High temp, vertical centrifugal pump

A vertical centrifugal, high-temperature technology, applied in the direction of non-variable pumps, non-volume pumps, pumps, etc., can solve the problems that the sealing method is difficult to seal, the service life of the pump is shortened, and it cannot be realized. It achieves a simple and practical structure, Prevents external leakage and improves hydraulic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

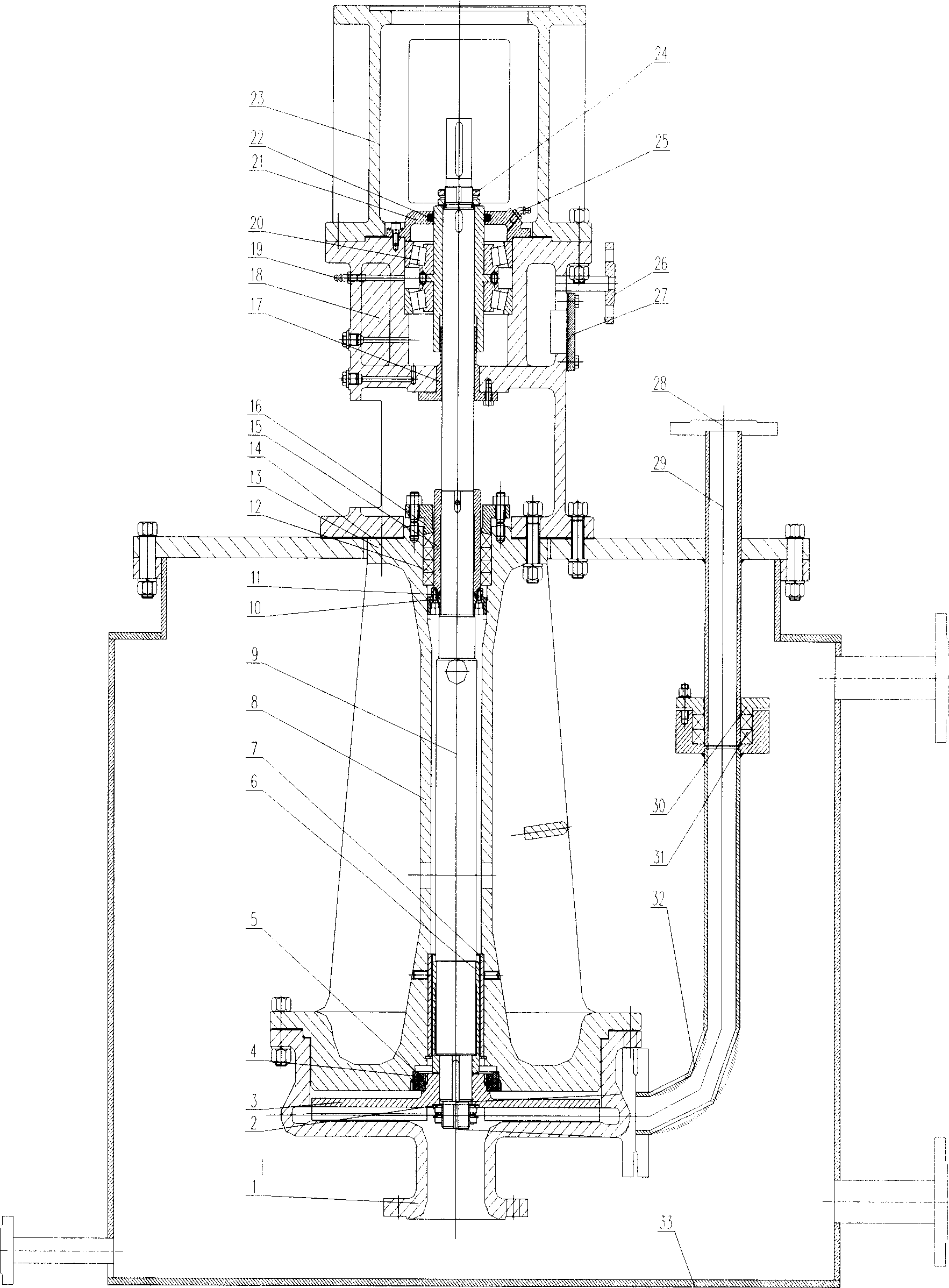

[0014] The structure of the utility model embodiment will be further described below in conjunction with the accompanying drawings.

[0015] The pump body 1 is connected with the support pipe 8, the bearing frame 18, and the motor frame 23 in sequence. The shaft 9 is a stepped shaft made of heat-resistant steel and other high-temperature resistant materials. The end of the shaft is connected with the straight blade impeller 3 in the pump body 1. Connection, the impeller is fixed on the shaft 9 through the lock nut 2, and is sealed with the support pipe, and the pump cover ring 4 and the impeller ring 5 form a sealing gap. The end of the shaft 9 is provided with a screw thread matched with the lock nut 2, and the shaft passes through the support tube 8, the bearing frame 18 and is connected with the output shaft of the motor in turn. The middle section of the shaft 9 is located at the upper bottom plate 13 of the support tube and is equipped with an effect ring 10 and a sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com