Impeller with an abradable tip

An impeller and blade technology, applied in the field of impellers that significantly improve the pumping efficiency, can solve the problems of the circulating fluid not being replaced or being sufficiently filtered, reducing the pumping efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Although the present invention has been described in terms of such a preferred mode of application of the invention as applied to a centrifugal water pump of an internal combustion engine, those skilled in the art will appreciate that the present invention is applicable to many liquid cycle applications, whether closed or open system. Accordingly, neither the preferred applications described in this specification nor the several alternative embodiments of this specification should limit the scope of the invention, departing from the invention as particularly recited in the appended claims.

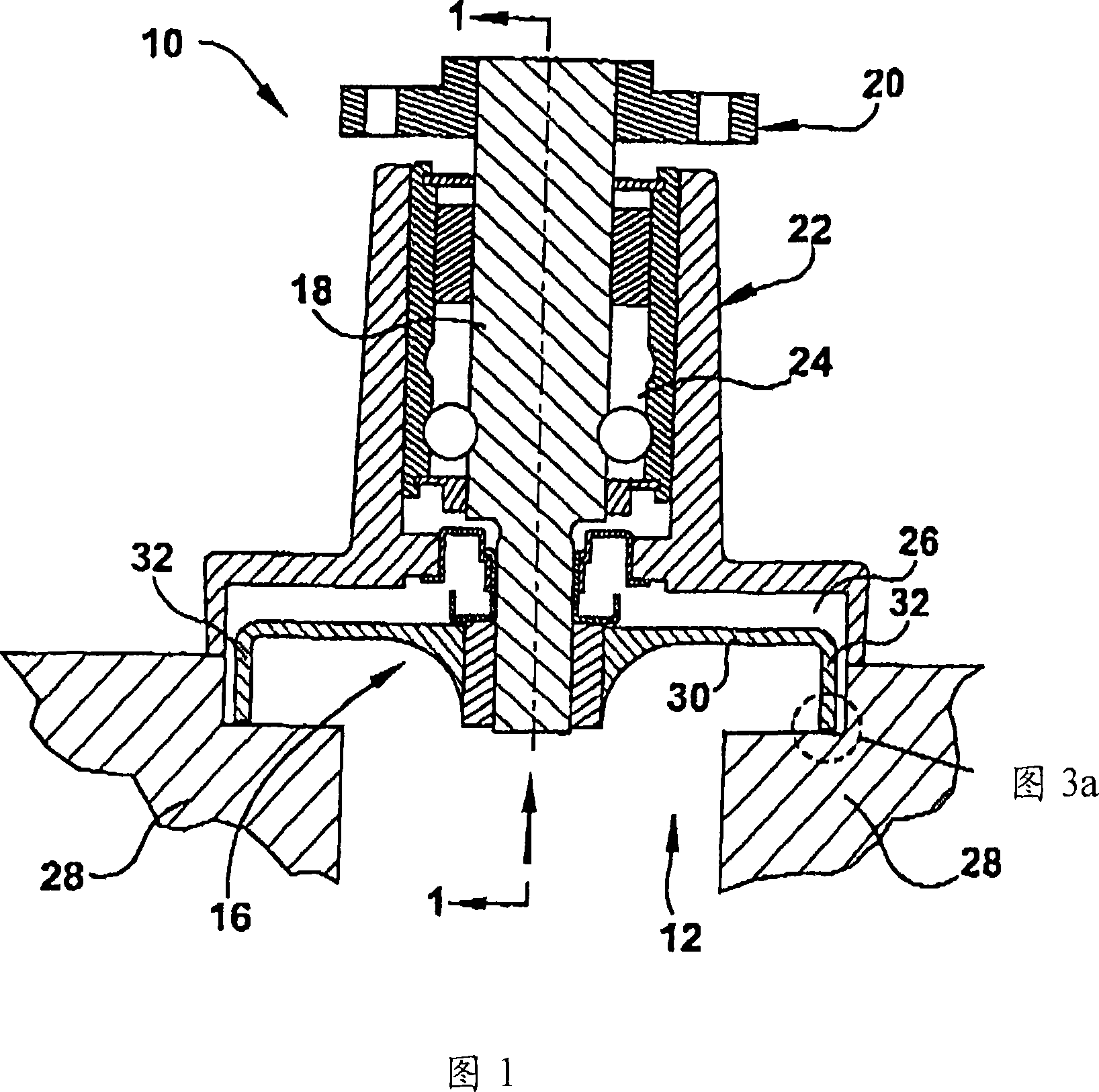

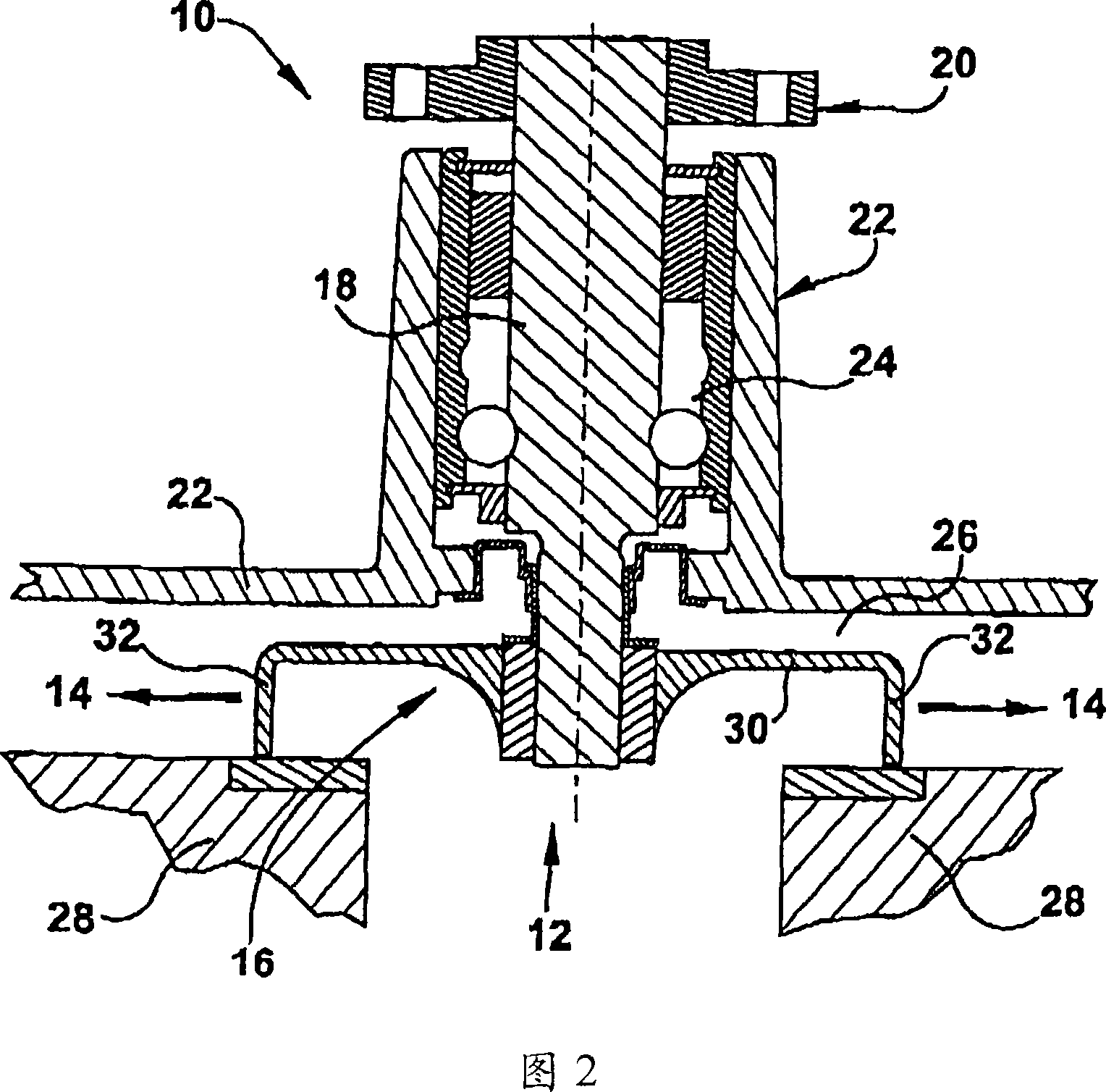

