Sealing edge cross-sectional profiles to allow brazing of metal parts directly to a metallized ceramic for vacuum interrupter envelope construction

A technology of metal components and cross-sections, applied in high-voltage air circuit breakers, electrical components, high-voltage/high-current switches, etc., can solve problems such as thickness reduction, lack of strength, and reduced mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

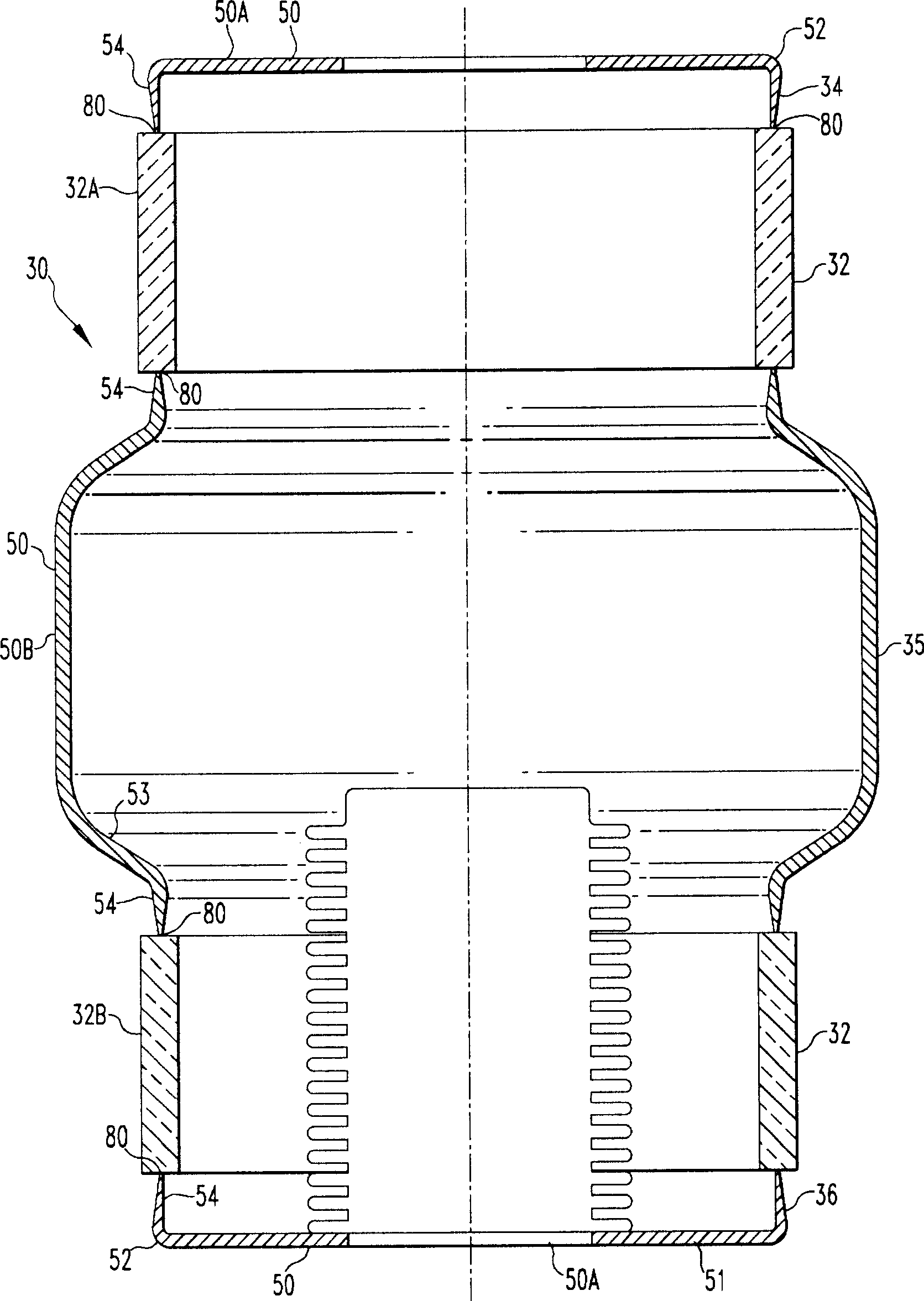

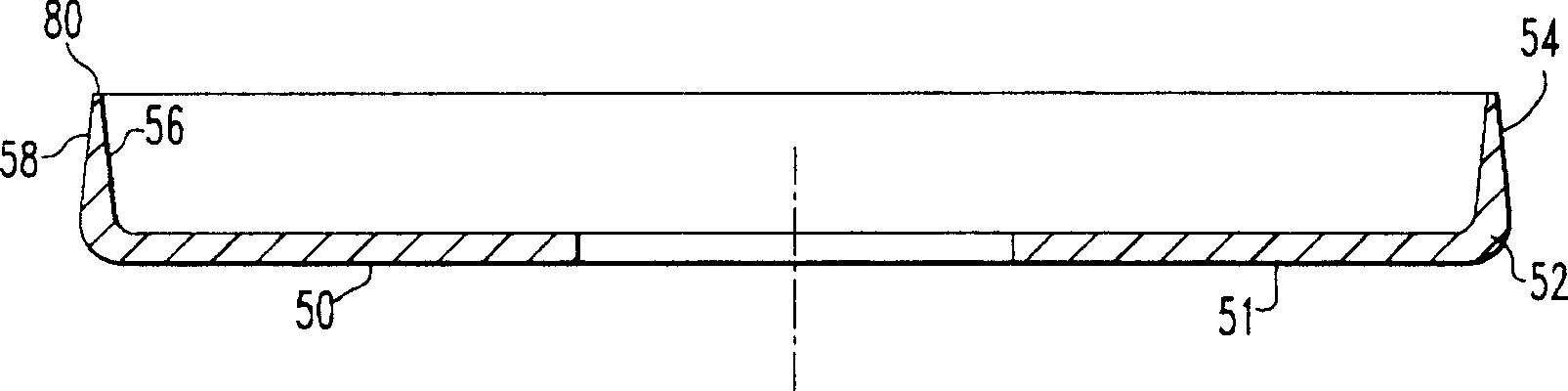

[0025] As used herein, words and phrases such as, but not limited to, "equilateral trapezoid" describing the shape or profile of the sealing edge refer to the shape or profile when viewed in cross-section as shown. It will be appreciated that in the preferred embodiment the sealing edge is actually a circular ring or other closed peripheral shape.

[0026] As used herein, the phrase "sealing edge" refers to the edge of the metal end cap or outer center shield attached to the ceramic portion of the vacuum interrupter chamber body. While certain shapes and contours of the sealing edge are shown in the figures only in association with the end cap or outer center shroud, it will be appreciated that the end cap or outer center shroud may use any particular shape or contour of the sealing edge .

[0027] As used herein, the phrase "... a gradual decrease in thickness" refers to a change in thickness over a length that occurs linearly in two or more steps and / or on a curve.

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com