Ball bearing

一种球轴承、轴承的技术,应用在球轴承领域,能够解决不能应用、高摩擦和磨损、减弱保持架强度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

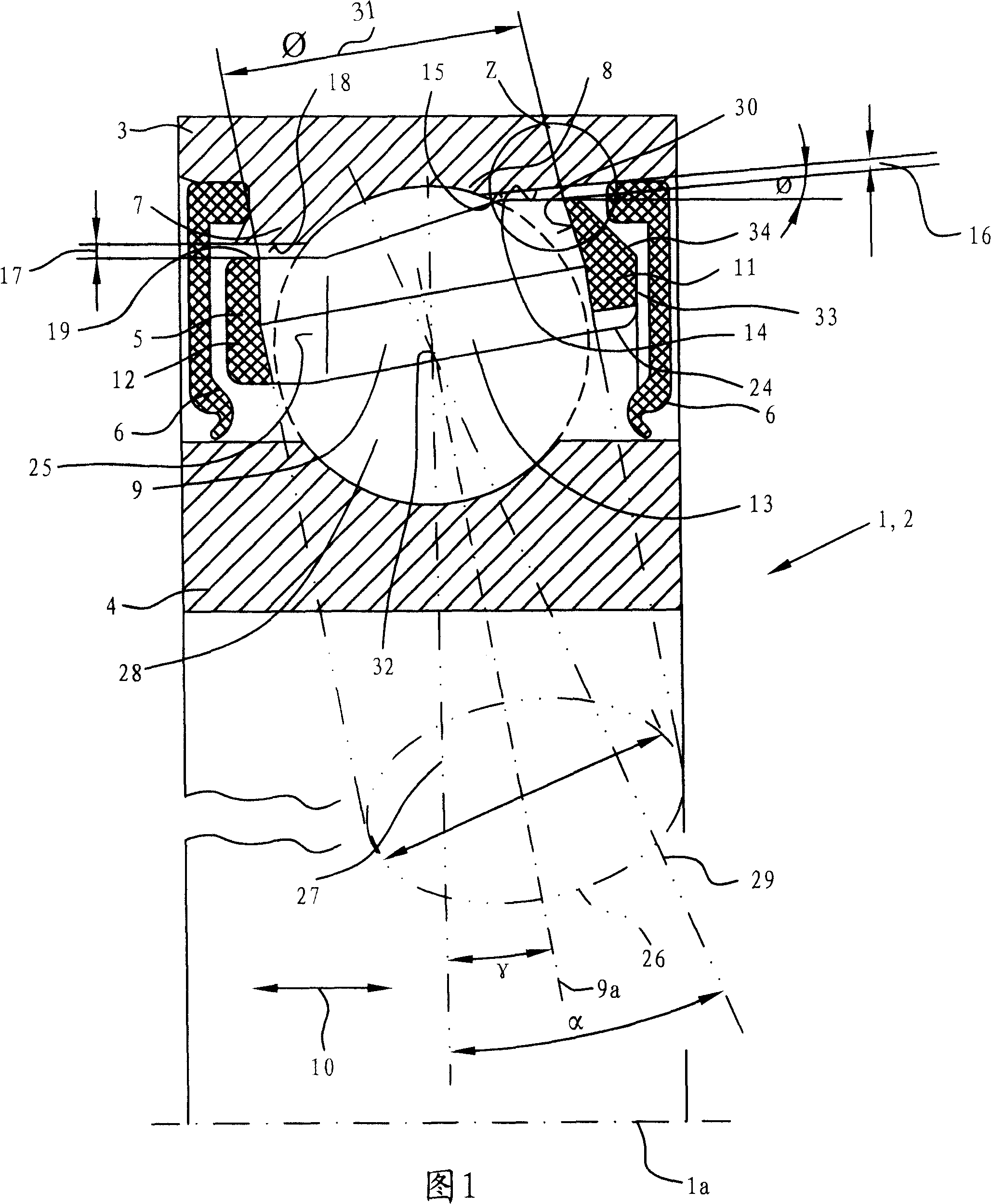

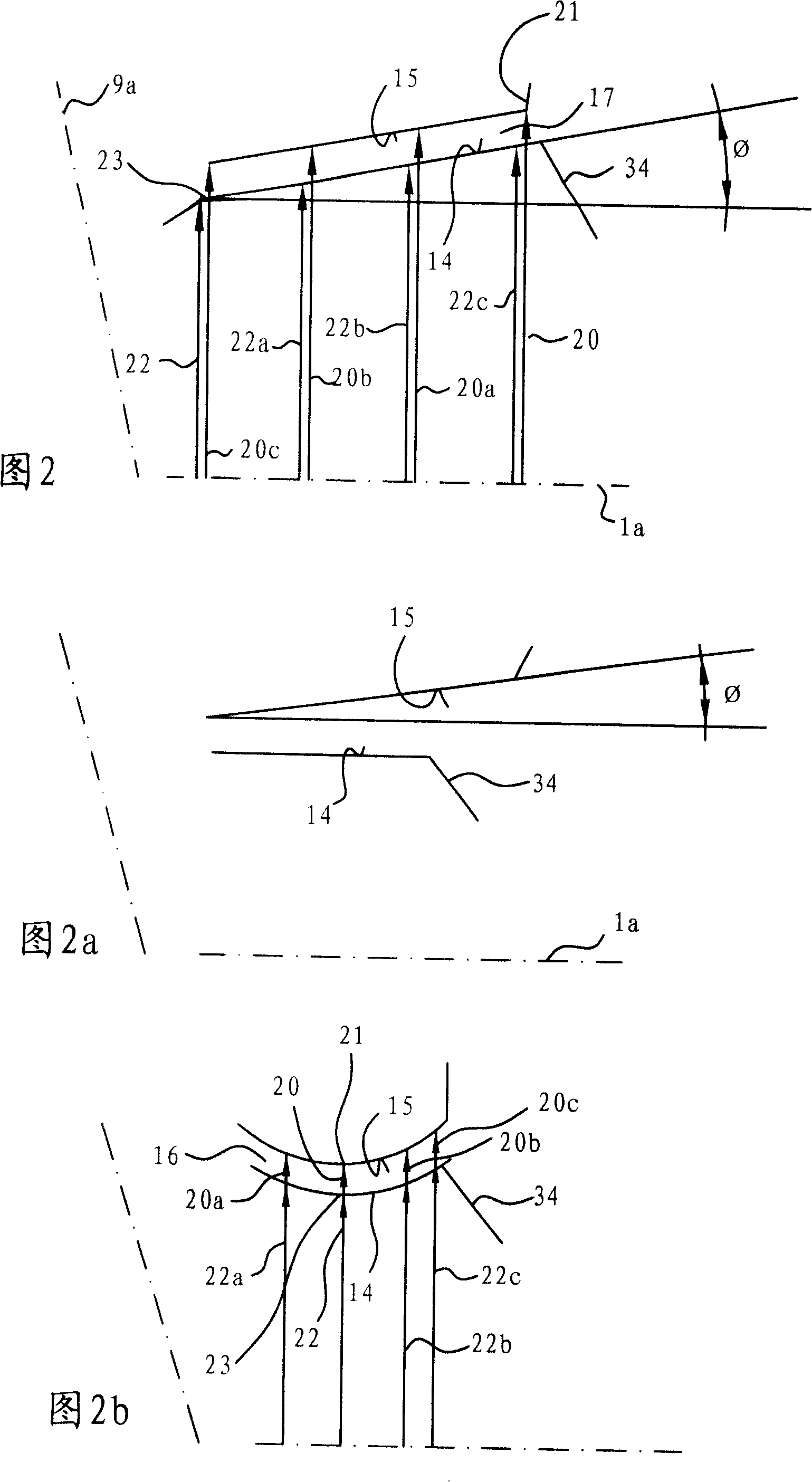

[0021] FIG. 1 shows a longitudinal section of an exemplary embodiment of a ball bearing 1 in the form of an angular contact ball bearing 2 for a spindle bearing, taken along the axis of rotation 1 a of the ball bearing. The ball bearing 1 has an outer ring 3 , an inner ring 4 and a cage 5 and is provided with a seal 6 . Shoulders 7 and 8 are formed on outer ring 3 . Compared with the low shoulder 8 , the high shoulder 7 protrudes to a greater extent radially in the direction of the axis of rotation relative to the bearing race 3 .

[0022] The cage 5 is provided on the circumferential side with pockets 9 adjoining one another about the axis of rotation 1 a of the ball bearing 1 , of which only one pocket 9 is shown in the illustration according to FIG. 1 and is longitudinally sectioned. Each pocket 9 is bounded in an axial direction indicated by a double arrow 10 by a first rib 11 and in a direction opposite to the first direction by a second rib 12 . Laths 13 extend between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com