Heat exchanger and use thereof

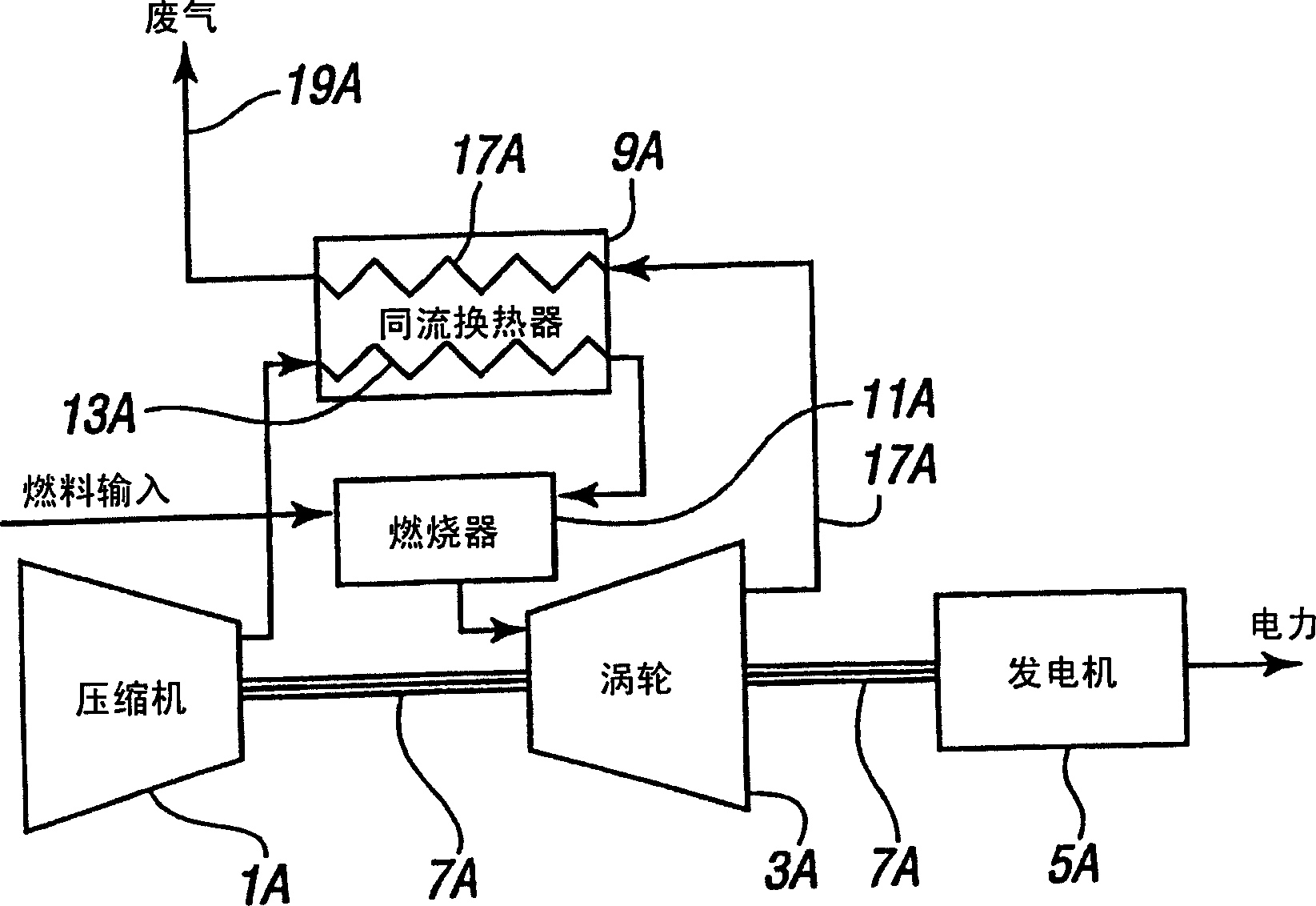

A heat exchanger, heat transfer surface technology, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as plate-pin design and unit design limitations, inability to withstand long-term work, etc. Achieve the effect of compensating expenses and enhancing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

