Removing method of gear-hobbing burr

A burr and gear hobbing technology, applied in the direction of components with teeth, gear teeth, belts/chains/gears, etc., can solve the problem of difficult removal of burrs, and reduce the process of dehairing by fitters or dehairing the end face of lathes. , the effect of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention: take machining shaft gear as example, it comprises the following steps:

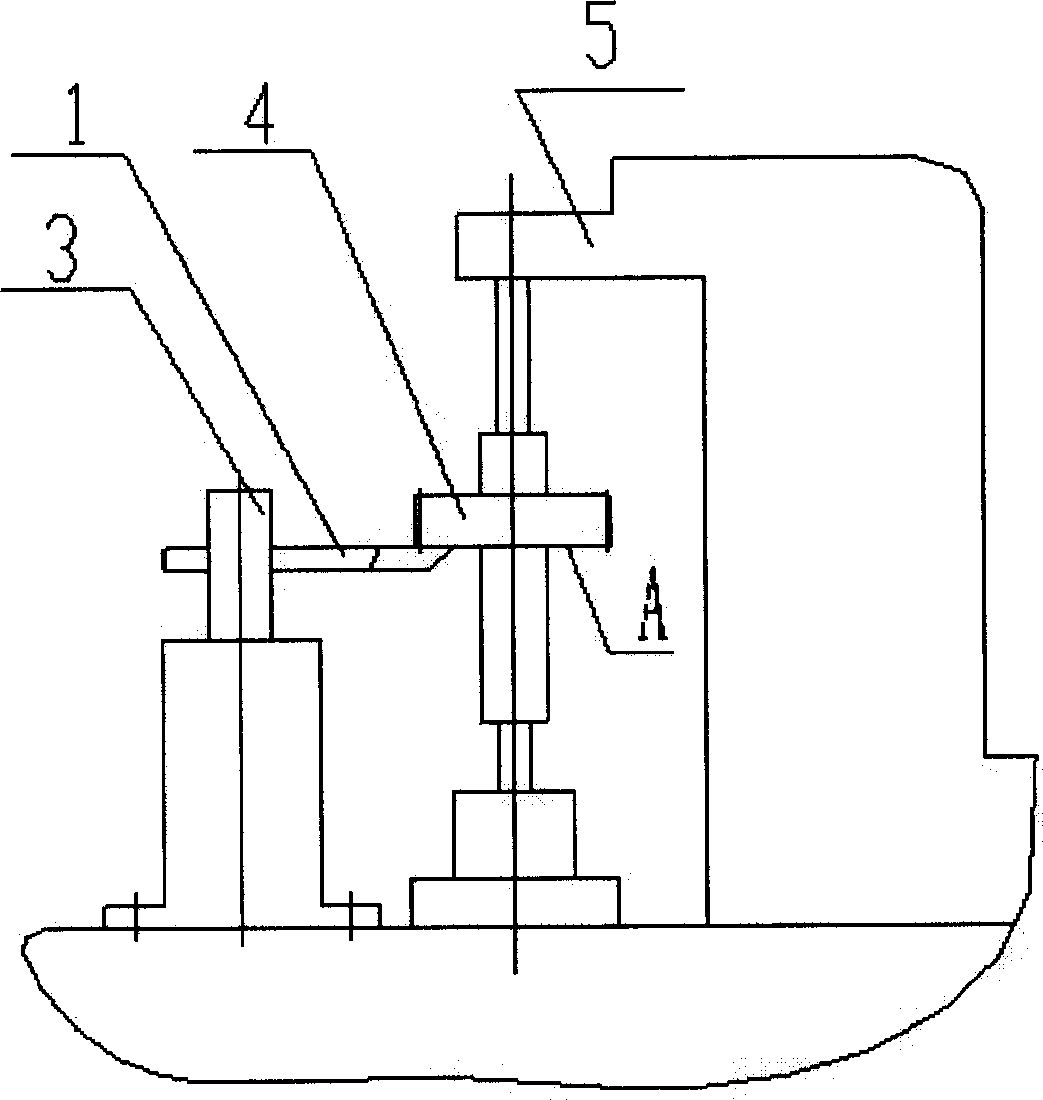

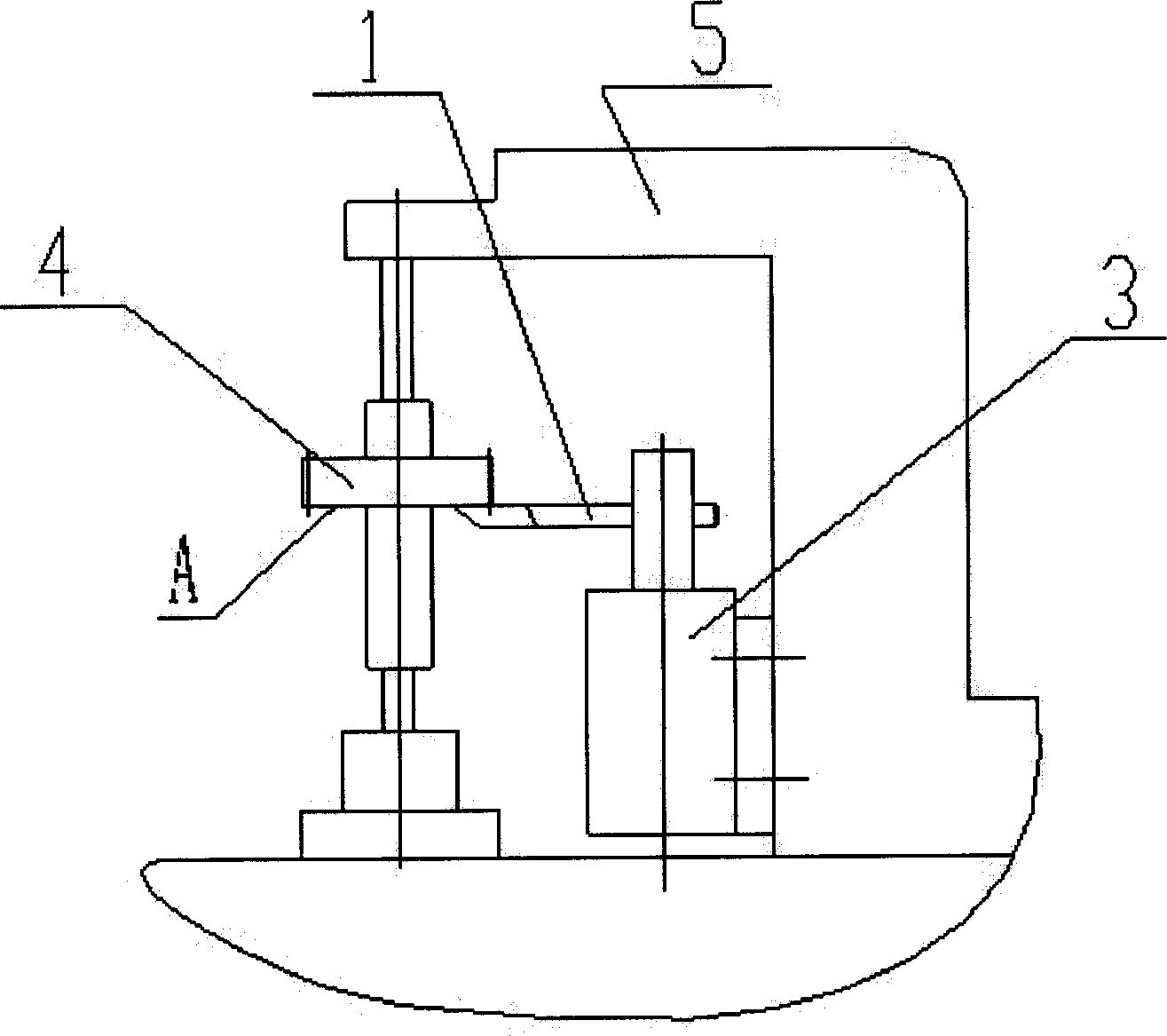

[0022] First, the gear shaft blank 4 to be processed is clamped on the gear hobbing machine 5, and the positioning is adjusted;

