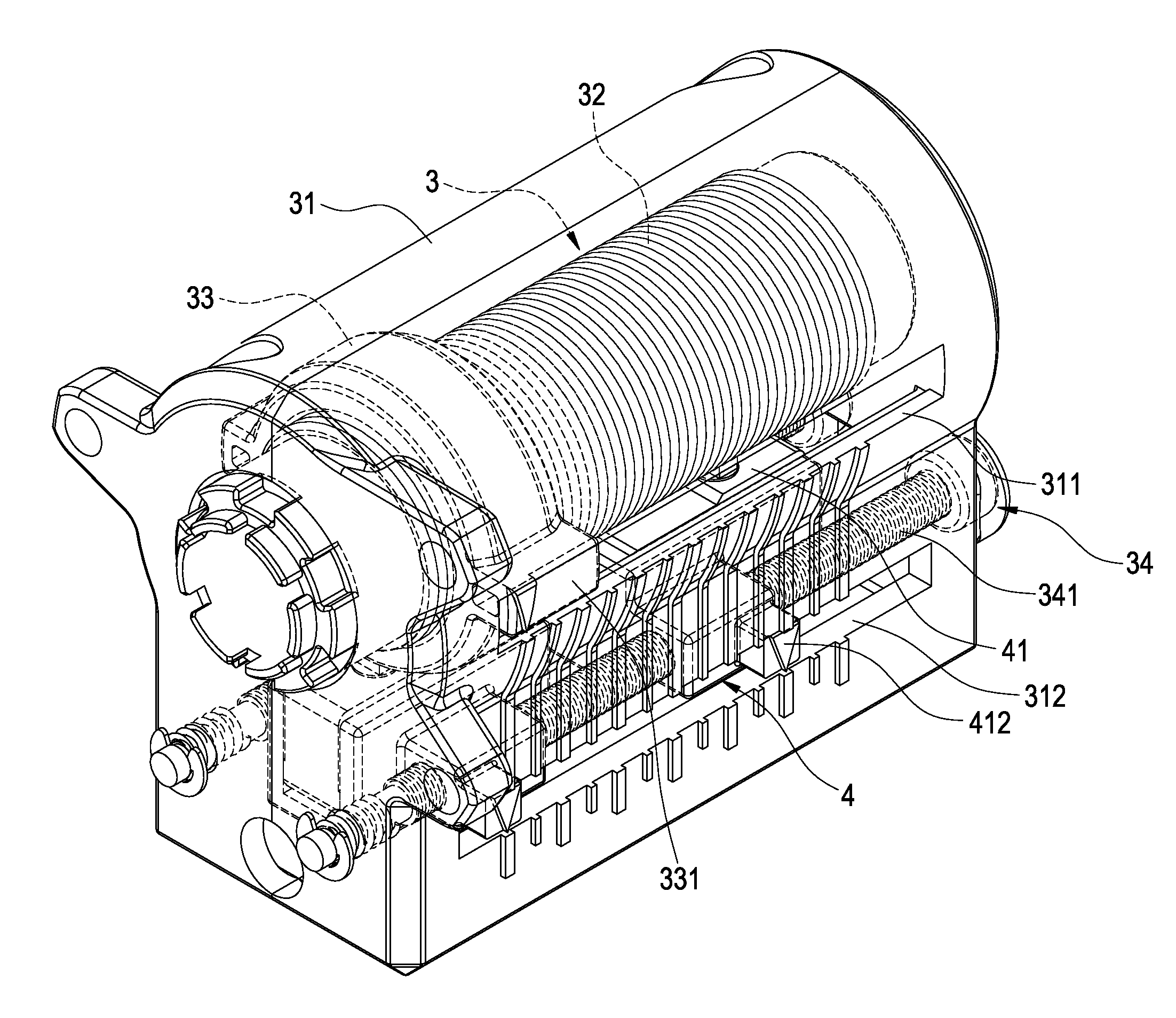

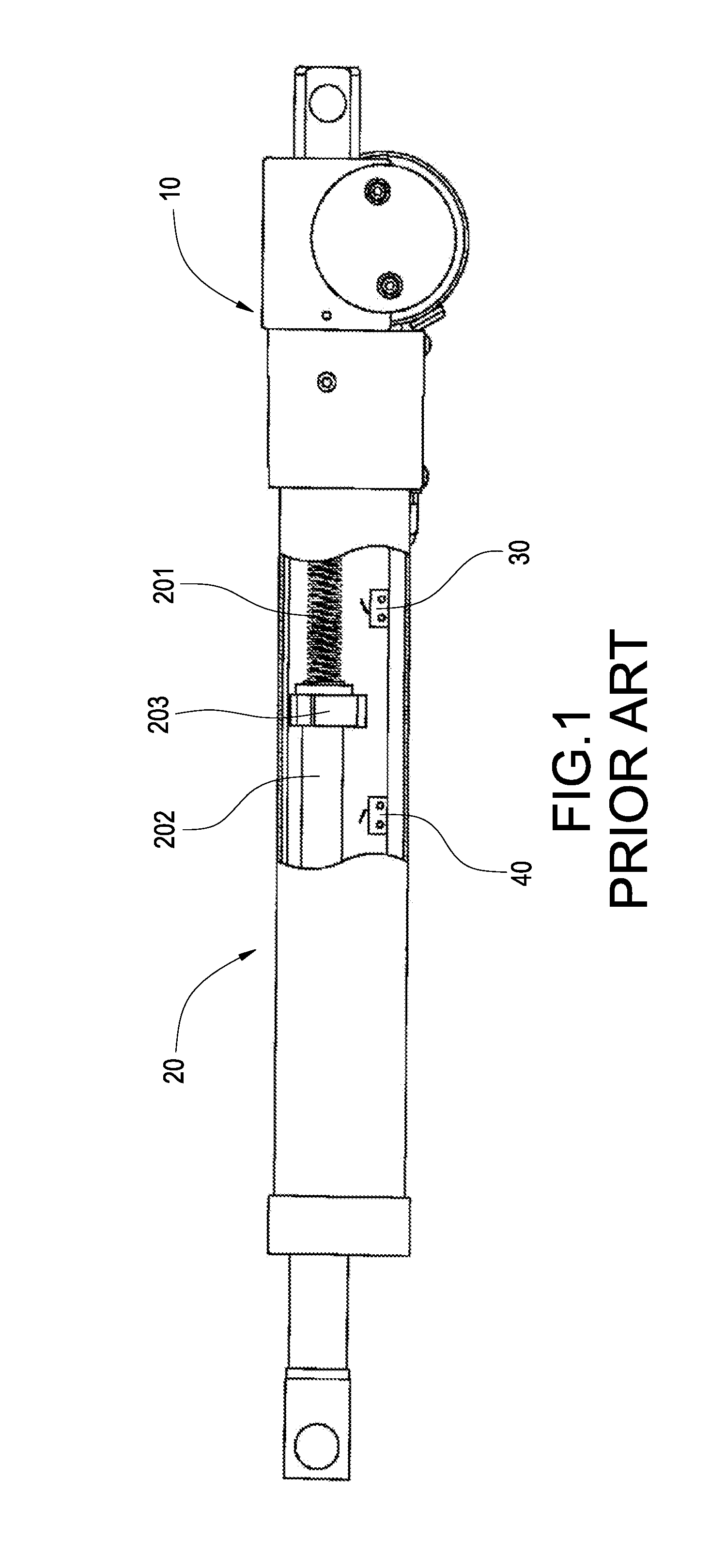

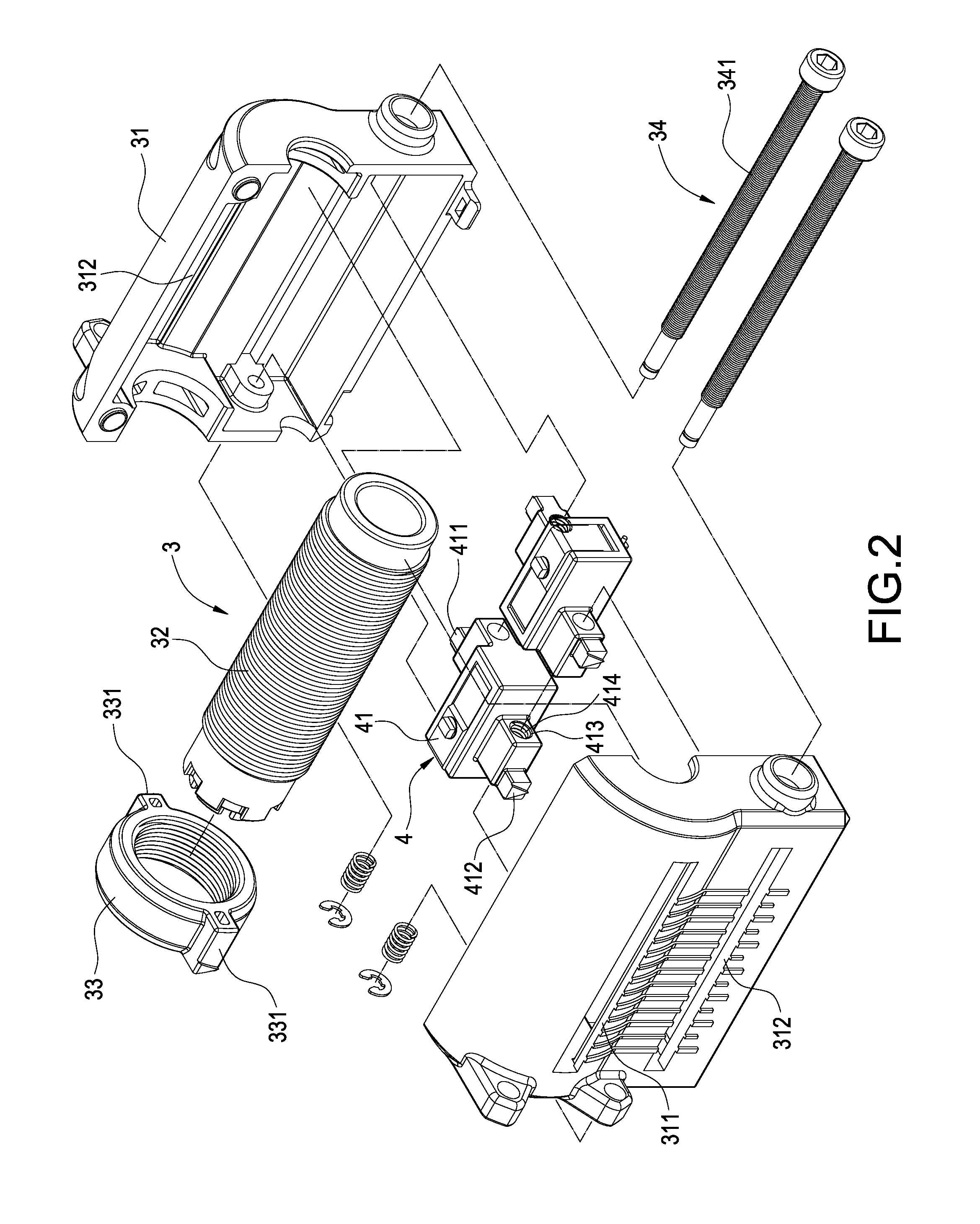

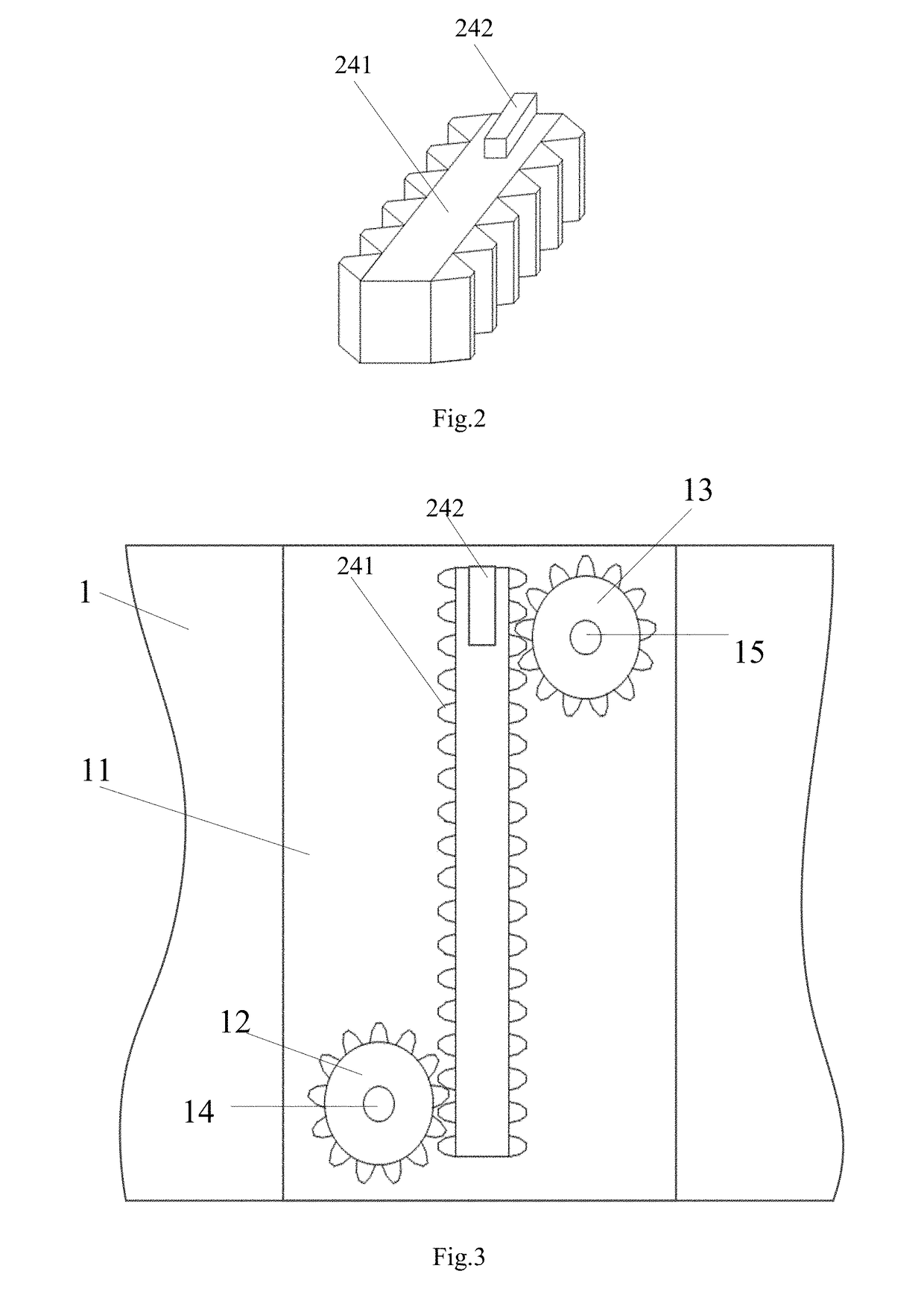

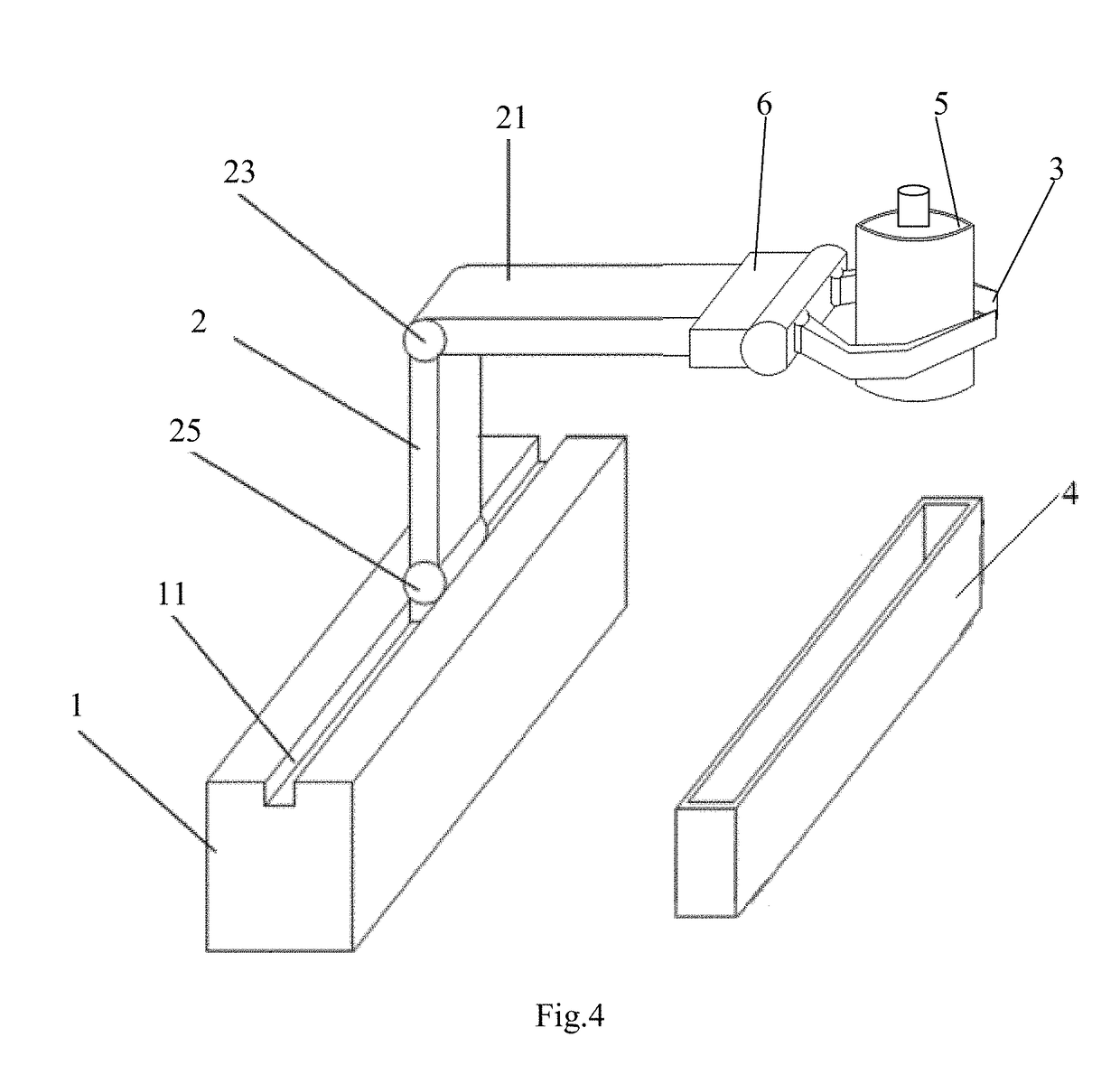

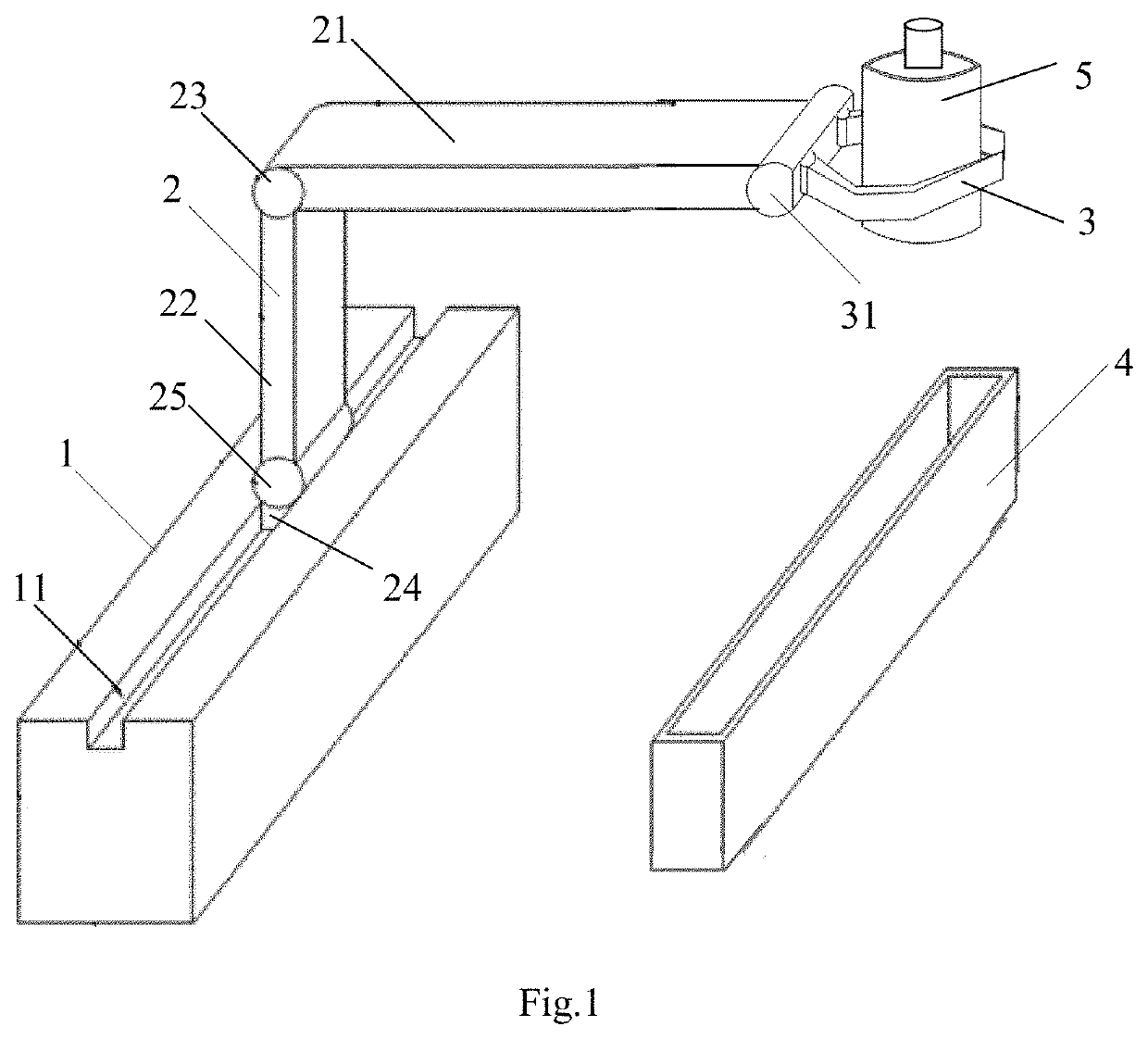

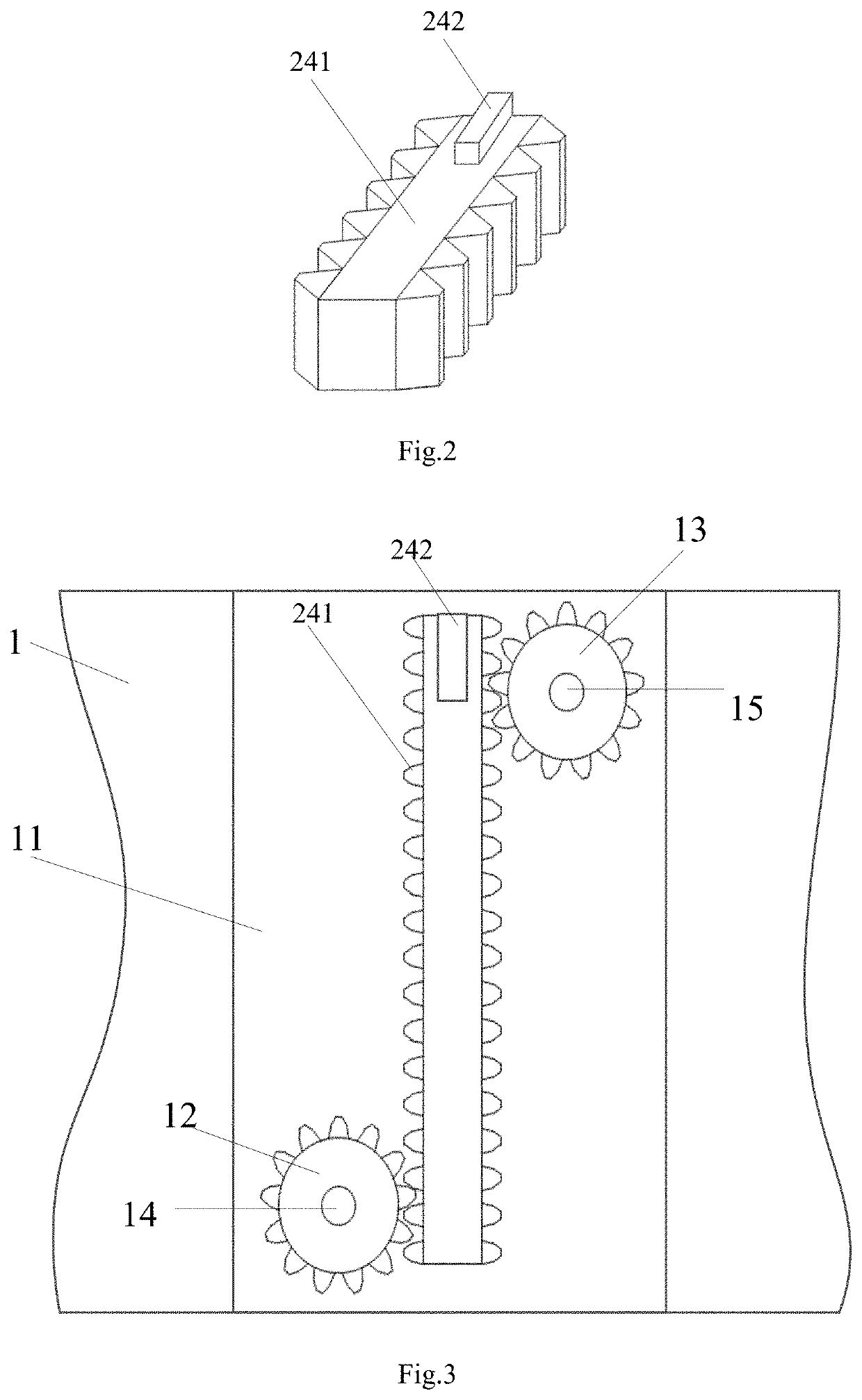

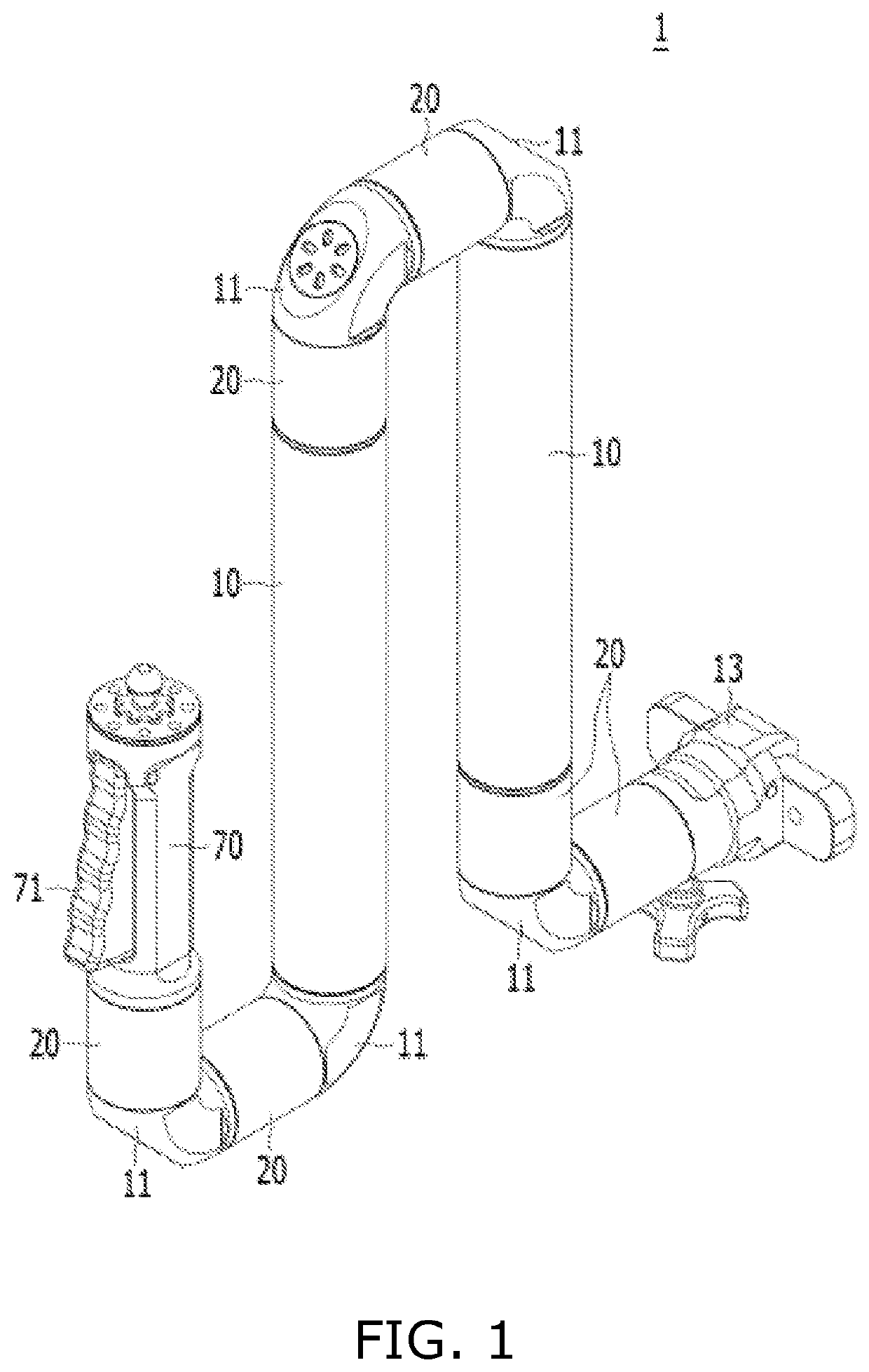

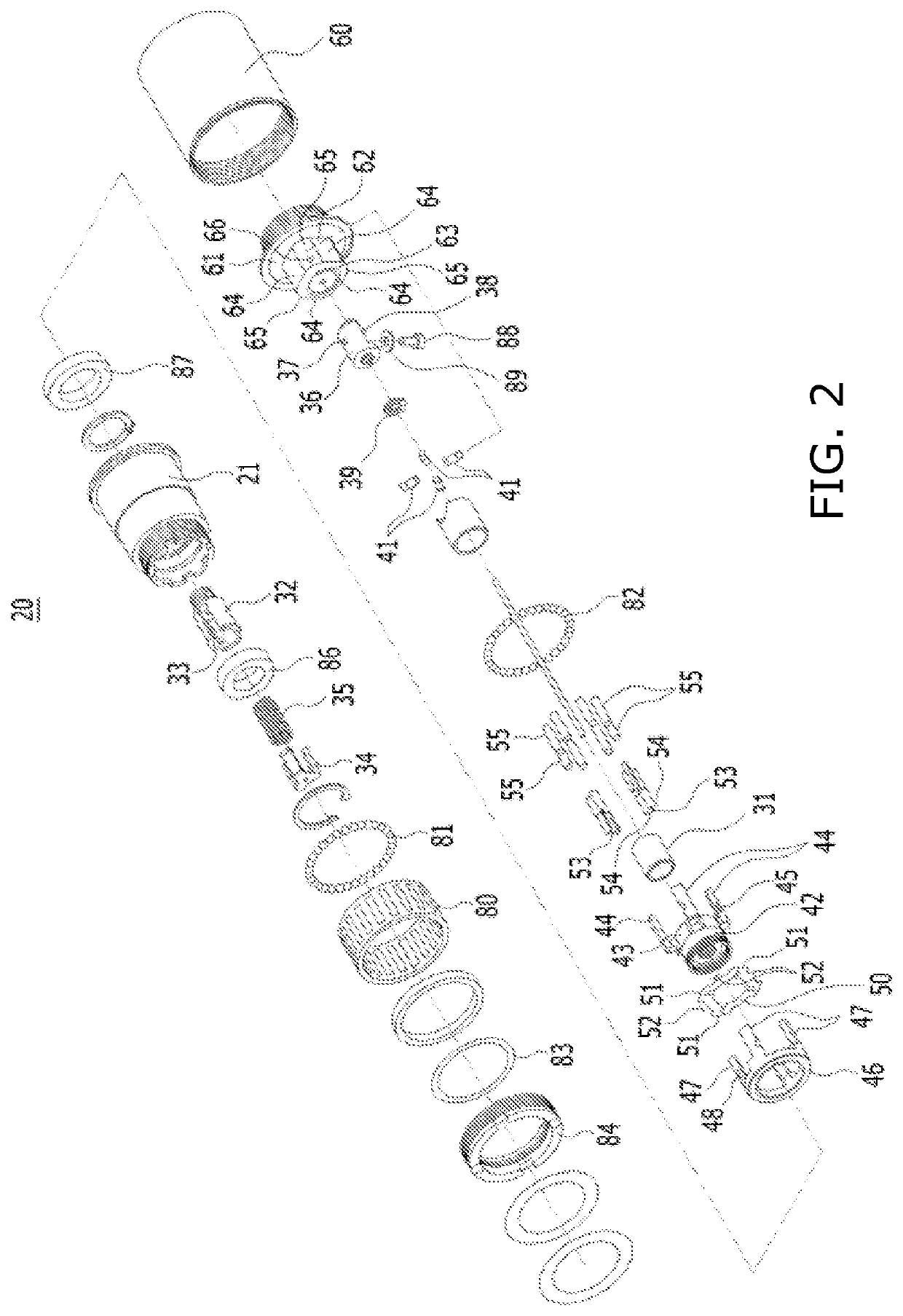

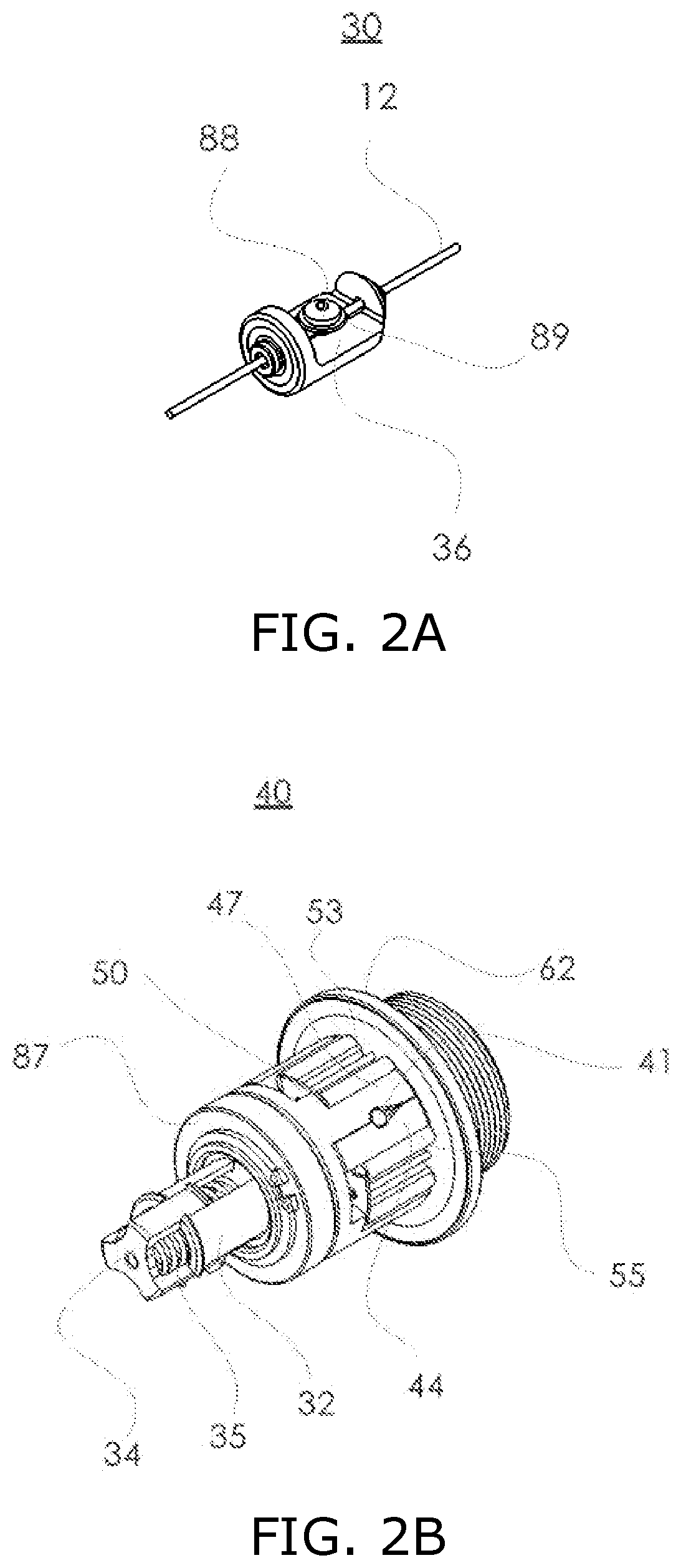

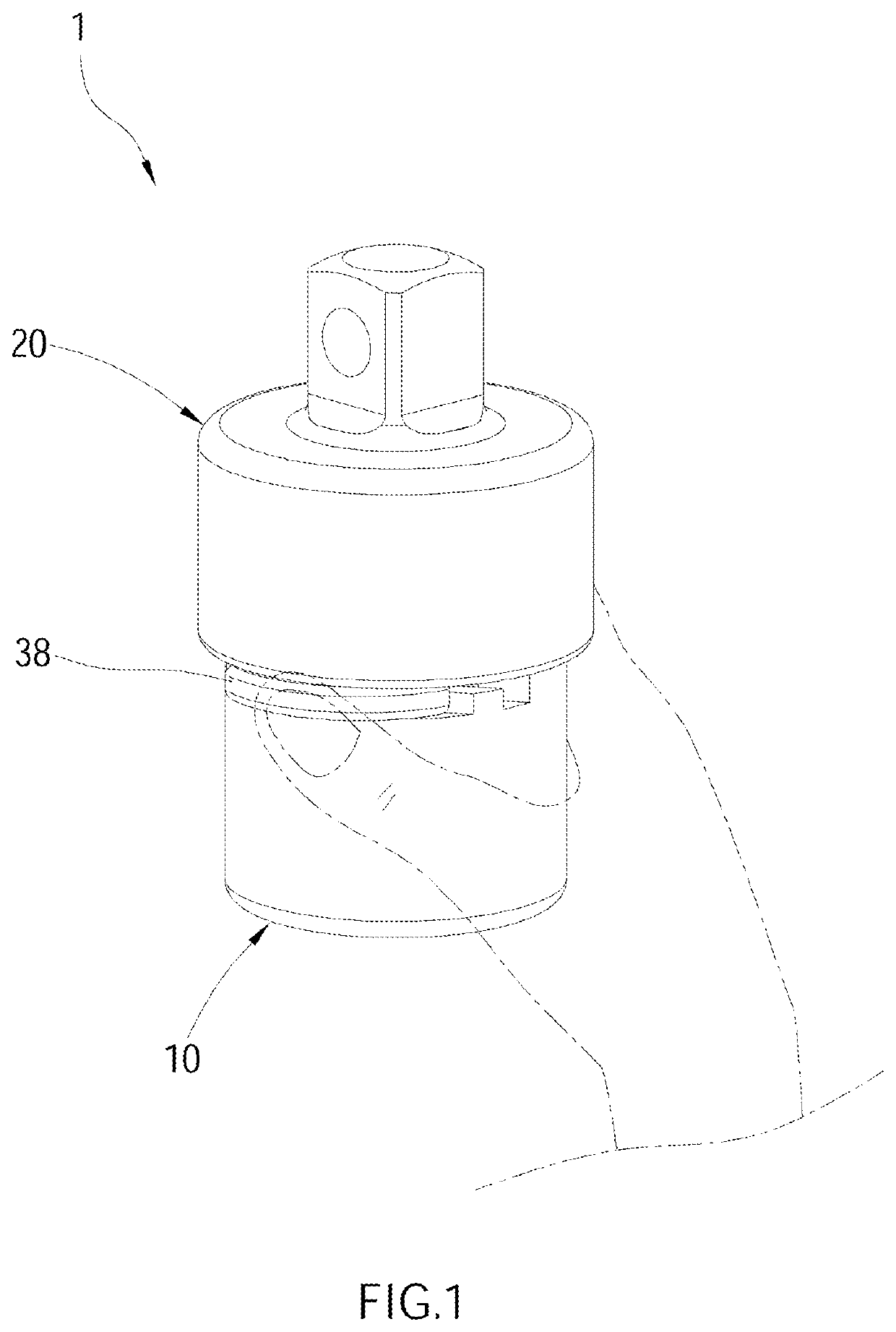

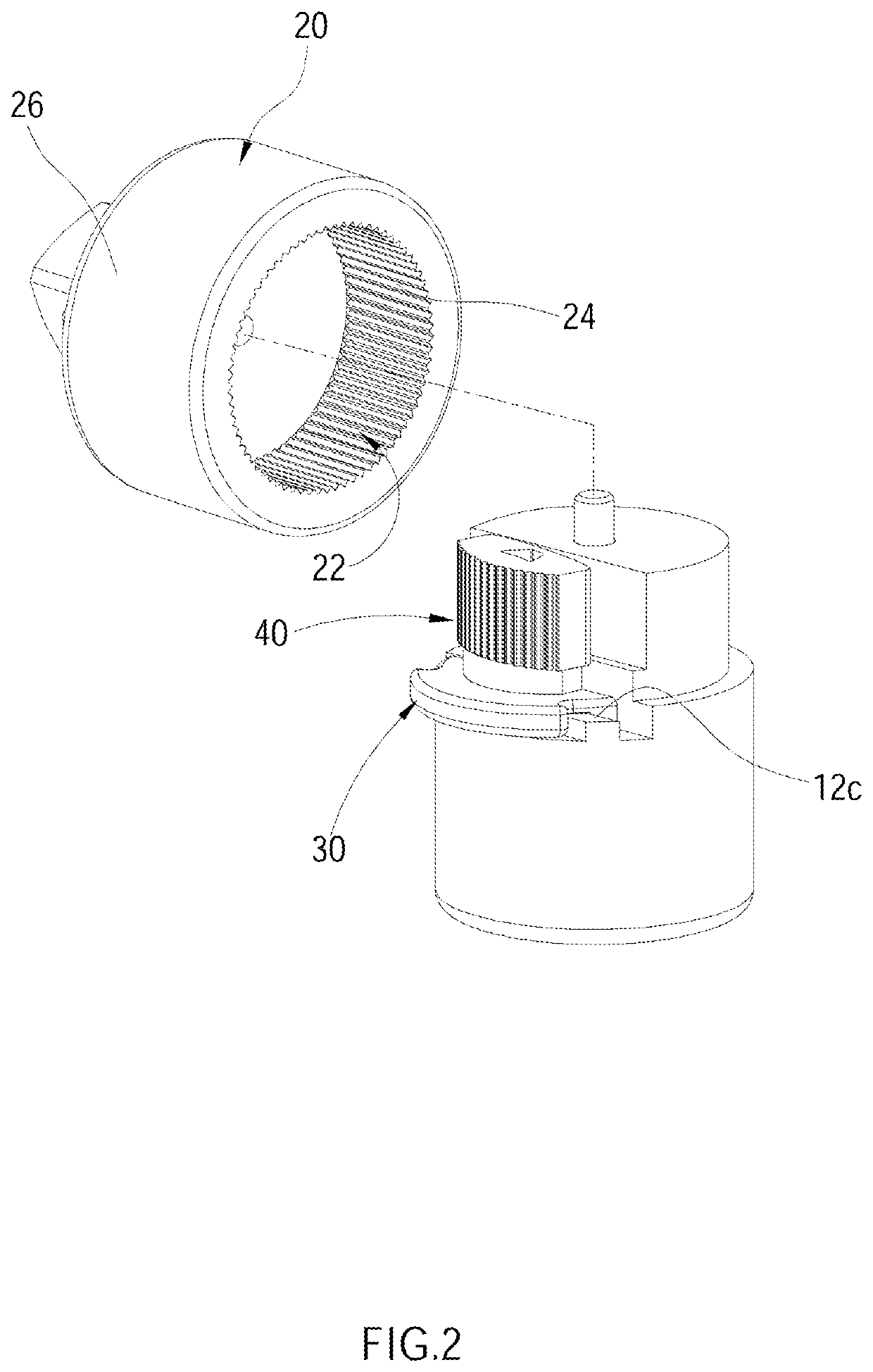

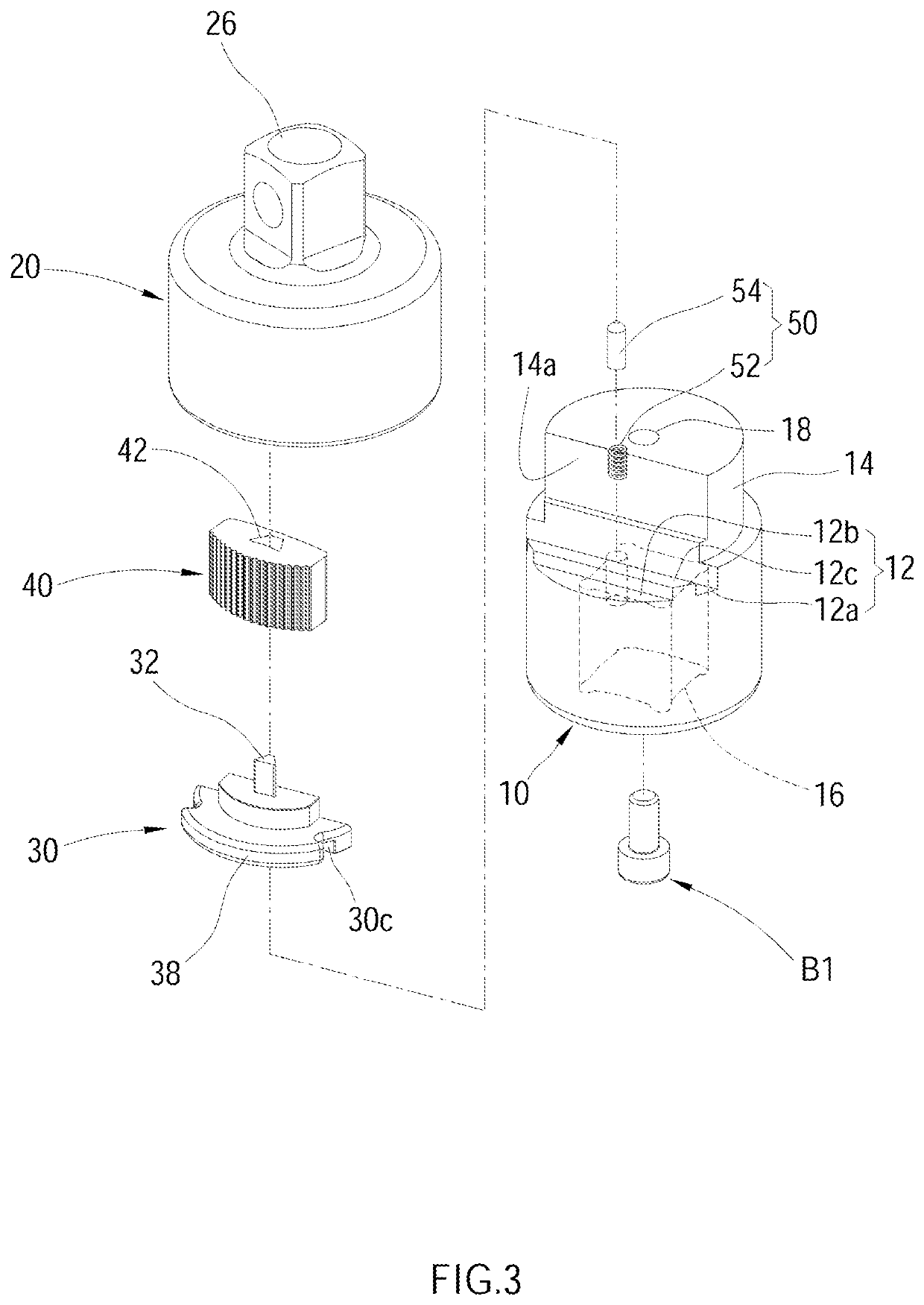

Gear motor having safety mechanism

ActiveUS8794087B2Reduce MechanismsReduce volumeToothed gearingsPortable liftingLeadscrewTouch switch

A gear motor having a safety mechanism includes a motor body, a speed reduction mechanism, a transmission mechanism, and a touch switch. The speed reduction mechanism includes a worm and a worm wheel drivingly engaged with the worm. The transmission mechanism includes a base fixed to the speed reduction mechanism, a lead screw rod pivotally connected to the base and rotatably driven by the worm wheel, and a nut threadedly connected to the lead screw rod. The touch switch is electrically connected to the motor body and provided aside the lead screw rod, thereby stopping the motor body when the nut contacts the touch switch. Thus, the gear motor not only controls the operation of the driven mechanism, but also allows various driven mechanisms to be mounted thereon. The assembled volume of the gear motor and the driven mechanism is reduced.

Owner:TIMOTION TECH CO LTD

Gear motor having safety mechanism

ActiveUS20130327168A1Increase safetyInspect and adjust easilyToothed gearingsTouch switchElectric motor

A gear motor having a safety mechanism includes a motor body, a speed reduction mechanism, a transmission mechanism, and a touch switch. The speed reduction mechanism includes a worm and a worm wheel drivingly engaged with the worm. The transmission mechanism includes a base fixed to the speed reduction mechanism, a lead screw rod pivotally connected to the base and rotatably driven by the worm wheel, and a nut threadedly connected to the lead screw rod. The touch switch is electrically connected to the motor body and provided aside the lead screw rod, thereby stopping the motor body when the nut contacts the touch switch. Thus, the gear motor not only controls the operation of the driven mechanism, but also allows various driven mechanisms to be mounted thereon. The assembled volume of the gear motor and the driven mechanism is reduced.

