Method for detecting 3d measurement data using allowable error zone

A technology of tolerance, three-dimensional measurement, applied in measurement devices, electrical digital data processing, special data processing applications, etc., can solve the problems of time-consuming, users can not be sure whether the comparison results of measurement data are accurate, reliability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Now, preferred embodiments of the present invention will be described in detail.

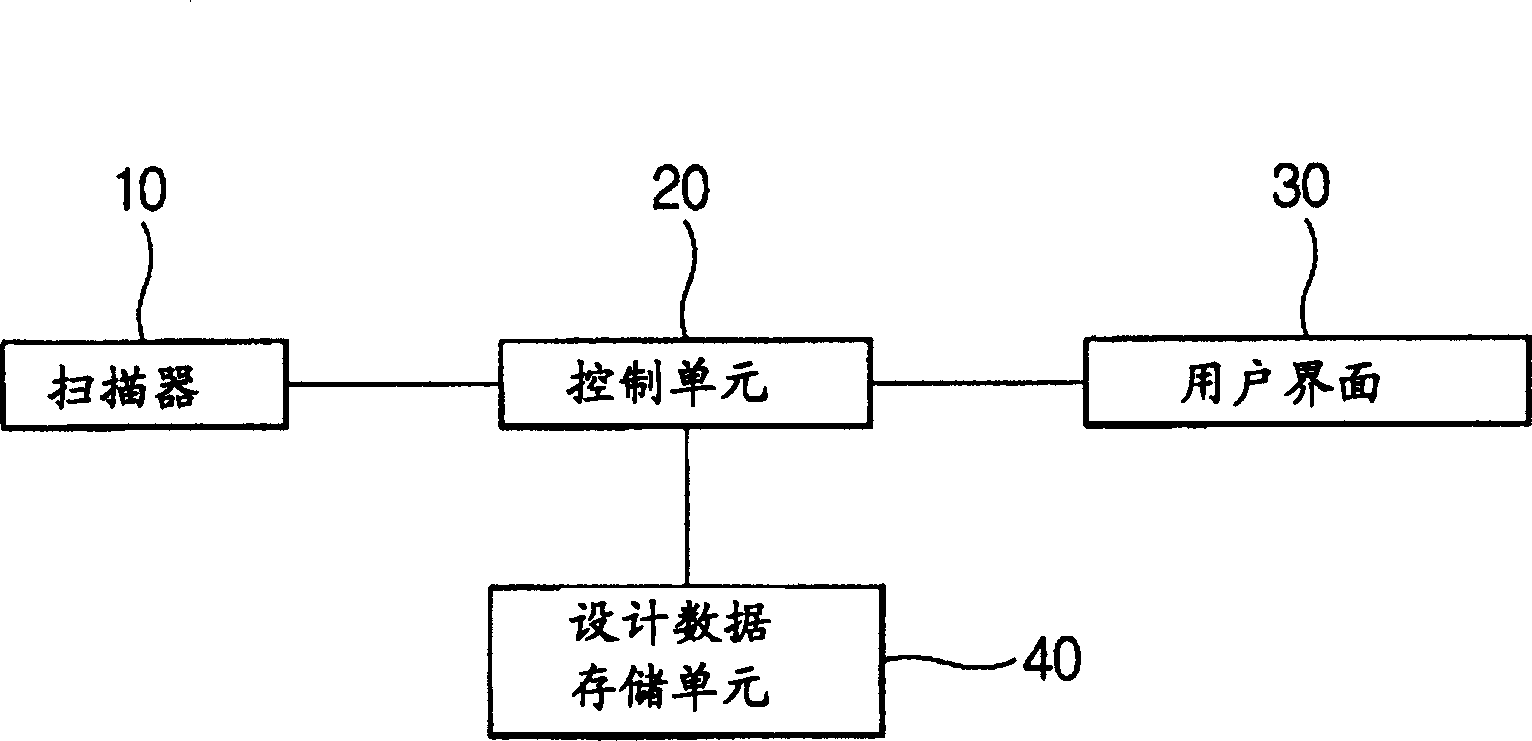

[0036] figure 1 is a block diagram of a system for detecting 3D measurement data using a tolerance zone in accordance with the present invention.

[0037] refer to figure 1 , the system includes: a scanner 10 for measuring the target to be measured; a control unit 20 for controlling the system as a whole; a user interface 30 for providing an interface to the user; and a design for storing the design data of the target data storage unit 40 .

[0038] The scanner 10 is a device for measuring a target and obtaining measurement data. The scanner 10 may be a non-contact 3D scanner.

[0039] The control unit 20 analyzes the design data of the target, sets auxiliary geometric figure data for measurement from the design data of the target, sets an allowable error area of the auxiliary geometric figure data for measurement based on allowable error information input from the user interface 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com