Cable connector

A cable connector and cable technology, applied in the direction of cable joints, etc., can solve the problems of corrosion, reducing cable life and line operation level, time-consuming and labor-intensive problems, and achieve the effects of reducing contact power loss, effective work for many years, and small contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

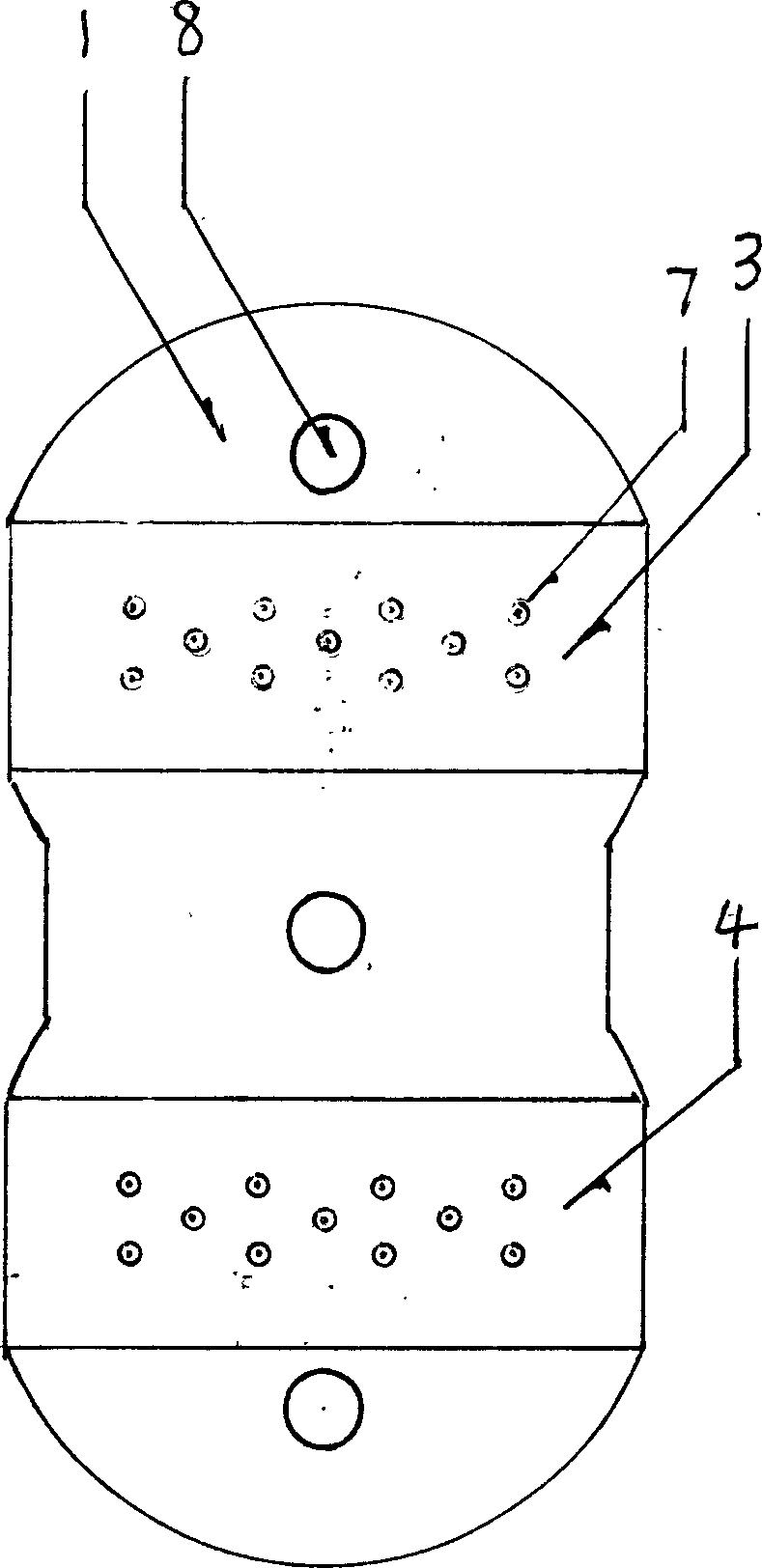

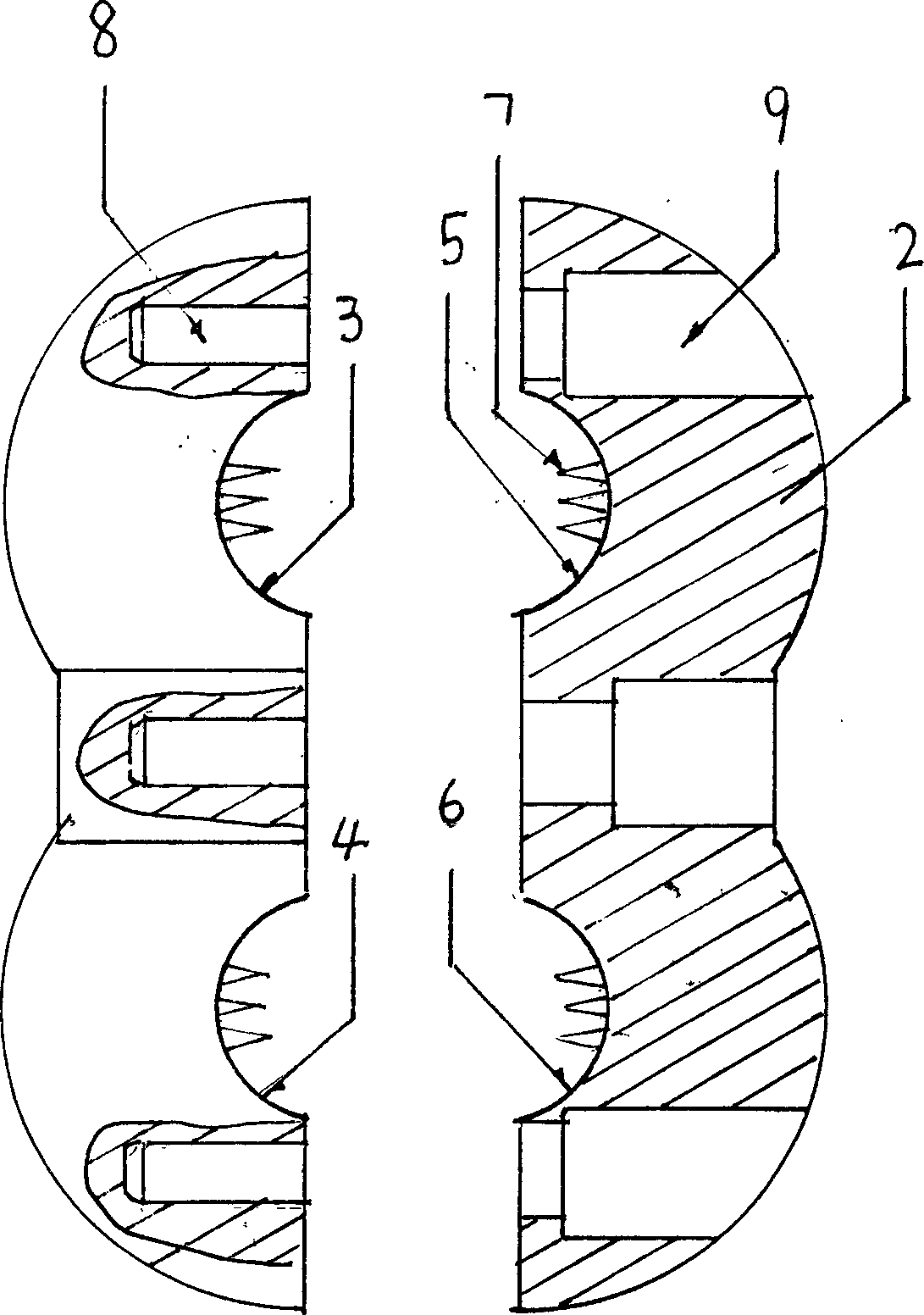

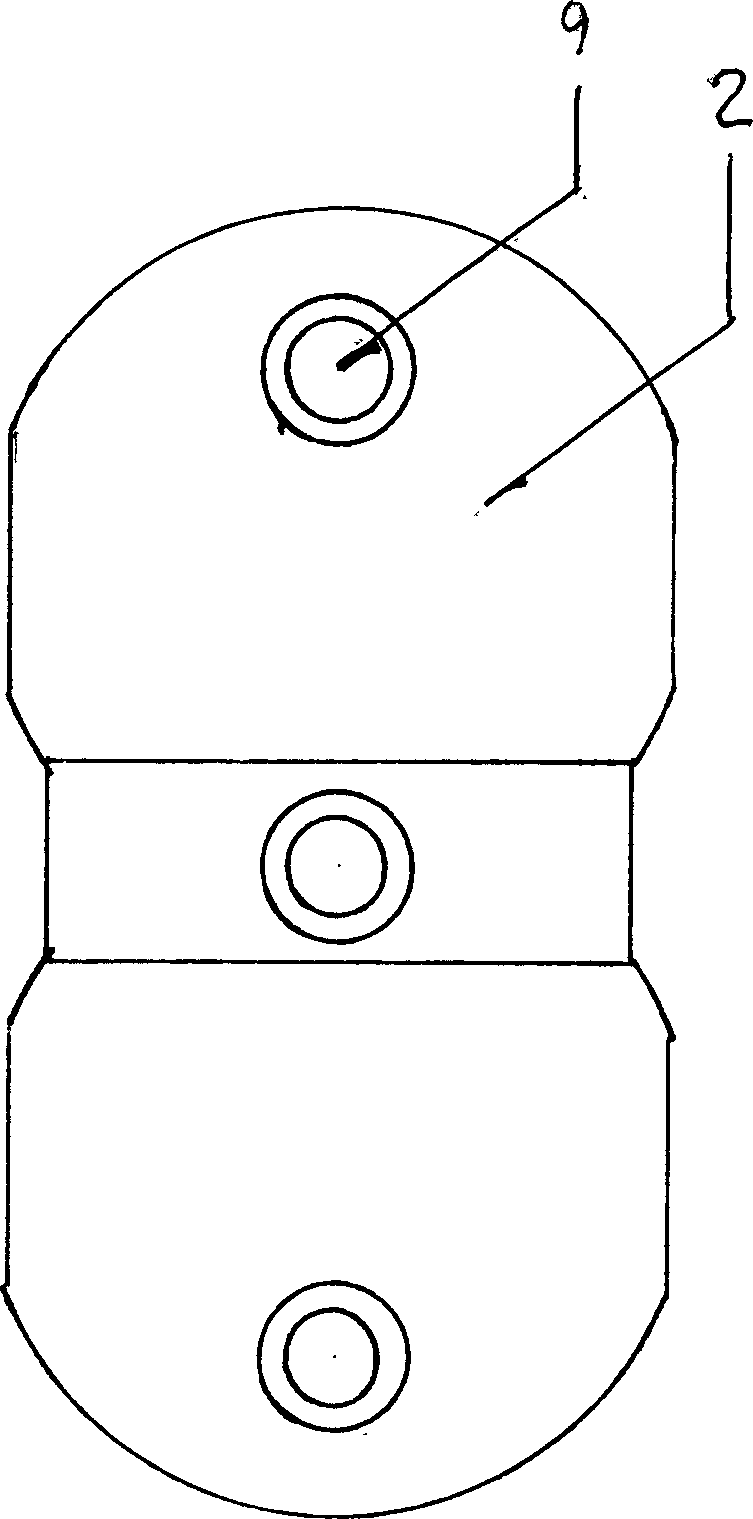

[0011] Such as Figure 1-3 The specific structure is as follows. The clamping inner arc surfaces 3 and 5 through the upper part of the connecting body are set for clamping the main cable, and the clamping inner arc surfaces 4 and 6 at the lower part of the connecting body are set for clamping branch cables. The two connecting bodies 1 and 2 Connecting holes 8 and 9 are set respectively, and they are connected as a whole by connecting bolts. Conical pinching thorns 7 are set on the clamping inner arc surfaces 3, 4, 5, and 6. The two connecting bodies 1, 2 and the conical pinching thorns 7 are both It is an aluminum alloy die-casting part, and the tapered pinch 7 is given by casting at the same time. The two connectors 1 and 2 are both excellent electrical conductors, and the two connectors are in the shape of two hemispheres and are combined to form two spheres.

[0012] When in use, place the main cable with insulation in the clamping inner arc surfaces 3 and 5 on the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com