Modularized heat pump unit

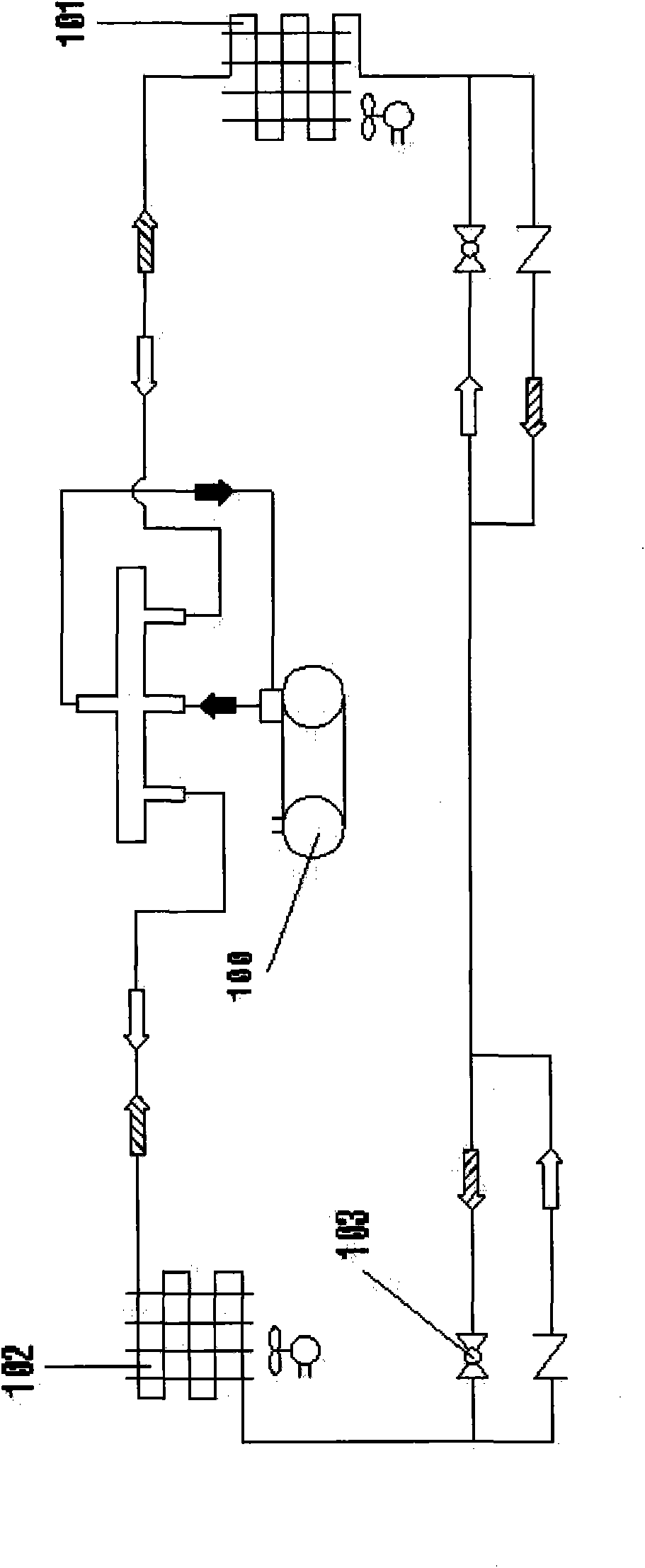

A heat pump unit, modular technology, applied in the direction of heat pumps, refrigerators, refrigeration components, etc., can solve the problems that cannot be modularized, cannot achieve cooling or heating of heat exchangers, and can only recover heat, save energy, improve The effect of comprehensive cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

