Drive shaft press-fitting device

A technology of press-fitting device and transmission shaft, which is applied in the direction of transportation and packaging, metal processing equipment, vehicle parts, etc., and can solve the problems of heavy load, sticking, transmission shaft cannot be reliably pressed into the hub, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred embodiments of the drive shaft press-fitting device according to the present invention are described in detail with reference to the accompanying drawings.

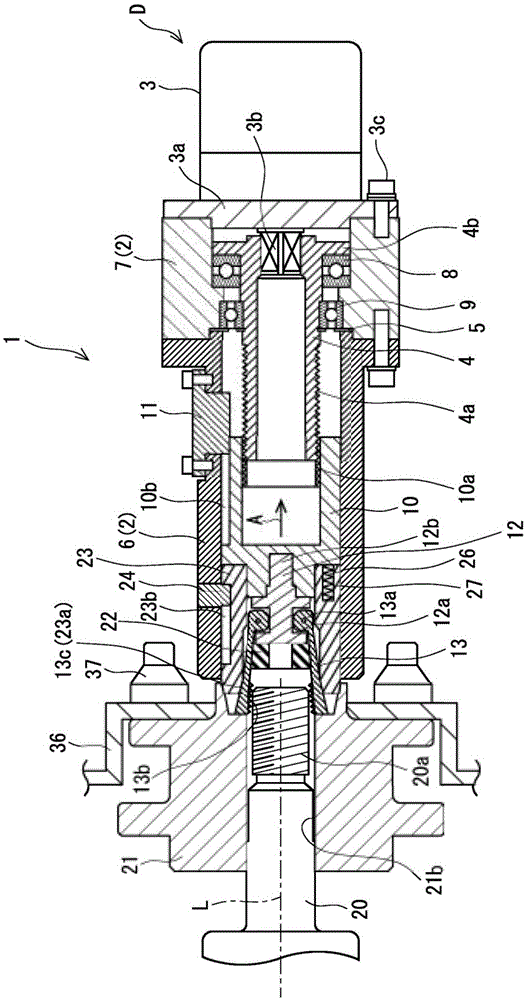

[0026] like figure 1 As shown in , the transmission shaft pressing device 1 for pressing a transmission shaft 20 into a hub 21 has a cylindrical outer frame 2 , and a motor 3 is fixed to the rear end of the outer frame 2 . The flange 3a of the motor 3 is fixed to the rear end of the outer frame 2 by bolts 3c, and the transmission shaft 3b of the motor 3 is inserted into the outer frame 2 . The rear end of the externally threaded shaft 4 is fixed to the transmission shaft 3b.

[0027] The outer frame 2 is composed of a cylindrical outer frame body 6 and a support accommodation portion 7 fixed to the rear end of the outer frame body 6 . A thrust bearing 8 and a radial bearing 9 for holding the externally threaded shaft 4 are accommodated in the support accommodation portion 7 . The thrust be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com