Device for roughly regulating or fine adjustment for paper banner through adding diluent water

A technology of dilution water and rough adjustment, applied in papermaking, papermaking machine, wet end of paper machine, etc., can solve the problems of increasing the difficulty of processing and manufacturing, affecting the adjustment effect of paper fiber orientation, installation impact, etc., achieving low equipment cost and avoiding clogging , to avoid the effect of cross-flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

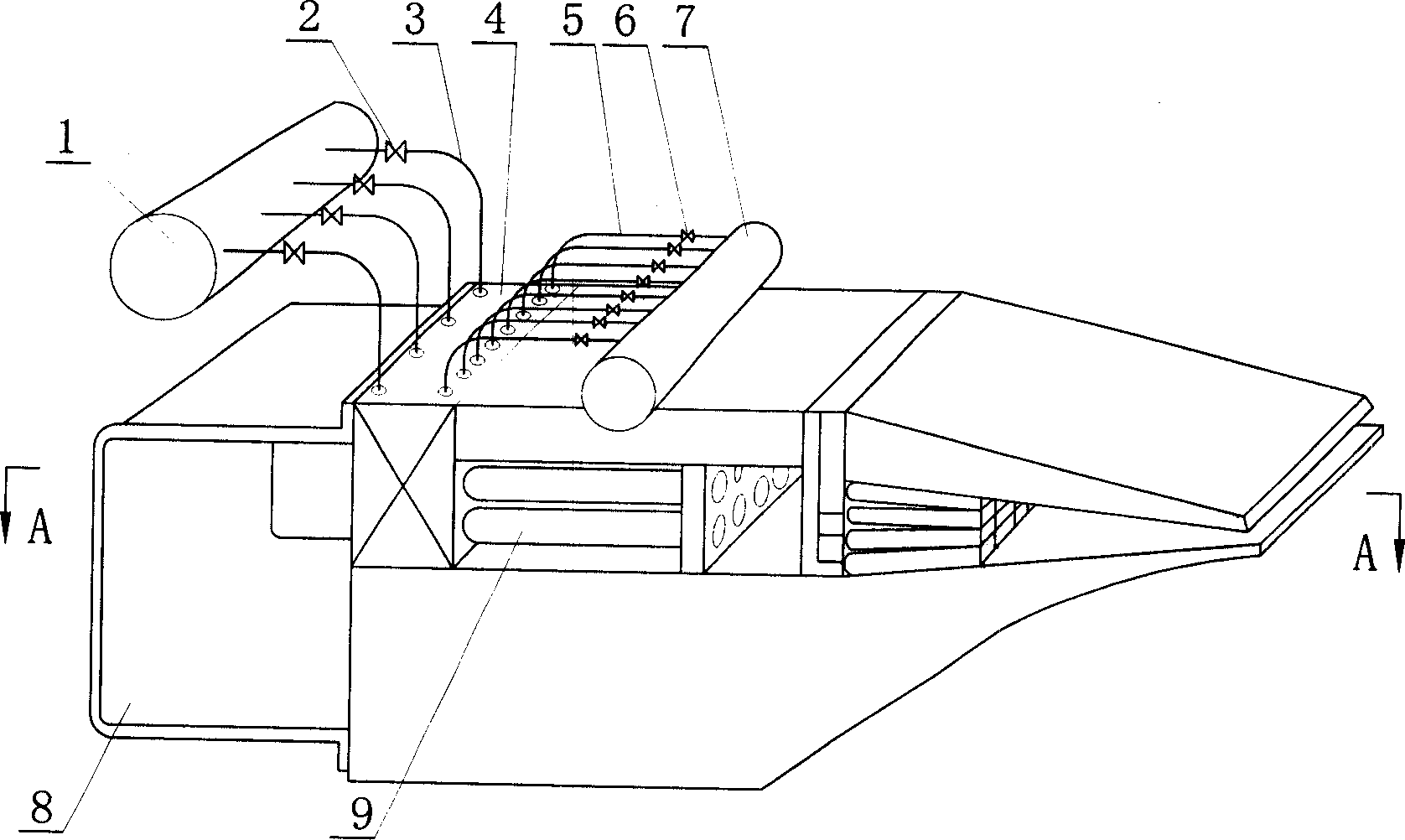

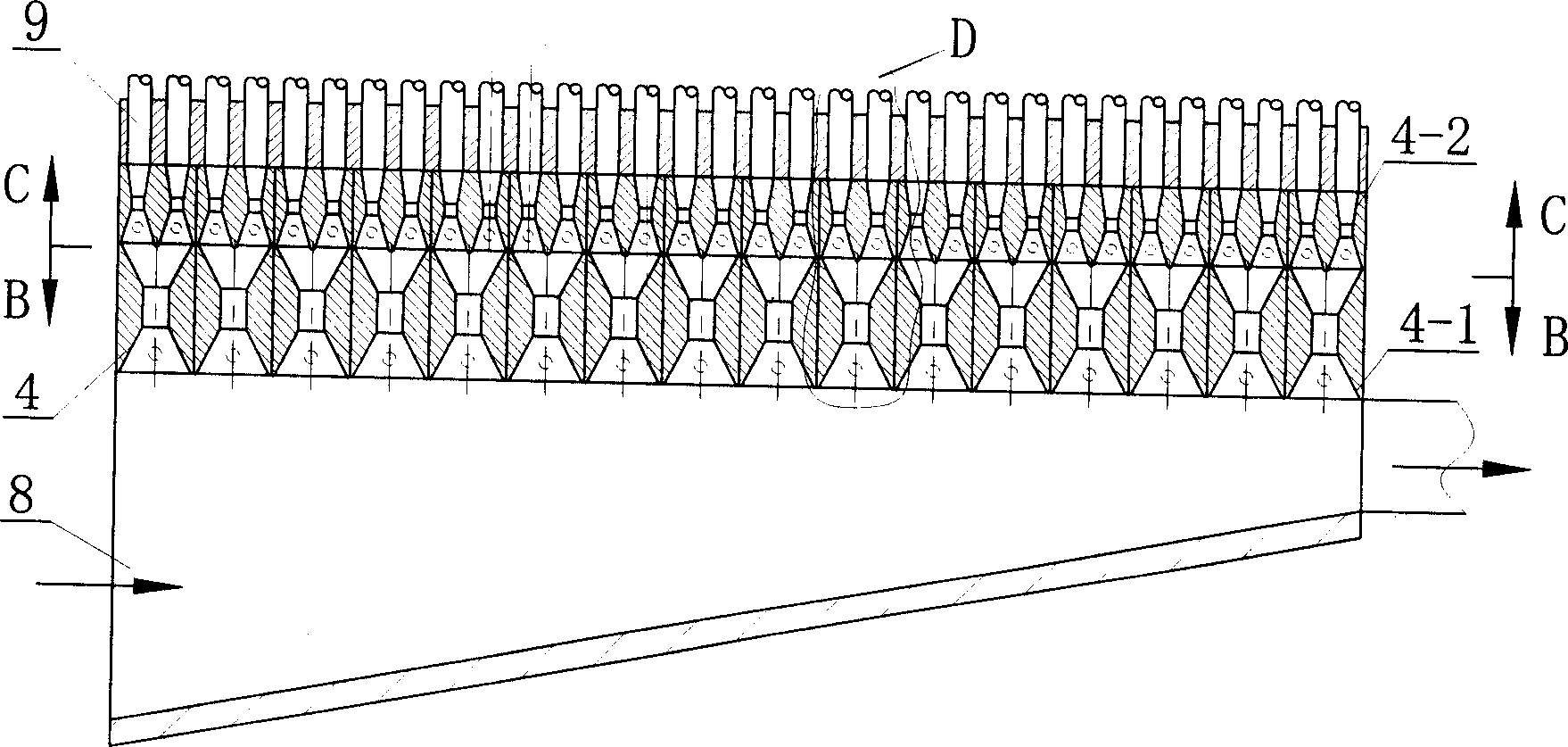

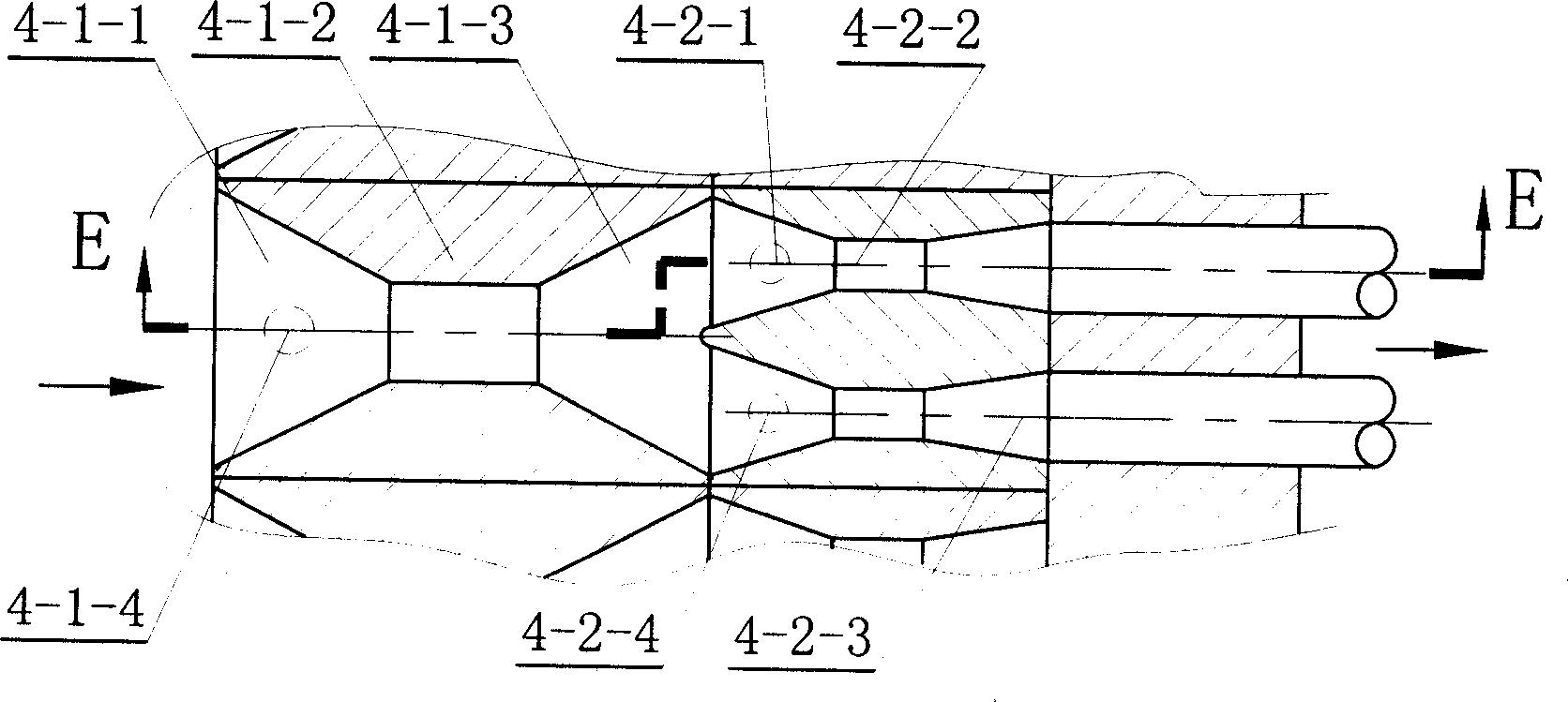

[0022] like figure 1 As shown, the dilution water is added to the headbox in two stages. The headbox includes a dilution water coarse adjustment system and a dilution water fine adjustment system. The dilution water coarse adjustment system consists of a dilution water main pipe 1, a regulating valve 2, a dilution water branch pipe 3 and a dilution water The dilution water fine-tuning system is composed of a dilution water main pipe 7 , a regulating valve 6 , a dilution water branch pipe 5 and a dilution water module 4 .

[0023] The dilution water main pipe (1, 7) is a tapered pipe, which can ensure that the flow and pressure entering the dilution water branch pipe (3, 5) are completely equal. The two sets of dilution water addition systems share a dilution water module 4, the first section of coarse adjustment diluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com