Collet-type splice and dead end fitting

A technology of collets and accessories, which is applied in the direction of cable joints, connecting contact materials, clamping/spring connections, etc., to achieve the effect of increasing the current-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] best way

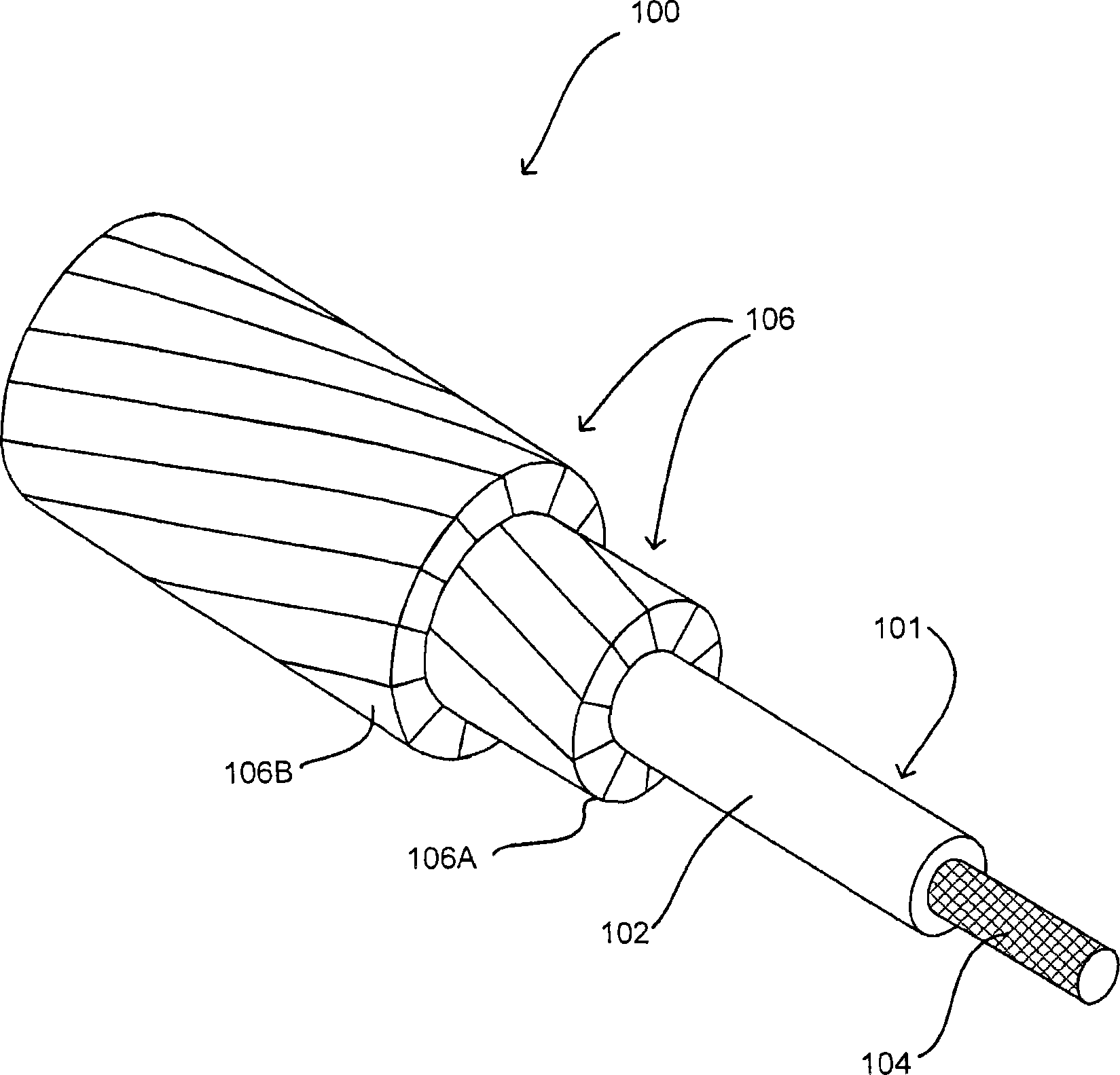

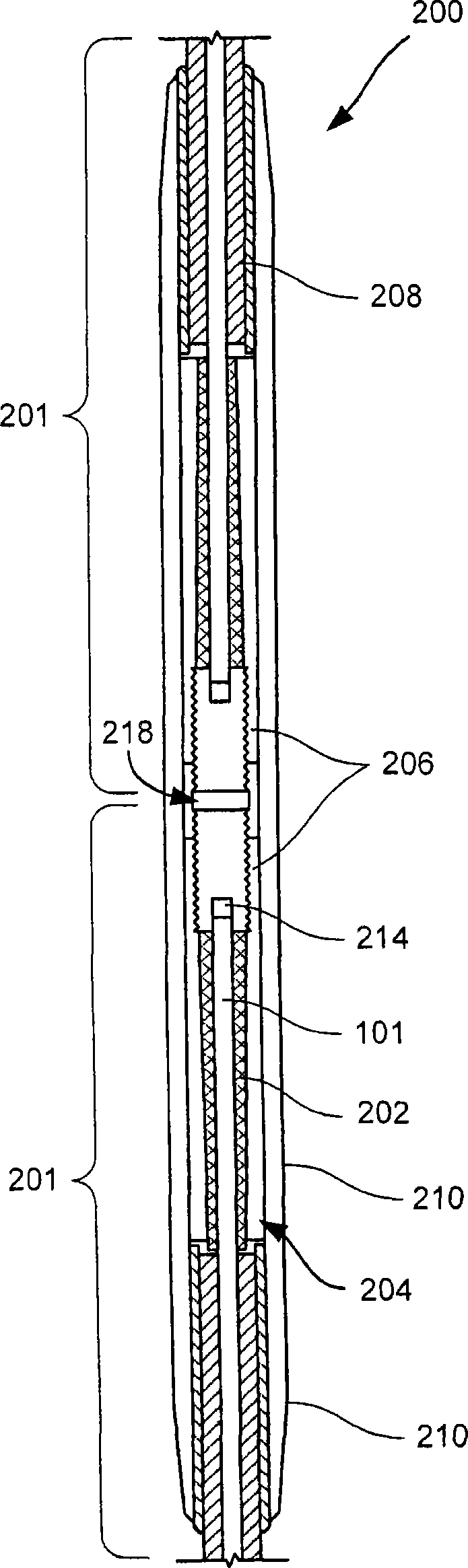

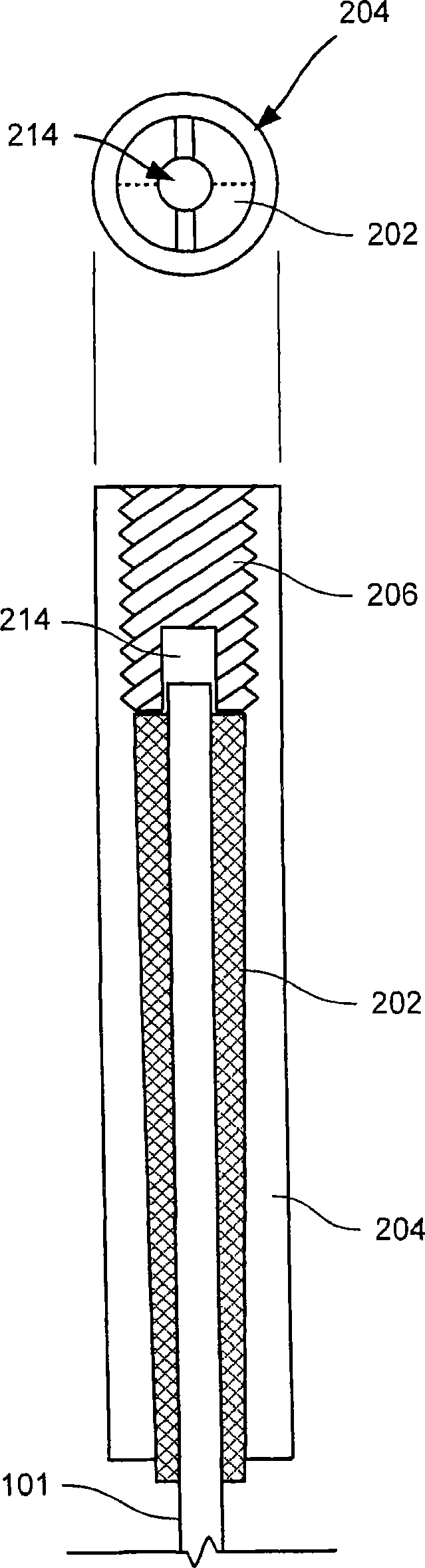

[0025] The present invention relates to a collet-type fitting for engaging and terminating an ACCC reinforced cable 100 . The collet-type fitting can join the composite core 101 of the ACCC cable 100 together. In addition to joining the composite core 101 , the splice should provide an electrical connection between two or more ACCC strengthened cables 100 . Alternatively, a collet type fitting may terminate the ACCC cable. The collet-type accessory may include a collet 202 , a collet housing 204 , and at least one compressor 206 . In a further embodiment, the collet fitting 201 may also include an aluminum filter sleeve 208 and the collet joint 200 may include an aluminum shell 210 that may cover the two collet fittings 201 and the connecting device 214 . In one embodiment, the compression member 206 and the connection device 214 are formed as a single piece. However, those skilled in the art will appreciate that in other embodiments these components are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com