Drum washing machine and method of controlling the same

The technology of a drum washing machine and its control method, which is applied in the field of washing machines, can solve the problems of delaying the start time of the main dehydration and increasing the power, and achieve the effect of shortening the laundry operation time, reducing the power and shortening the start time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention will be described in detail as follows.

[0043] ***Description of symbols for main components in the drawings***

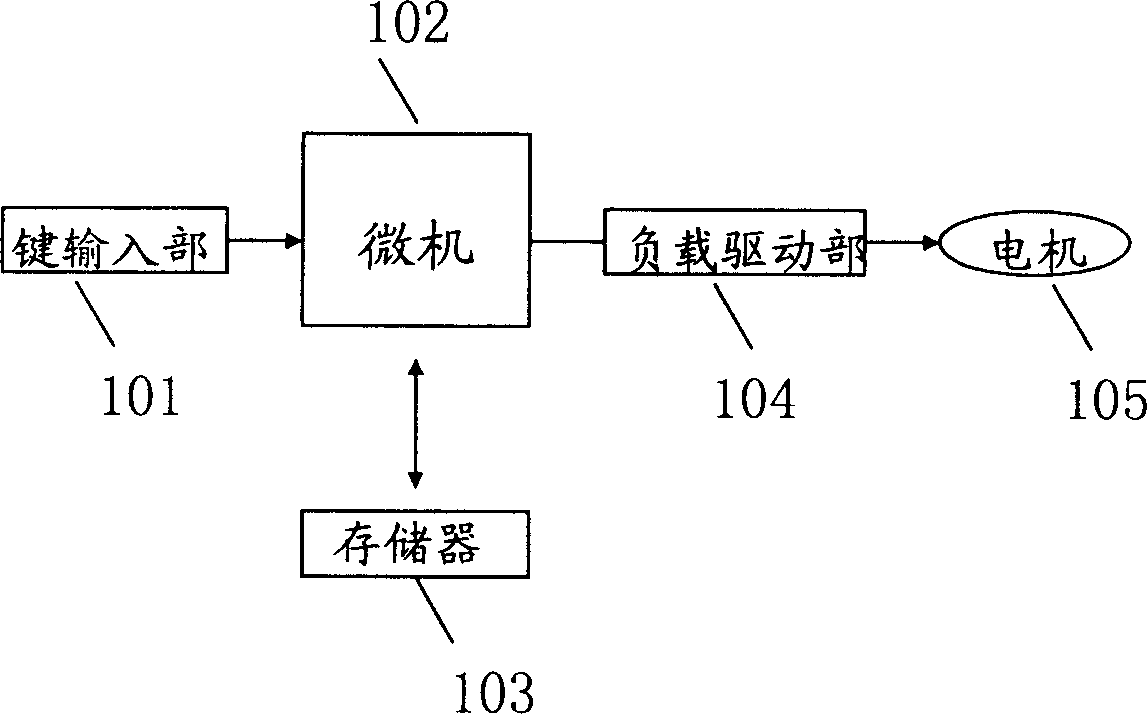

[0044] 101: key input unit 102: microcomputer

[0045] 103: Memory 104: Load driver

[0046] 105: motor

