Dual-speed multifunctional electric hammer

A multi-functional, two-speed technology, applied in the direction of portable motorized devices, impact tools, light impact tools, etc., can solve the problems of low efficiency and achieve the effect of compact structure, simple operation and convenient function conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

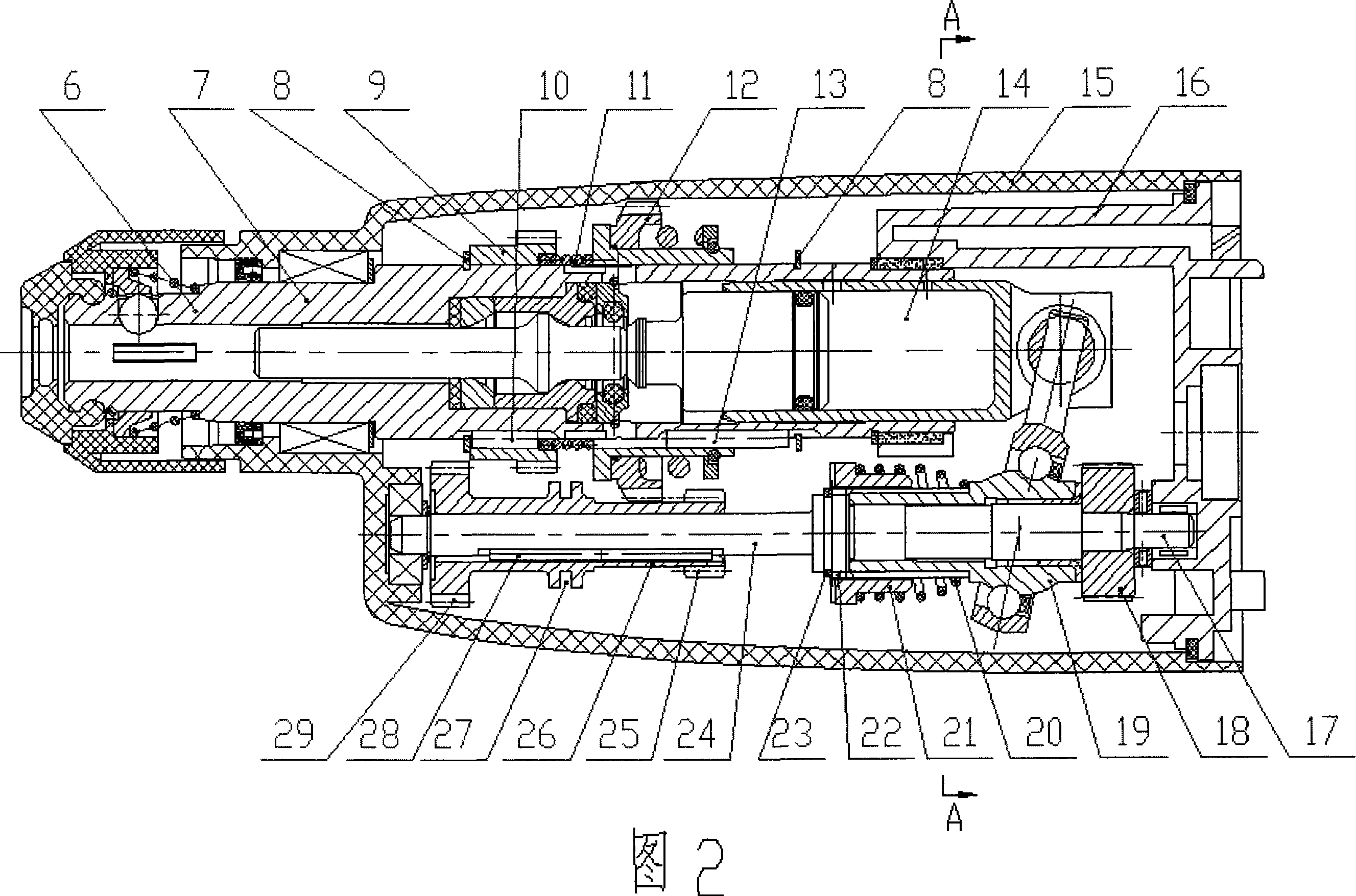

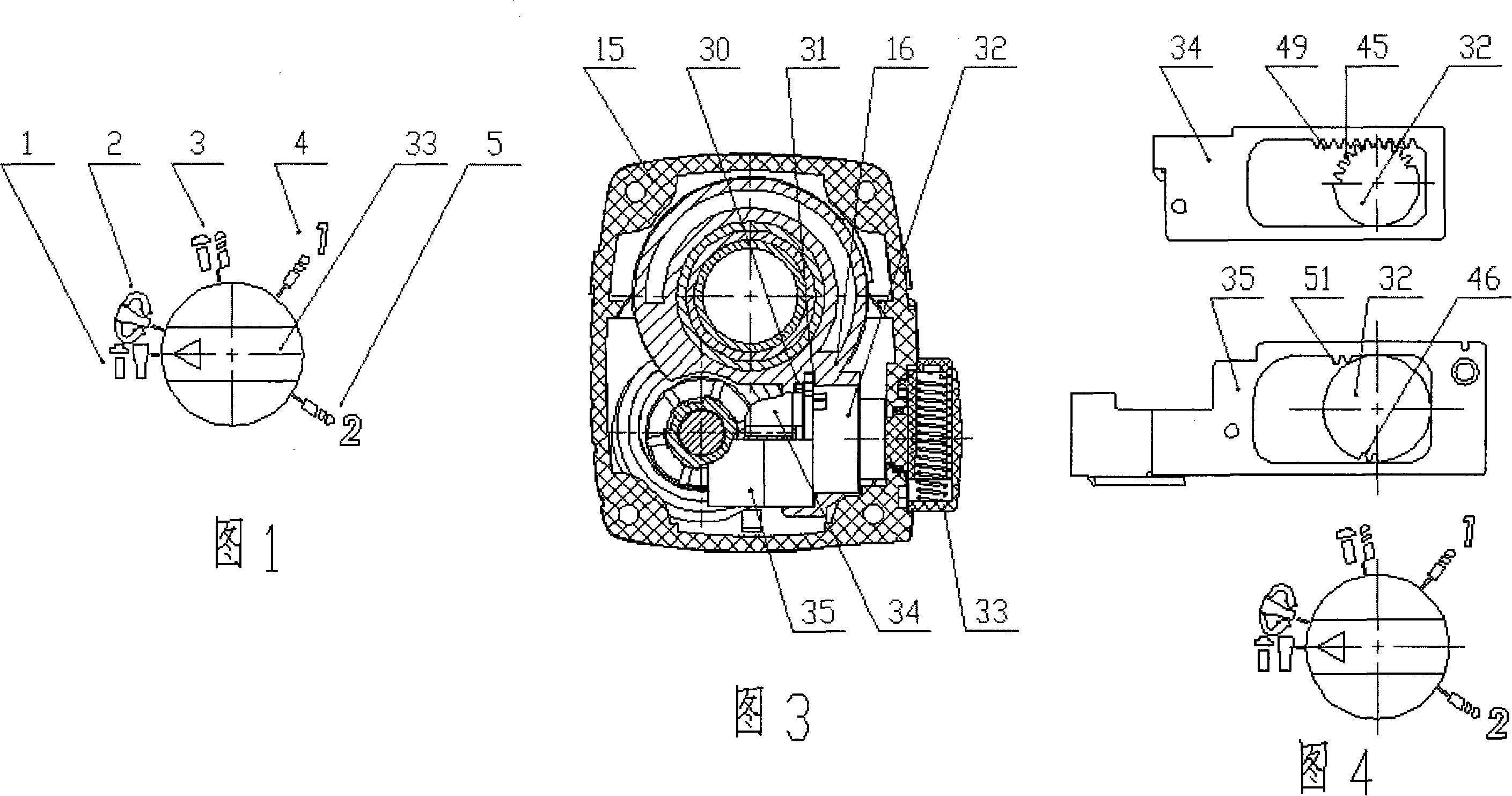

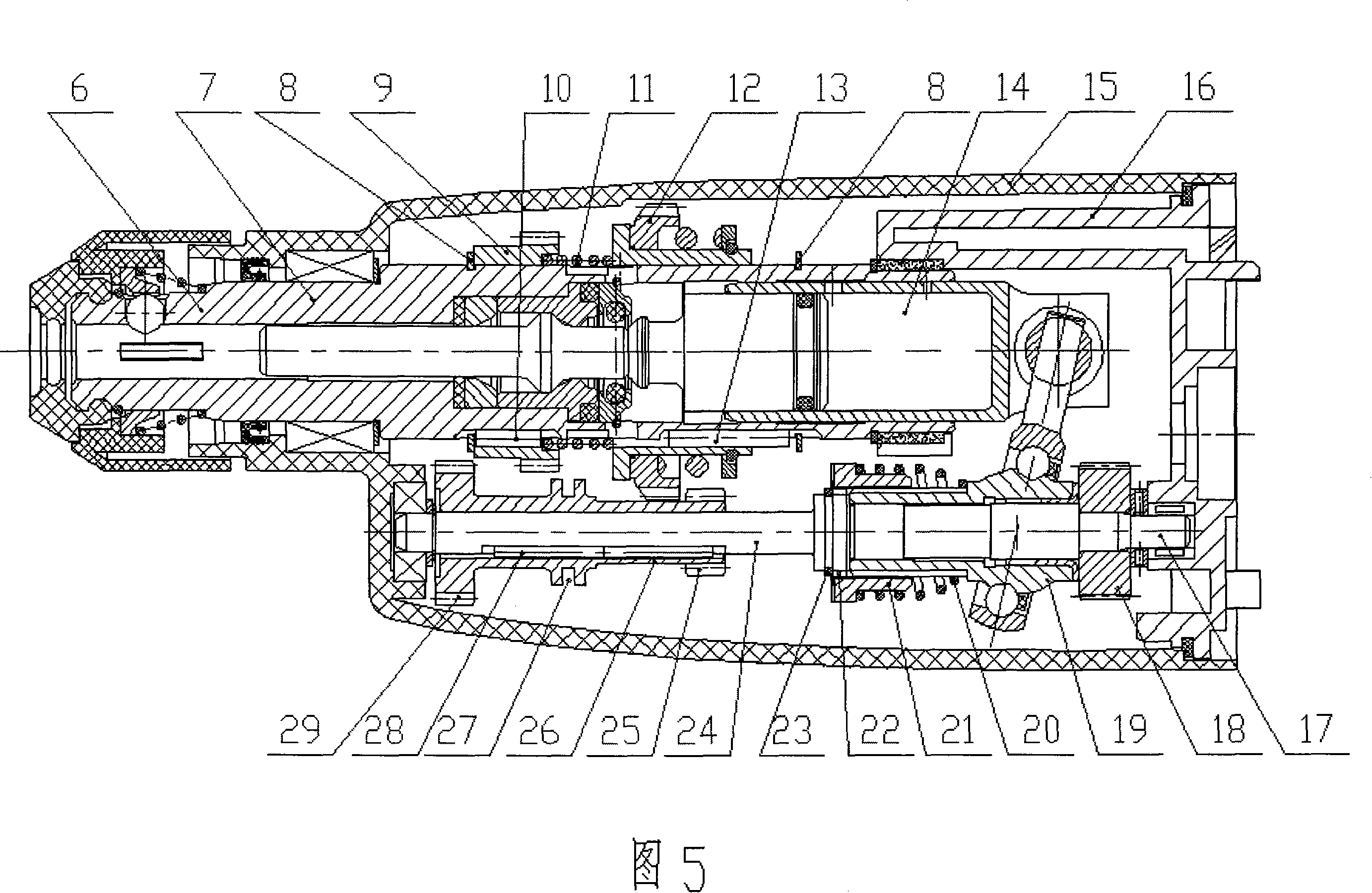

[0039] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0040] Embodiment The double-speed multifunctional electric hammer shown in the drawings includes a front part and a rear part (not shown); the front part is a transmission control part, and the rear part is a power part.

[0041] The front-end components include a front-end housing 15, a base 16 connected to the front-end housing 15, a drive shaft assembly 17, an impact shaft assembly 6, a low-speed bull gear 12, a high-speed bull gear 9, a bull gear return spring 11, a low-speed slide plate 34, and a high-speed gear. Slide plate 35, slide plate spring 41, sliding pinion assembly 26, inner knob 32, outer knob 33, anti-rotation plate 44, wherein:

[0042]The transmission shaft assembly 17 is mainly composed of a transmission shaft 24, a gear 18 sleeved on the transmission shaft 24, a swing rod bearing 19 sleeved on the transmission shaft 24, and a gear that can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com