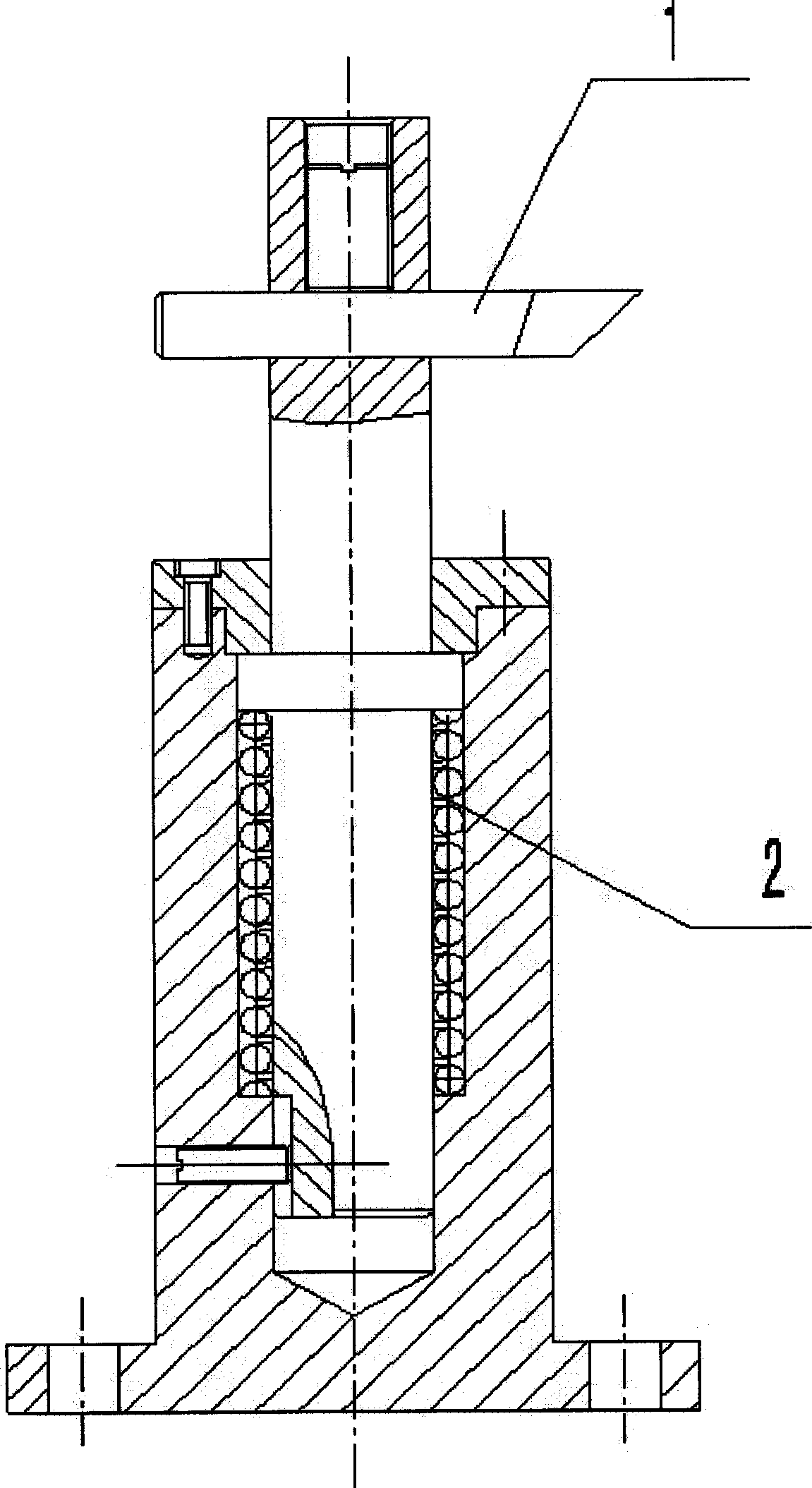

[0023] The second, the special-purpose elastic knife rest 3 that has depilator 1 is installed on the base of gear hobbing machine 5, as figure 2 shown; or the special elastic knife rest 3 with the depilatory knife 1 is installed on the small column of the gear hobbing machine 5, as image 3 As shown; adjust the position of the deburring knife 1, first make the deburring knife 1 slightly exceed the design position of the tooth root in the horizontal direction, and slightly higher than the cutting surface of the workpiece in the vertical direction, that is, the A surface, and then press down on the deburring knife 1 , so that the dehairing knife 1 is closely attached to the cutting surface A of the workpiece under the action of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com