Owner:TIMOTION TECH CO LTD

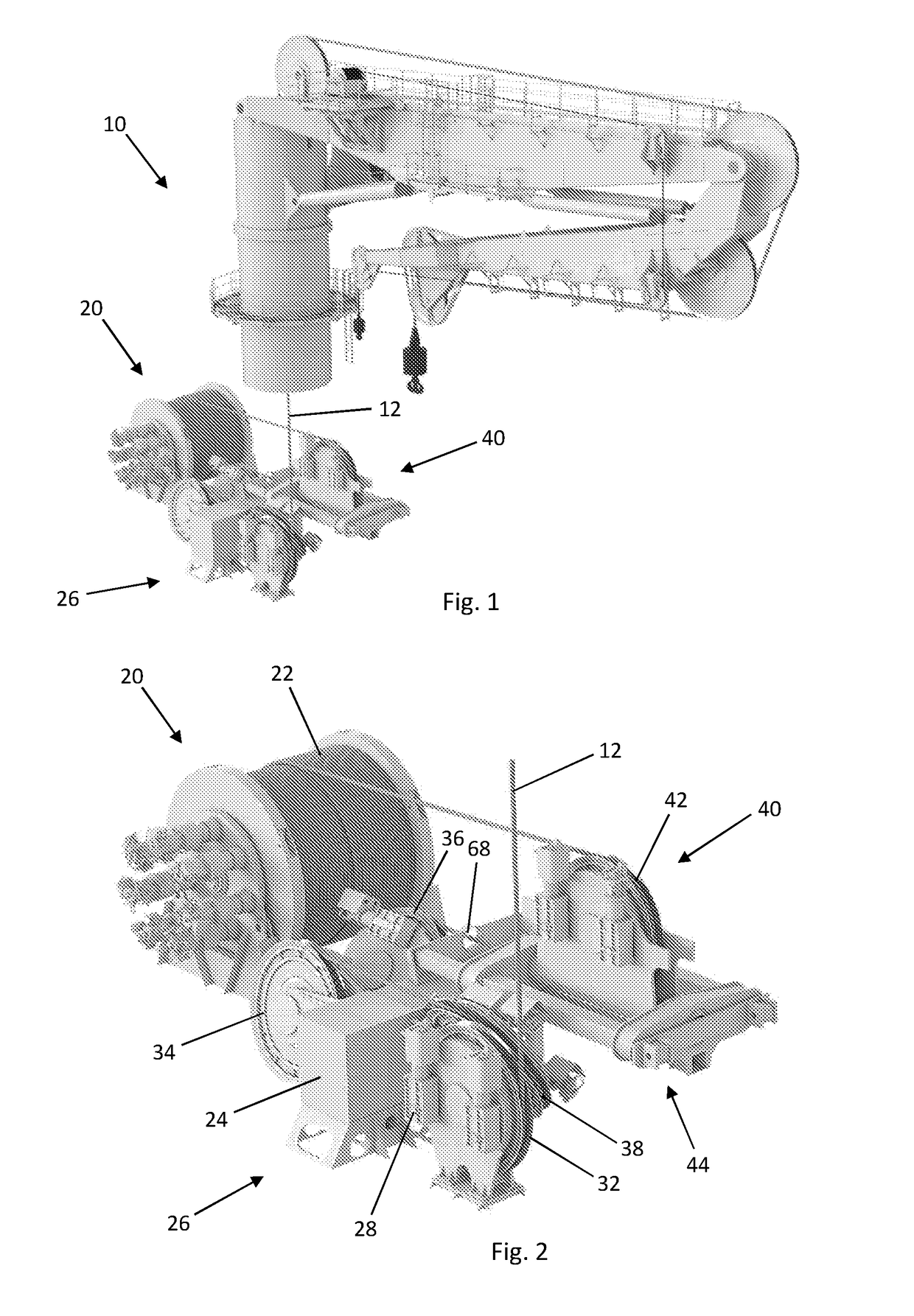

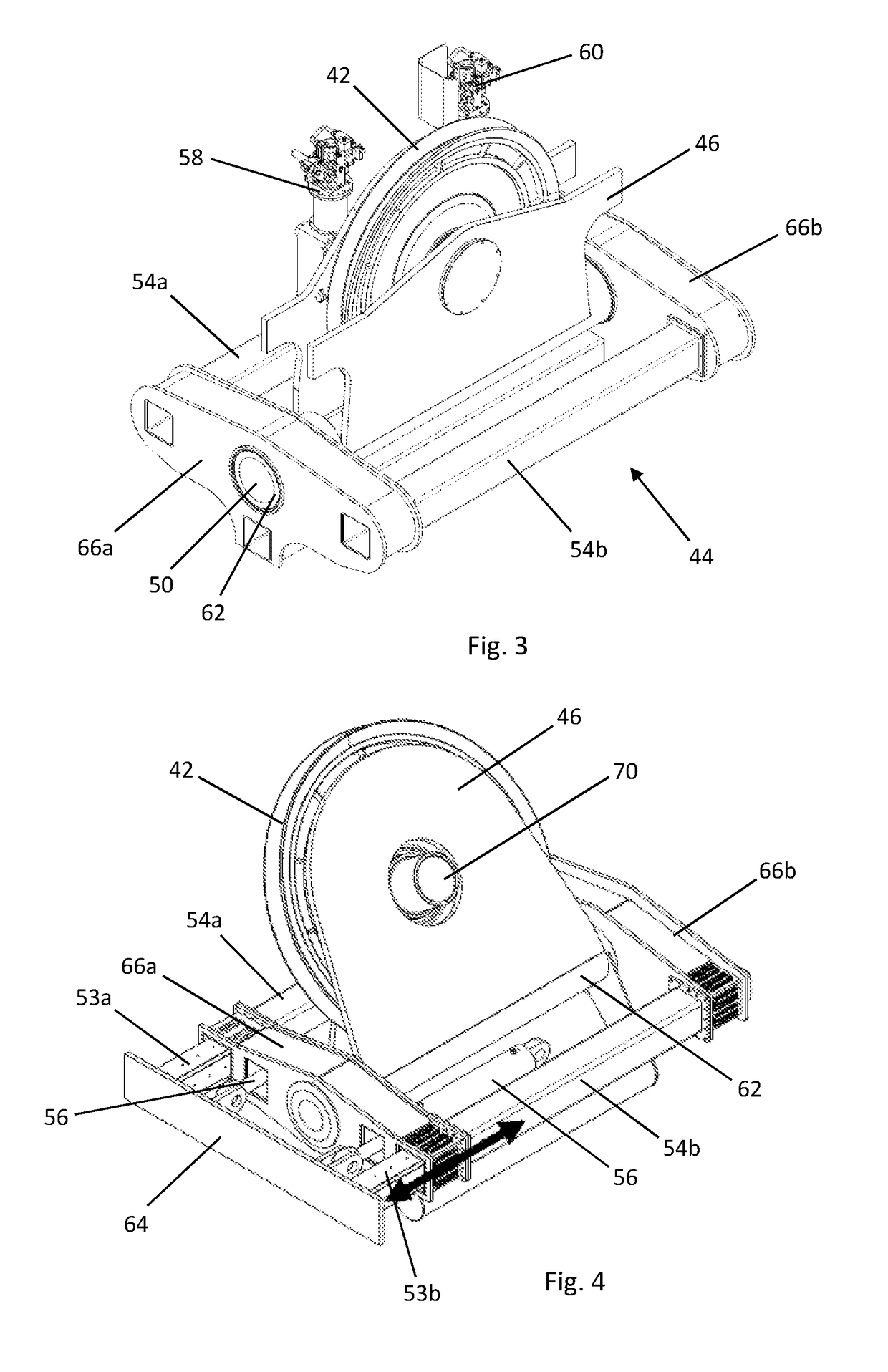

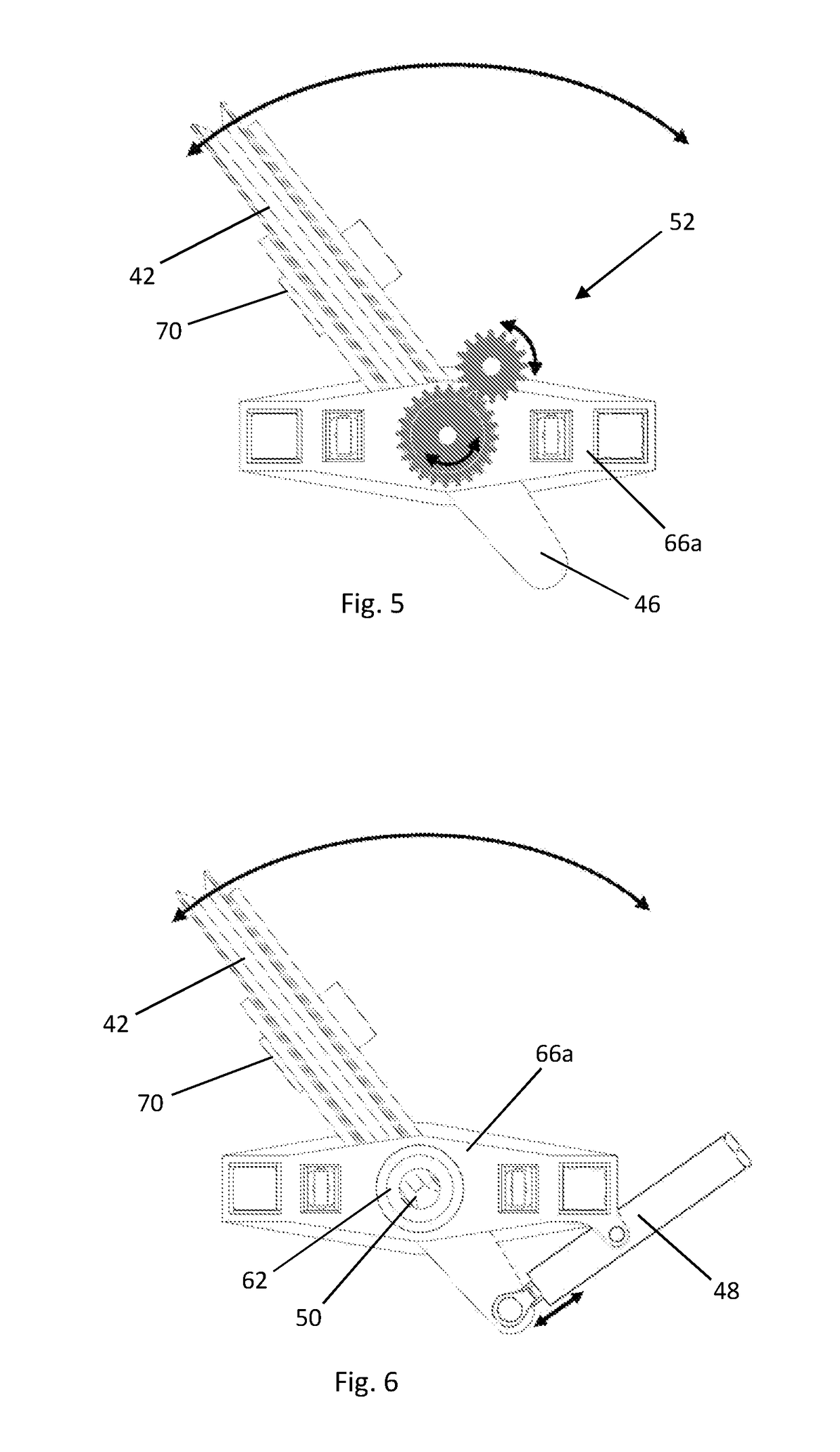

System and spooling device for spooling of a rope on a winch drum

InactiveUS20180346296A1Improve securityCompact and simple to useFilament handlingWinding mechanismsWinchSpooling

A spooling apparatus (40) for spooling and regulating the pull of a rope (12) or a cable that shall be spooled onto or out from a winch drum (22), comprising a spooling sheave (42) onto which the rope (12) is guided before it is spooled onto the winch drum (22), where the spooling apparatus (40) comprises a linearly moving slide (44) and that the spooling sheave (42) is mounted in the slide (44) so that it can be tilted sideways. Also described is a system for the spooling in of a rope (12) or a cable that shall be spooled onto or out from a winch drum (22) comprising a winch (20) with said winch drum (22) and a traction unit (26) for the tension on the rope (12), and also a spooling apparatus (40).

Owner:ROLLS ROYCE MARINE

Automotive leather cutting station

InactiveCN1853883AMoving linearLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusEngineeringVertical axis

Owner:SETON SOUTH AFRICA

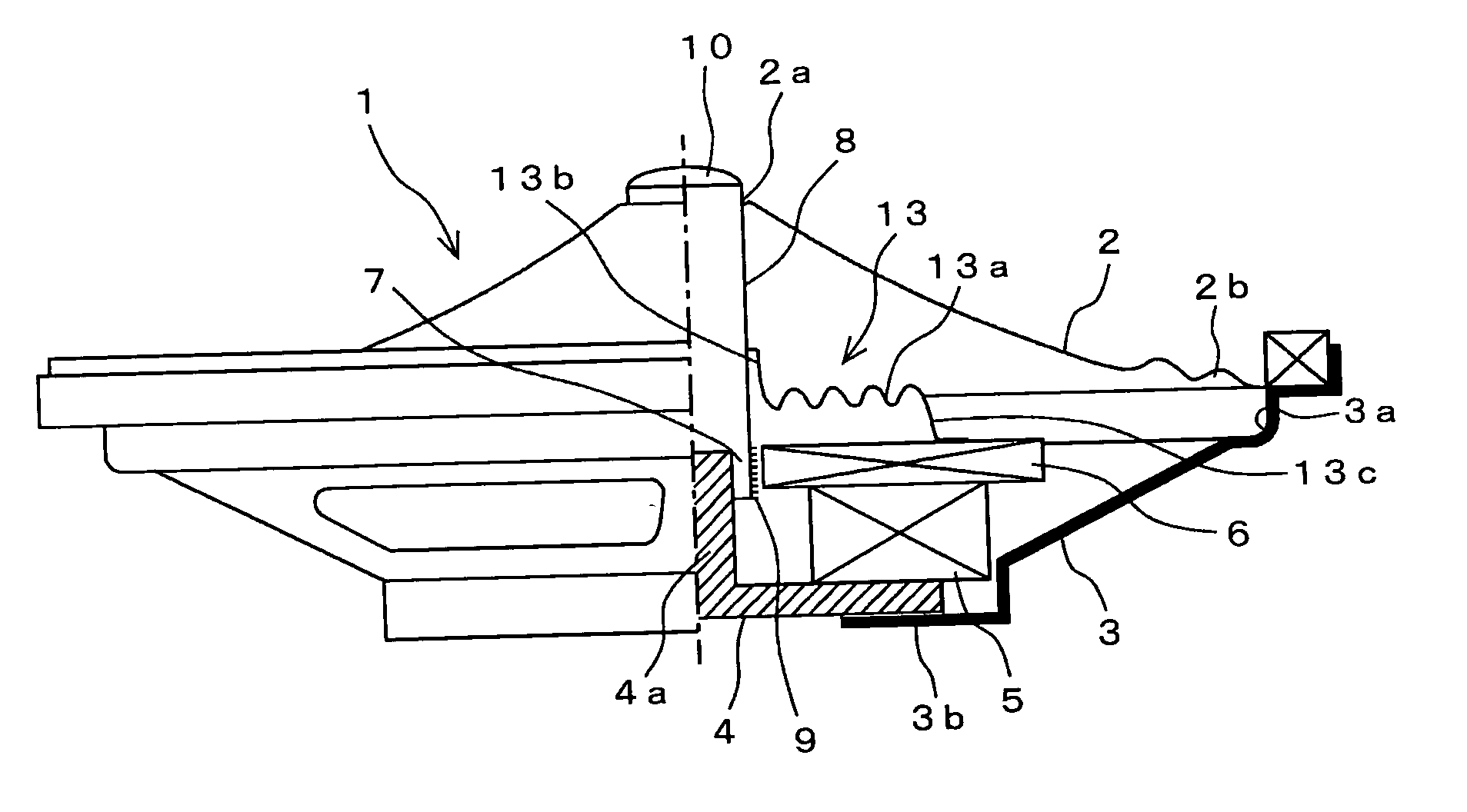

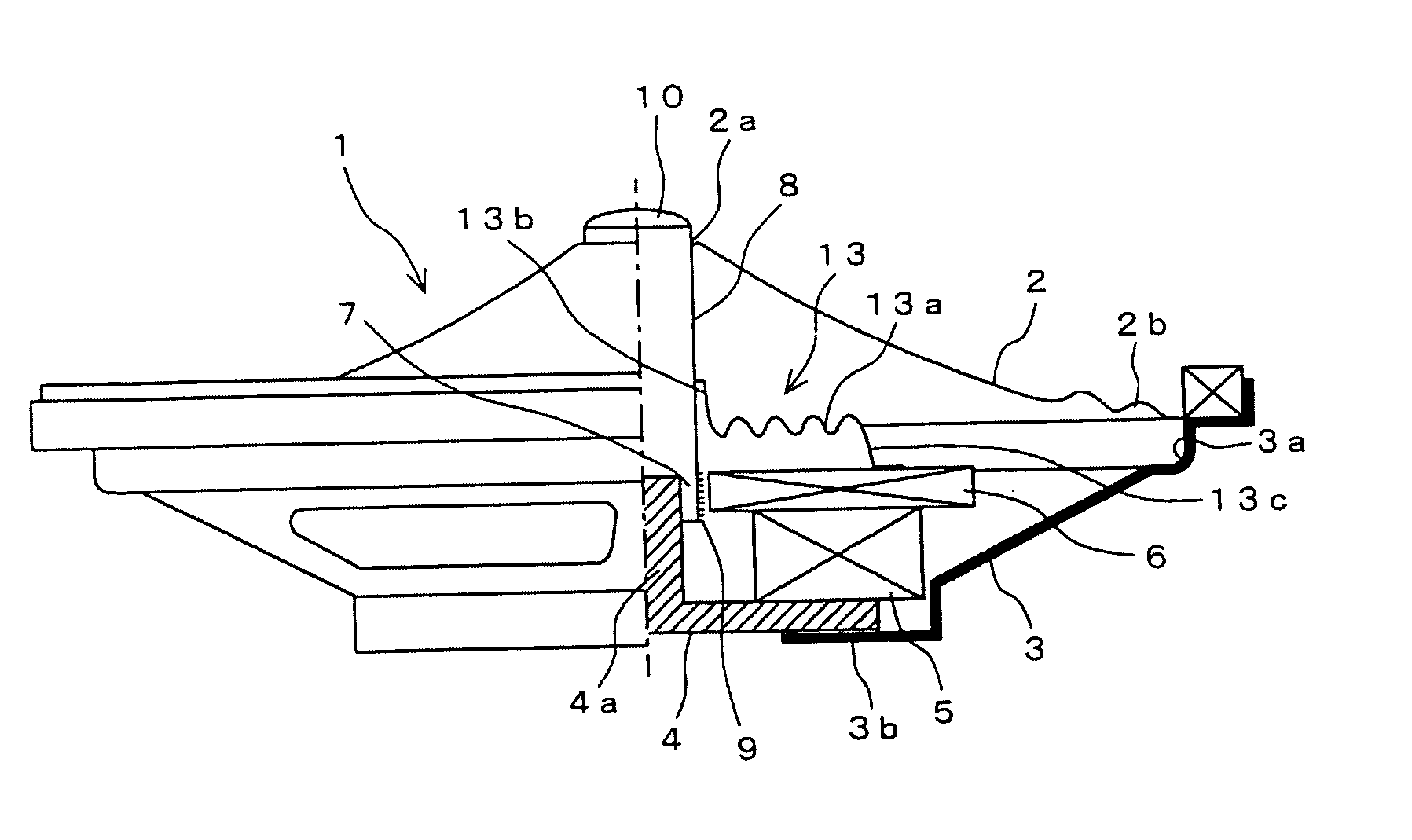

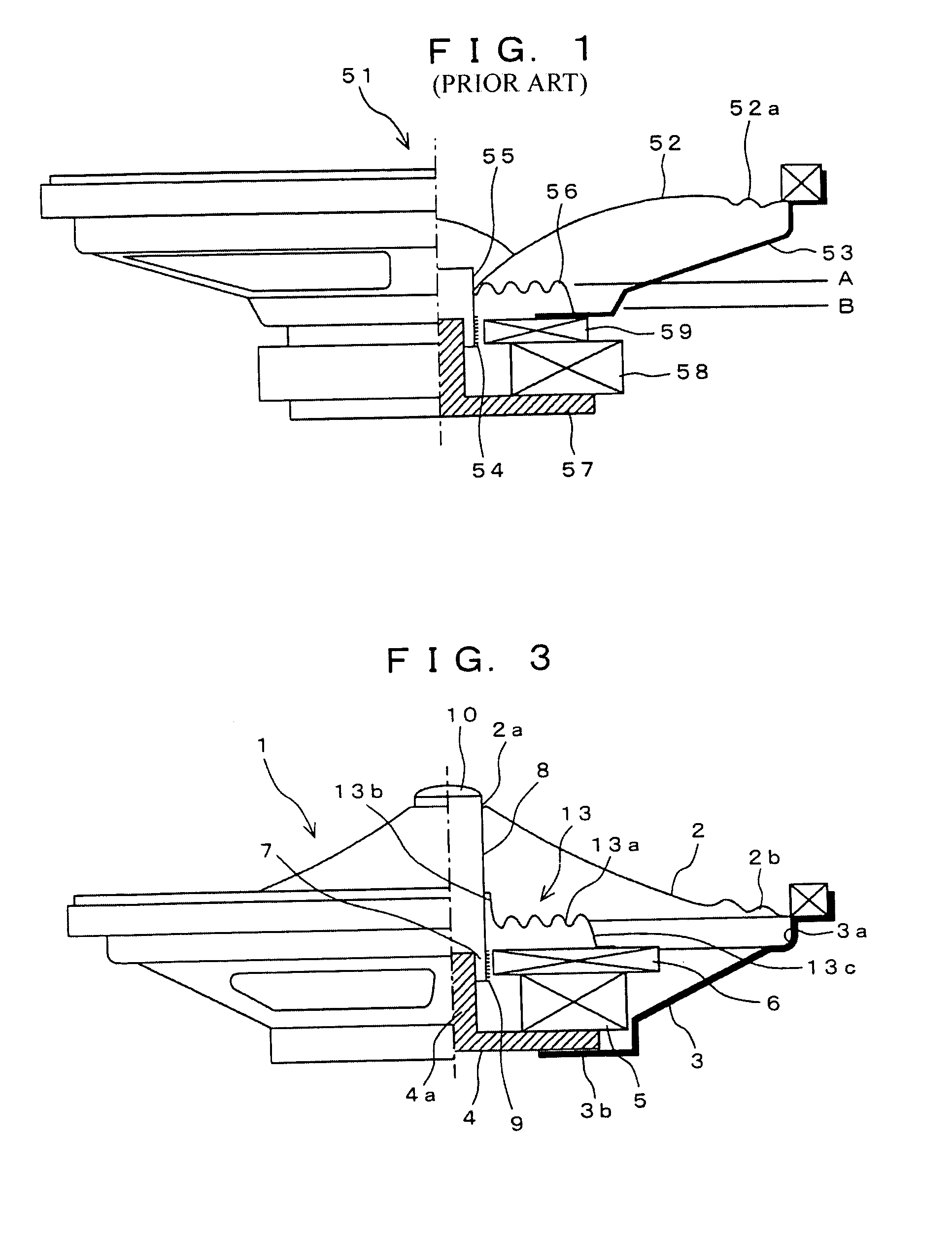

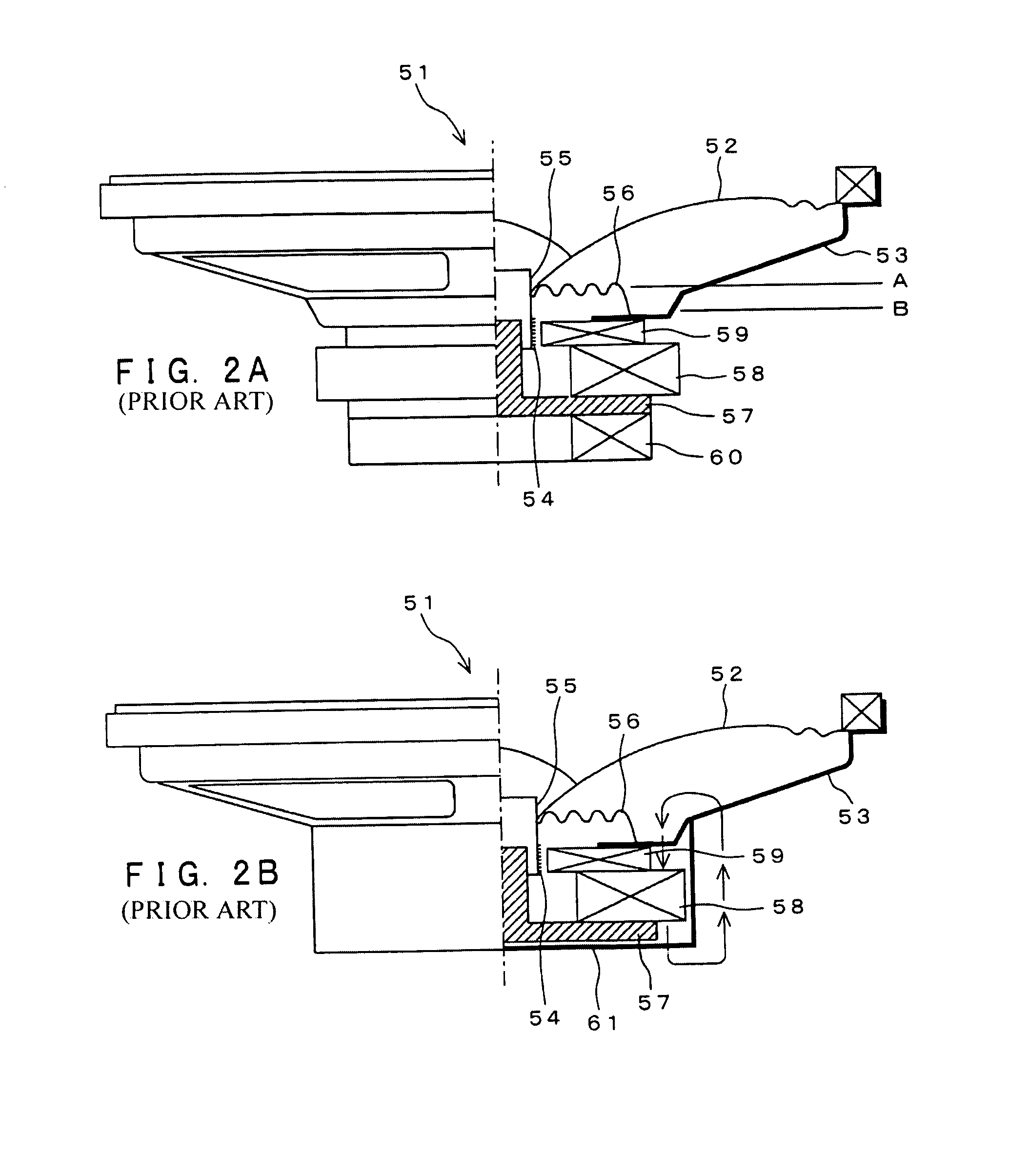

Speaker apparatus

InactiveUS7171015B2Preventing the bobbin from vibrating laterallyMoving linearTransducer detailsNon-planar diaphragms/conesBobbinEngineering

A speaker apparatus has a frame to which a convex paper is attached. A bobbin with a voice coil is attached to the paper cone. A magnetic circuit is formed inside the frame. A damper suspending the bobbin is composed of a corrugation portion, which is positioned orthogonal to the bobbin in an inactivity of the speaker apparatus. The damper also includes a first leg portion extending forward along a vibration direction of the bobbin from an inner periphery end of the corrugation portion, and a second leg portion extending backward along the vibration direction of the bobbin from an outer periphery end of the corrugation portion. The first and second leg portions have substantially the same length.

