Inking device of printing press

A technology for printing presses and equipment, applied in the field of inking equipment, which can solve problems such as frequent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

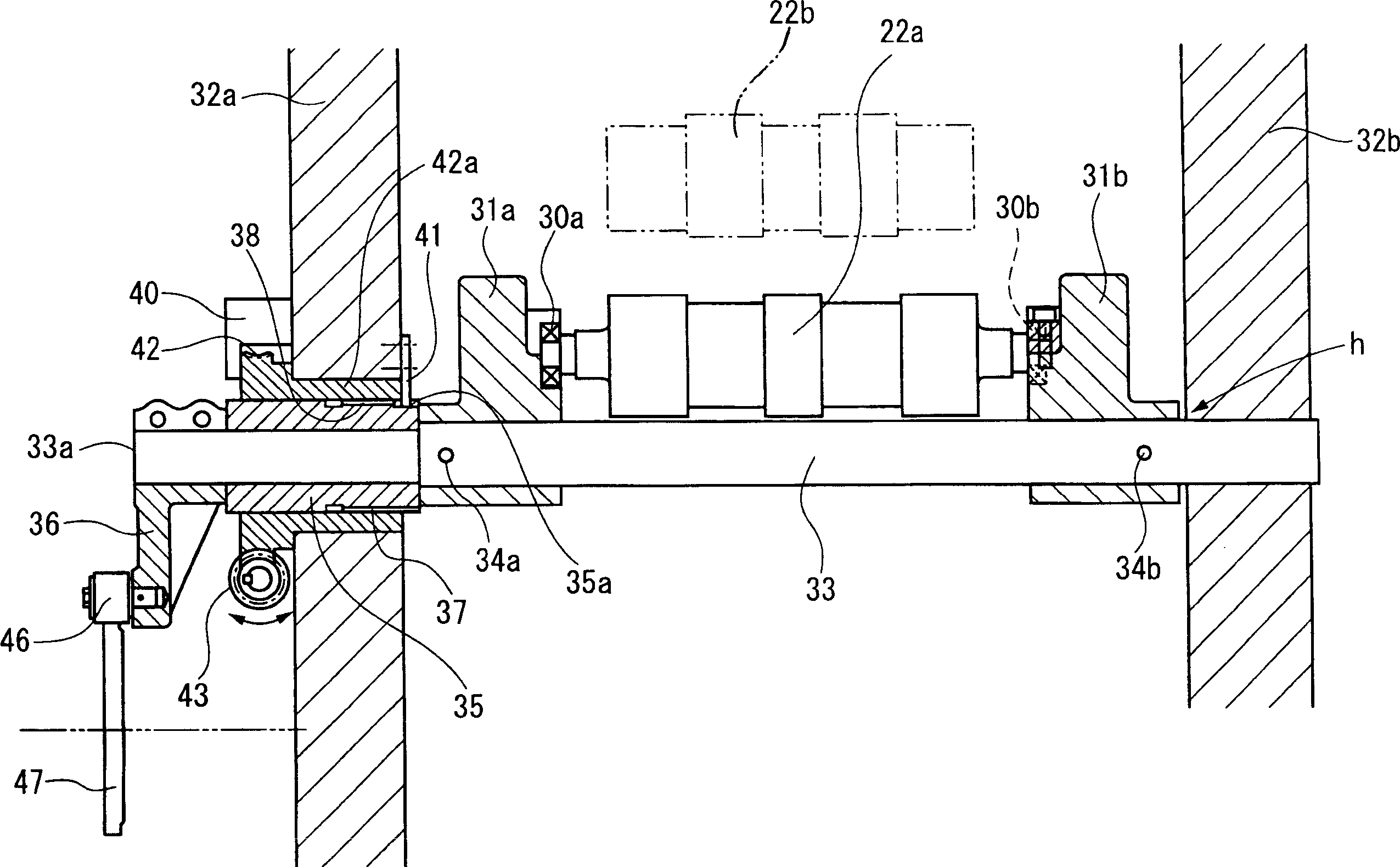

[0055] Figure 4 is a basic structural diagram of an inking unit, showing Embodiment 2 of the present invention. Figure 5 It is a structural diagram of the motor drive unit.

[0056] In this embodiment, the motor 53 is used to rotationally drive the worm shaft 43 in Embodiment 1 instead of the operating shaft 45 having the handle 44 with a dial, and the potentiometer 52 is used to detect the worm gear 42 integrated with the worm wheel 42 via the gears 50, 51. The amount of rotation of the bearing portion 42a (ie, the amount of movement of the ink feed rollers 22a, 22b). Other characteristics are identical with embodiment 1, therefore omit repeated description, and figure 1 The same parts in are given the same figure 1 The same reference numerals.

