Power-supply connector

A technology of power plugs and plugs, which is applied in the direction of circuits, electrical components, contact parts, etc., can solve the problems of not being able to apply power plug boards of various specifications, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

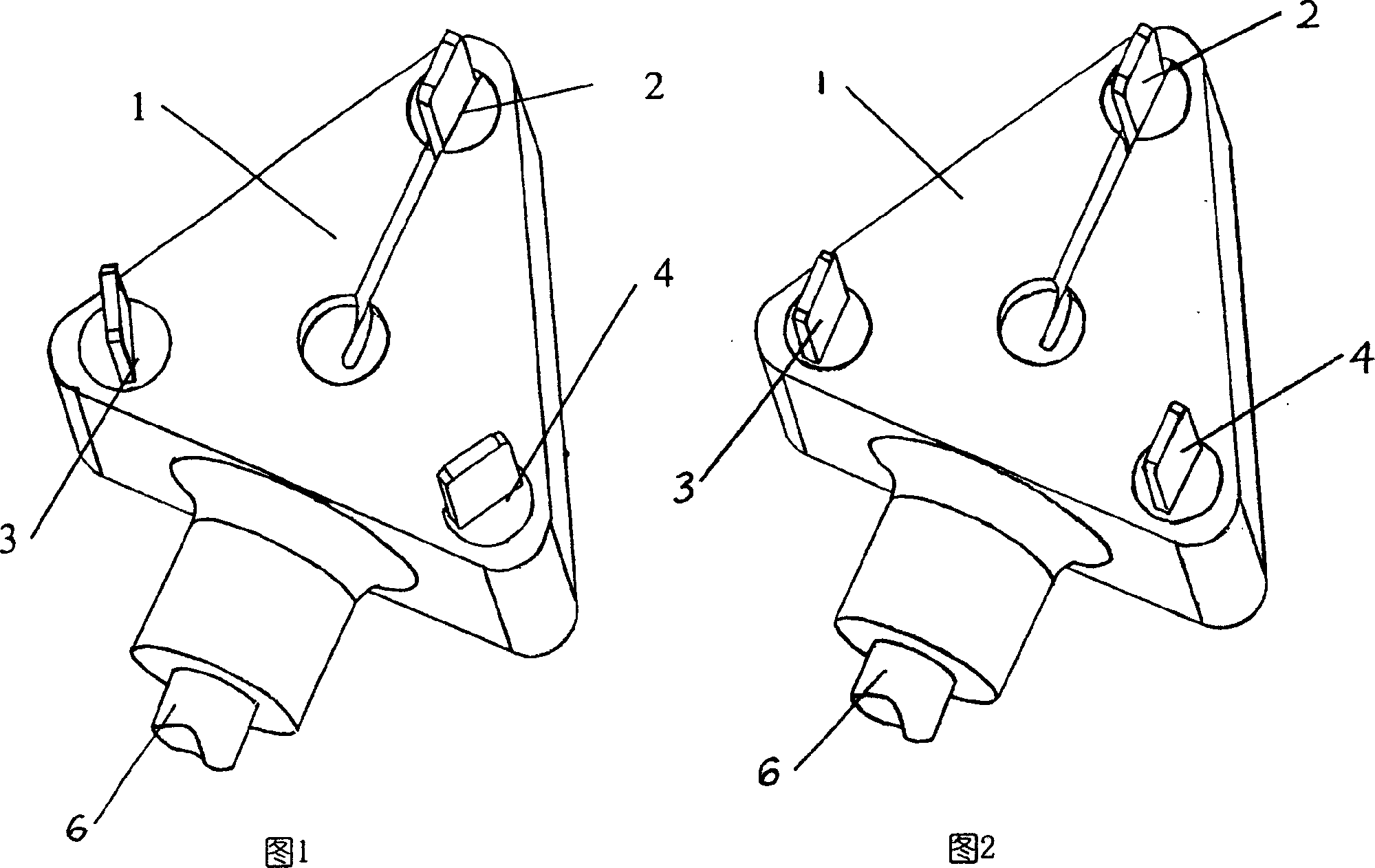

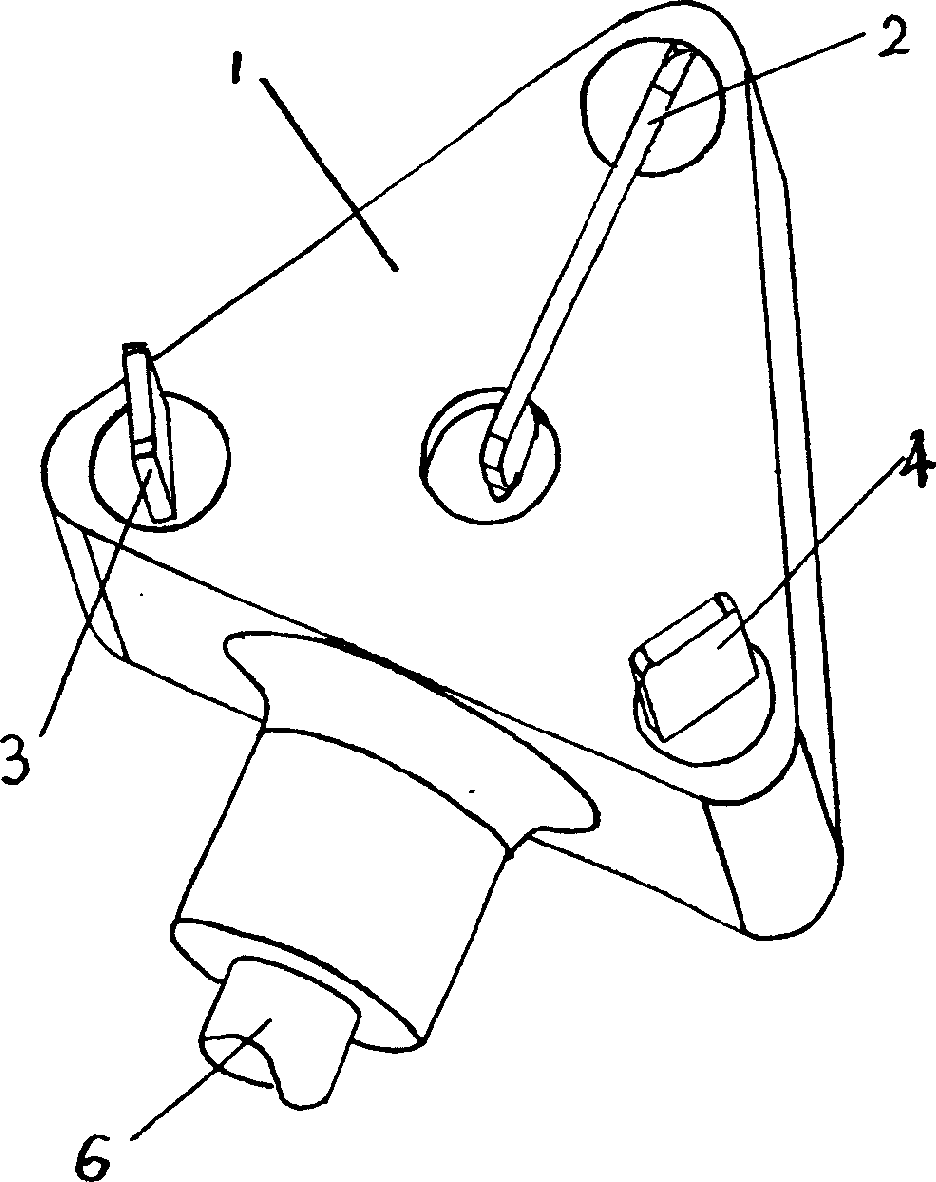

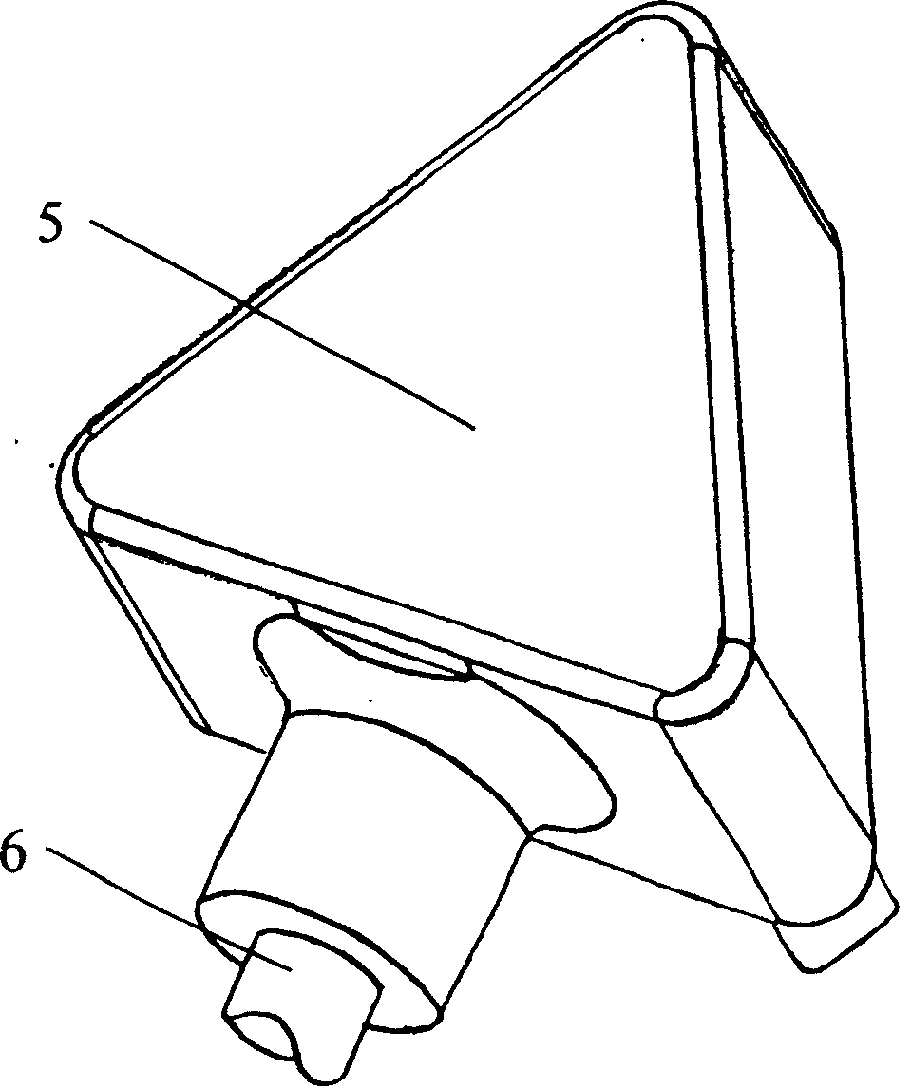

[0018] Referring to FIG. 1 , the plug includes an injection-molded insulating plug base 1 , positive and negative pole assemblies 3 and 4 , ground wire pole assembly 2 , jack 18 and power leads 6 . Positive and negative electrode assemblies 3 and 4 have the same structure, see Figure 8 , are all composed of socket spring piece 10, terminal post 11, insulating sleeve 12 and plug piece 13, which are rotatably installed in the two round holes below the base 1 through the insulating sleeve 12, so that it can be installed according to the needs of the plug board. Go to the oblique position as shown in Figure 1, or the straight position as shown in Figure 2. There is also a round hole with a rectangular slot under the base 1, and the ground pole assembly 2 is installed in the round hole, which can be used on the three-wire plug board. see Figure 7 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com