Owner:SONY CORP

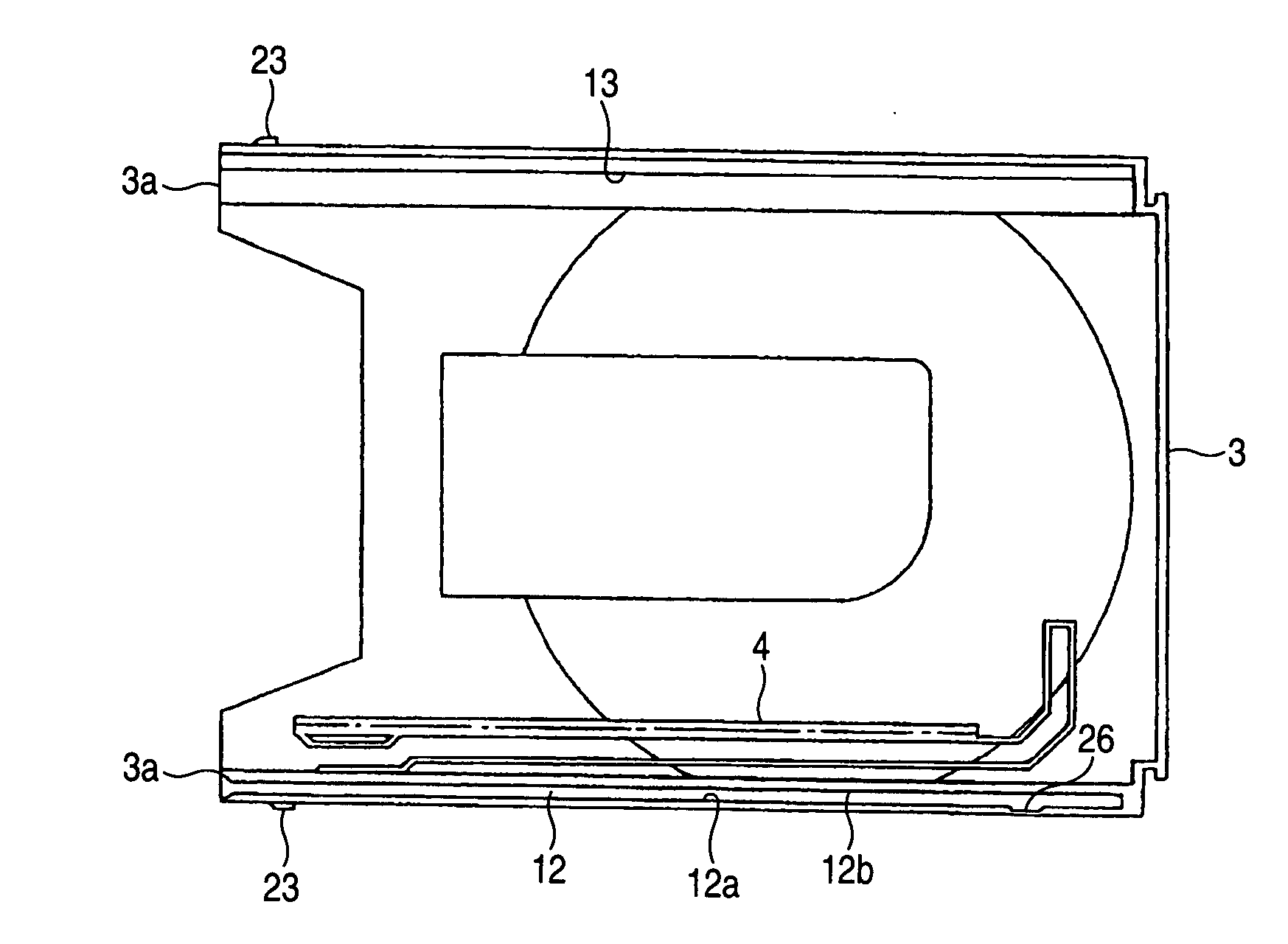

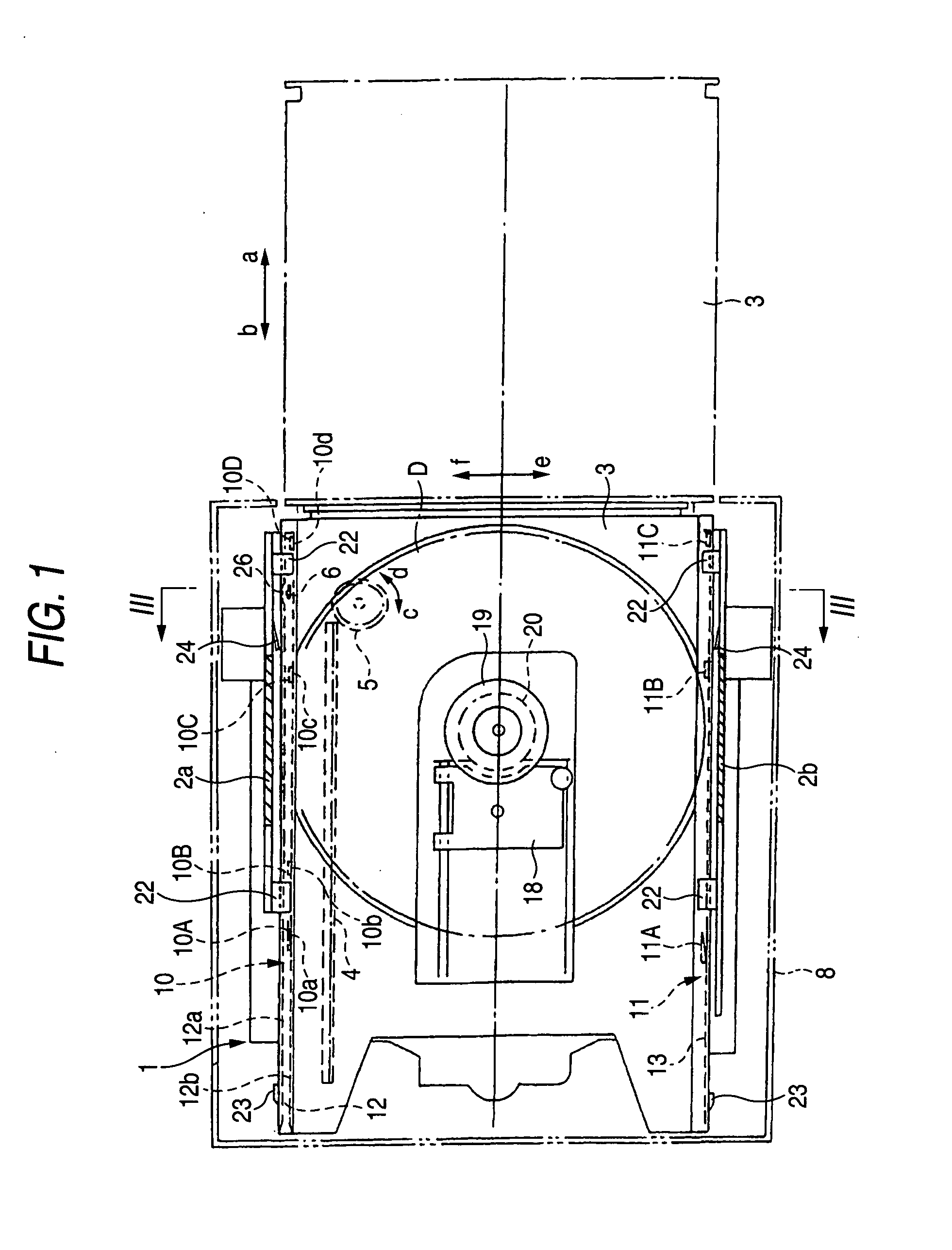

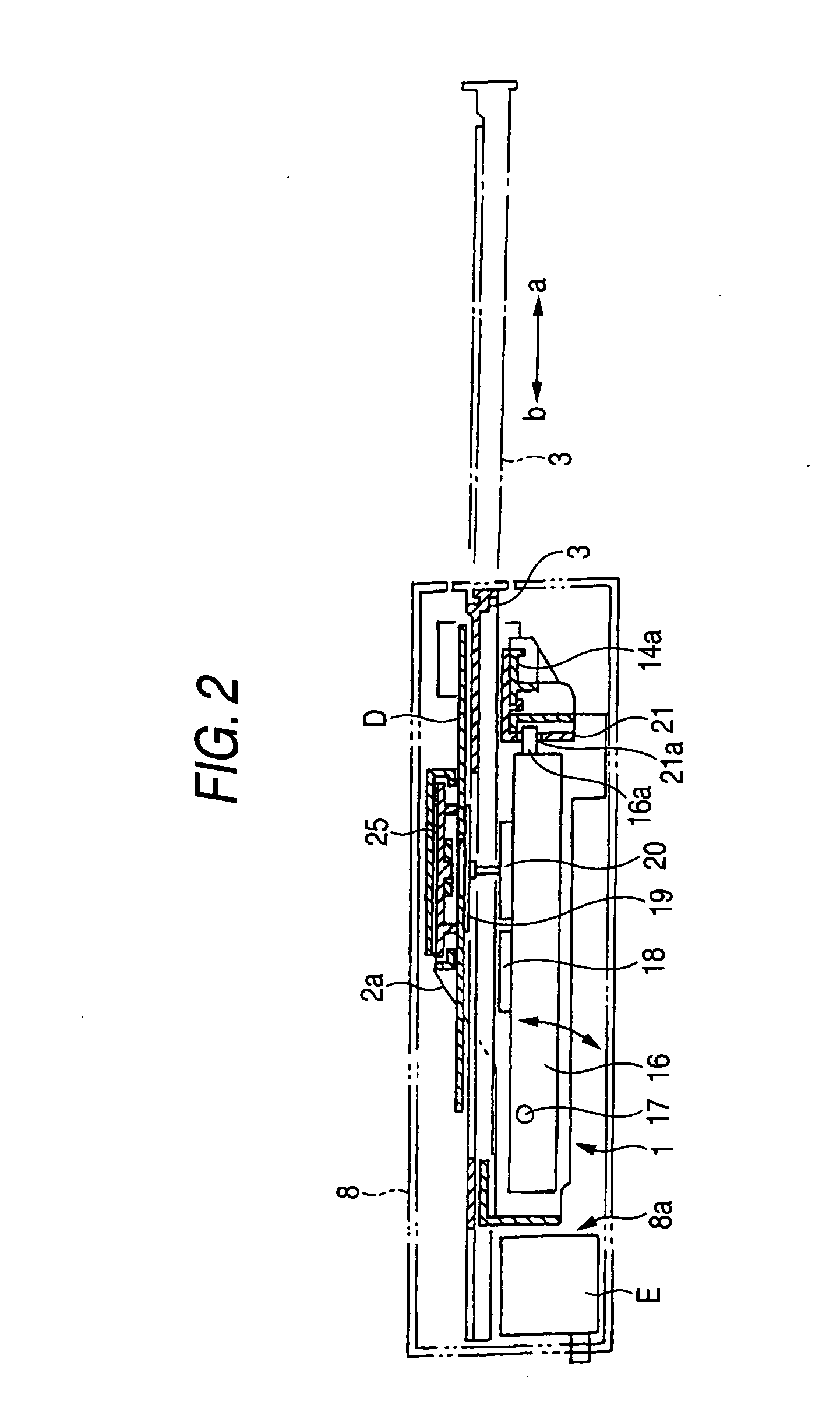

Disk player

InactiveUS20050015787A1Reduce contact resistanceLow costRecord information storageRecord carrier contruction detailsLower faceMechanical engineering

In guide grooves formed at both side edges of a lower face of a tray and fitted to a pair of left and right guide members of a cabinet, the guide groove substantially in a U-like shape on one side is inserted with a front end portion of an elastic plate integrally projected at a front portion of the cabinet, a recess portion is formed at a portion of one side face of the guide groove 12 opposed to the elastic plate in a state of containing the tray into the cabinet, and formed such that by bringing the one side face of the guide groove 12 into elastic contact with the elastic plate opposed to the recess portion in moving the tray forward, other side face of the guide groove is brought into contact with reference guide faces of the guide member on one side to thereby prevent the tray from being inclined.

Owner:FUNAI ELECTRIC CO LTD

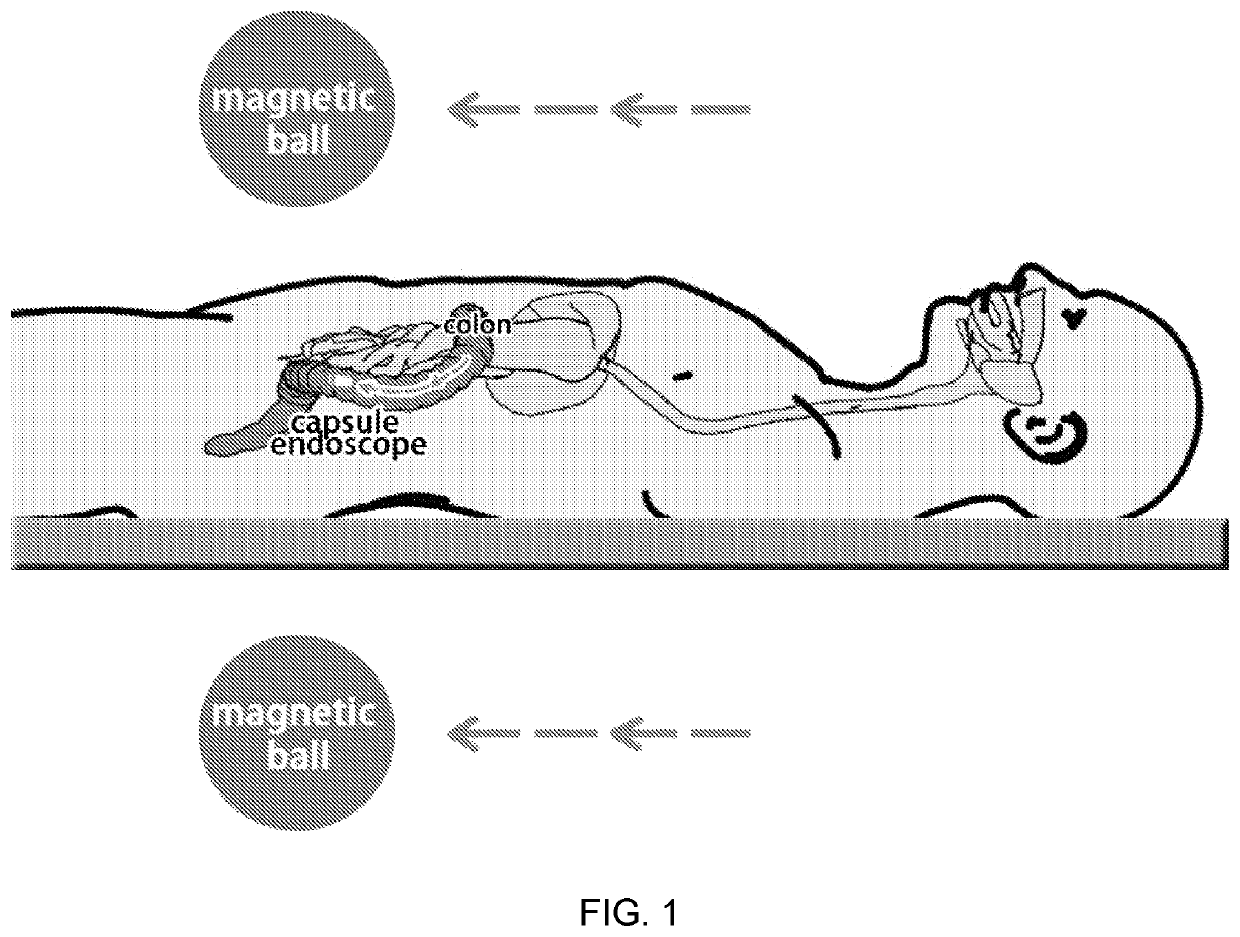

System and method for using a capsule device

ActiveUS10478047B2Controllable and tranquil mannerMoving linearGastroscopesEndoscopesEngineeringMagnetic field

The present invention discloses a method to move a magnetic capsule linearly both horizontally and linearly in a very controllable fashion, wherein the direction of a combined external magnetic field, the force experienced by the magnetic capsule, the movement direction of the capsule and magnetic direction of the magnetic capsule can be all aligned in parallel to each other.

Owner:ANKON MEDICAL TECH (SHANGHAI) CO LTD

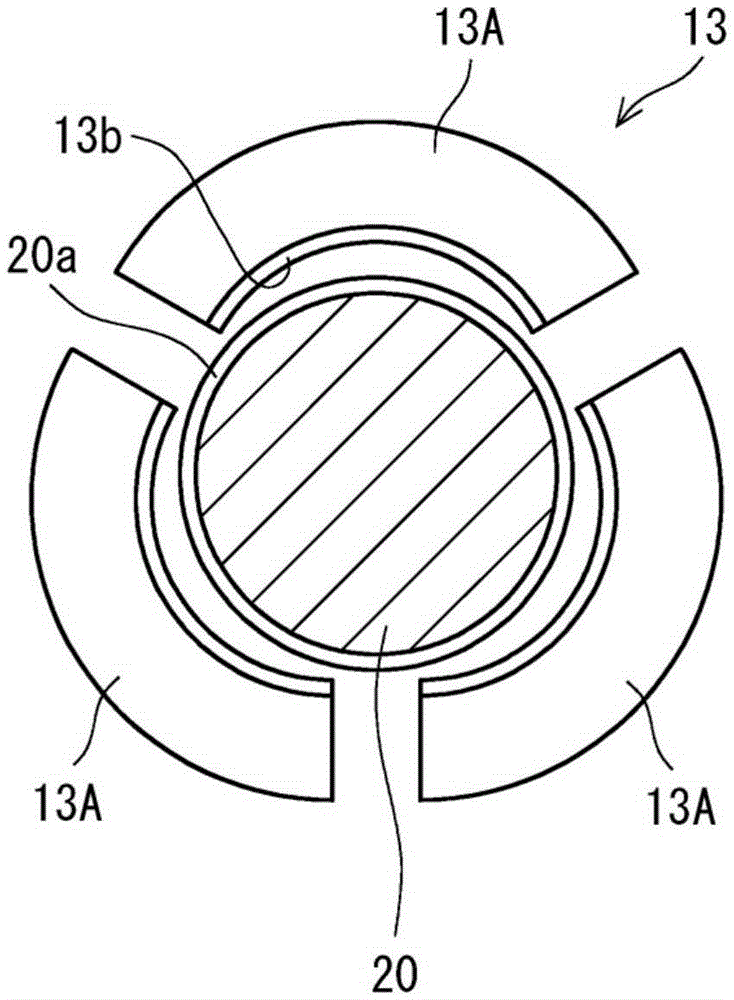

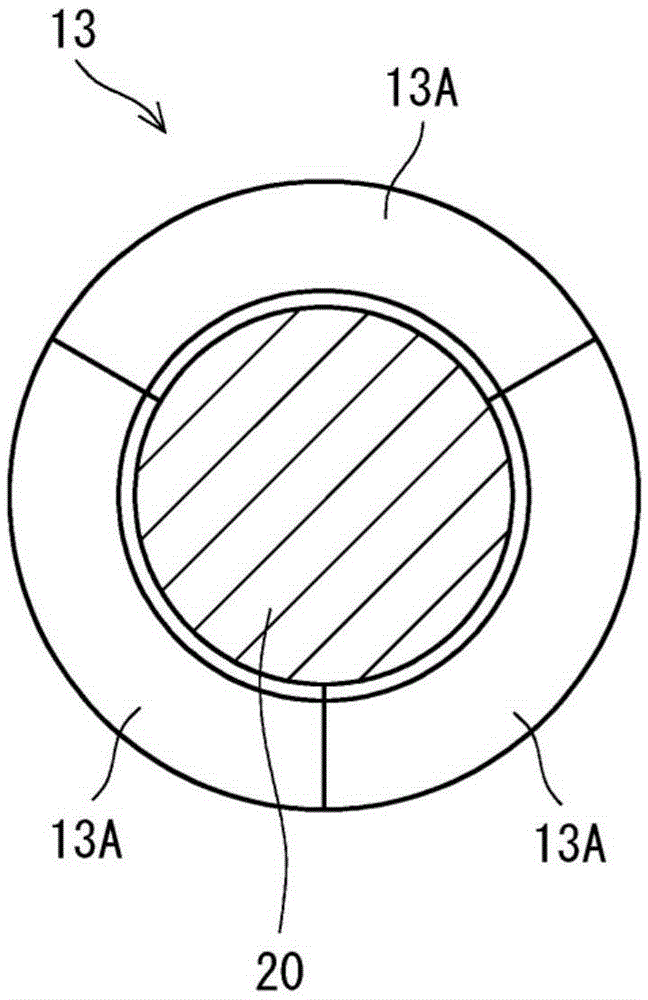

Drive shaft press-fitting device

InactiveCN105563080AMoving linearReliable press-inVehicle componentsMetal working apparatusLinear motionDrive shaft

The invention relates to a drive shaft press-fitting device. In the drive shaft press-fitting device, when a collet chuck (clamp) is moved backward by a linear motion means, the end part of the collet chuck closes by collaboration of a tapered surface of the collet chuck and an engagement part of a sleeve, and thereby the collet chuck holds an external thread part of the drive shaft. When the collet chuck is further moved backward by the linear motion means, the drive shaft is drawn out of the axle hub by the collet chuck, and thereby the drive shaft is pressed into the axle hub. After press-fitting, when the collet chuck is moved forward by the linear motion means, the collet chuck opens to be away from the external thread part of the drive shaft by a biasing means.