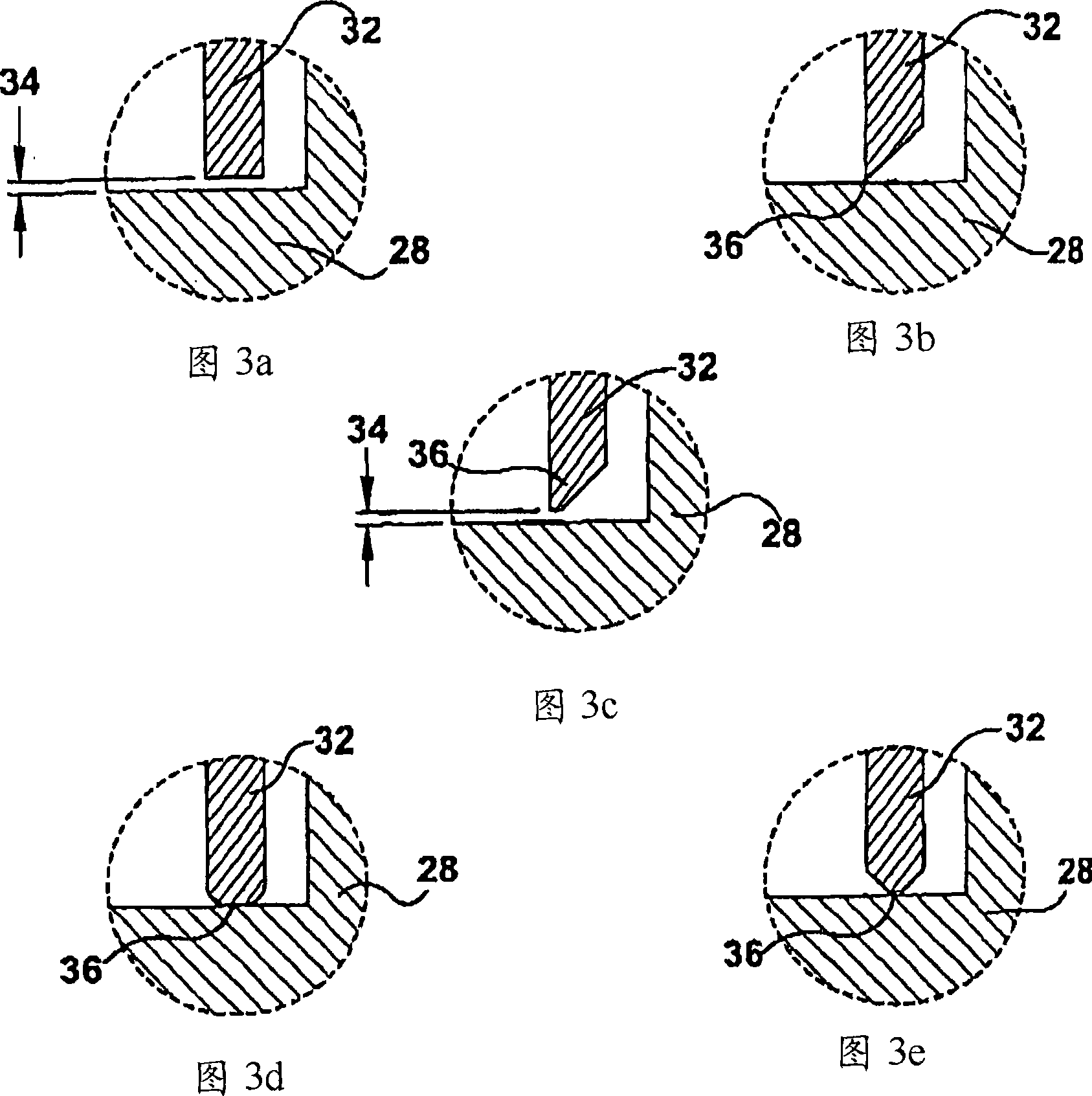

[0023] Referring now to the drawings, and particularly to FIGS. 1 and 2, a partial cross-section of a single-stage centrifugal pump 10 is shown. The pump 10 is positioned between an inlet hole 12 and an outlet hole 14 to force liquid from the water inlet hole 12 to the outlet hole 14 . The pump 10 includes an impeller 16 mounted on the end of a drive shaft 18 which is then connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com