Glass top plate for drop-in type cooking stove

A technology for glass panels and stoves, which is applied in the field of glass panels, and can solve problems such as large opening area, insufficient combustion air volume, and difficulty in adequately supplying combustion air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

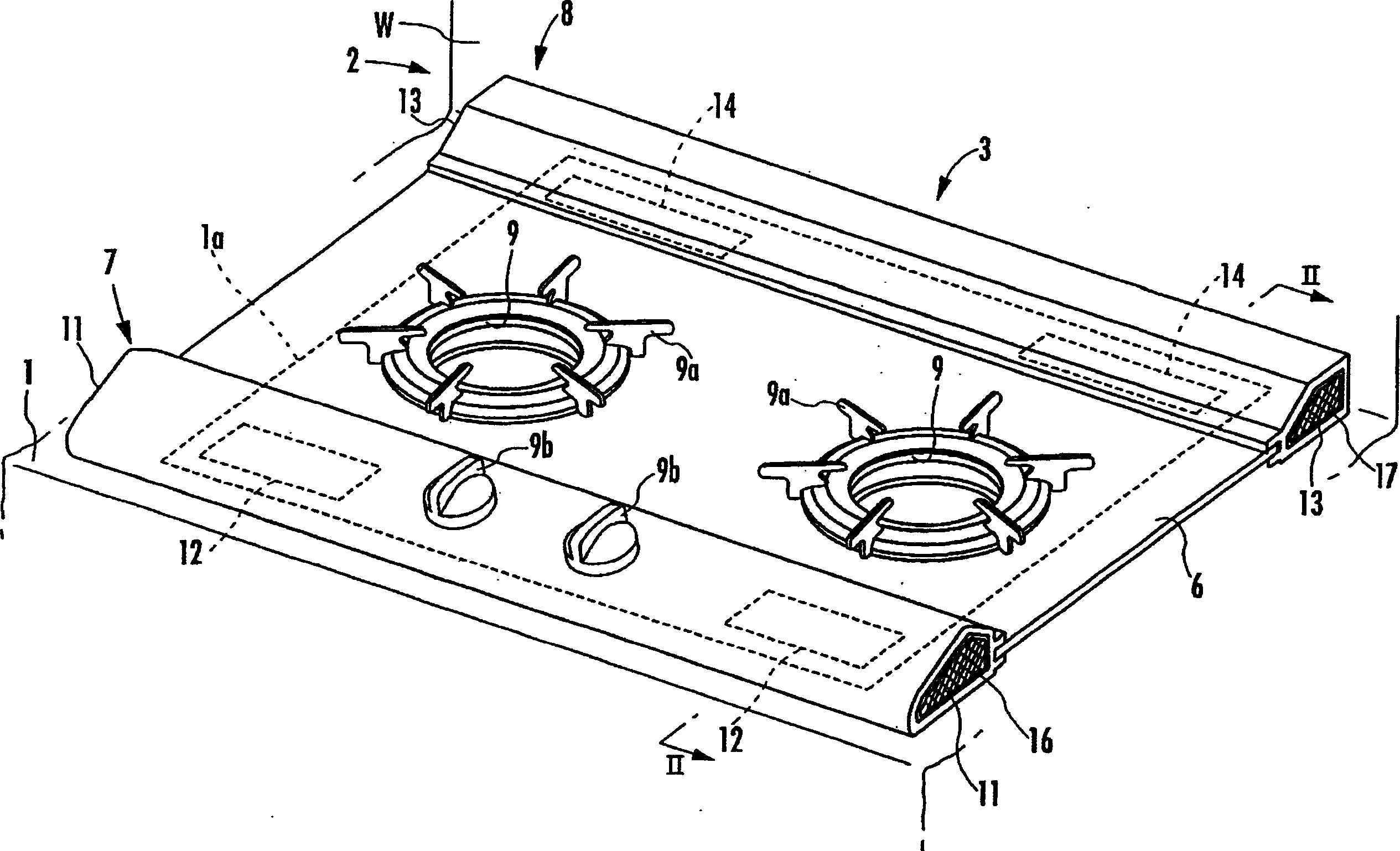

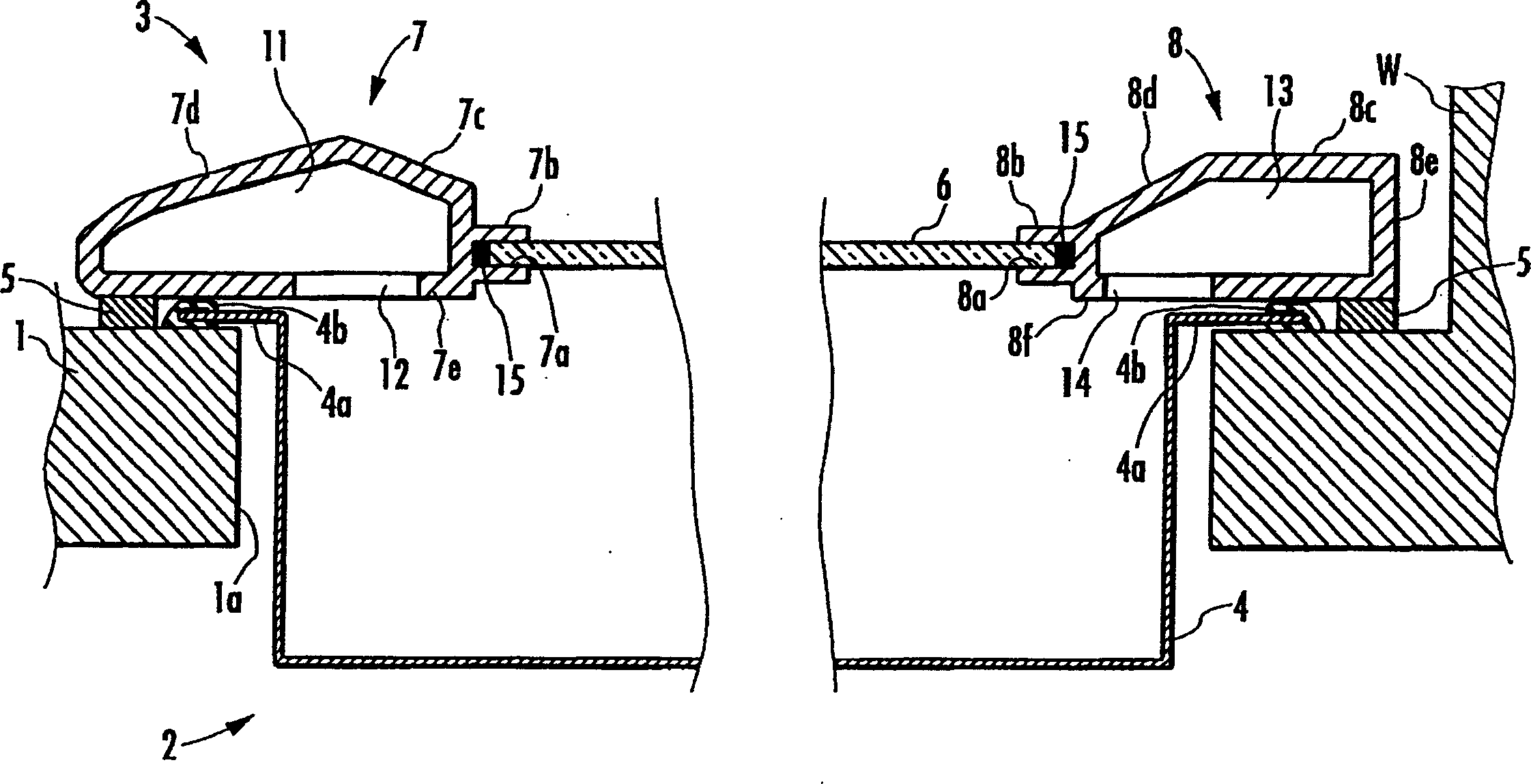

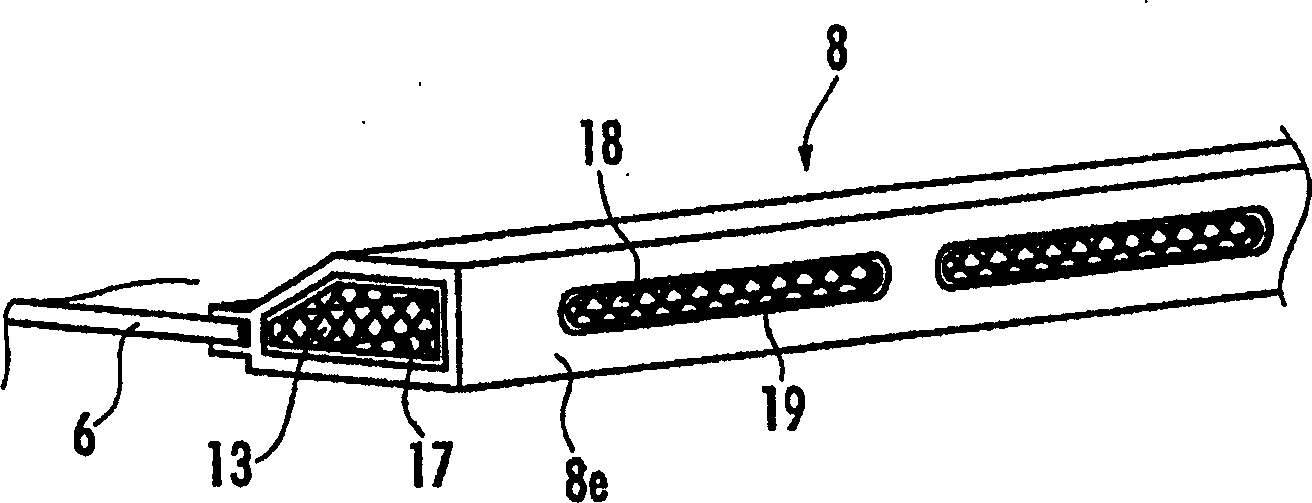

[0032] Below, refer to figure 1 An example of embodiment of the glass panel for built-in stoves of this invention is demonstrated to FIG. 8. FIG. First, explain figure 1 and figure 2 The glass panel of the 1st example of the 1st Embodiment shown.

[0033] figure 1 Shown is the state of assembling the built-in stove 2 on the countertop 1 of the kitchen system. The stove 2 has: a glass panel 3 placed on the surface of the countertop 1, and figure 2 The shown upper surface is a box-shaped furnace body 4 with an open surface. On the upper edge of the furnace main body 4, a flange portion 4a protruding outward is formed. Therefore, when the stove main body 4 is dropped into the opening 1a provided on the table top 1, the flange portion 4a is locked on the opening edge of the stove opening 1a, and the stove main body 4 is suspended on the table top 1. .

[0034] In addition, a gasket 4b is provided on the outer peripheral edge of the flange portion 4a, and the flange po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com