Multi-functional modularization heat pump machine set

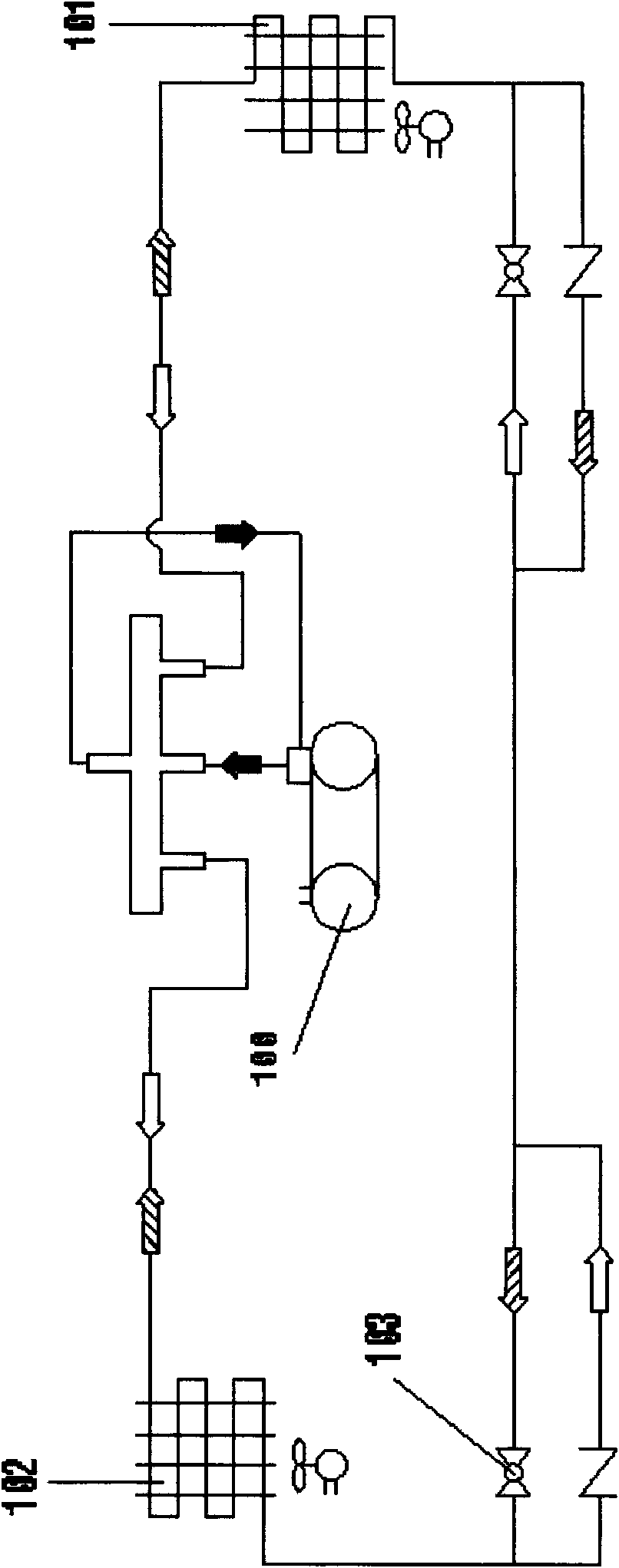

A heat pump unit, modular technology, applied in the direction of refrigerators, compressors, refrigeration components, etc., can solve the problems of inability to realize cooling or heating of heat exchangers, inability to modularize, and inability to recover cooling capacity, etc., to improve comprehensive refrigeration Efficiency, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

