Installing and closure method of steel arched bridge arch rib large segment and lifting system

A lifting system and technology for steel arch bridges, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as long construction period, low installation accuracy of arch ribs, and influence on navigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

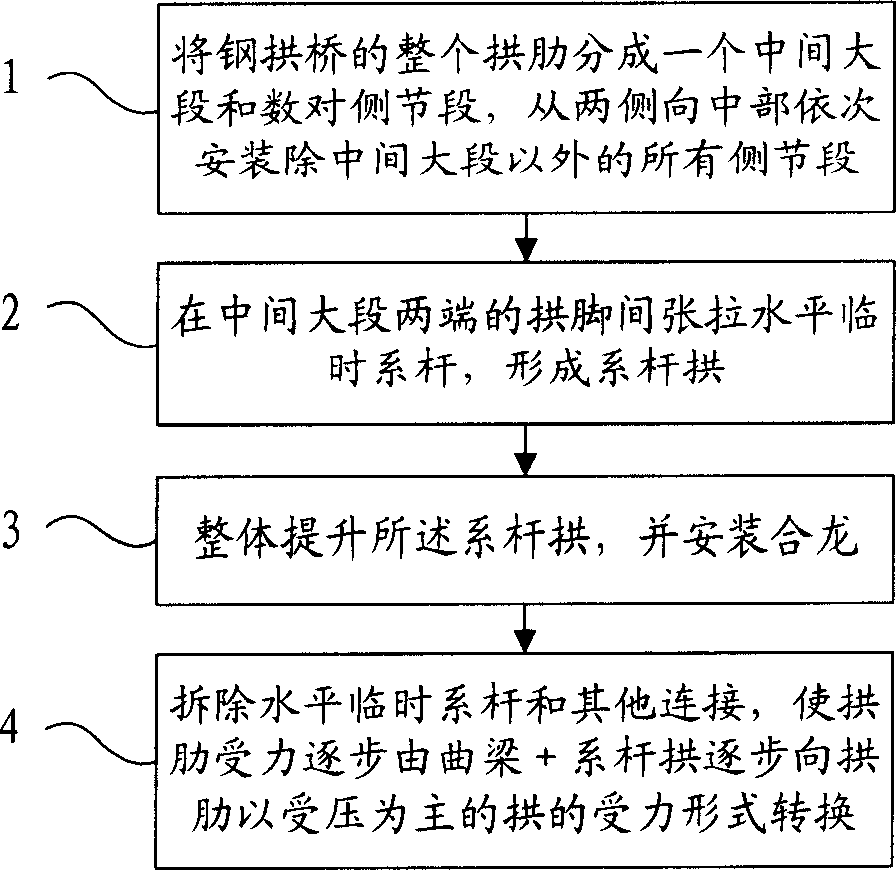

[0057] figure 2 It is a flow chart of Embodiment 1 of the installation closing method of the present invention. like figure 2 As shown, this embodiment includes steps:

[0058] Step 111, dividing the entire arch rib of the steel arch bridge into a large middle section and several pairs of side sections;

[0059] Step 112. Install the pairs of side segments sequentially by means of cable hoisting or suspension hoisting;

[0060] Step 113, tensioning temporary cable-stayed buckles on the installed arch ribs;

[0061] Step 2. Stretch horizontal temporary tie rods between the arch feet at both ends of the middle section to form a tie rod arch;

[0062] Step 311, integrally hoisting the tie-rod arch through the hoisting tower on the arch rib, and closing it with the installed arch rib;

[0063] Step 411, remove the horizontal temporary tie rods, so that the stress of the arch ribs is gradually converted from the stress of the curved beam + the tie rod arch to the stress form...