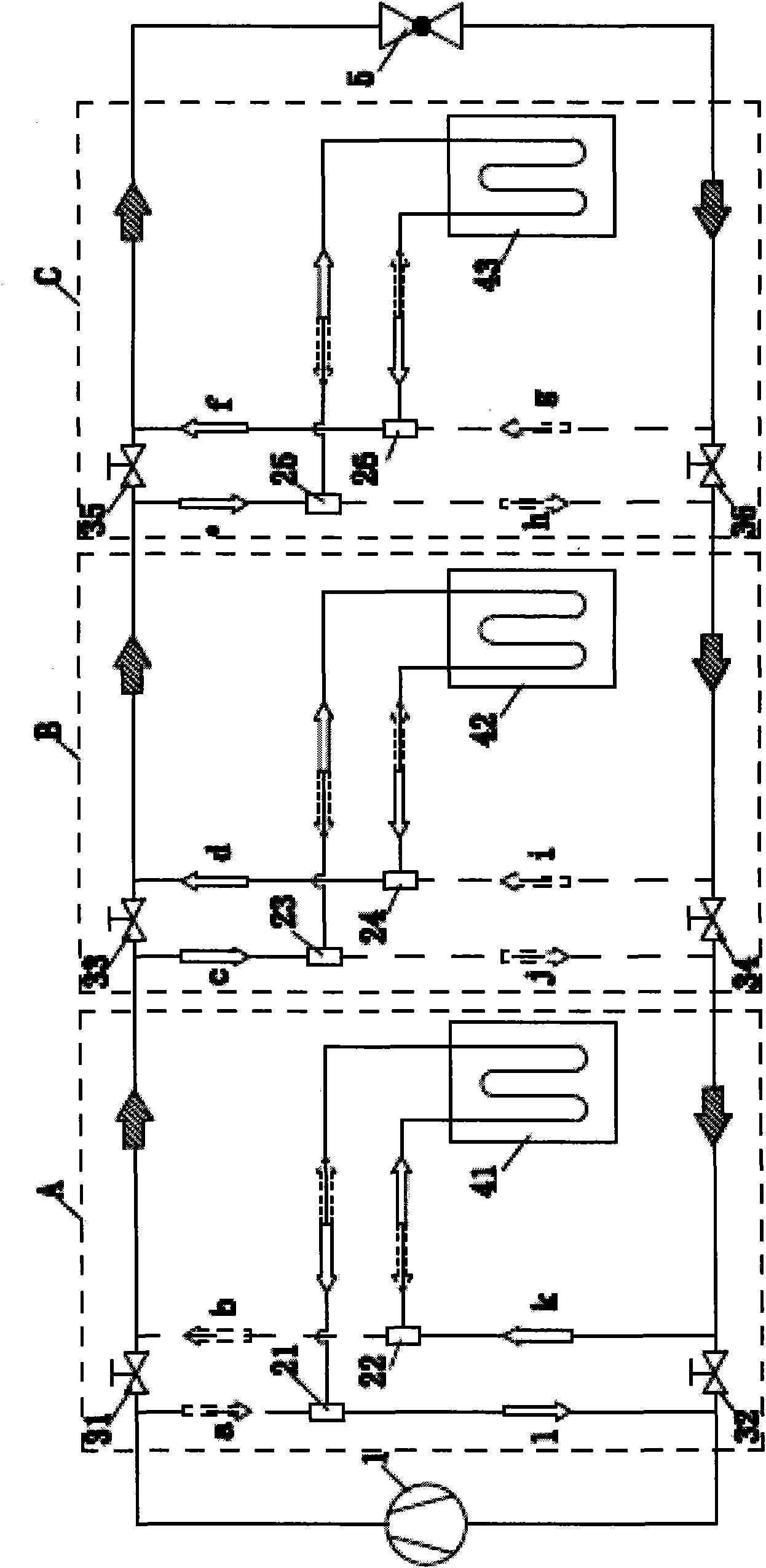

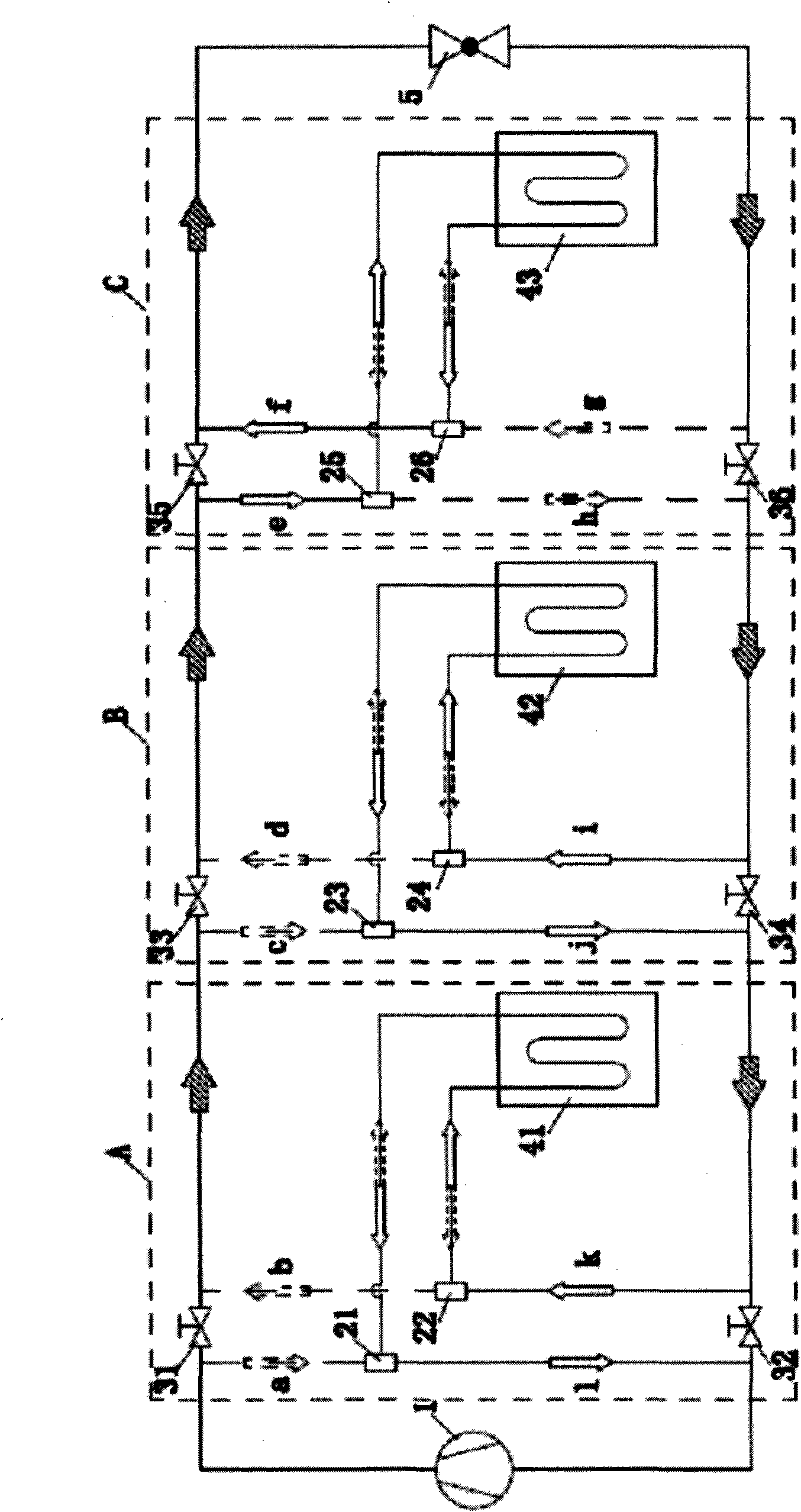

[0011] In order to facilitate the description of the present invention, some circulation directions in the drawings are marked with letters a, b, c, etc.

[0012] The modularized heat pump unit includes a compressor 1 and an electronic expansion valve 5, and at least two modules are connected in parallel between the connection loop between the compressor 1 and the electronic expansion valve 5, wherein the modules include a first three-way valve and a second three-way valve , the first solenoid valve, the second solenoid valve and the heat exchanger, the three ports of the first three-way valve are respectively connected to one end of the first solenoid valve, the second solenoid valve and the heat exchanger, and the ports of the second three-way valve The three ports are respectively connected to the first solenoid valve, the second solenoid valve and the other end of the heat exchanger; the two ends of the first and second solenoid valves are respectively connected between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com