Electronic element automatic moving loader

A technology of electronic components and transfer devices, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as deviation from the initial position, inability to adsorb electronic components, transfer and pick-and-place actions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

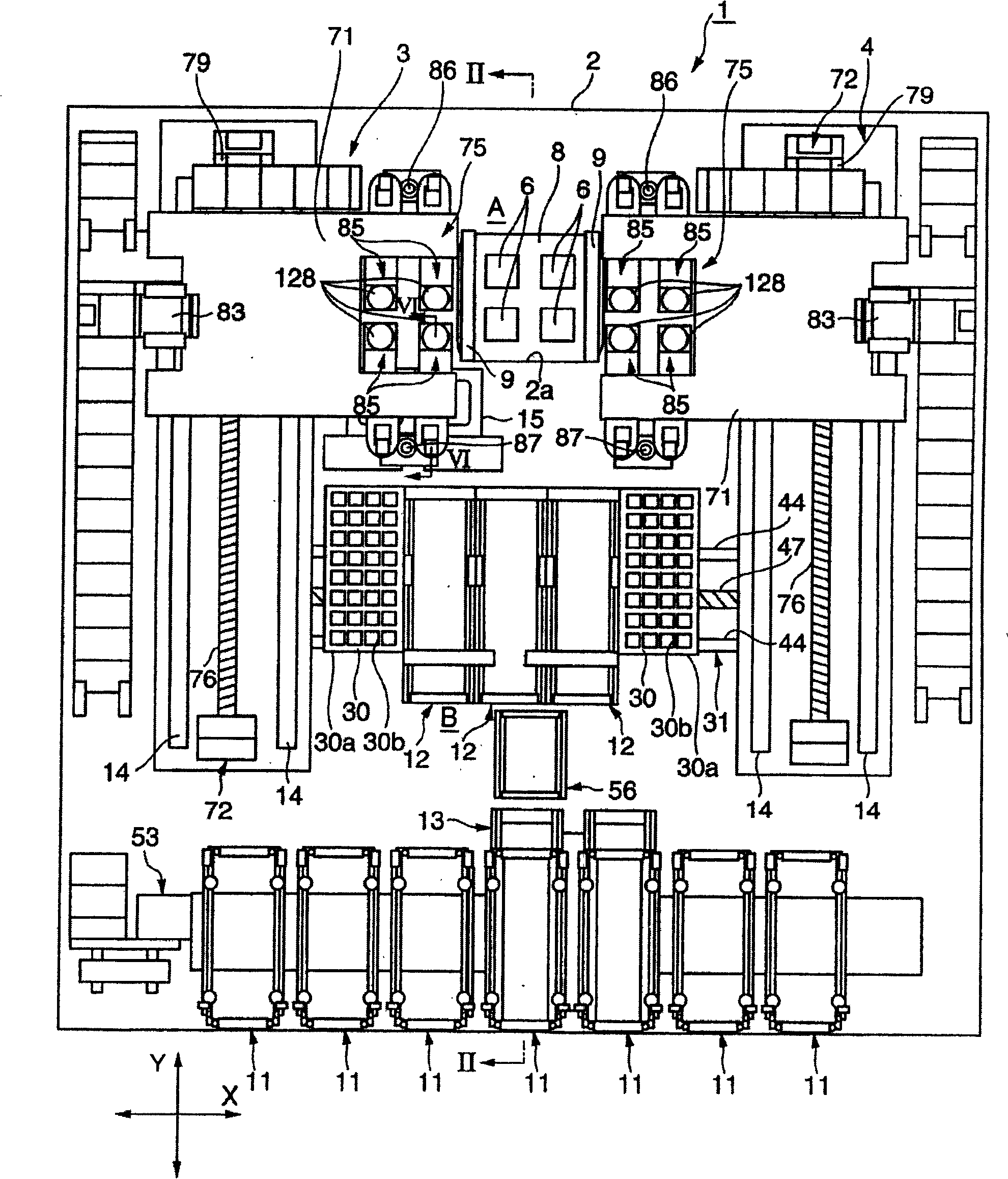

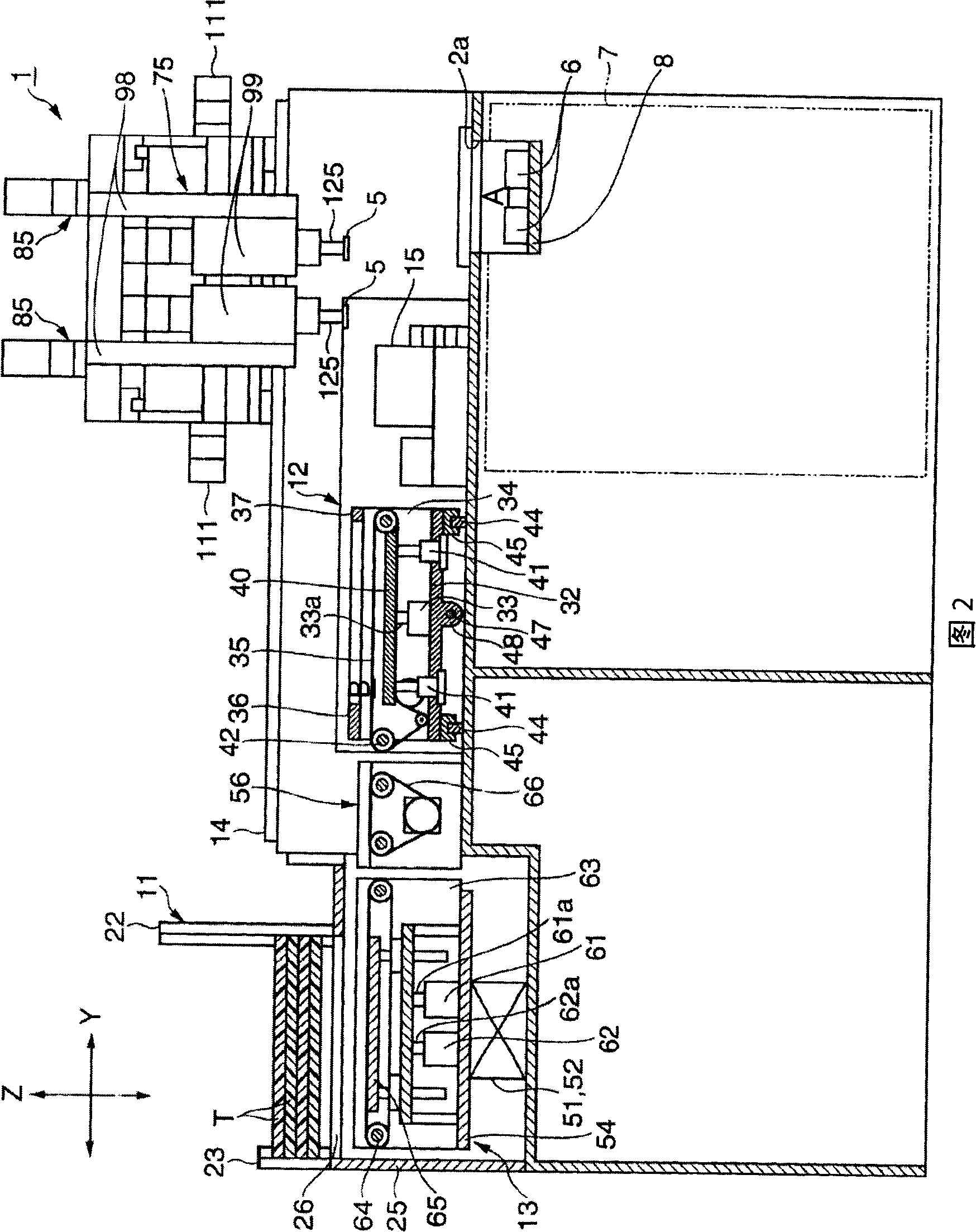

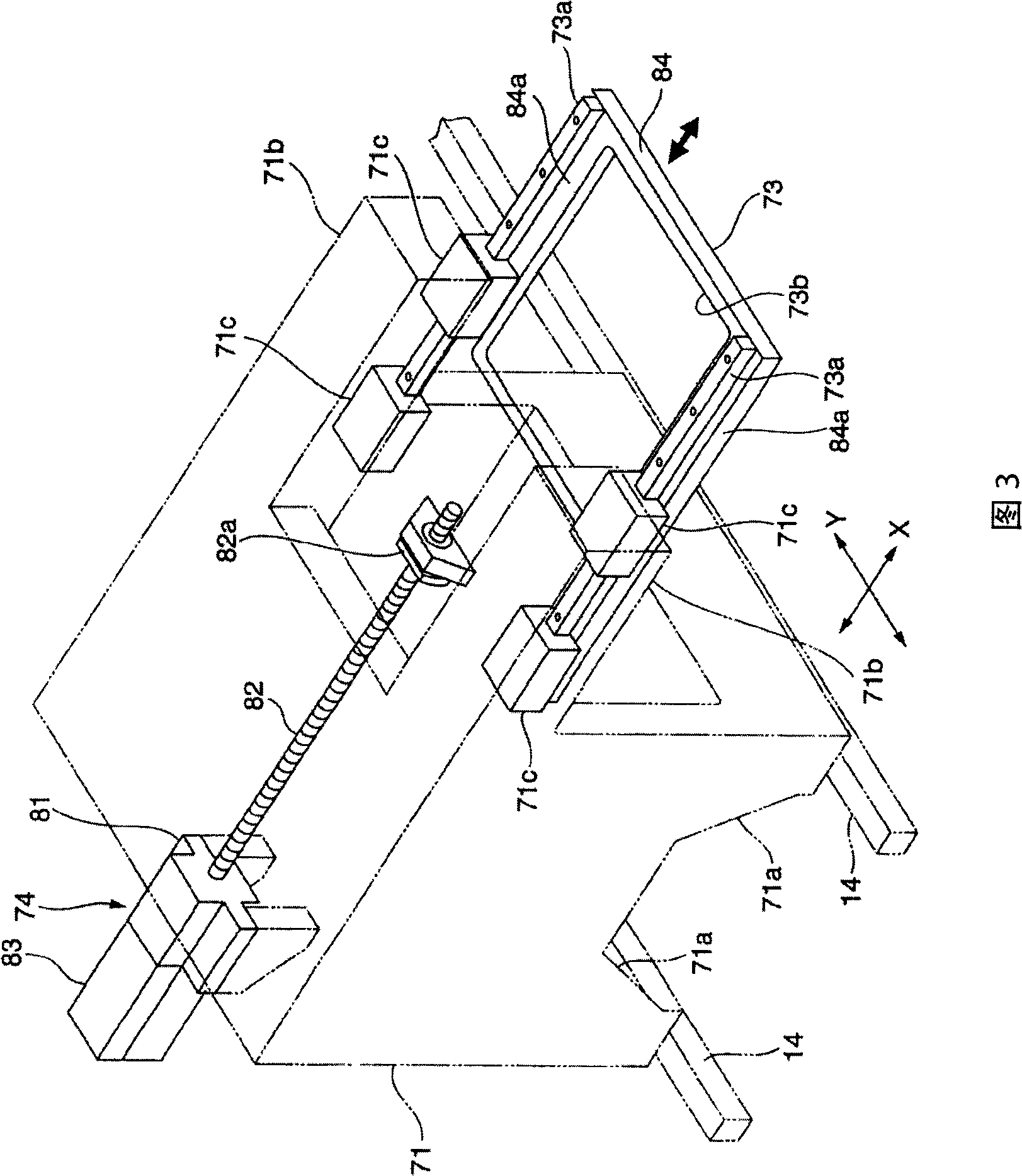

[0051] Below, combine Figure 1 to Figure 22 An embodiment of the electronic component automatic transfer device in the present invention will be described in detail.

[0052] figure 1 It is a plan view of the electronic component automatic transfer device in the present invention. In this figure, a pallet support device and a stocker are depicted without a pallet placed above. figure 2 yes figure 1 The II-II line profile, image 3 is a perspective view illustrating the structure of the component moving device, Figure 4 is a perspective view of the head unit, Figure 5 is a perspective view illustrating the direction of movement of the unit cells, and only two unit cells are depicted in this figure. Image 6 Is a side view of a unit cell, broken to show the connected parts of the structural components. figure 1 The cutting position is shown by line VI-VI in . Figure 7 It is a sectional view showing the suction nozzle part enlarged.

[0053] Figure 8 It is a struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com