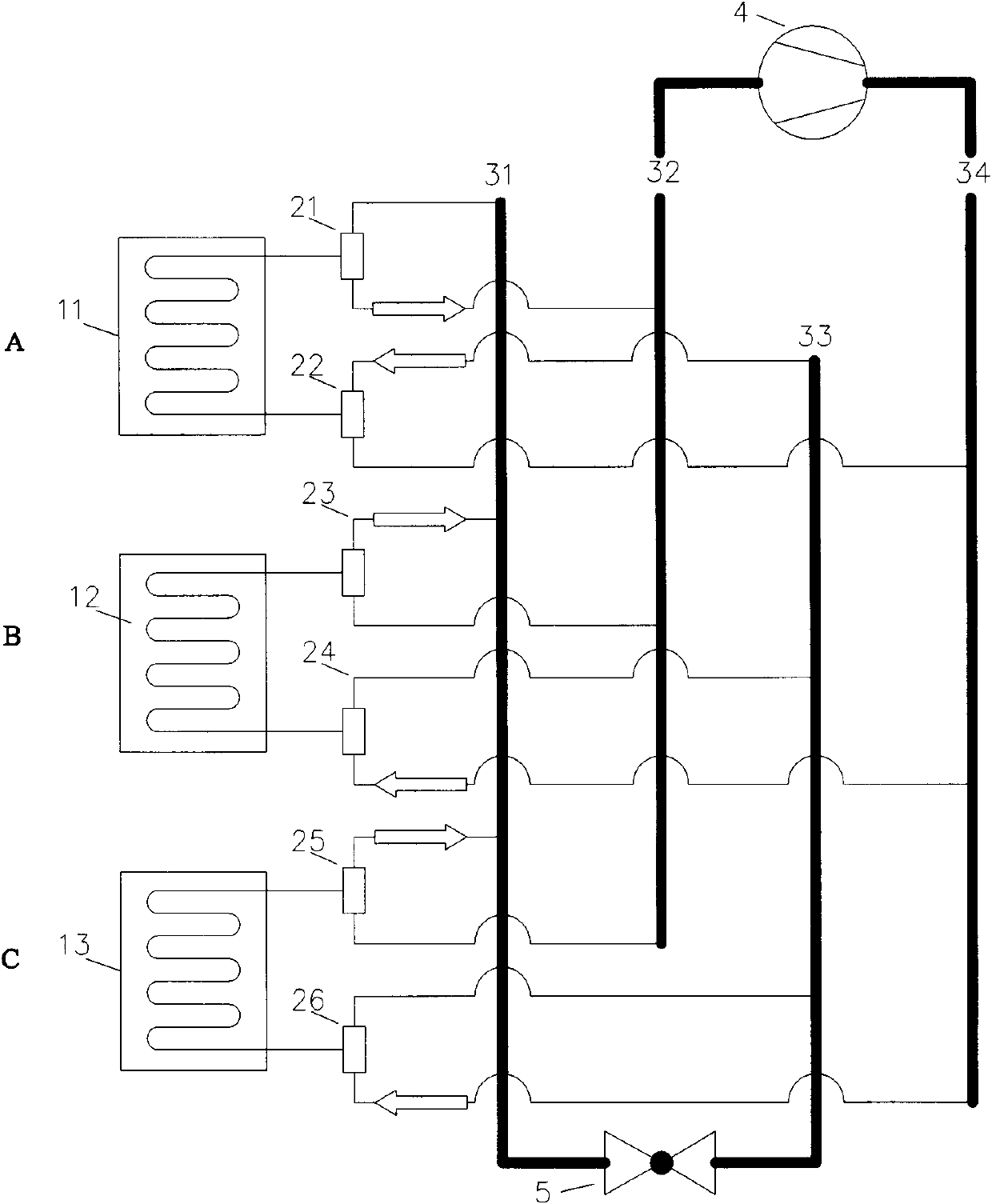

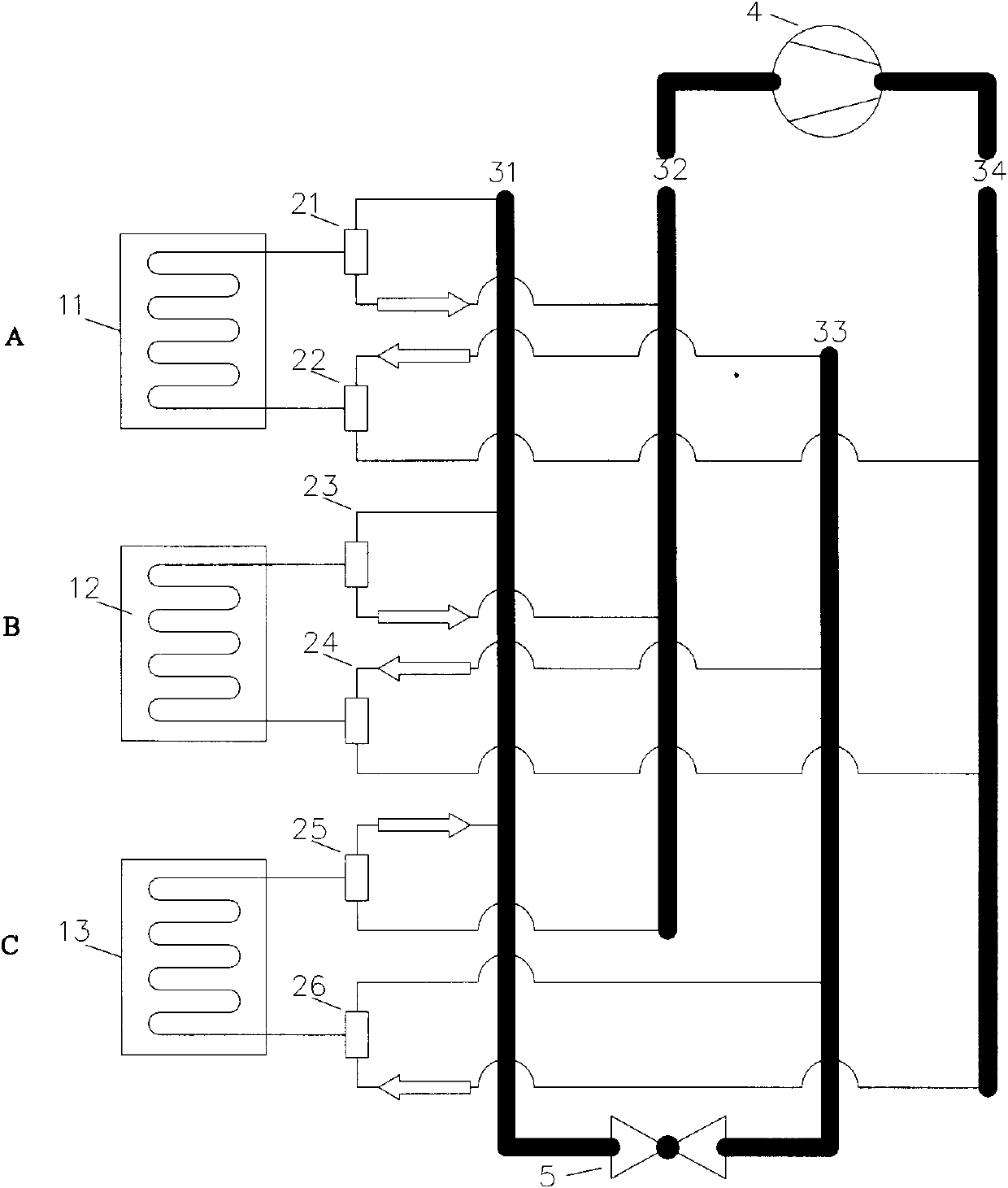

[0012] The multifunctional modularized heat pump unit of the present invention includes a compressor 4, an electronic expansion valve 5, and four main pipes: a first main pipe 31, a second main pipe 32, a third main pipe 33, and a fourth main pipe 34. At least two identical modules connected in parallel to the four dry pipes 3 connecting the compressor 4 and the electronic expansion valve 5, wherein the modules include a first heat exchanger 11, a first three-way valve 21 , the second three-way valve 22, the three ports in the first three-way valve 21 are respectively connected to one end of the first heat exchanger 11, the first dry pipe 31 and the second dry pipe 32; in the second three-way valve 22 The three ports are respectively connected to one end of the first heat exchanger 11 , the third dry pipe 33 and the fourth dry pipe 34 .

[0013] The present invention is further described by way of example below. For ease of illustration, the three-way valves and heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com