Embodiment 2

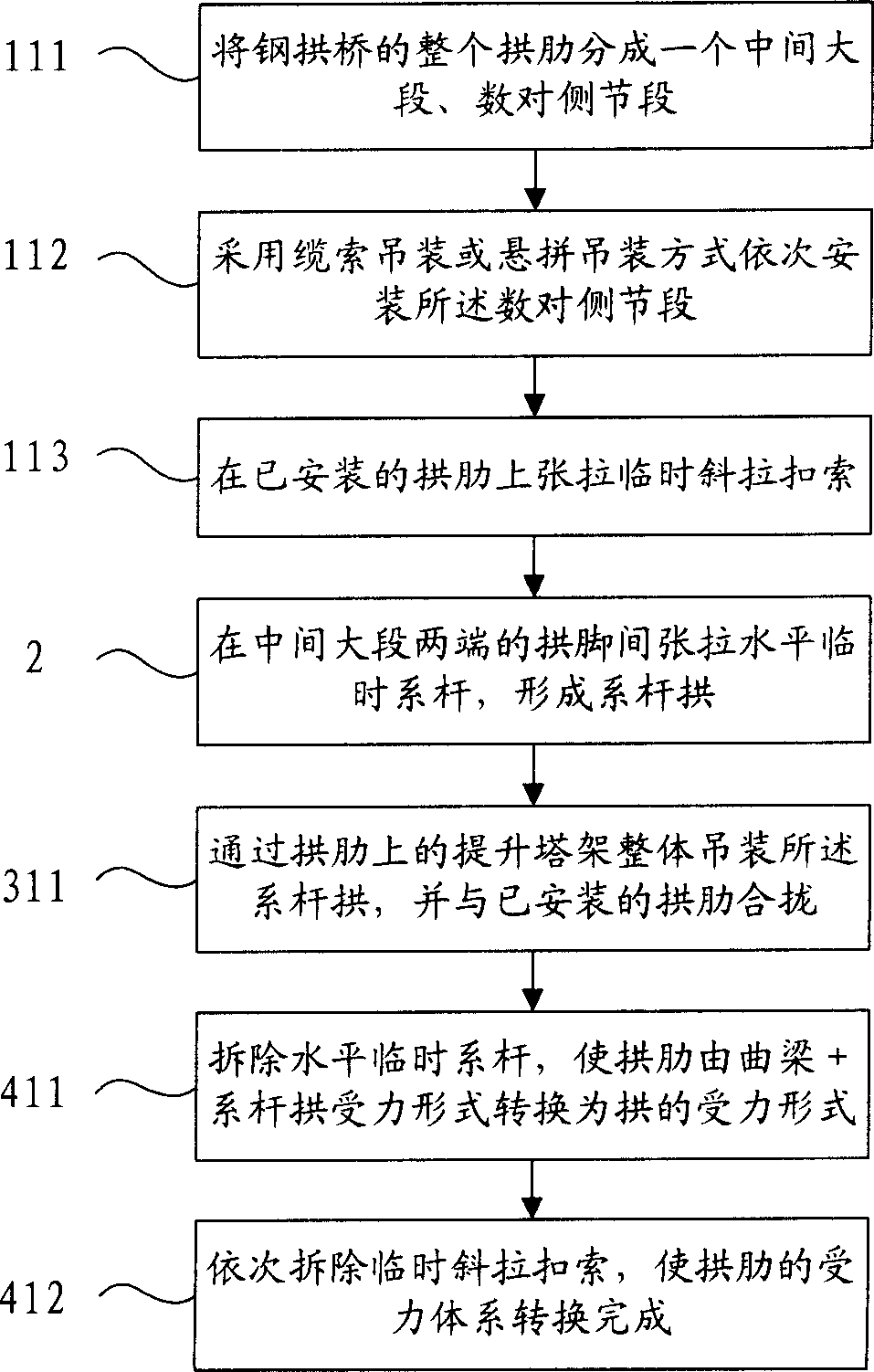

[0067] Figure 4 It is a flow chart of Embodiment 2 of the installation closing method of the present invention. like Figure 4 As shown, this embodiment includes steps:

[0068] Step 121, dividing the entire arch rib of the steel arch bridge into a middle section and a pair of side sections;

[0069] Step 122, lifting the large side section into place and supporting it on the outer lifting tower and the middle lifting tower;

[0070] Step 2. Stretch horizontal temporary tie rods between the arch feet at both ends of the middle section to form a tie rod arch;

[0071] Step 321, lifting the tie bar arch through a hoisting system consisting of a back cable, a middle hoisting tower, and a pressing tower cable, and closing it with the pair of side large sections;

[0072] Step 421, removing the horizontal temporary tie rods, so that the stress of the arch ribs is gradually converted from the stress form of the curved beam + tie arch to the stress form of the arch rib mainly un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com