Method for winnowing tobacco material using inertia and its device

A technology for tobacco materials and air separation equipment, which is applied in the fields of tobacco, tobacco preparation, chemical instruments and methods, etc., can solve the problems such as the sorting accuracy cannot meet the requirements, and achieves the advantages of large production capacity, low mechanical energy consumption of equipment and guaranteed product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

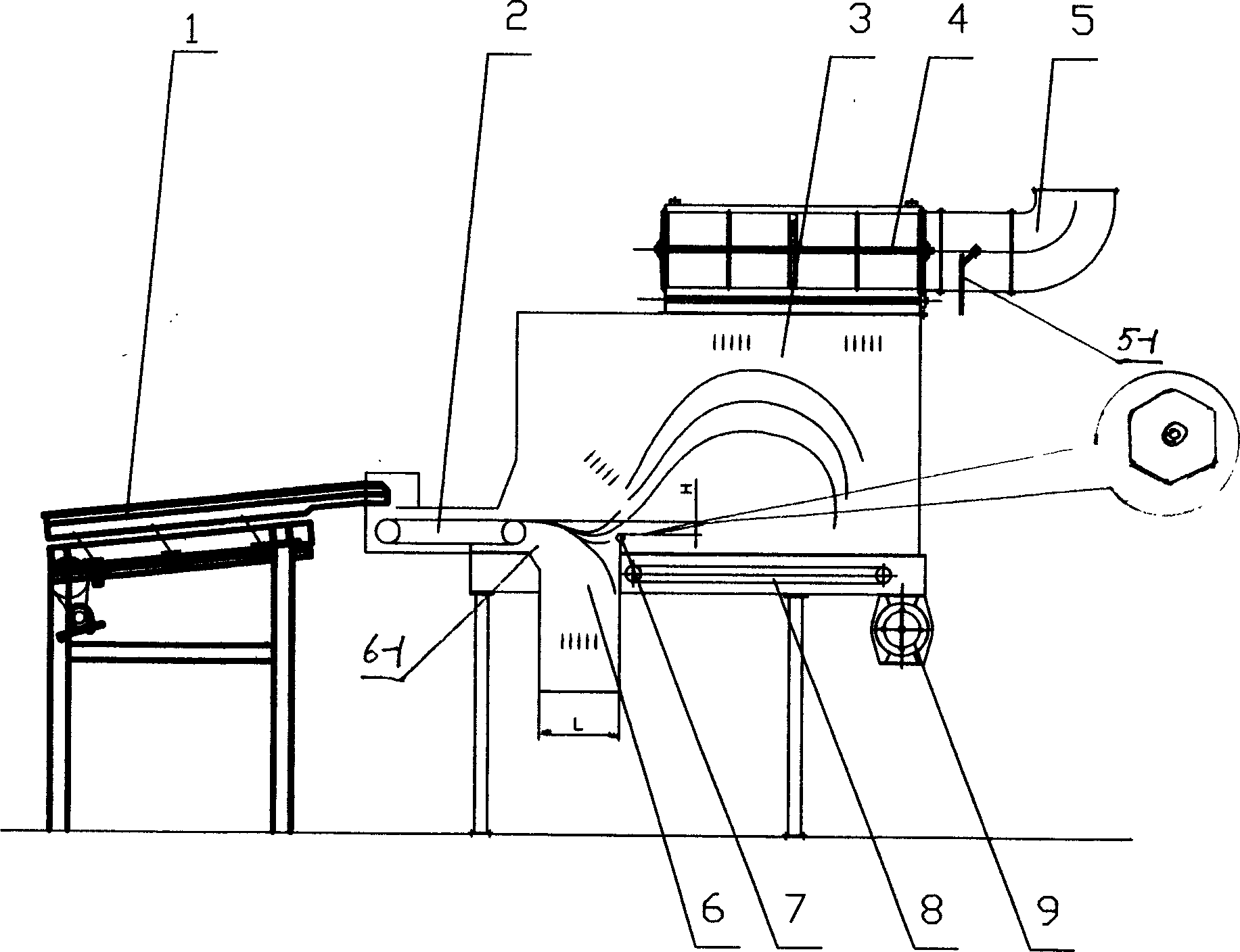

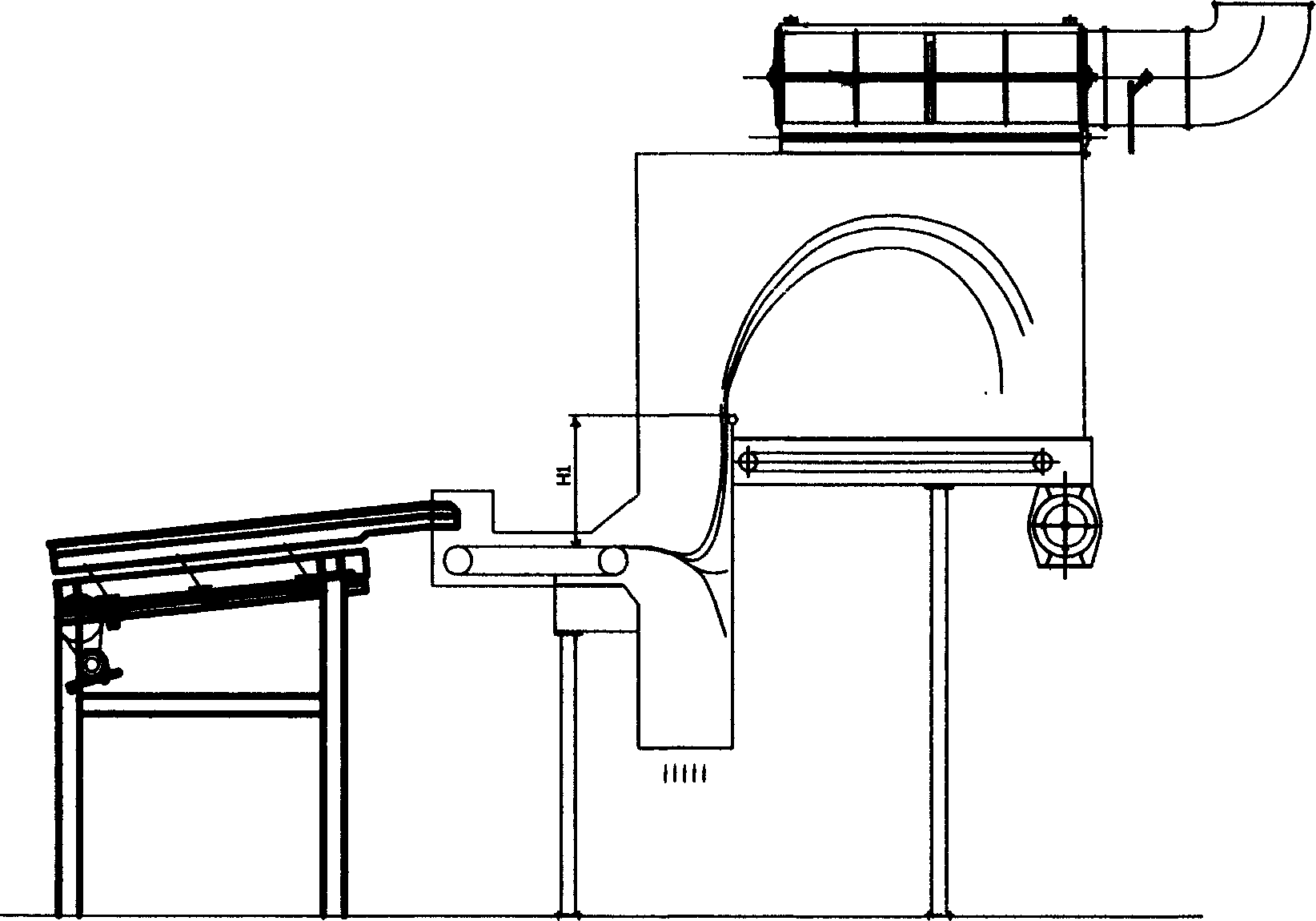

[0019] figure 1 It is an embodiment of the present invention, and the purpose of this embodiment is to separate the foreign matter from the shredded tobacco after drying, mainly to separate the foreign matter such as tobacco stems and agglomerates from the shredded tobacco, so as to improve the purity of the cut tobacco.