[0057] According to the above construction, in addition to the same actions and effects as in Embodiment 1, an advantage can be obtained that the position adjustment of the ink feed rollers 22a, 22b can be performed automatical...

Embodiment 3

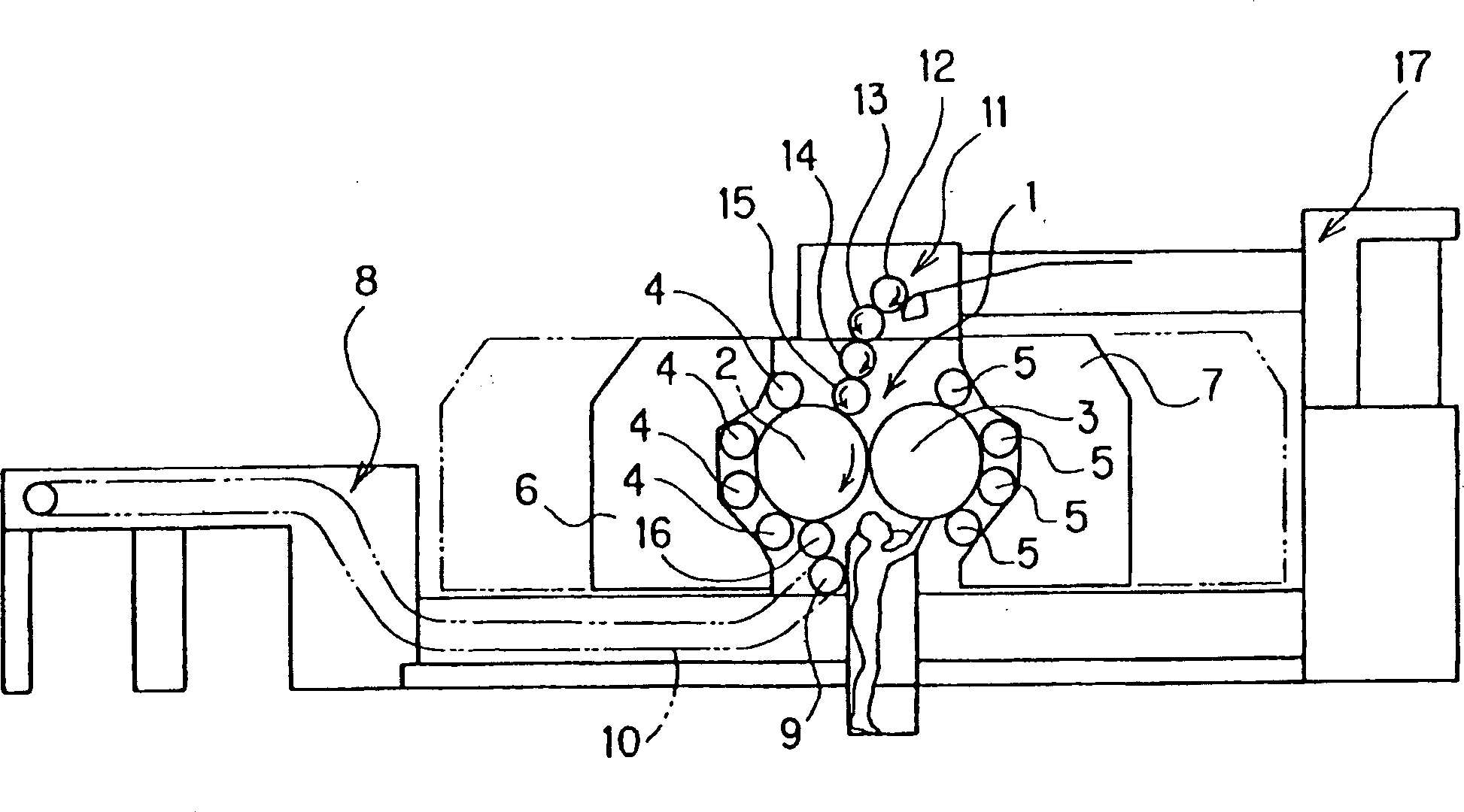

[0059] Image 6 is a basic configuration diagram of an inking unit, showing Embodiment 3 of the present invention.

[0060] In this embodiment, the worm shaft 43 in Embodiments 1 and 2 is housed in the frame 32a to obtain a compact machine configuration. Other characteristics are identical with embodiment 1, therefore omit repeated description, and figure 1 with 4 The same parts in are given the same figure 1 with 4 The same reference numerals.