Owner:TOYOTA JIDOSHA KK

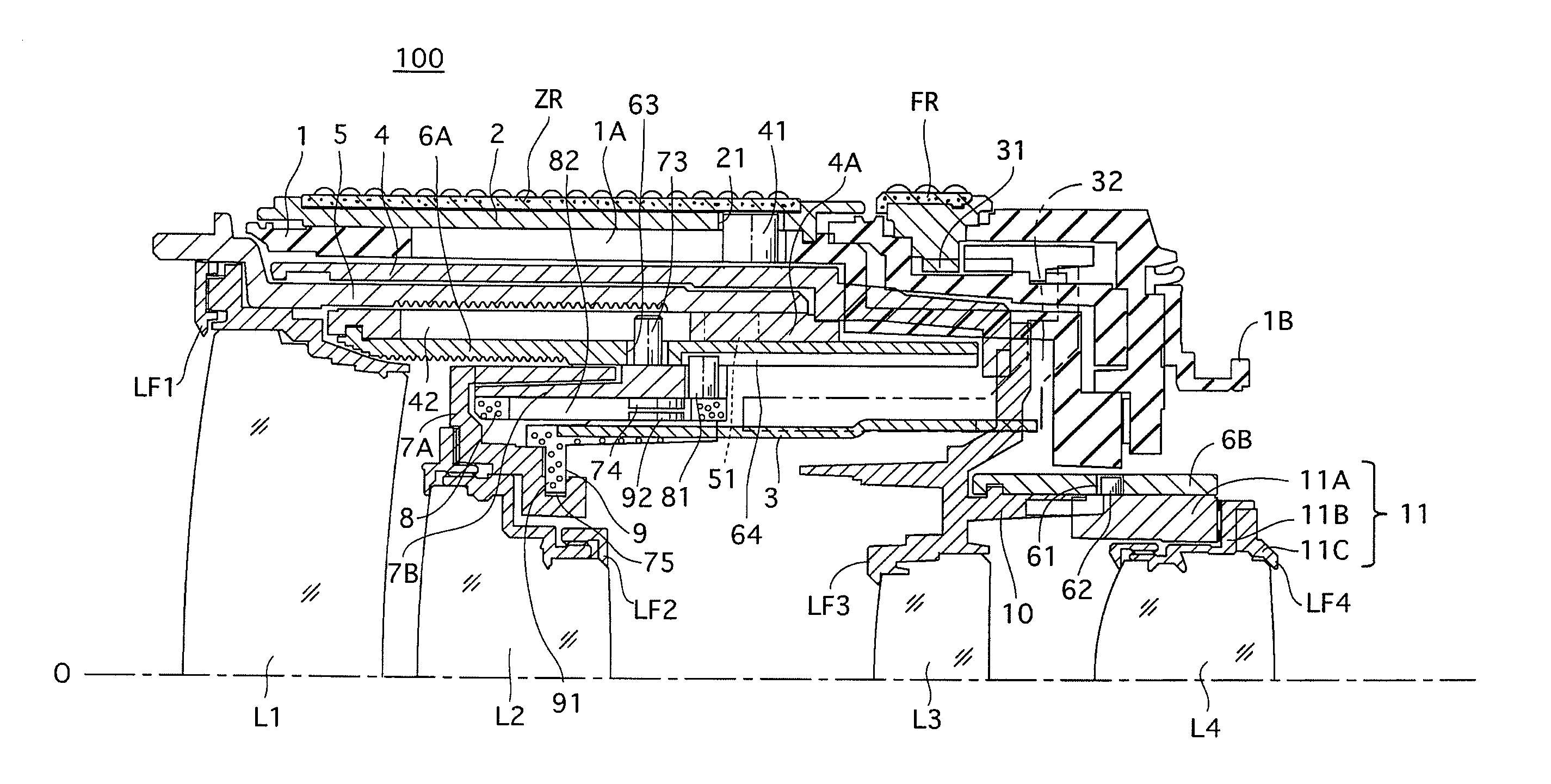

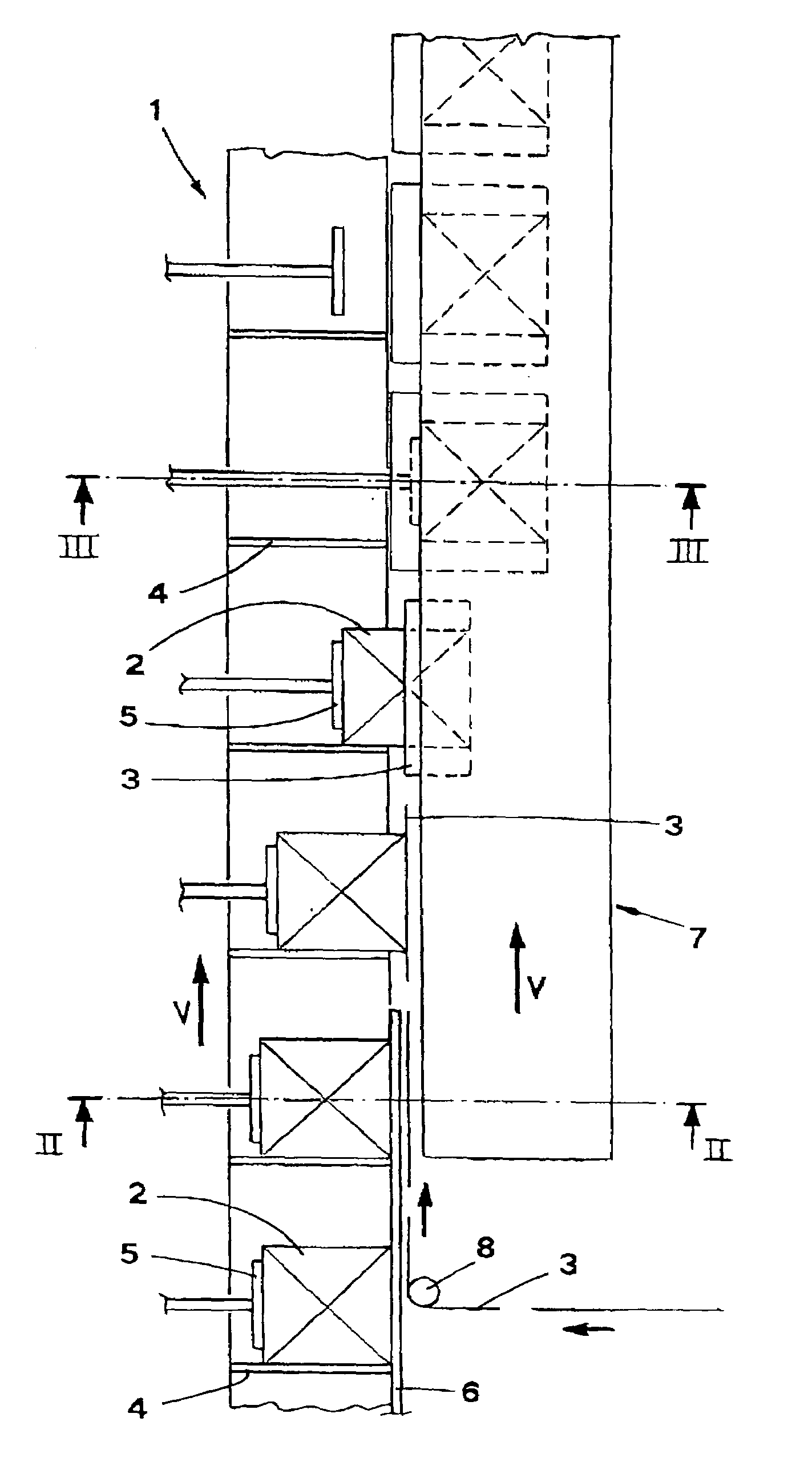

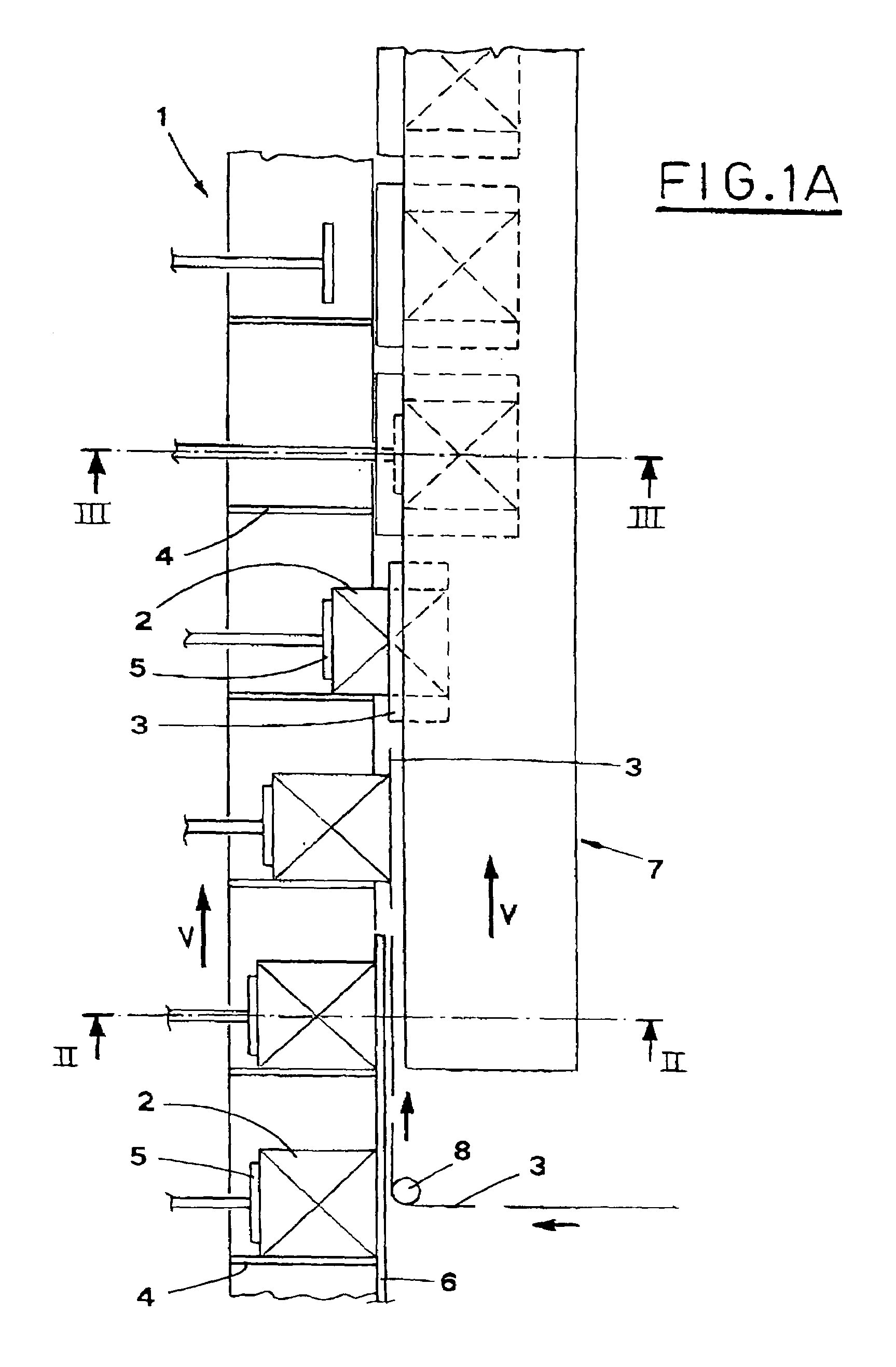

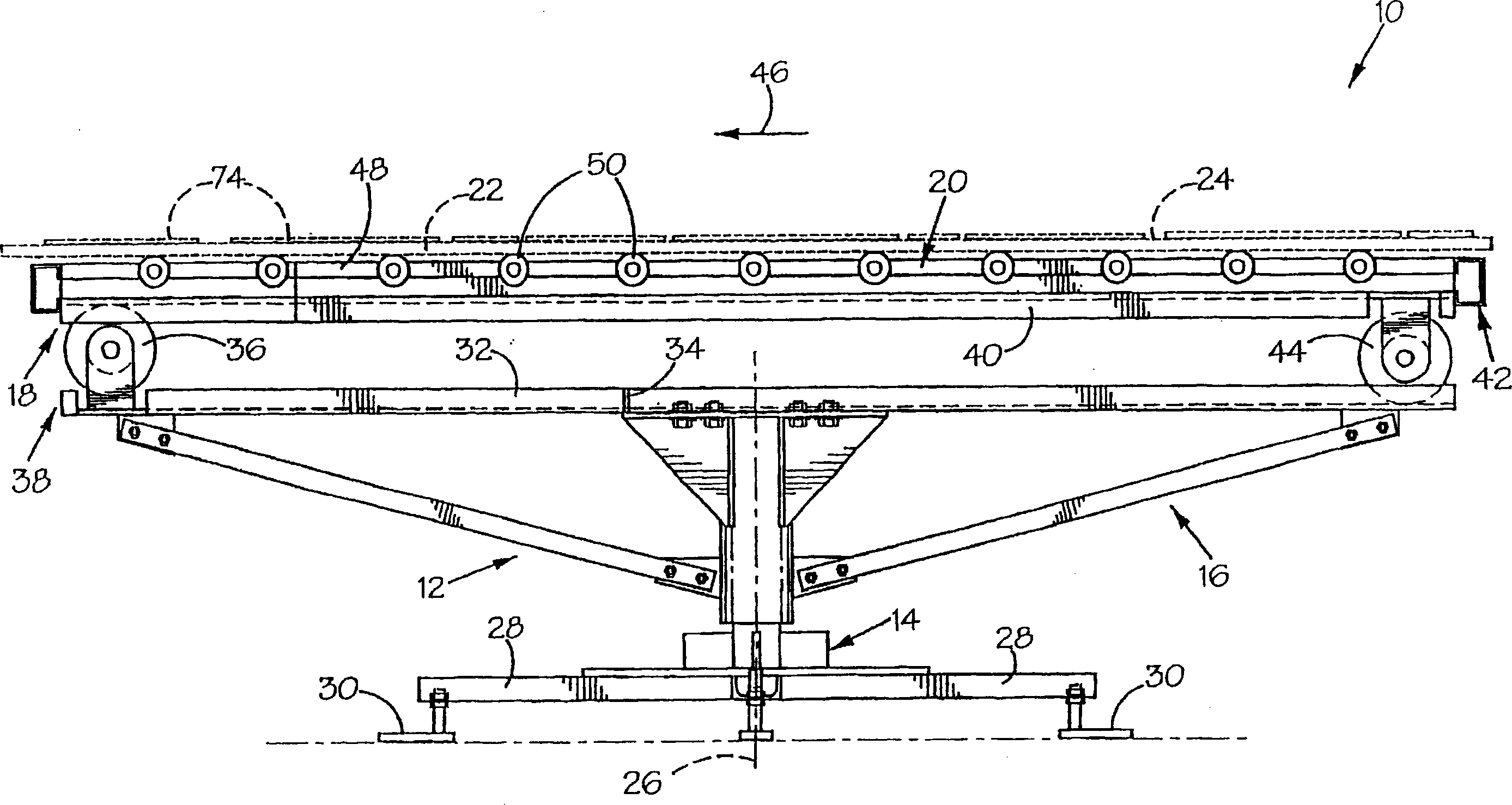

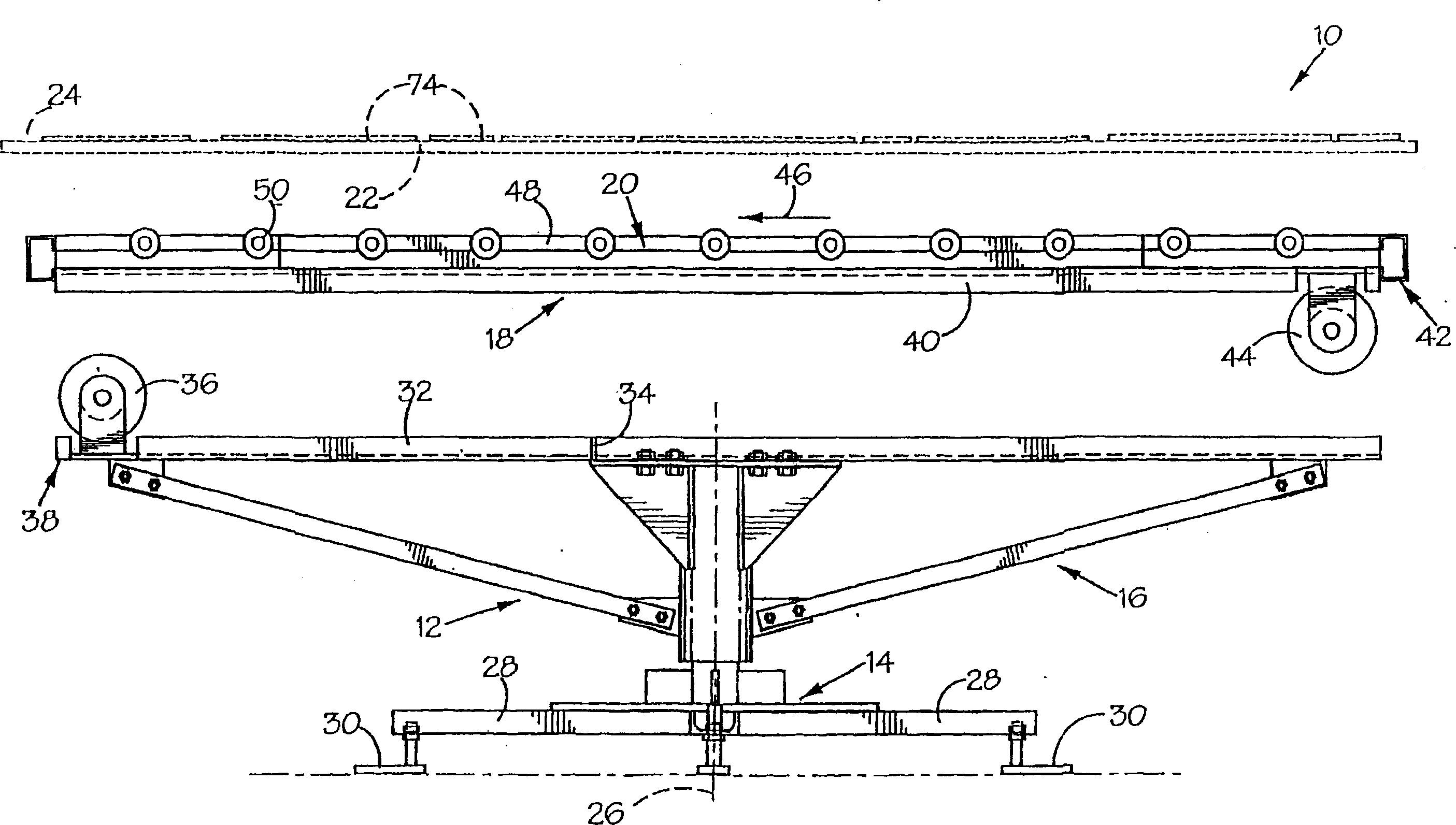

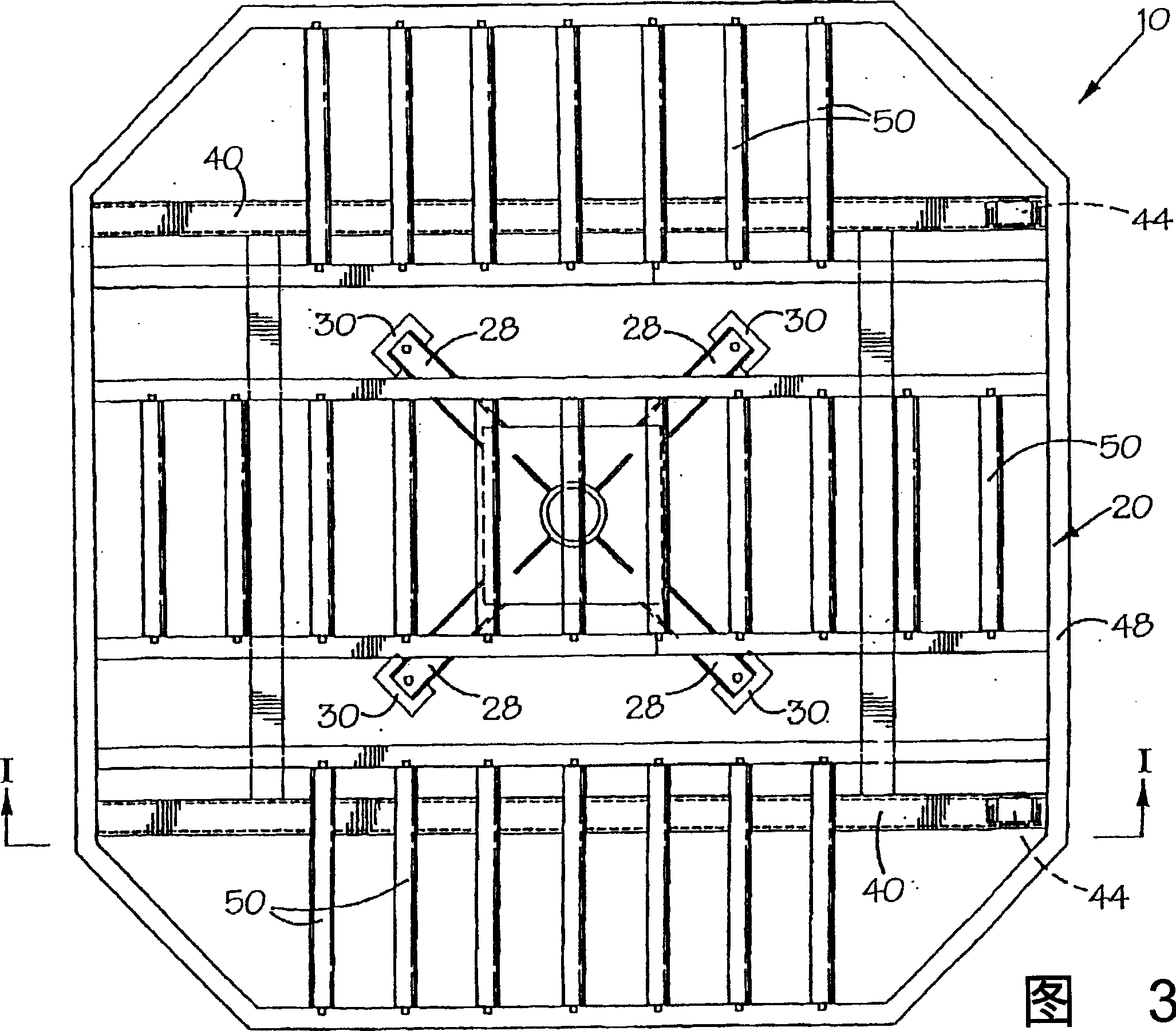

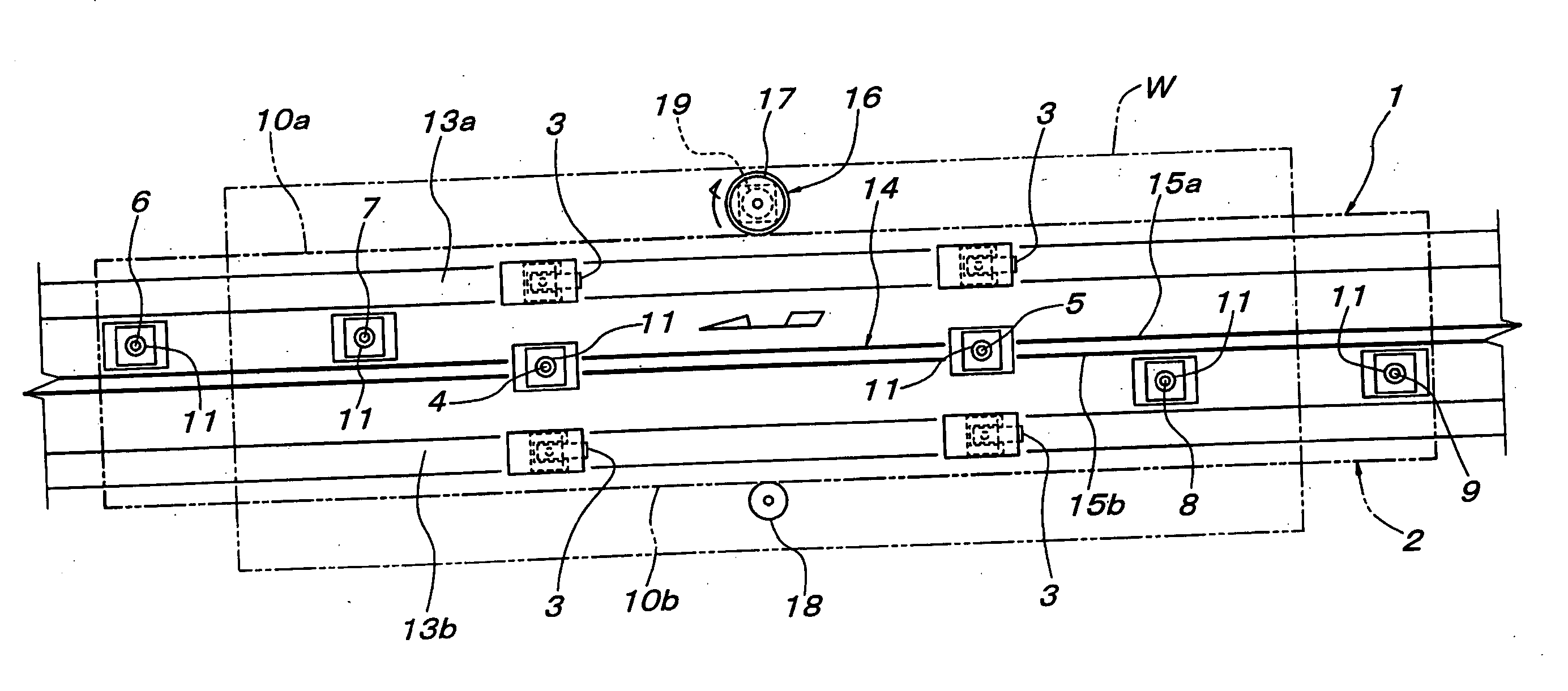

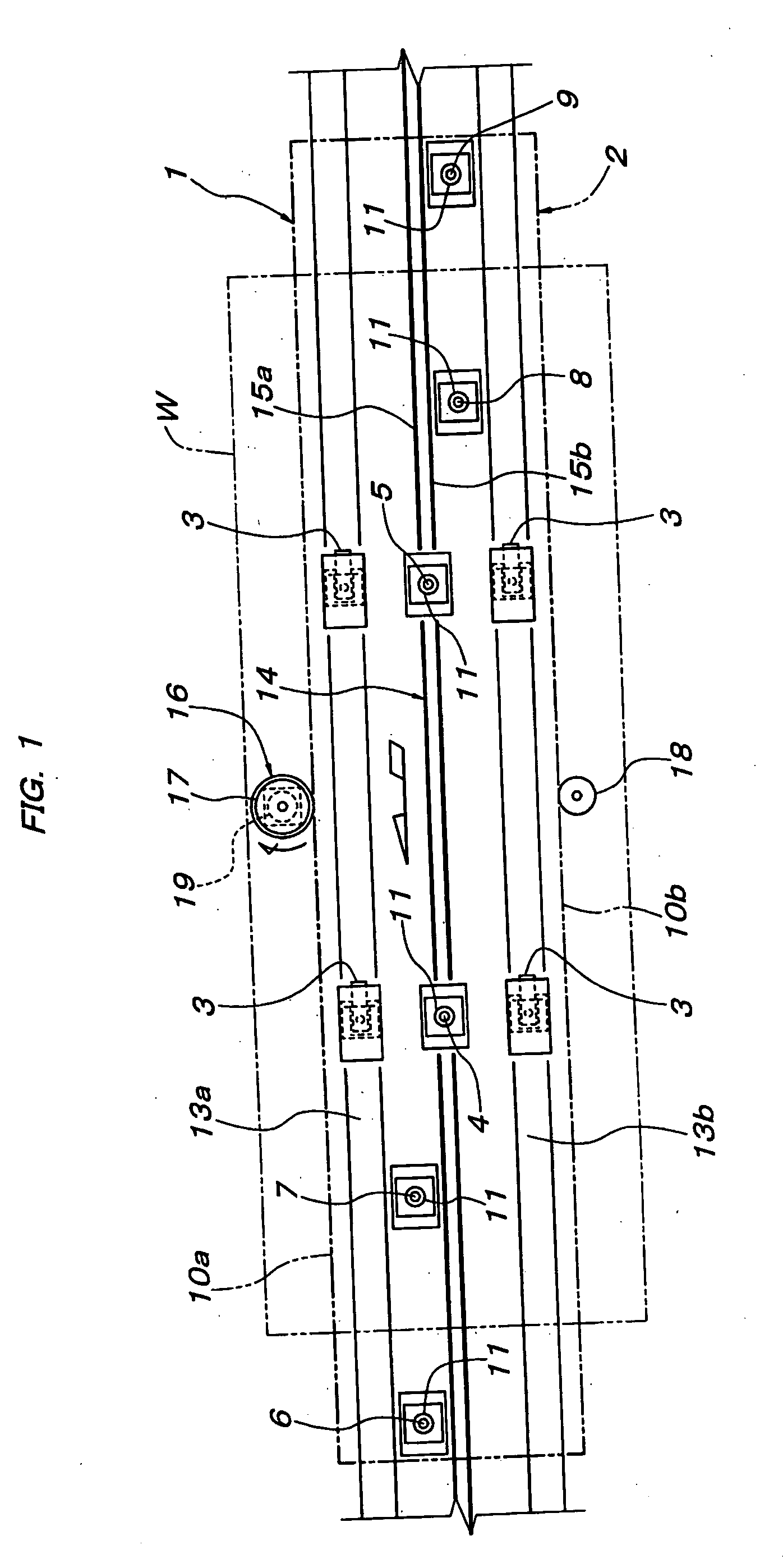

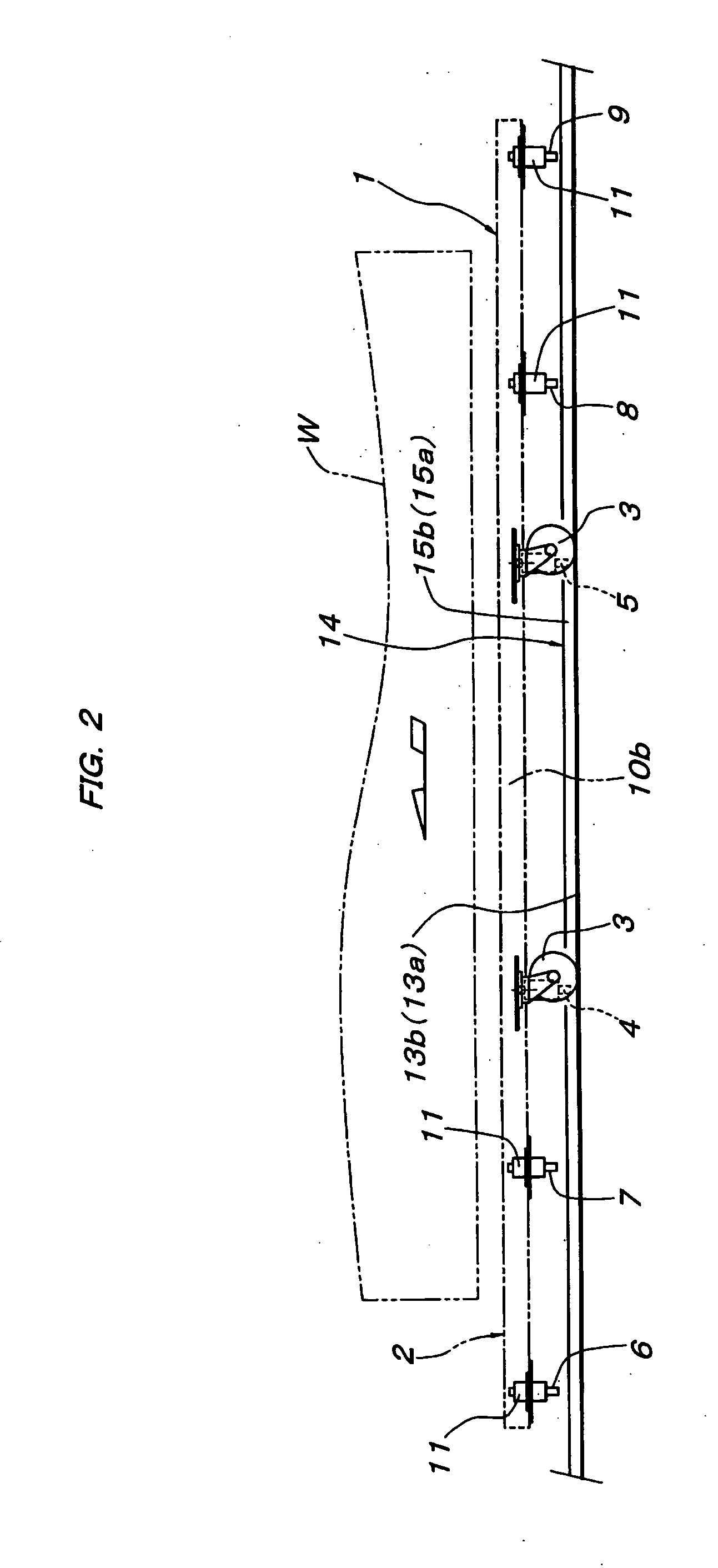

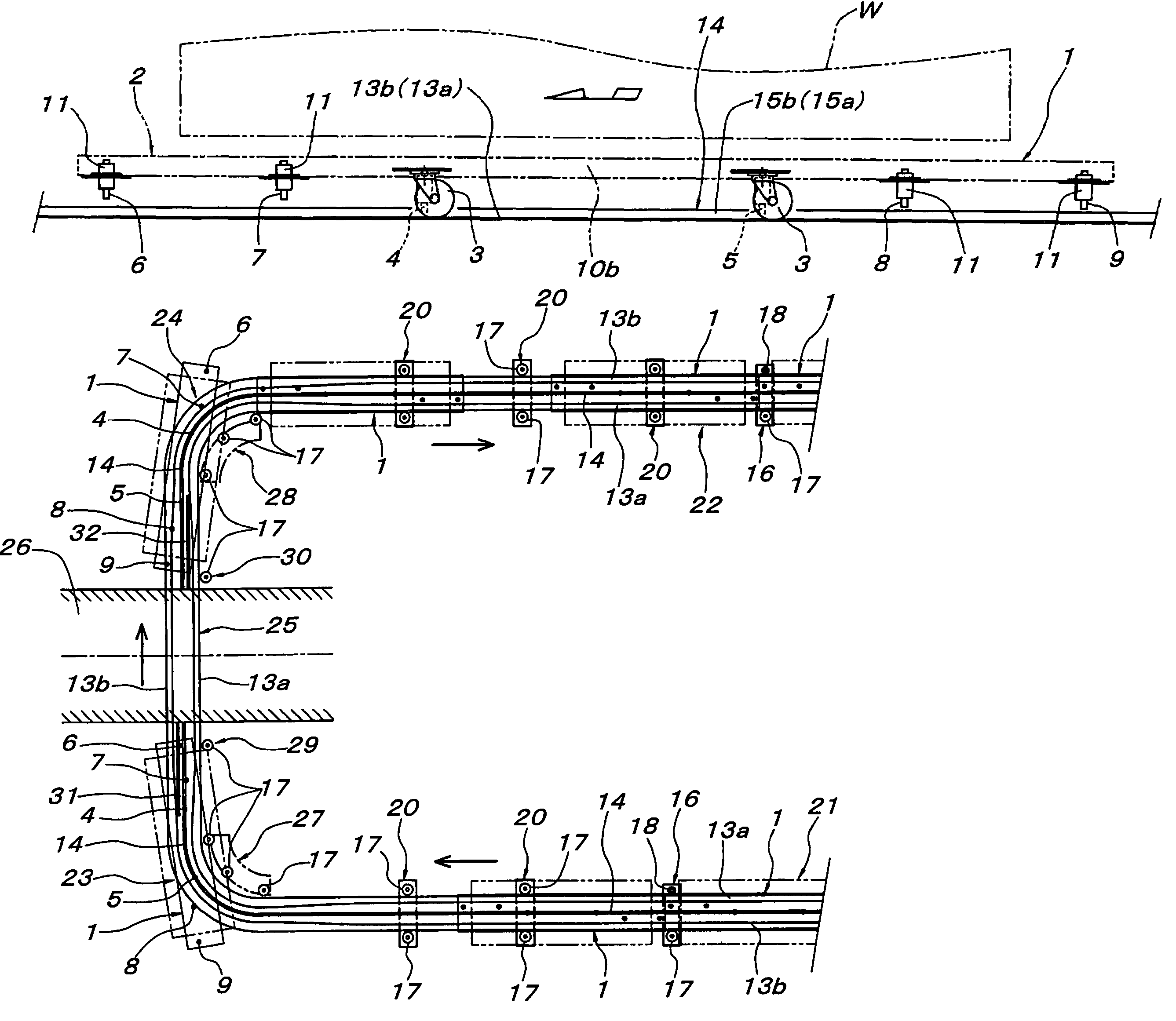

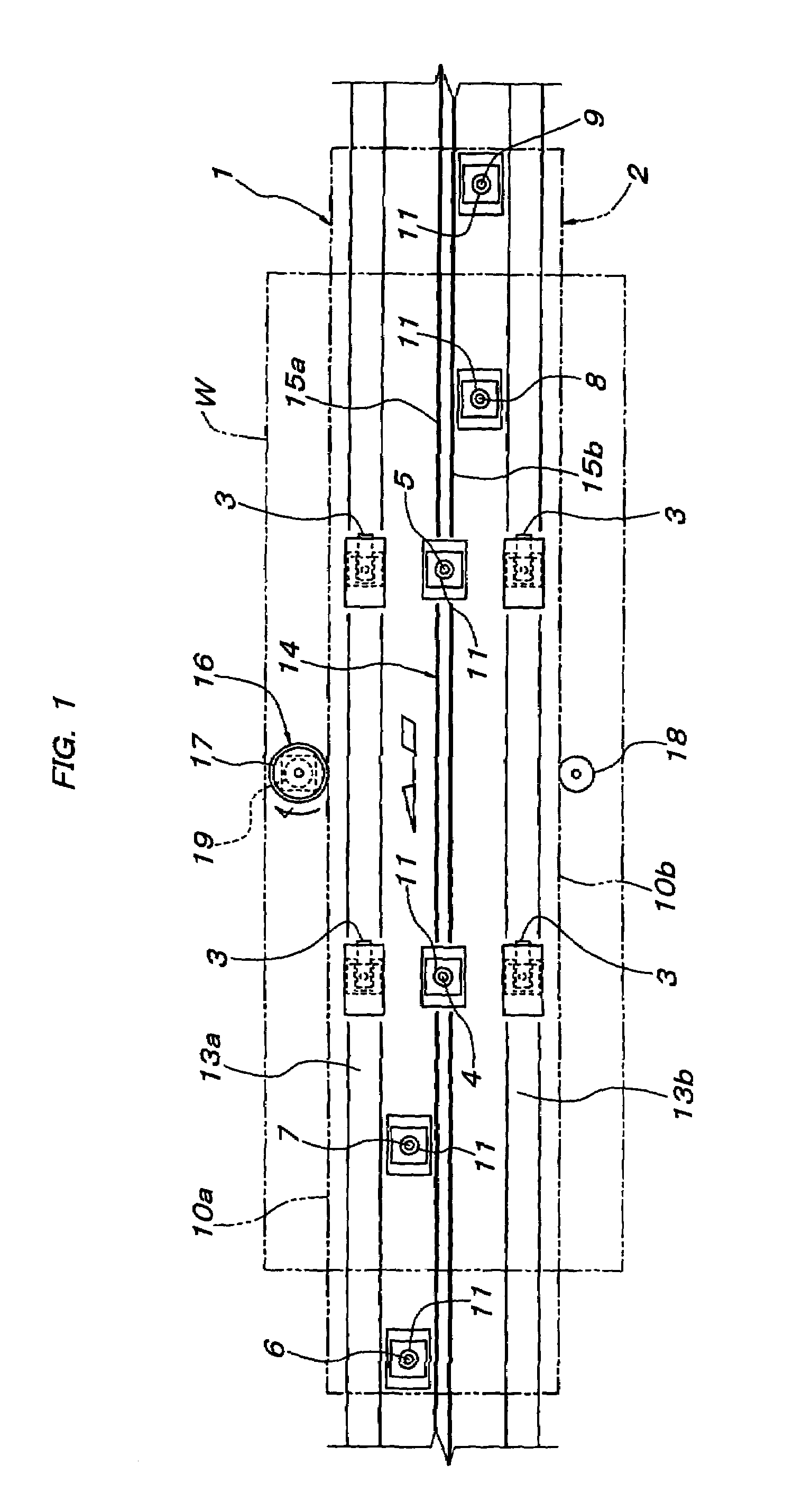

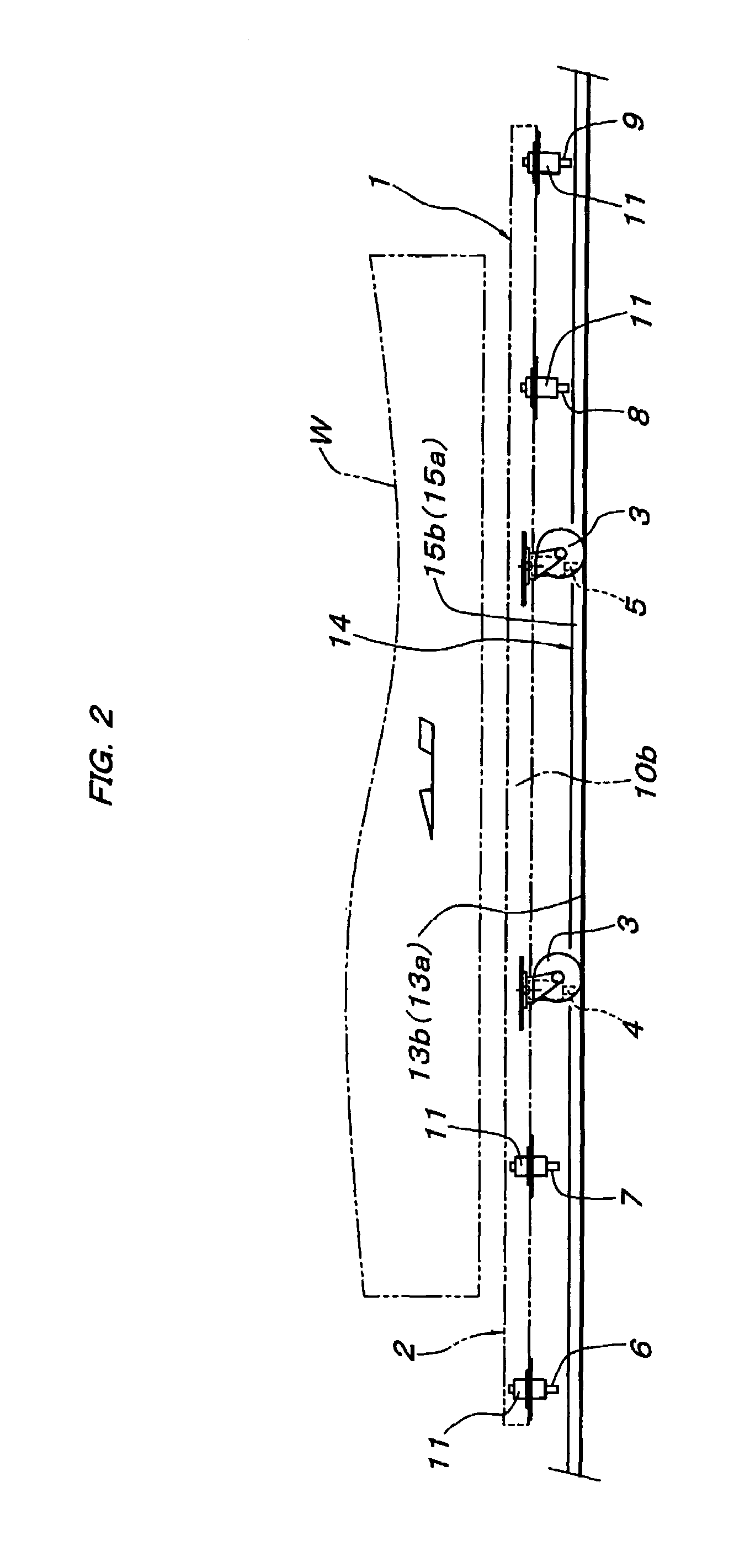

Carriage type conveyor

A friction-drive carriage type conveyor includes a carriage 1 for running in a running direction along a horizontal track including a first track section and a second track section, which crosses a passage 26. Friction drivers 29 and 30 are fitted on both sides of the passage 26 to drive the carriage 1 across it. A main guide rail 14 lies along the whole length of the first track section. A rear auxiliary guide rail 31 lies along the first track section and is upstream of the passage 26. A front auxiliary guide rail 32 lies along the first track section and is downward of the passage 26. The carriage 1 is fitted with a pair of main guided members 4 and 5 for engaging with the main guide rail 14, a pair of front auxiliary guided members 6 and 7 for engaging with the front auxiliary guide rail 32, and a pair of rear auxiliary guided members 8 and 9 for engaging with the rear auxiliary guide rail 31. The main guided members 4 and 5 are spaced from each other in the running direction. The front auxiliary guided members 6 and 7 are forward of the main guided members 4 and 5 and spaced from each other in the running direction. The rear auxiliary guided members 8 and 9 are backward of the main guided members 4 and 5 and spaced from each other in the running direction. The auxiliary guided members 6-9 are positioned on either side of the main guide rail 14. While the carriage 1 is passing across the passage 26, at least two of the guided members 4-9 engage with the associated guide rail or rails 14, 31 and / or 32 on one or both sides of this passage. This ensures that the carriage 1 passes linearly across the passage 26.