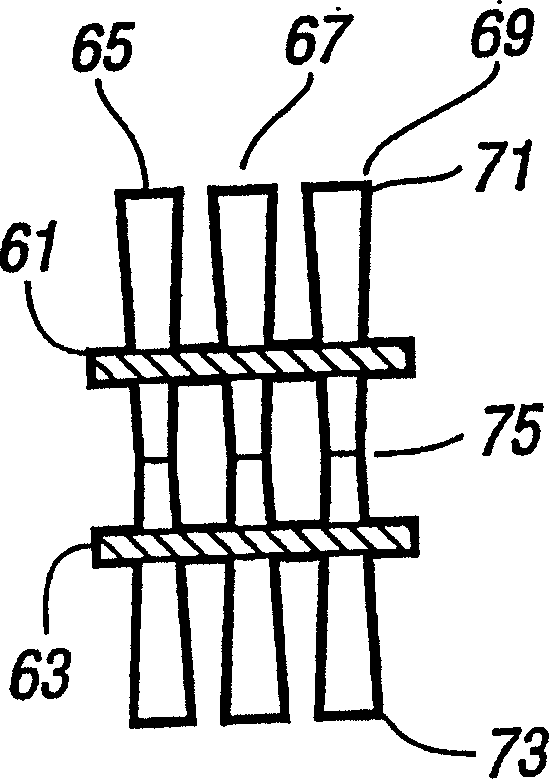

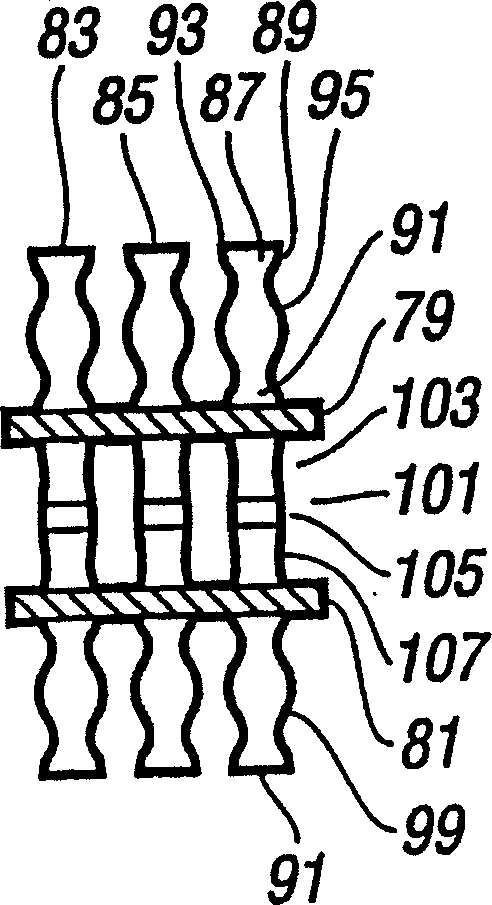

[0079] In the various embodiments described below, only two sets of plates are shown for convenience. However, it will be appreciated that in practice there will be a plurality of such plate sets.

[0080] figure 2 is a perspective view of a part of the core 1 of the recuperator according to the first embodiment of the invention. The core comprises a plurality of stacked or stacked pairs of plates, each pair of plates connected together by a pin passing through it. Such as figure 2 As shown, the partial stack comprises two plate pairs 3 , 5 . As shown in the upper part of the figure, the first board pair 3 includes an upper board 7 and a lower board 9 . The lower plate pair 5 also includes an upper plate 11 and a lower plate 13 .

[0081] In the core, all the plates are substantially planar (ie flat plates) and are arranged at a distance from each other, with their main planes spaced from each other in a parallel manner.

[0082] Accordingly, the plates 7 of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com