Embodiment 4

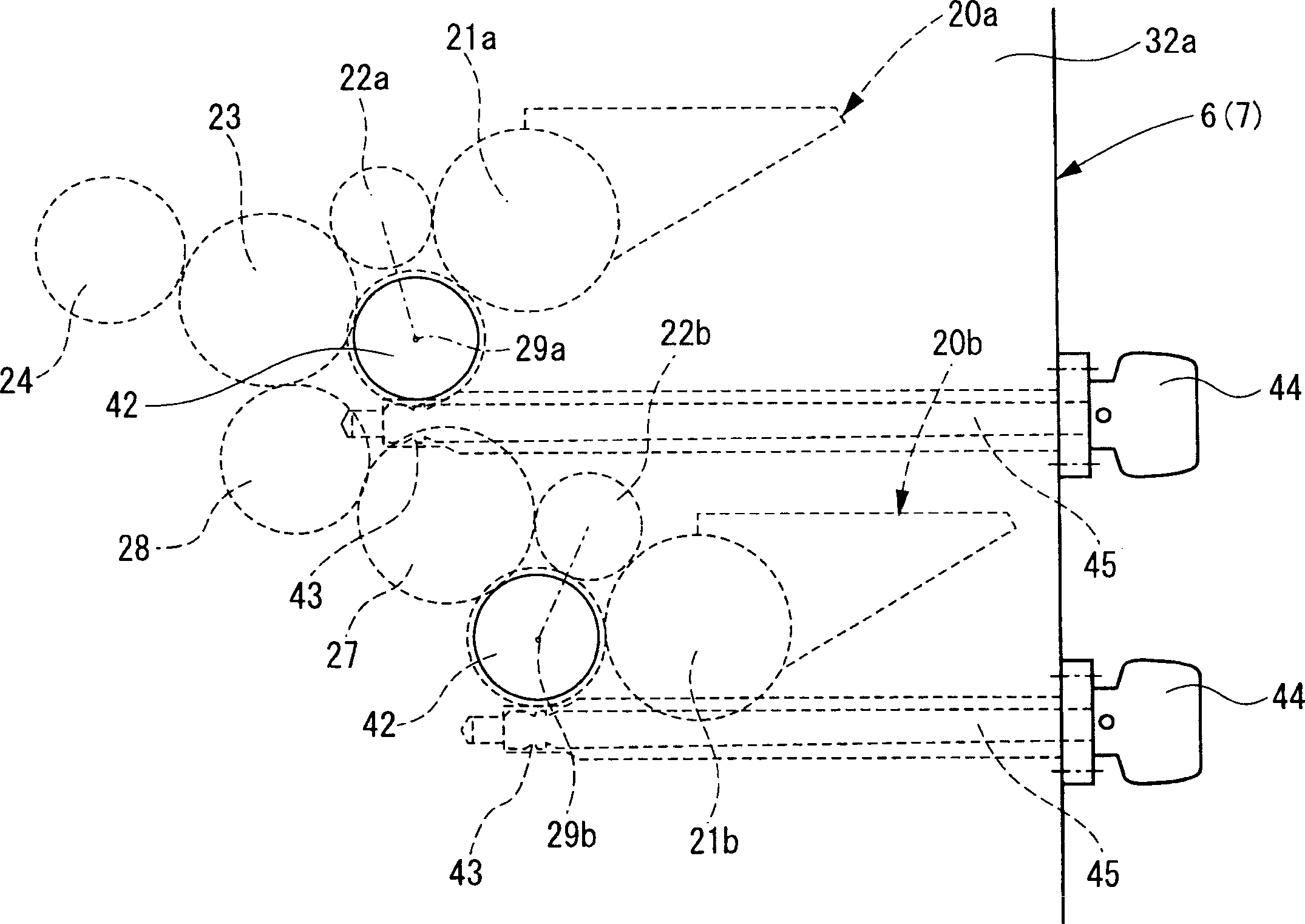

[0062] Figure 7 is a basic configuration diagram of an inking unit, showing Embodiment 4 of the present invention.

[0063] In this embodiment, the opposite ends of the shaft 33 in Embodiment 1 are formed as small diameter portions 33a, 33b; , 39b support to be rotatable and move (slide) along the axial direction of the needle bearings 60a, 60b; The diameter portion 33b is connected.

[0064] The operating shaft 45 as a driving device and having a dial handle 44 is rotatably supported parallel to the shaft 33 by the frame 32b via a support 64 assembled in an L-shape and also serving as a bracket 61 as a moving member. (to be described later). A pair (ie, left and right) of rollers 62a and 62b as engaging portions and restricting members is rotatably provided on a bracket 61 screwed onto the threaded engagement portion 45a of the operation shaft 45 and slidably fitted On the guide rod portion 64 a of the support member 64 . The aforementioned disk 63 is positioned between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com