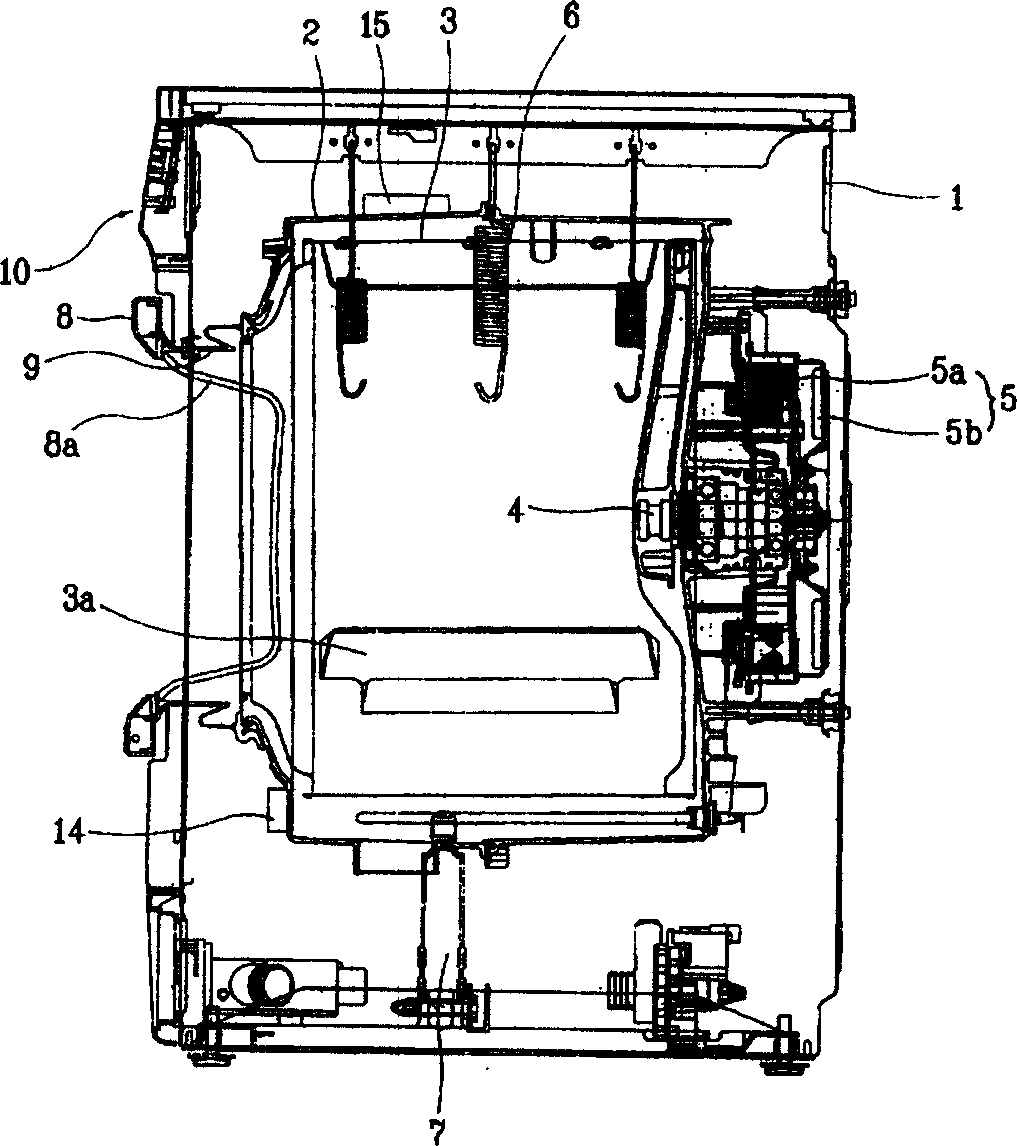

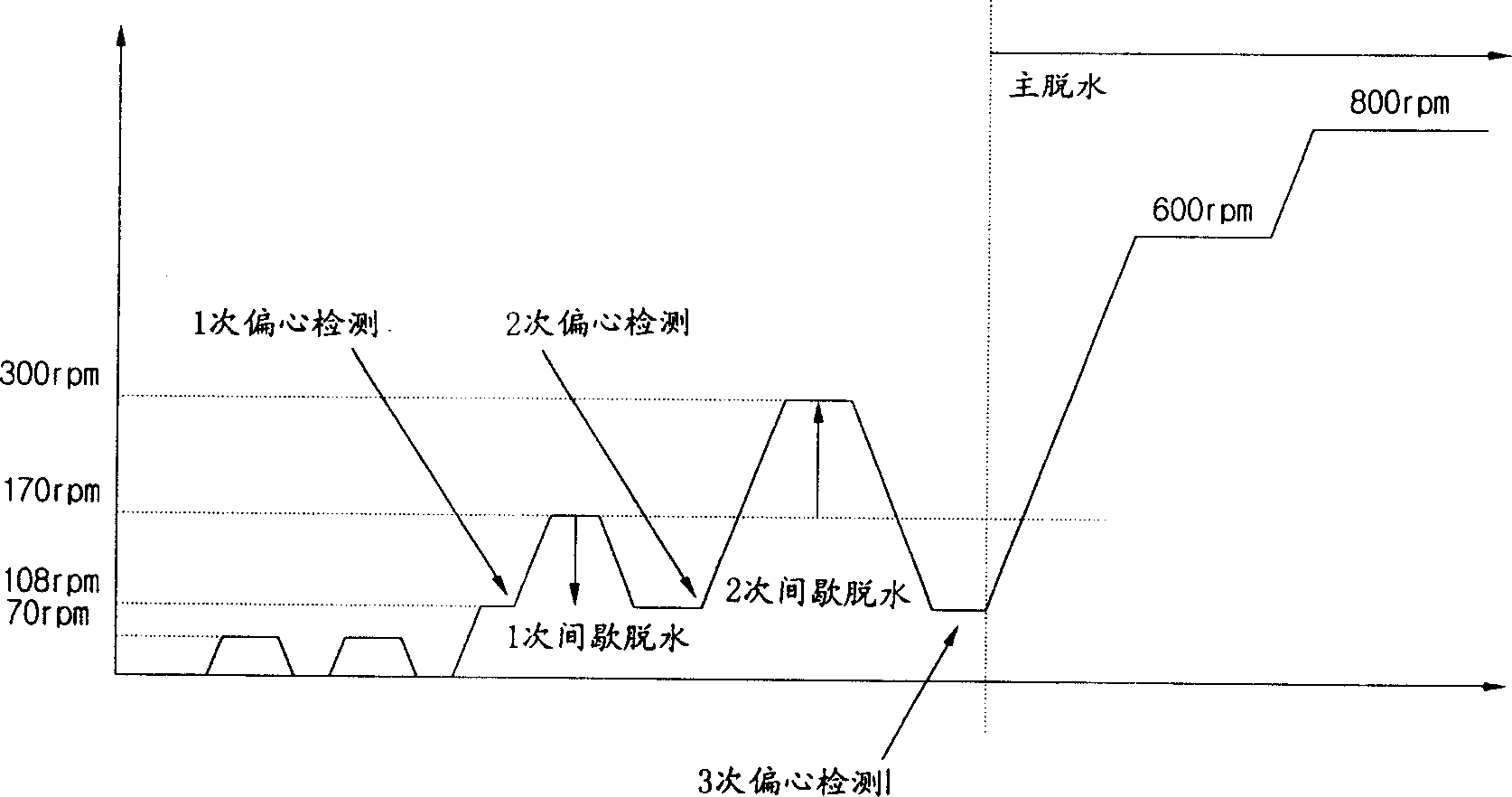

[0047] see image 3 , Figure 4 , Figure 5 As shown, the invention of the drum washing machine and its control method, such as image 3 As shown, the drum washing machine in the present invention includes the following parts: a key input part 101, which is used to input the user's request command; control command, and detect the amount of eccentricity when entering the dehydration stroke, and control the washing machine to no longer perform the preset intermittent dehydration operation according to the above-mentioned detected results; Controlling the driving of the motor 105; the m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap