Multifunctional electric hammer

A multi-functional, electric hammer technology, applied in the directions of portable mobile devices, striking tools, portable impact tools, etc., can solve the problems of damage to the front end casing, inconvenient operation, etc., and achieve the effect of convenient function conversion, compact structure and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

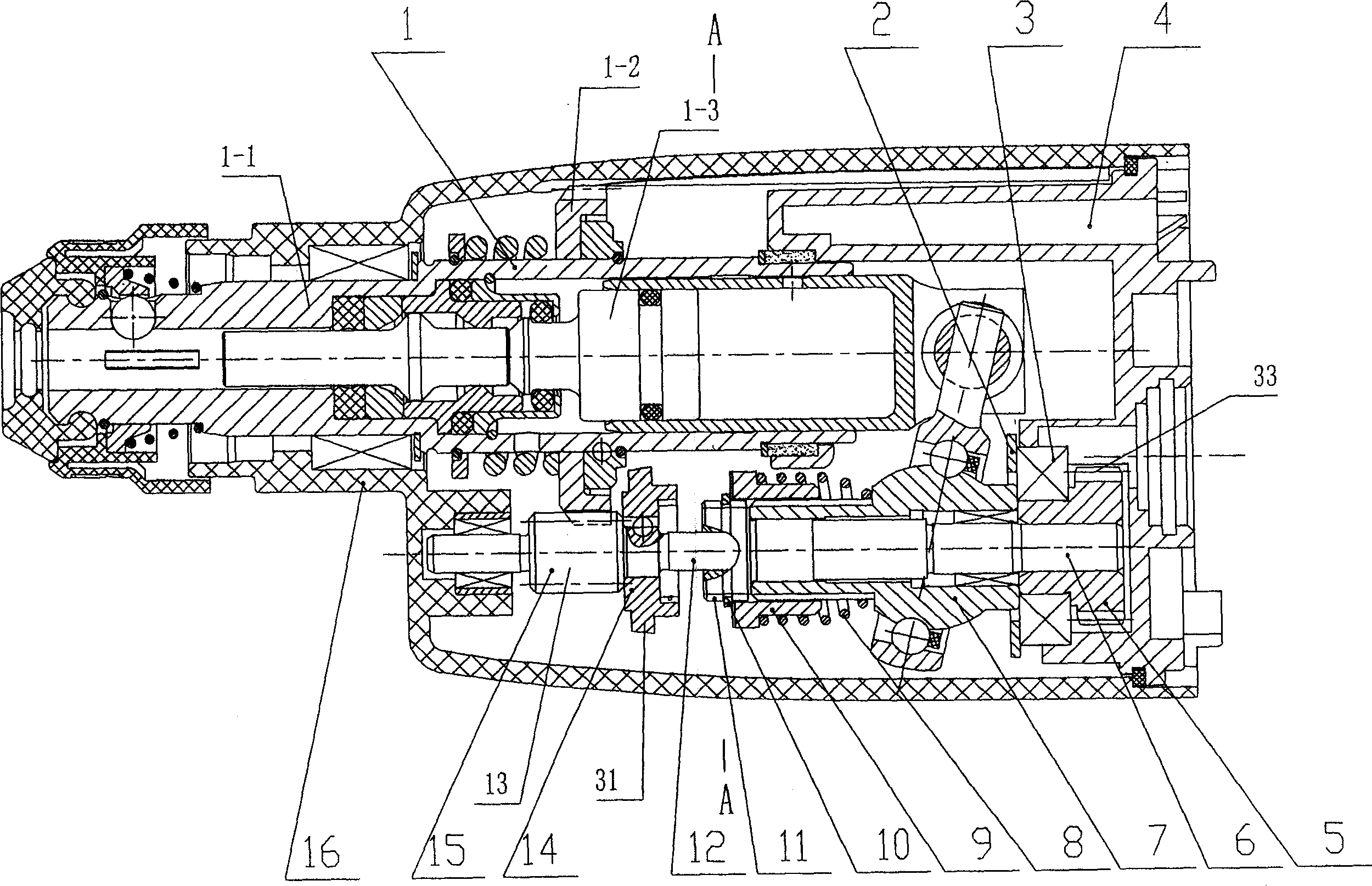

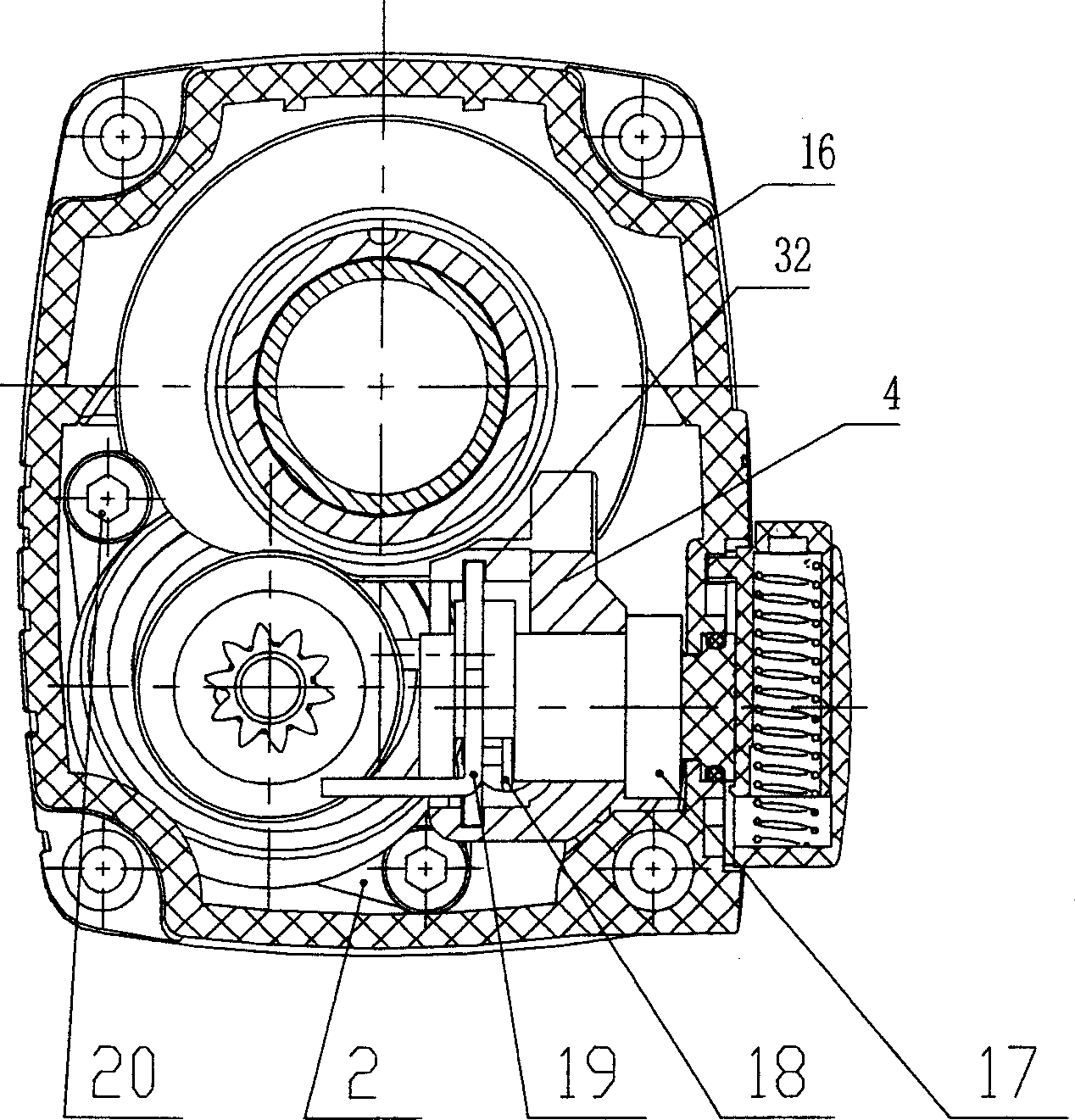

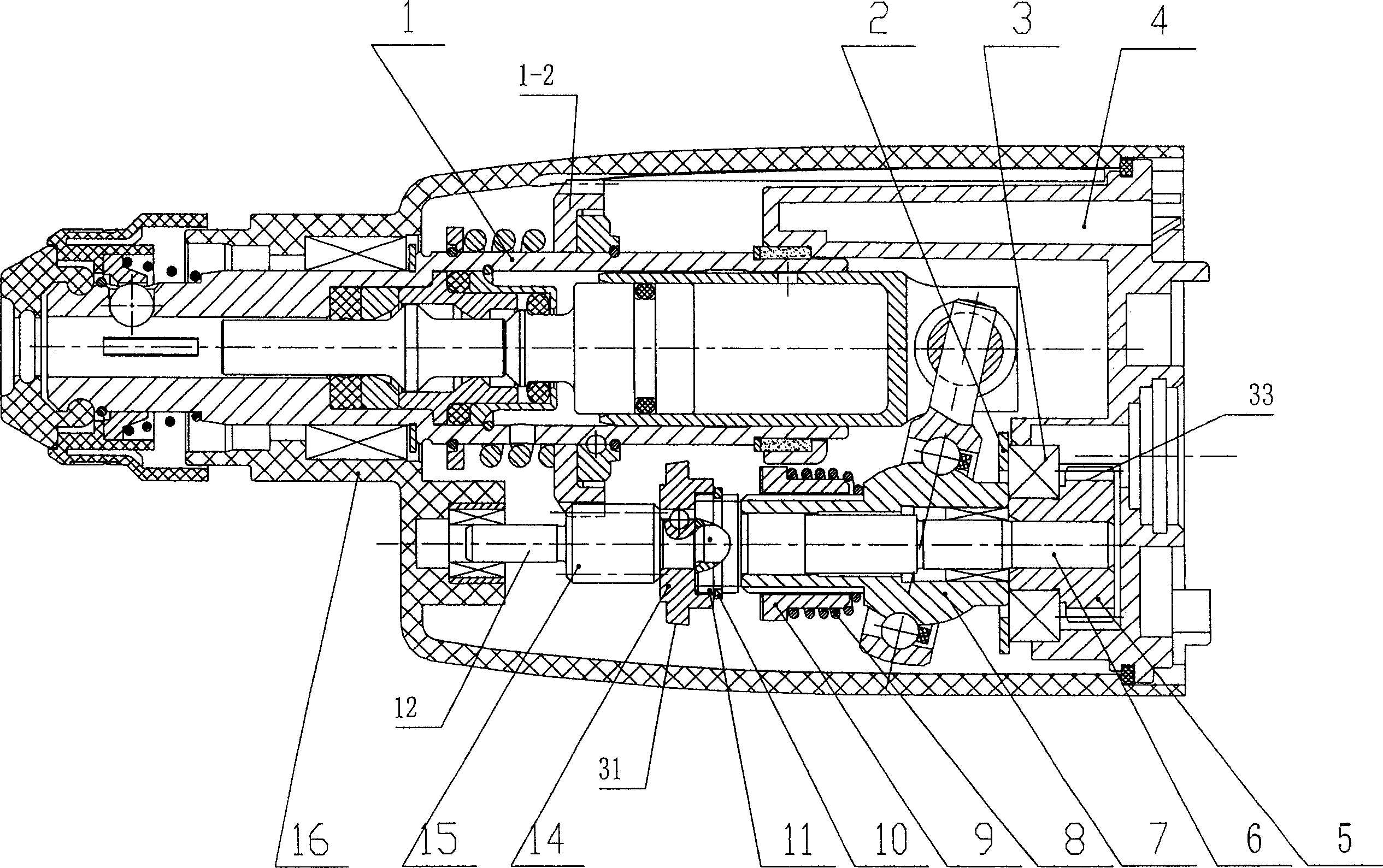

[0026] The multifunctional electric hammer shown in the figure includes a front-end part and a rear-end part (not shown); the front-end part is a transmission control part, and the rear-end part is a power part.

[0027] The front end components include a front end housing 16, a base 4 connected to the front end housing 16, a transmission shaft assembly 5, an impact shaft assembly 1, a sliding gear assembly 13, a slide plate 19, a slide plate spring 18, an eccentric pin 25, a cam 24, and a knob 17 .

[0028] The transmission shaft assembly 5 is mainly composed of a transmission shaft 6, a swing rod bearing 7 sleeved on the transmission shaft 6, a transmission clutch 9 which is sleeved on the swing rod bearing 7 and can slide axially to engage or separate from the transmission shaft 6, and is arranged on the swing shaft. The clutch spring 8 between the rod bearing 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com