Owner:DAIFUKU CO LTD

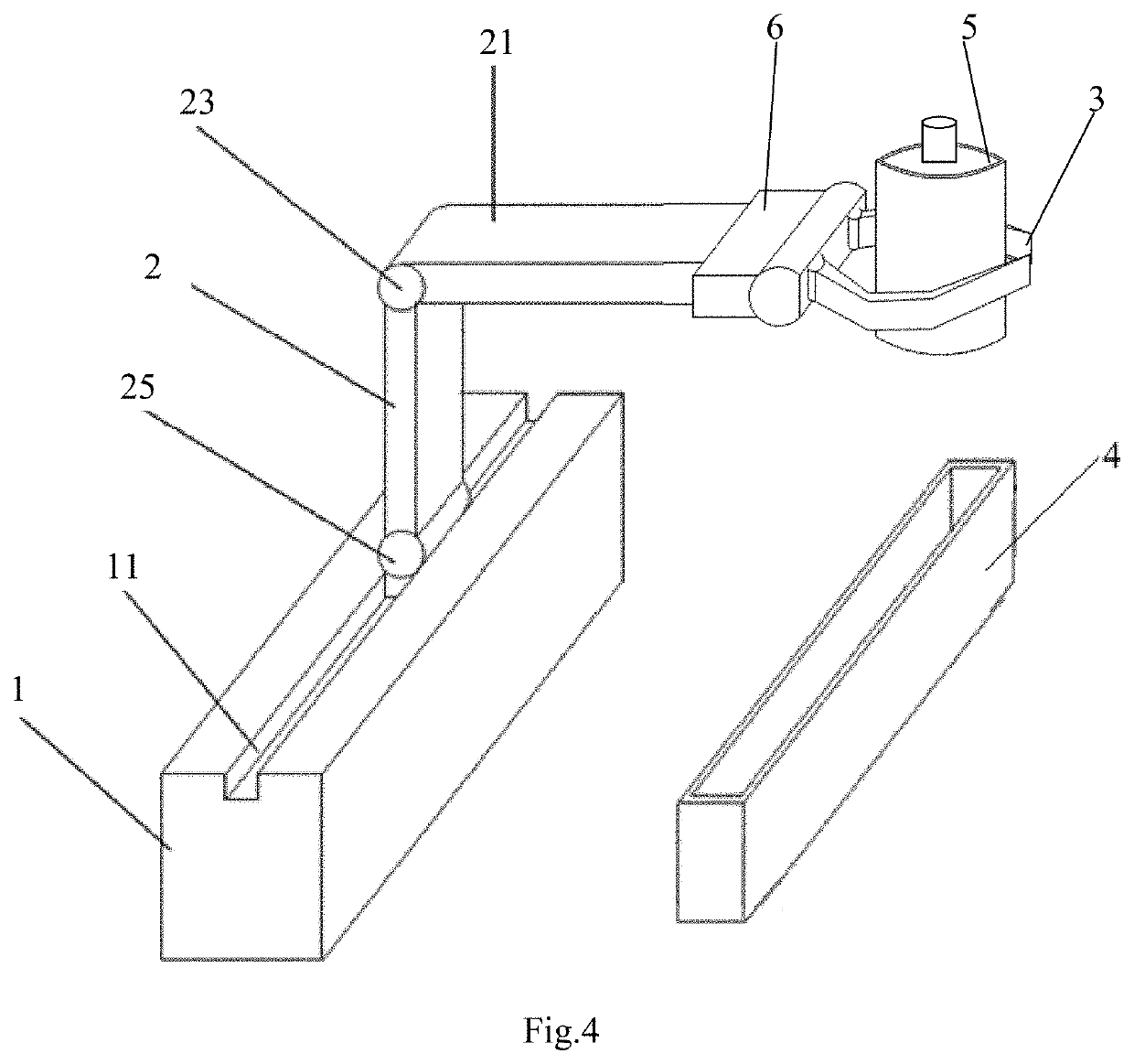

Feed device for crucible

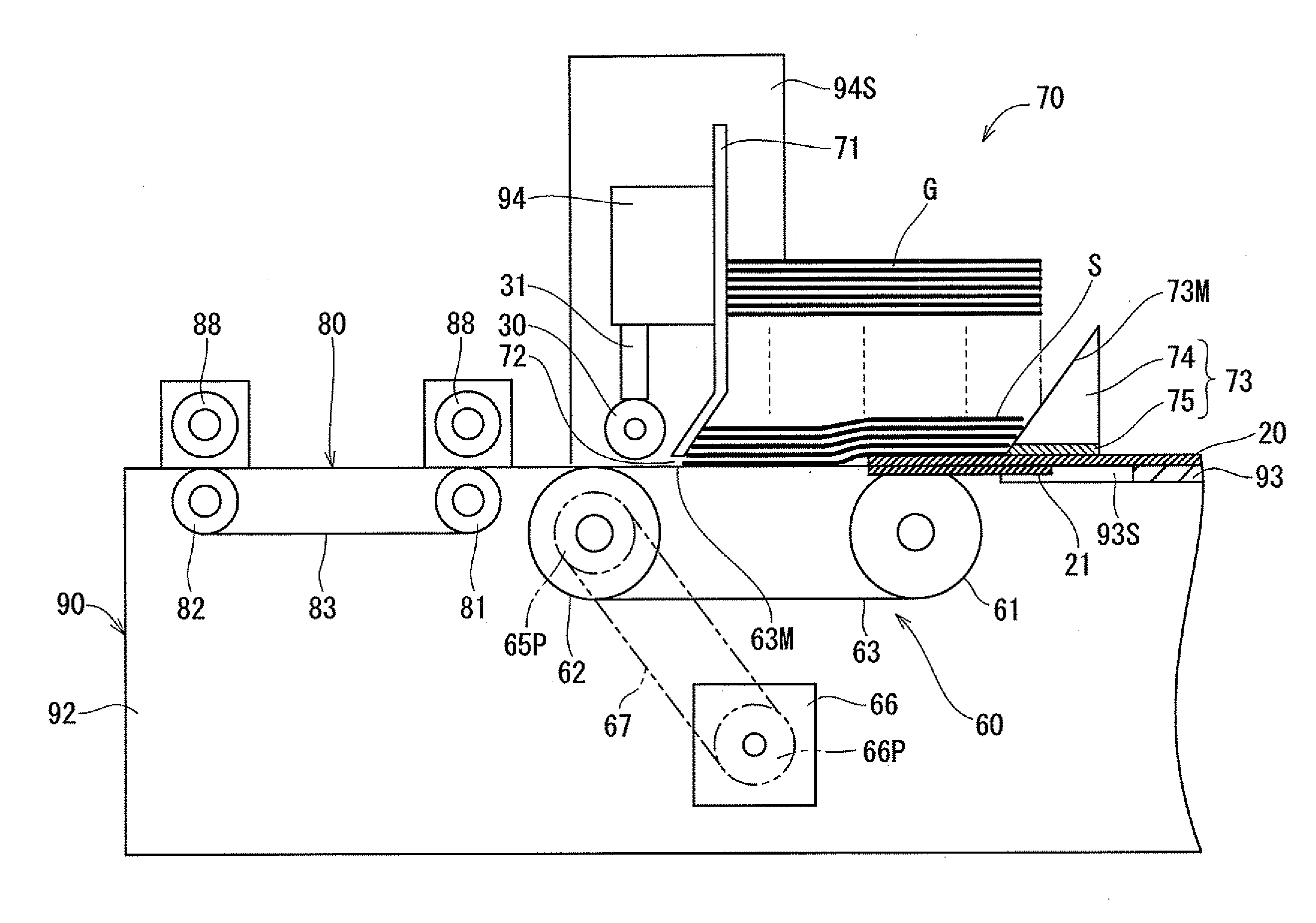

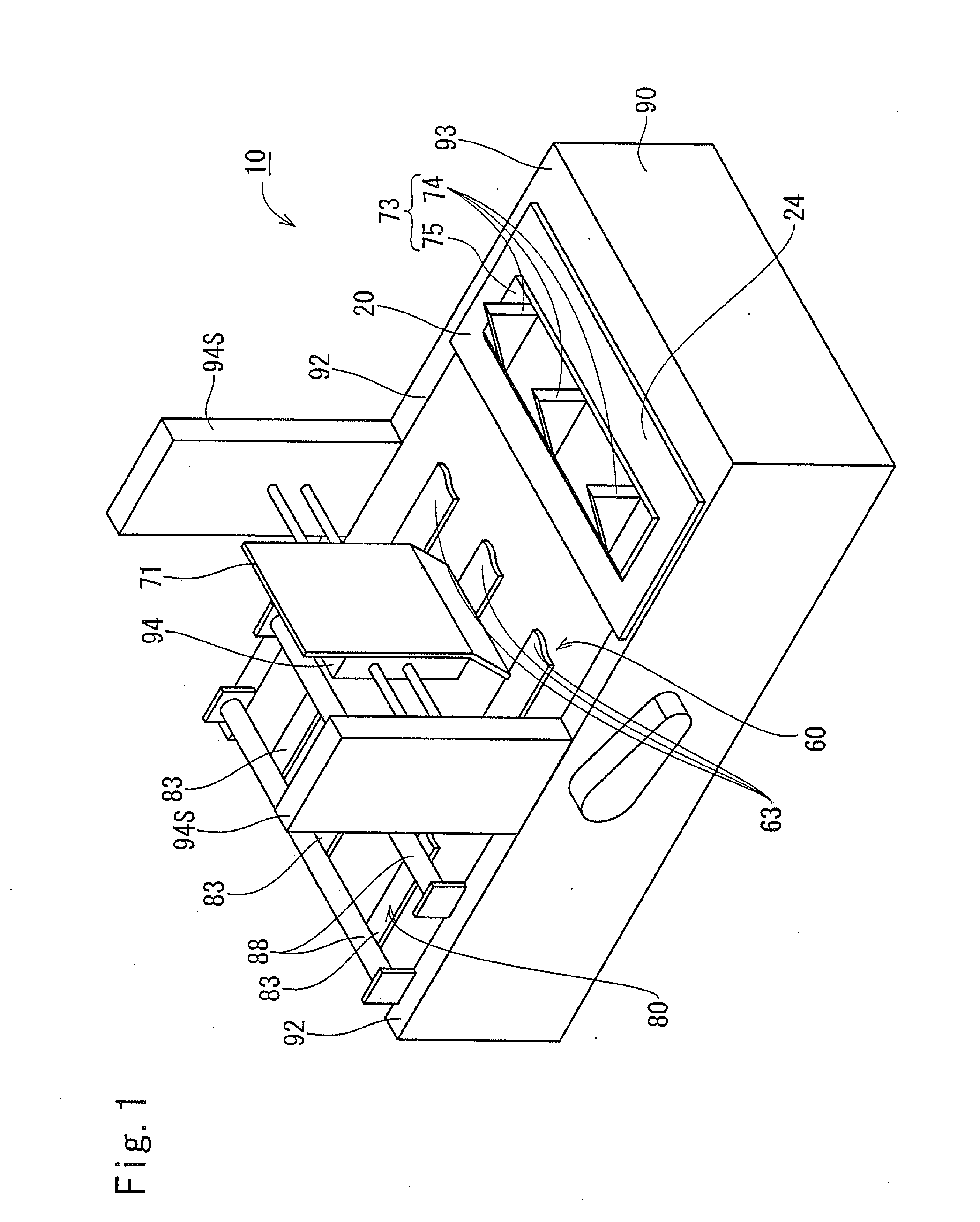

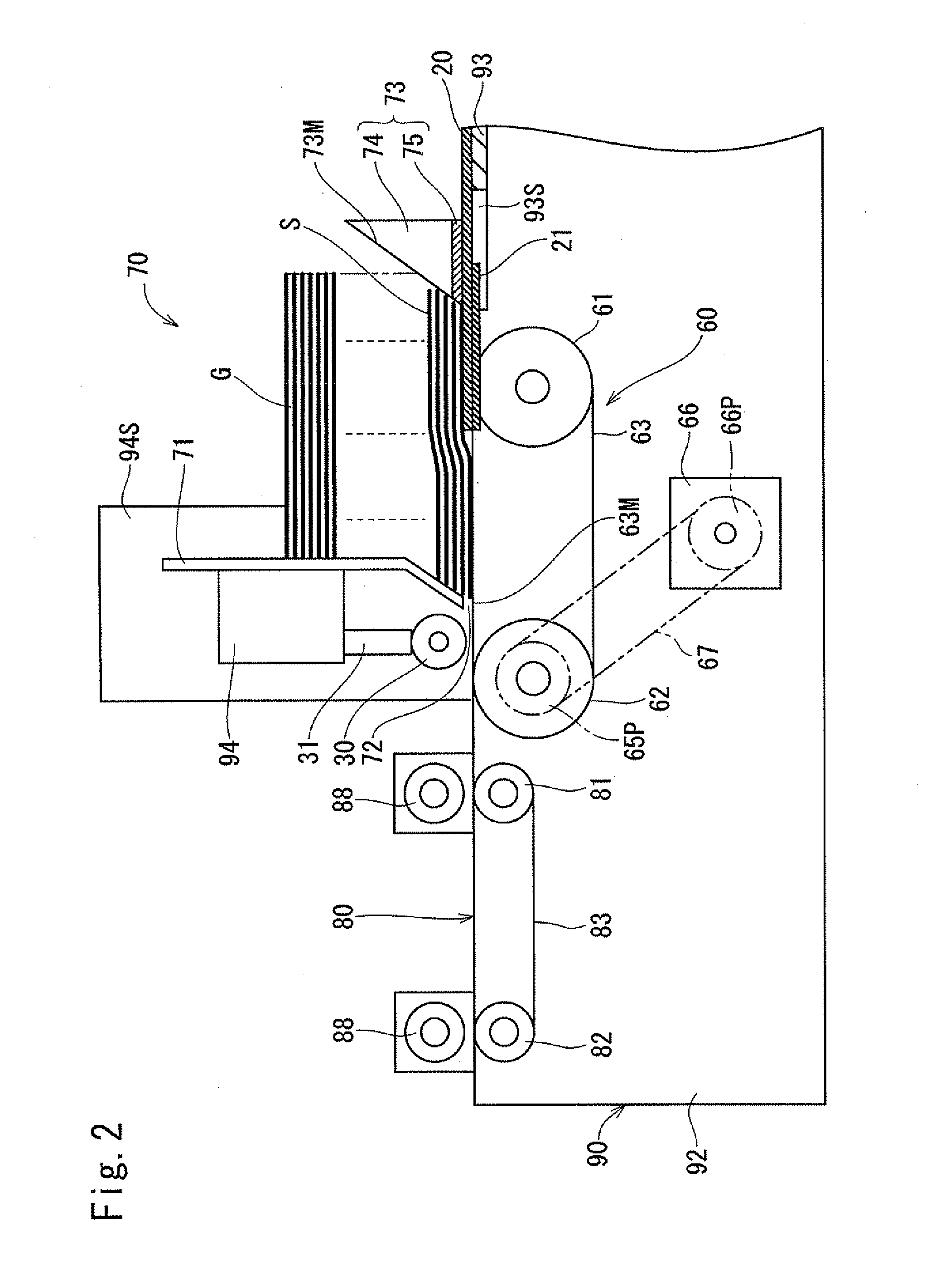

ActiveUS20190016541A1Increase productivityLow production costVacuum evaporation coatingSputtering coatingCrucibleEngineering

This application discloses a feeding device for a crucible, belonging to the field of display technology. The feeding device includes: a base, a robot arm and a bottle holder. The base is movably connected to one end of the robot arm, the one end of the robot arm can move linearly on the base, a motion trajectory of the robot arm is parallel to a lengthwise direction of the crucible. The bottle holder is disposed at the other end of the robot arm and the bottle holder is rotatable at the other end. This application can protect operator's health, improve production efficiency and reduce production costs.

Owner:BOE TECH GRP CO LTD +1

Carriage type conveyor

ActiveUS7093543B2Moving linearAvoid stopRailway tracksPropulsion railway systemsFriction driveEngineering

A friction-drive carriage type conveyor includes a carriage 1 for running in a running direction along a horizontal track including a first track section and a second track section, which crosses a passage 26. Friction drivers 29 and 30 are fitted on both sides of the passage 26 to drive the carriage 1 across it. A main guide rail 14 lies along the whole length of the first track section. A rear auxiliary guide rail 31 lies along the first track section and is upstream of the passage 26. A front auxiliary guide rail 32 lies along the first track section and is downward of the passage 26. The carriage 1 is fitted with a pair of main guided members 4 and 5 for engaging with the main guide rail 14, a pair of front auxiliary guided members 6 and 7 for engaging with the front auxiliary guide rail 32, and a pair of rear auxiliary guided members 8 and 9 for engaging with the rear auxiliary guide rail 31. The main guided members 4 and 5 are spaced from each other in the running direction. The front auxiliary guided members 6 and 7 are forward of the main guided members 4 and 5 and spaced from each other in the running direction. The rear auxiliary guided members 8 and 9 are backward of the main guided members 4 and 5 and spaced from each other in the running direction. The auxiliary guided members 6–9 are positioned on either side of the main guide rail 14. While the carriage 1 is passing across the passage 26, at least two of the guided members 4–9 engage with the associated guide rail or rails 14, 31 and / or 32 on one or both sides of this passage. This ensures that the carriage 1 passes linearly across the passage 26.

Owner:DAIFUKU CO LTD

Cut-sheet feeder

InactiveUS20130292895A1Reduce generationSmoothly handRegistering devicesArticle separationSheet materialEngineering

A cut-sheet feeder has a feed belt, a belt contact amount adjuster, and an inclined guide member. The belt makes contact with the lowermost cut sheet of a stack of cut sheets and feeds forward the cut sheet. The belt contact amount adjuster supports the stack of cut sheets while lifting the read portion thereof from the feed belt. The inclined guide member protrudes further upward than the belt contact amount adjuster and has a guide surface inclined forwardly downward. The guide surface lifts up the rear end portion of the stack of cut sheets and shifts forward the lowermost cut sheet. The position of the adjuster in the front-rear direction and the position of the guide member in the front-rear direction can be adjusted individually.

Owner:EZAWA JIMUKI

Vehicle switch

ActiveUS7893800B2Different strengthReduce troubles caused by the lubricating agent, gasDC motor speed/torque controlContact operating partsLower limitControl circuit

A vehicle switch includes a magnet mounted to an operating unit accommodated in an external packaging such that the operating unit can move linearly. A magnetic detector is placed so as to receive different strength of the magnetism from the magnet in the two cases that the operating unit is at the upper limit position and at the lower limit position. A control circuit coupled to the magnetic detector opens and closes a switching device in response to strength of the detected magnetism.

Owner:PANASONIC CORP

Camera module

ActiveUS9197802B2Minimization requirementsAvoid it happening againTelevision system detailsColor television detailsOptical axisCamera module

There is provided a camera module including: a lens barrel including at least one lens disposed on an optical axis; a housing having the lens barrel disposed therein; and first and second elastic members elastically supporting upper and lower portions of the lens barrel, respectively, wherein the first and second elastic members include a fixed side coupled to the housing and a driving side coupled to the lens barrel, respectively, the fixed side and the driving side being disposed to face each other based on the optical axis.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Feed device for crucible

ActiveUS10676288B2Increase productivityLow production costVacuum evaporation coatingSputtering coatingControl engineeringMechanical engineering

Owner:BOE TECH GRP CO LTD +1

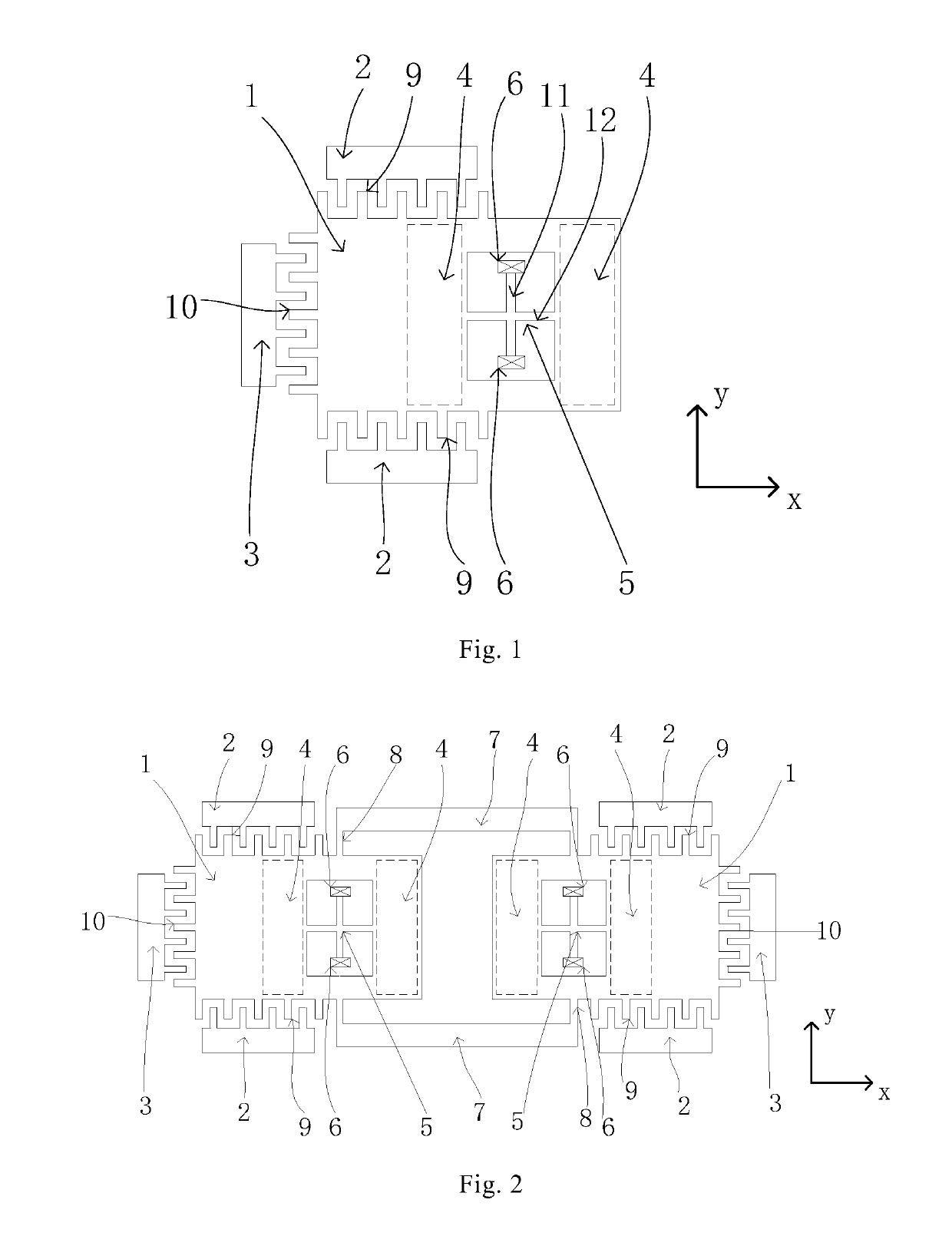

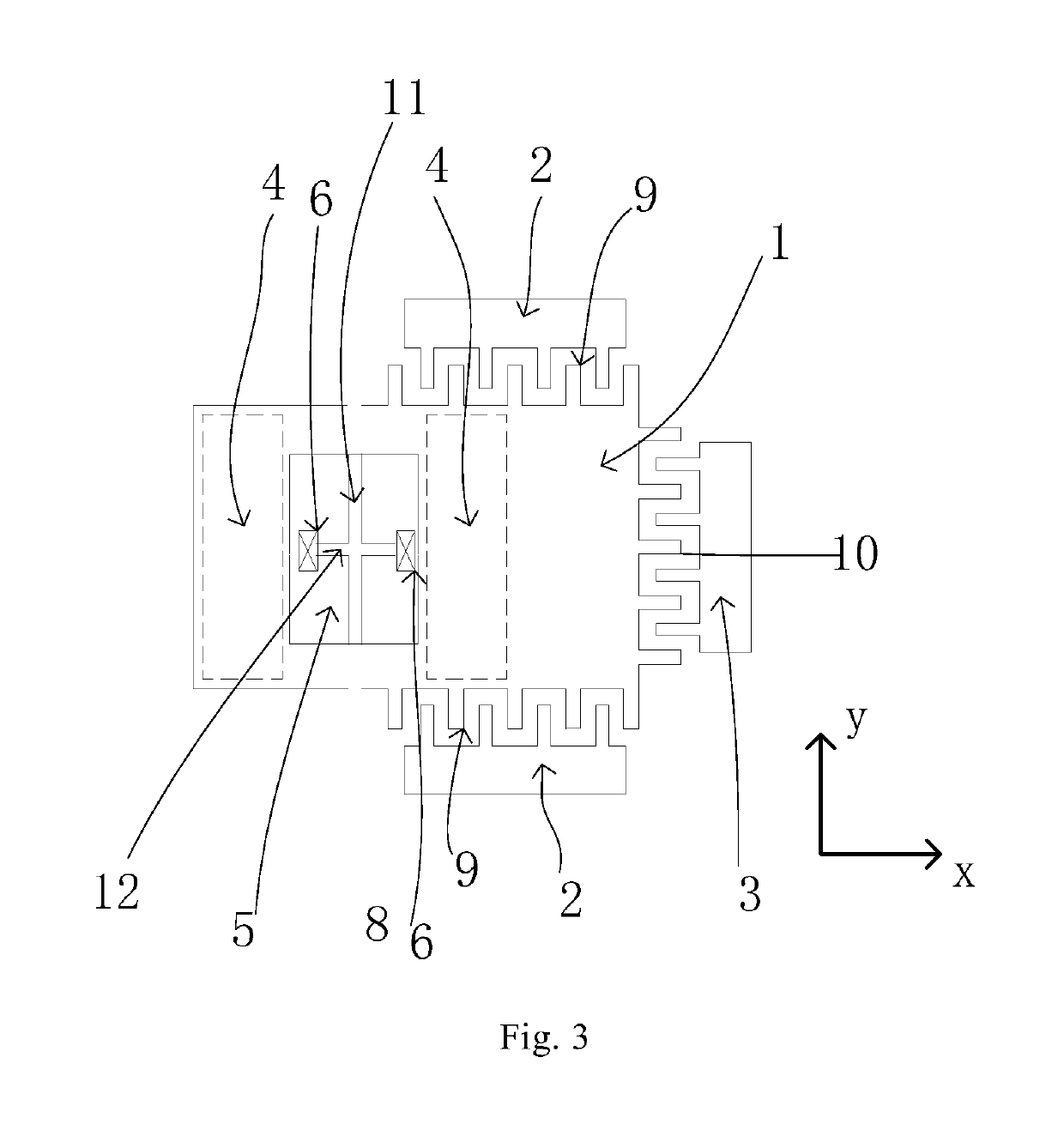

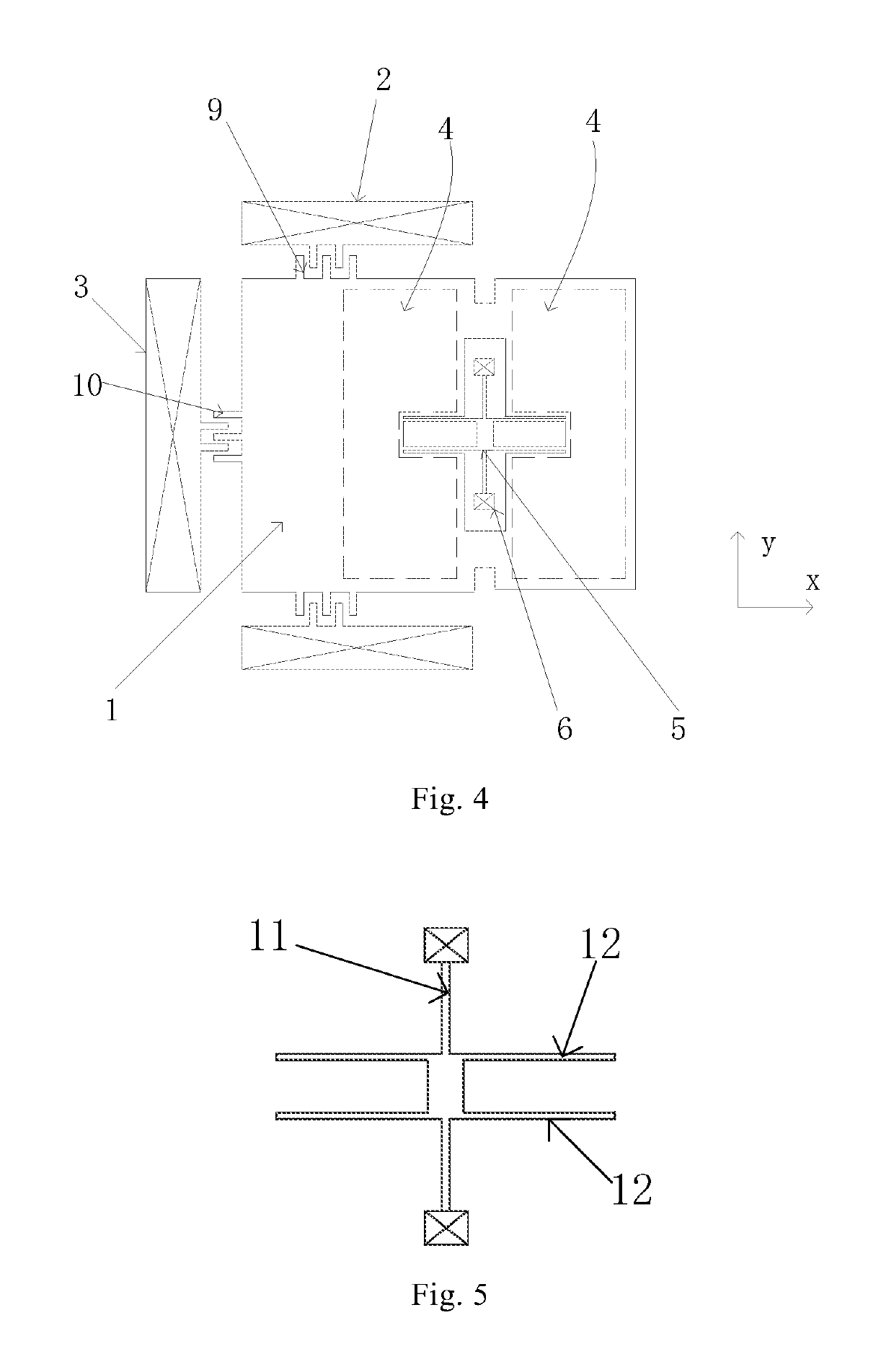

Inertia measurement module and triaxial accelerometer

ActiveUS10473686B2Simple structureHigh measurement accuracyAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsLinear motionCapacitance

An inertia measurement module and three-axis accelerometer, comprising a first pole piece (4) located on a substrate and a mass block (1) suspendingly connected above the substrate via elastic beams (11, 12); the elastic beams (11, 12) includes a first elastic beam (12) and a second elastic beam (11), two ends of the second elastic beams (11) being connected to an anchor point (6) of the substrate, two ends of the first elastic beam (11) being connected to the mass block (1); a center of the first elastic beam (12) and / or the second elastic beam (11) deviates from a center of gravity of the mass block (1); the mass block (1) is further provided with a first movable electrode (9) and a second movable electrode (10) in a Y-axis and an X-axis direction; the movement of one axis in a plane of the inertia measurement module cannot be affected by an eccentric structure feature, such that both X-axis movement and Y-axis movement are linear movements, thus not intensifying an inter-axis coupling, and also not reducing displacement of a mass block on the X-axis and the Y-axis, thus improving capacitance detection precision.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

Articulated support device

ActiveUS11226065B1Moving linearAvoid enteringEndoscopesShaft for rotary movementEngineeringMechanical engineering

Disclosed herein is an articulated support device. The articulated support device is formed to include a plurality of links connected to each other. A device stand is detachably coupled to the front end of the articulated support device and the rear end of the articulated support device is fixedly coupled to a structure detachably. The connection portions of the plurality of links are fixed not to move relative to each other or the connection portions are released to be rotatable relative to each other through an operation of a handle part provided on a front side of the articulated support device. The articulated support device includes a plurality of rotation and fixing units. Each of the plurality of rotation and fixing units includes a front link connection adapter, a wire central binding portion, a rotation regulation portion, a casing pipe, and an inner connection pipe.