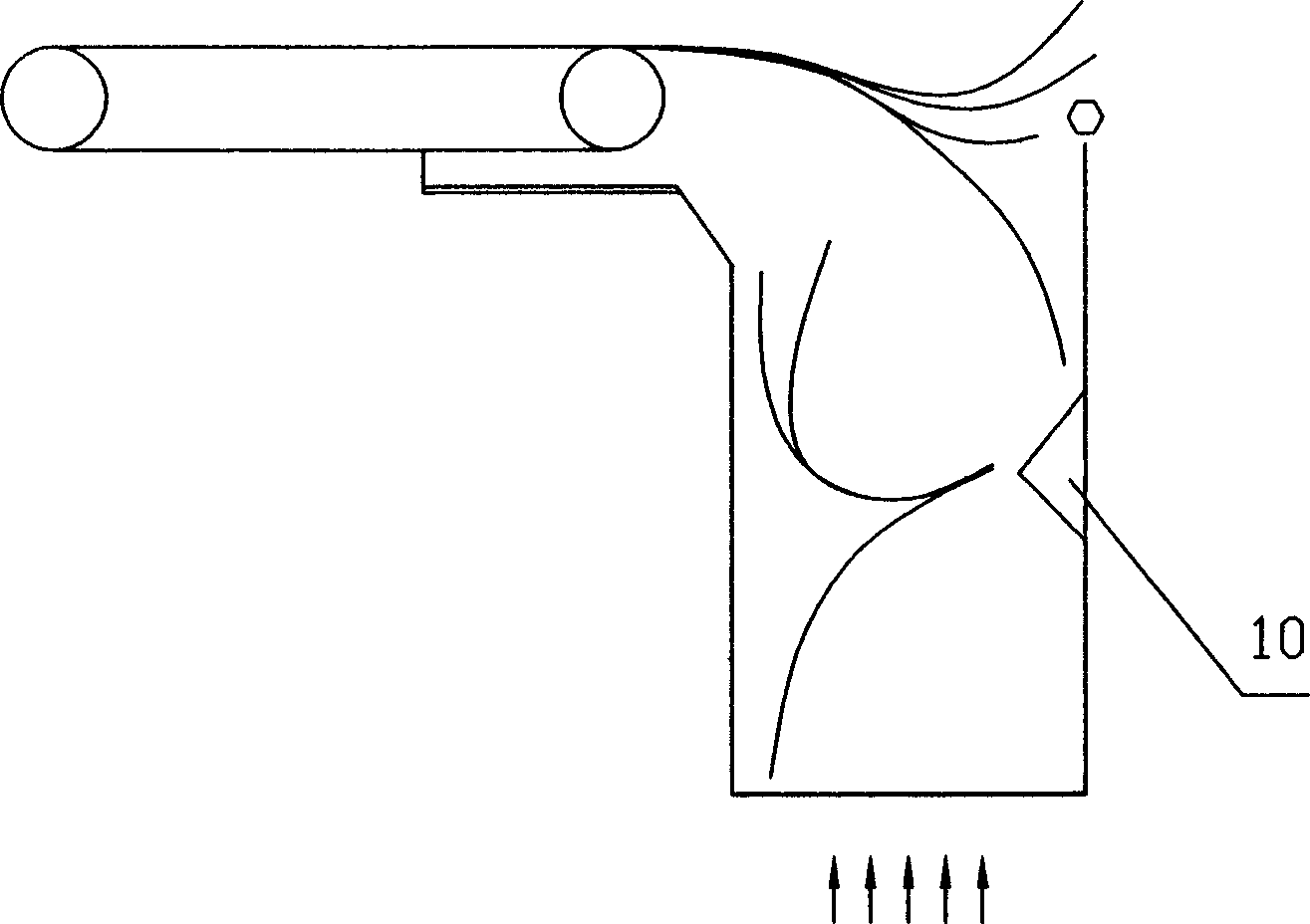

[0020] Such as figure 1 As shown, the bottom of the box body 3 is equipped with a conveying bottom belt 8, and an air separation chamber 6 is installed between the bottom belt 8 and the high-speed belt conveyor 2. The belt surface of the high-speed belt conveyor 2 is higher than the belt surface of the bottom belt 8, and the bottom belt 8 The other end of the discharge air lock 9 is installed, and the combination of the bottom belt 8 and the air separation chamber 6 is equipped with a clockwise turning material roller 7. The position of the material roller 7 is below the forward direction of the high-speed belt conveyor 2. The air outlet on the top of 3 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com