Owner:JUNG KYU SUNG

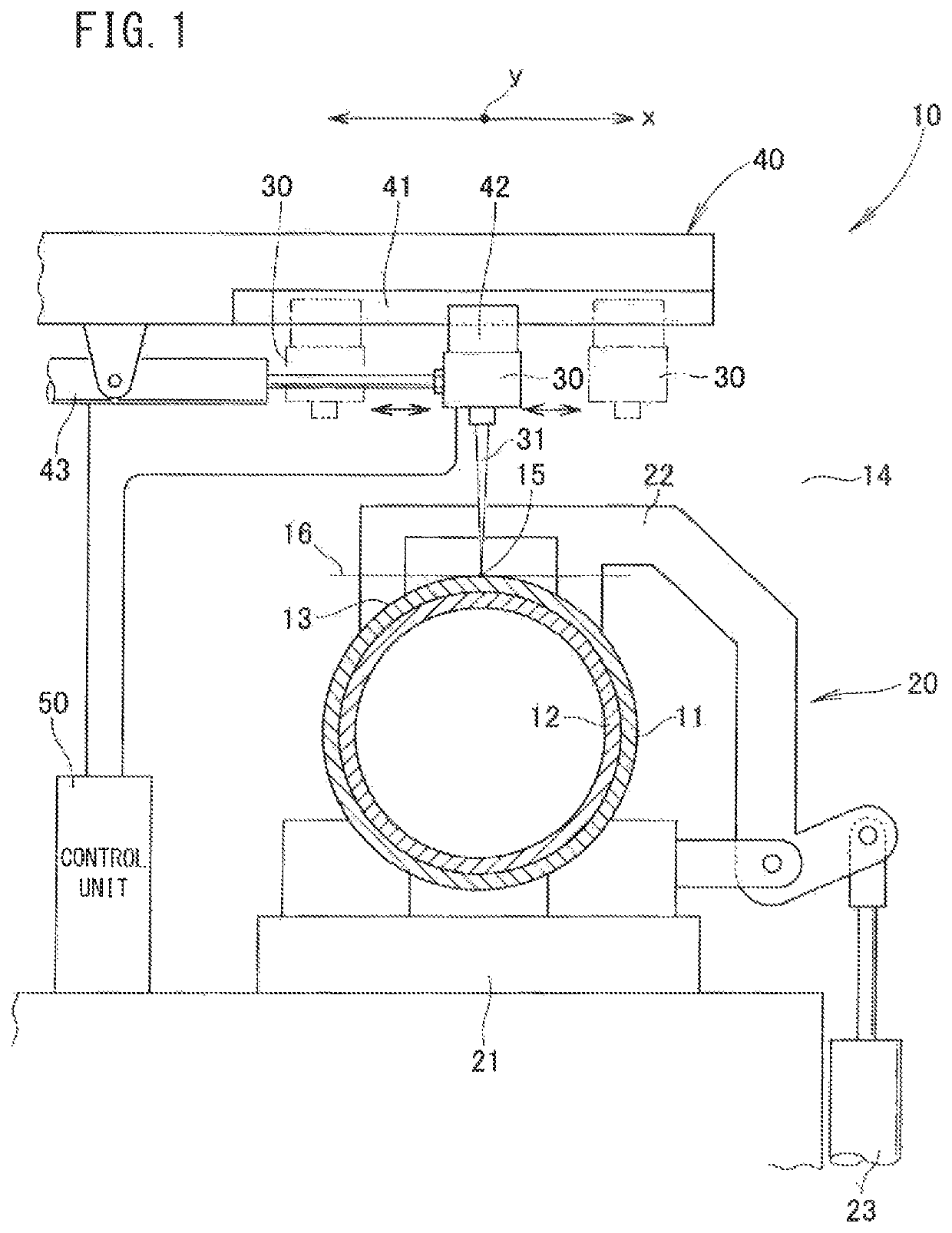

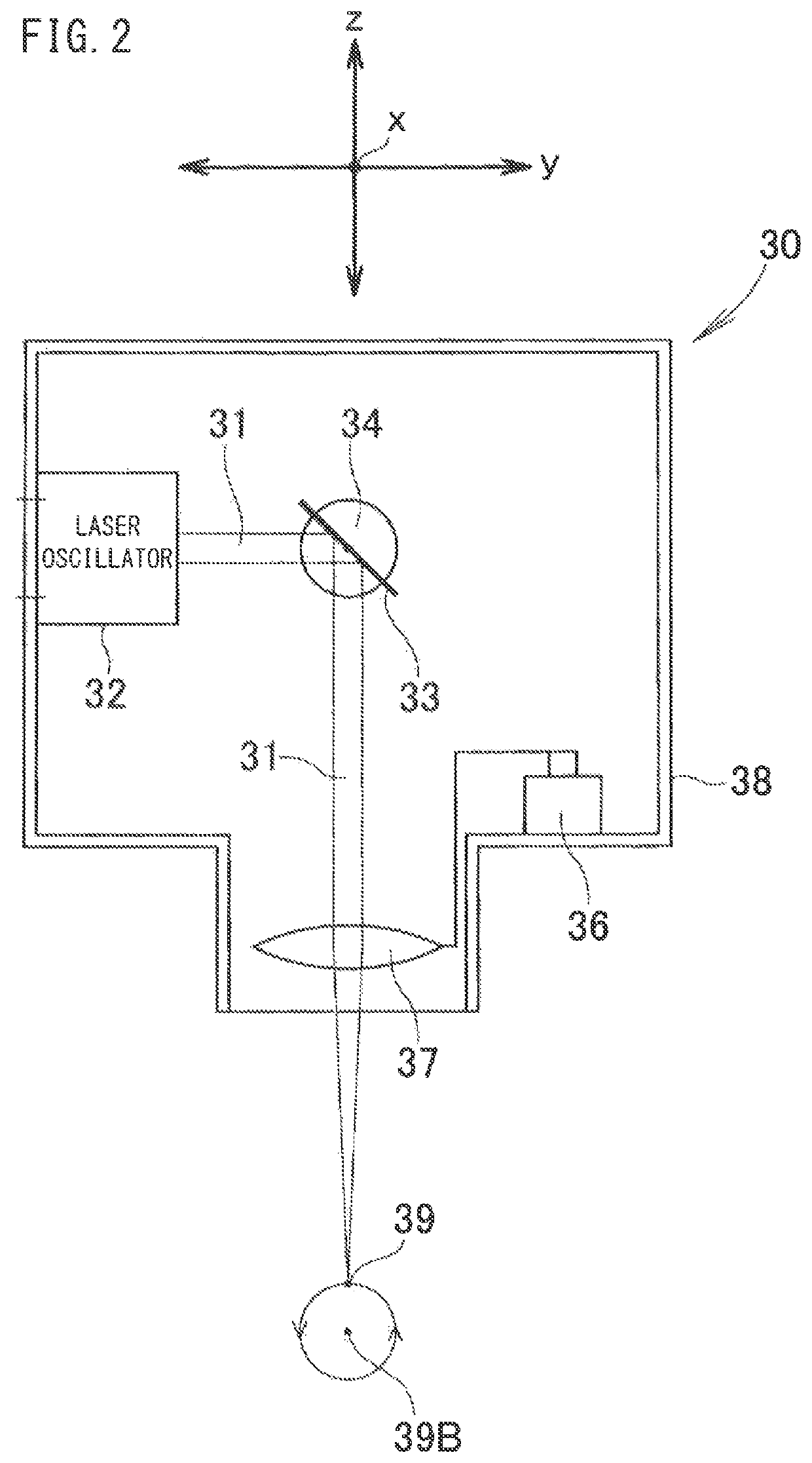

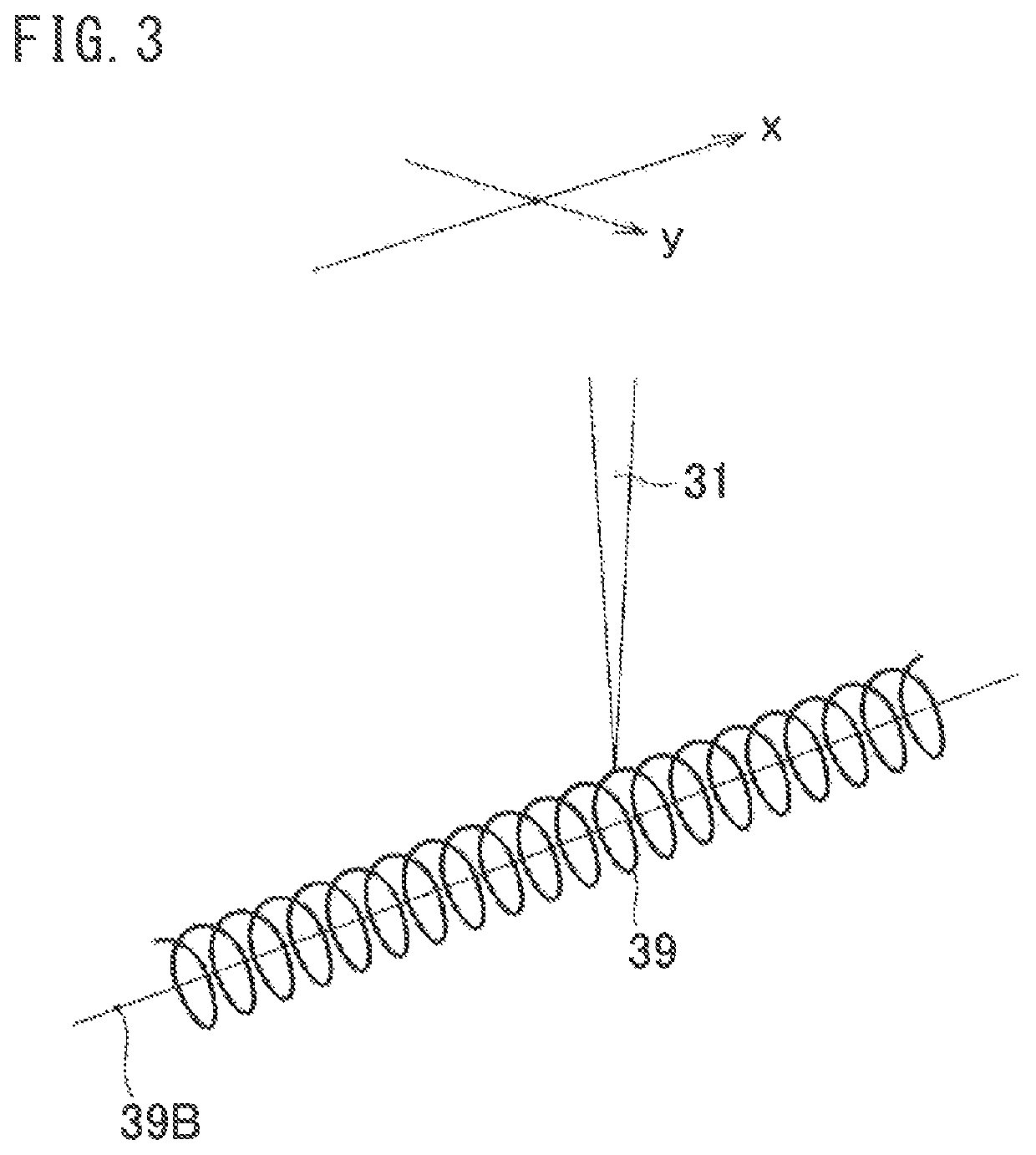

Laser welding device and laser welding method

ActiveUS10730139B2Add depthAvoid lack of depthWelding/cutting auxillary devicesPipeline systemsEngineeringMaterials science

This laser irradiation mechanism includes a control unit which has a function allowing the focal point of a laser beam to describe a circle, performs control such that the focal point describes a spiral, and performs control such that the central axis of the spiral moves along a curved surface.

Owner:HONDA MOTOR CO LTD

Ratchet tool

ActiveUS20210362302A1Easy to operateEasy to operate with one handSpannersWrenchesRatchetLinear motion

A ratchet tool comprises a base, a ratchet body, a switching member and a pawl member. The base has a rail and is movable with linear motion along the rail between a first position and a second position, the ratchet body has plural teeth, and the pawl member is engaged with the switching member and comprises plural ratchet teeth, a first abutting portion and a second abutting portion. When the switching member is movable to the first position, the pawl member is pivotally rotated to a third position to make the ratchet teeth mesh with the teeth and the first abutting portion abut against the base, therefore the ratchet body enables to rotate along a first rotation direction. When the switching member is movable to the second position, the pawl member is pivotally rotated to a fourth position to make the ratchet teeth mesh with the teeth and the second abutting portion abut against the base, therefore the ratchet body enables to rotate along a second rotation direction.

Owner:KING TONY TOOLS

Varifocal lens barrel

InactiveUS8976460B2Reduced lens assembly errorImprove imaging effectMountingsOptical axisOptoelectronics

A varifocal lens barrel includes a plurality of lens groups, each of which are linearly movable in the optical axis direction thereof without rotating about the optical axis during a zooming operation and during a focusing operation, including a base barrel which is linearly movable in the optical axis direction by rotation of a zoom operational ring, wherein lens frames of the respective lens groups are each supported by the base barrel.

Owner:RICOH IMAGING COMPANY

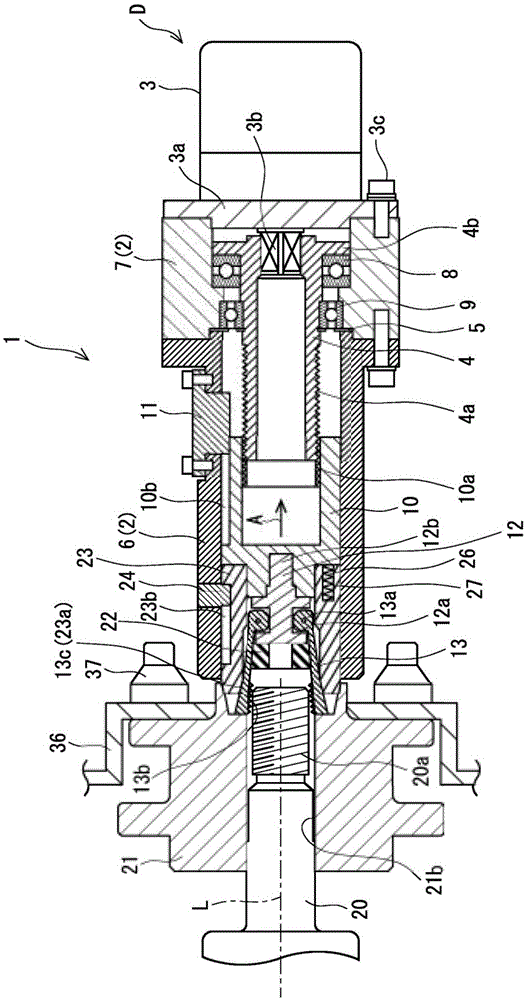

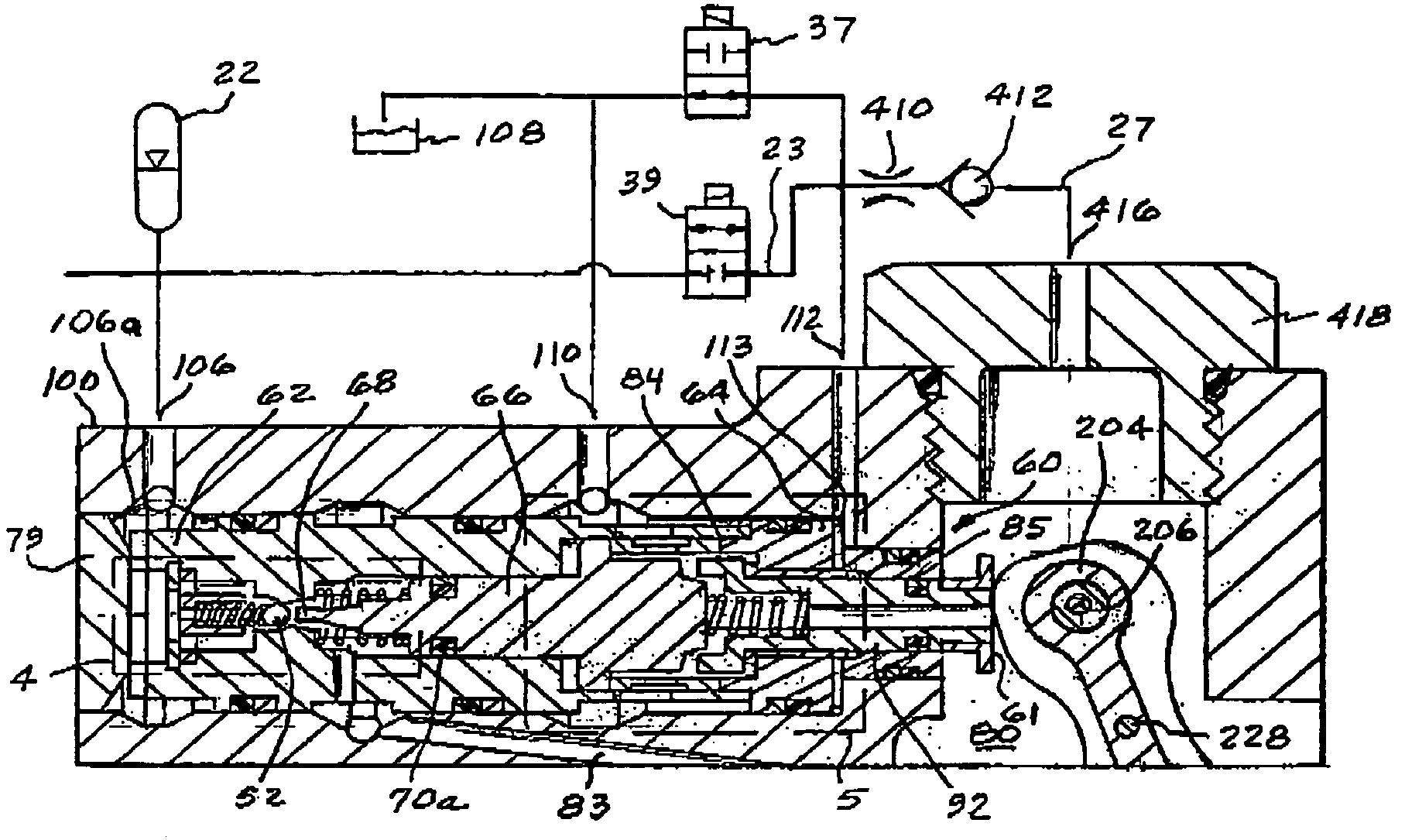

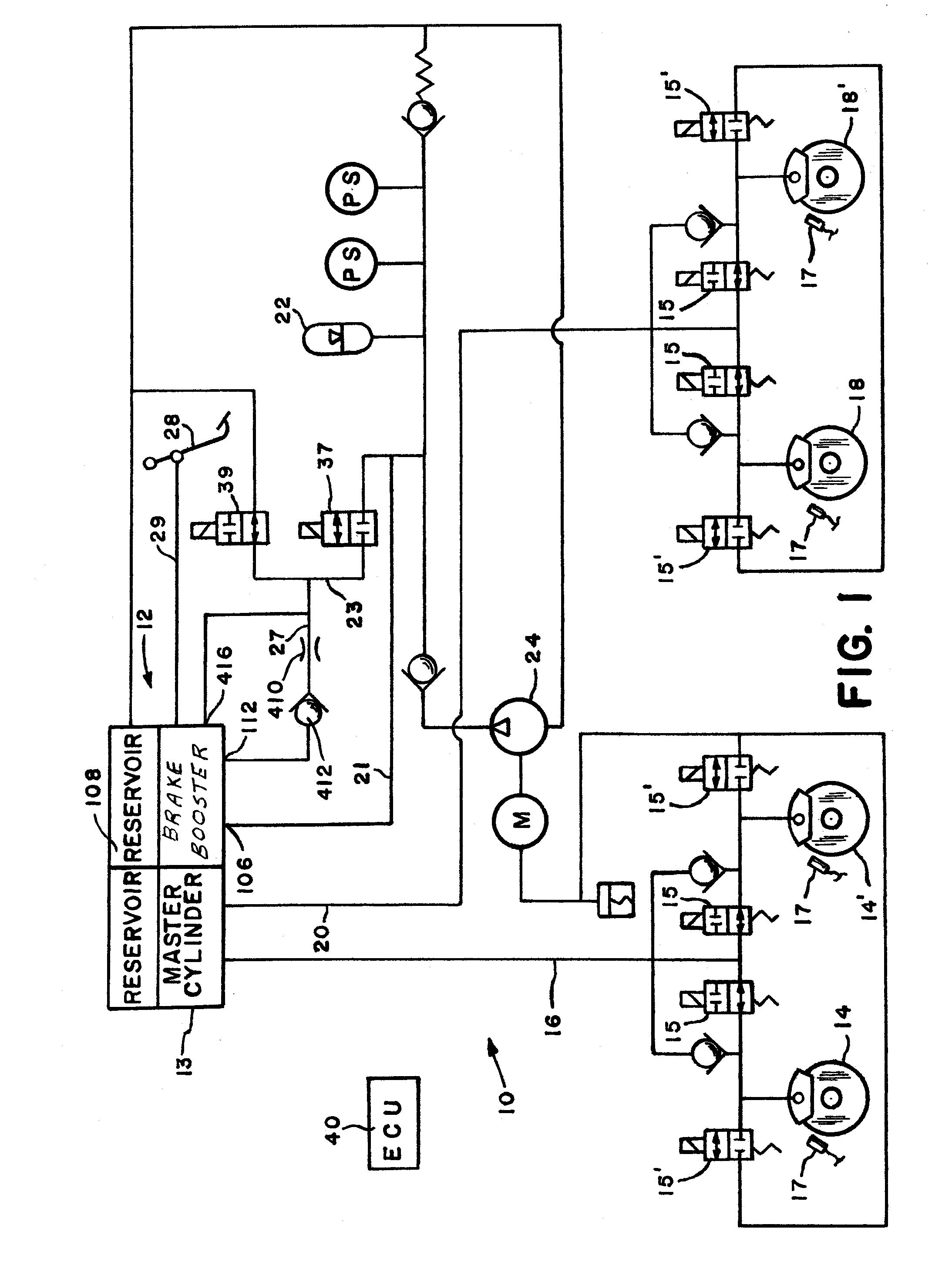

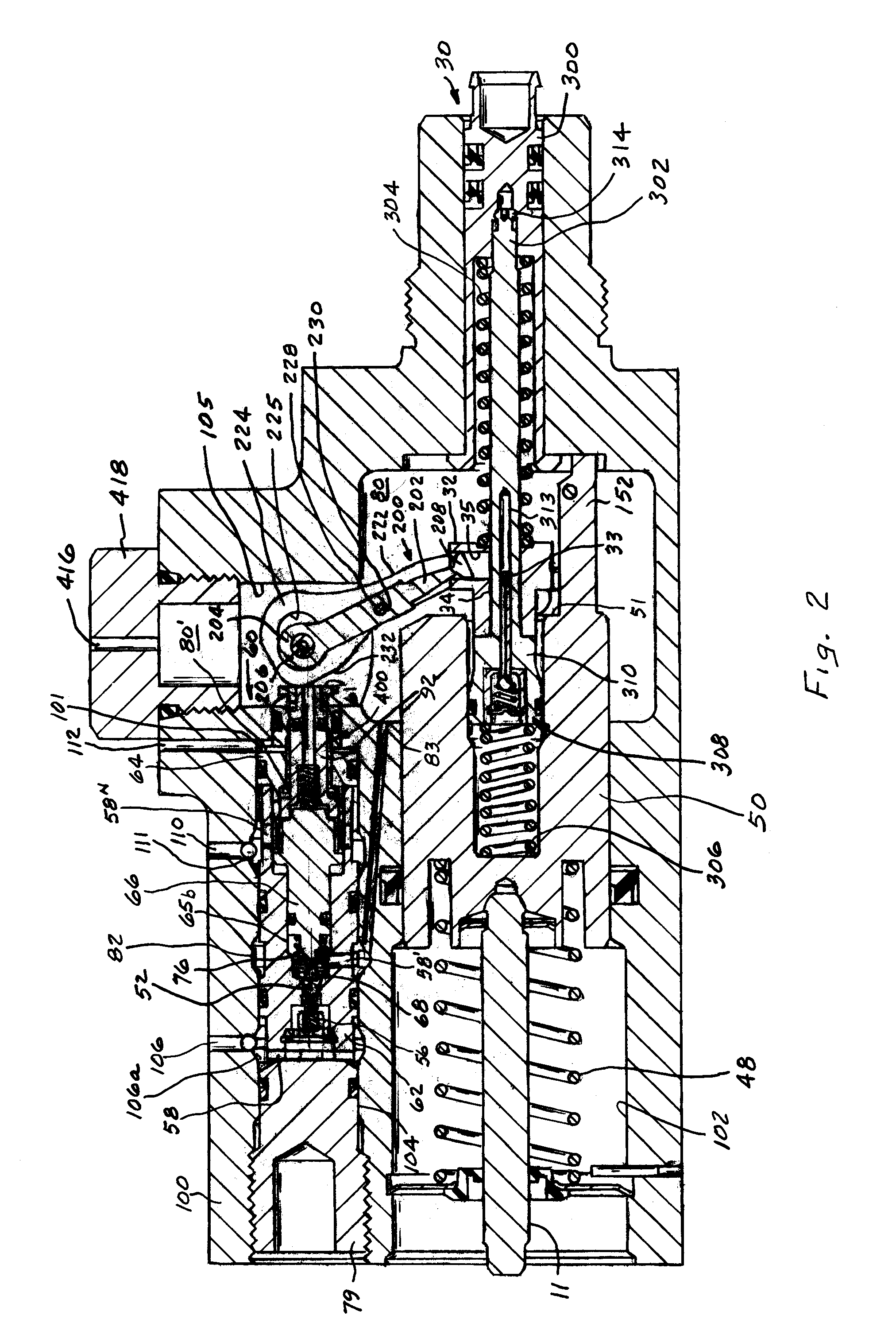

Control valve for a hydraulic brake booster

ActiveUS6990812B2Reduce oscillationReduce noise levelBraking action transmissionRotary clutchesEngineeringActuator

A control valve of a hydraulic brake booster for use in a brake system. The control valve is characterized by a shuttle member having a stem on a first end and an annular projection on a second end. The stem has an annular surface thereon that is matched with an orifice from an supply chamber such that metered pressurized fluid is uniformly presented to an actuation chamber to effect a brake application while the annular projection is matched with a flange on an actuator piston such that the pressurized fluid present in the actuation chamber is uniformly metered to a reservoir.

Owner:ROBERT BOSCH CORP

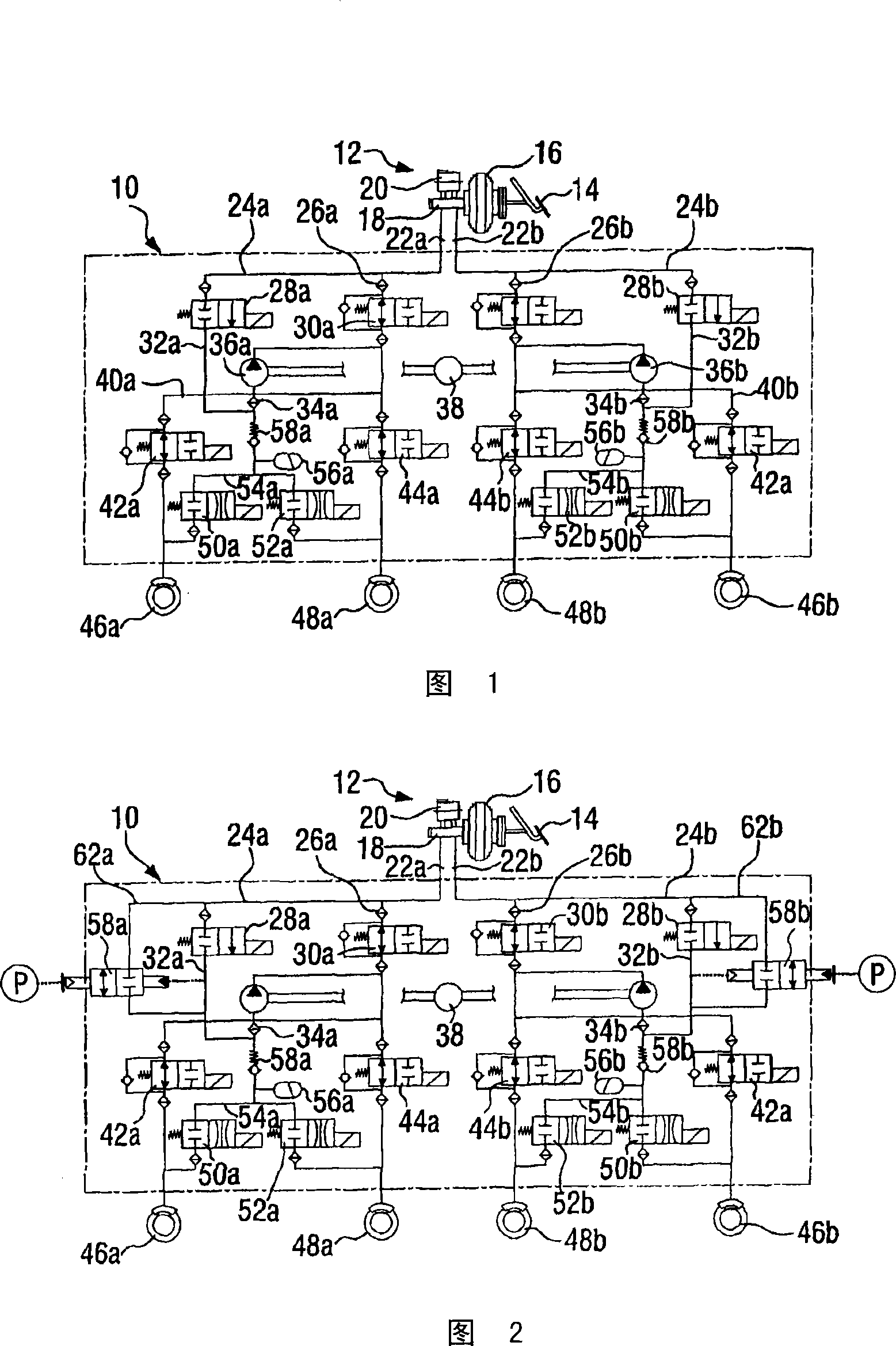

Vehicle brake system having a pump

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com