Tray valve for a tray column

A technology of plate towers and trays, applied in the direction of control valves, valve devices, functional valve types, etc., can solve problems such as easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

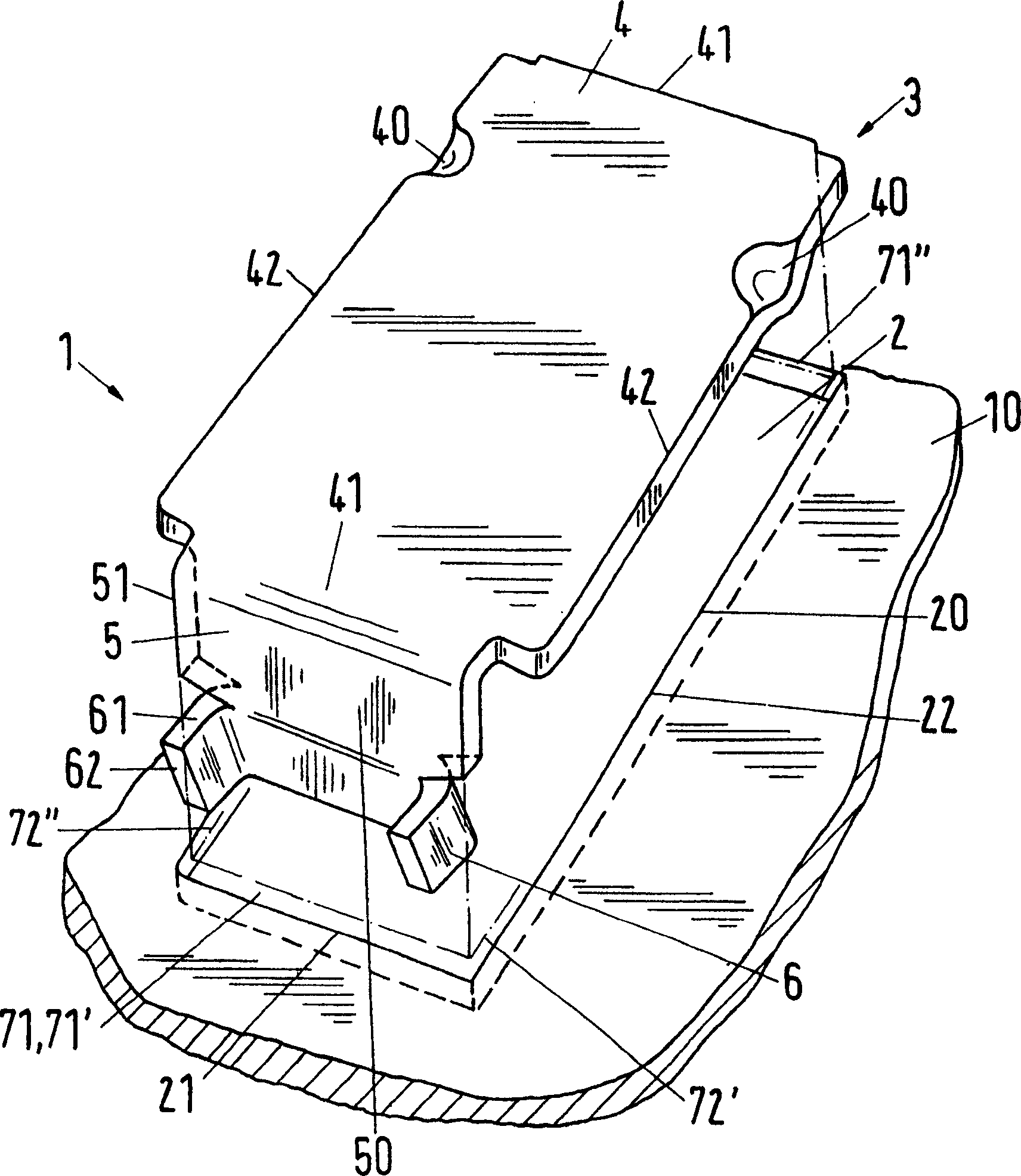

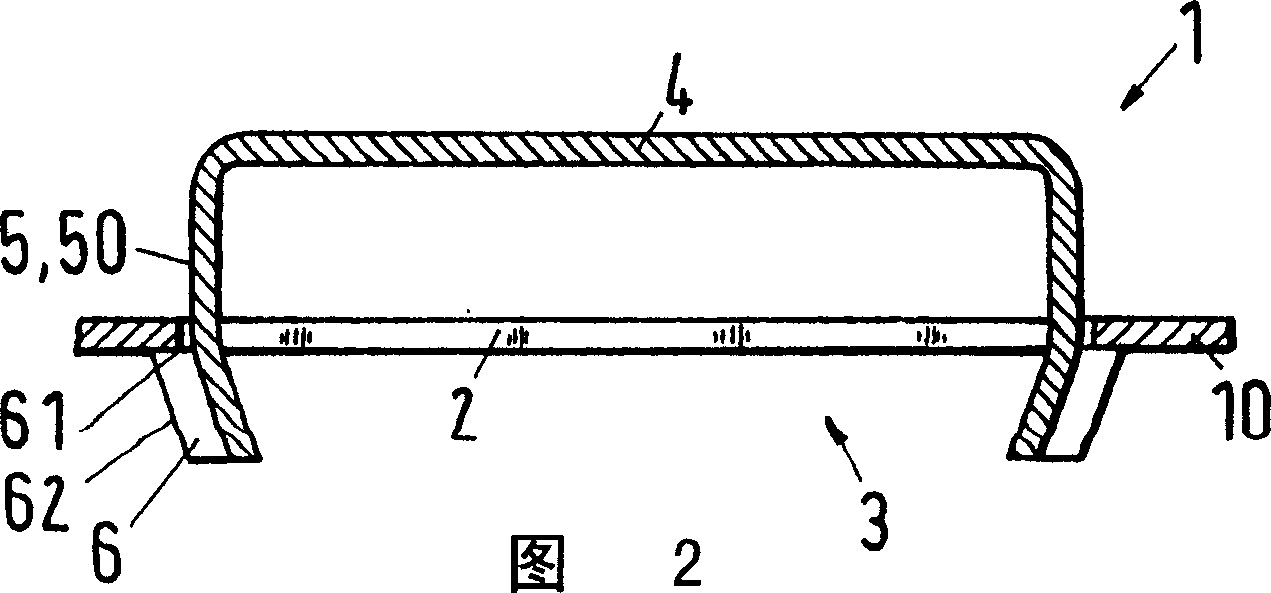

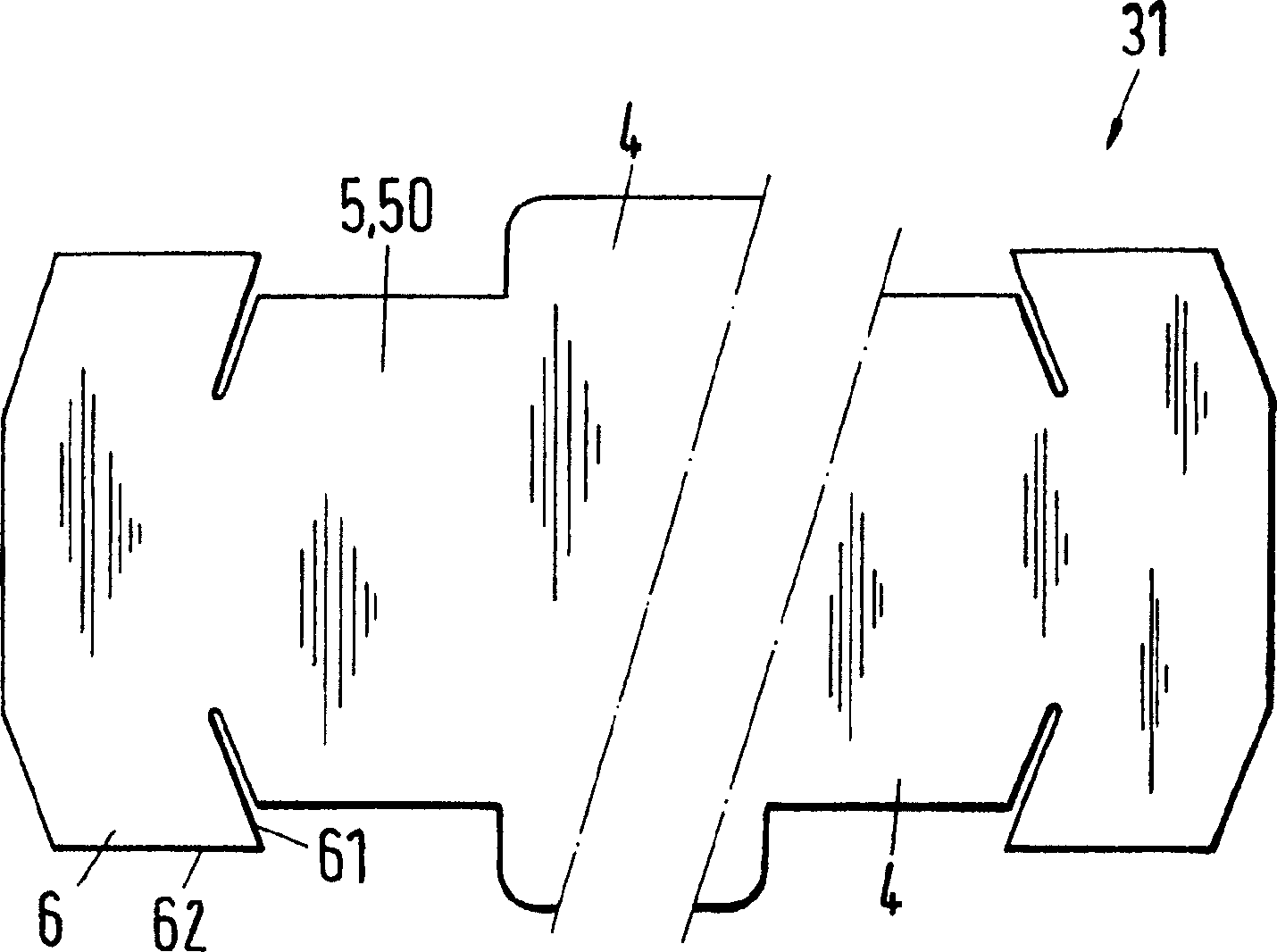

[0018] A first embodiment of a tray valve 1 having a tray opening 2 in a tray 10 and a valve body 3 according to the invention is shown in figure 1 and 2 in. The valve body 3 allowing variable passage of steam through the tray opening 2 is shown separately therefrom. FIG. 2 shows a longitudinal section through a tray valve 2 with an insert valve body 3 . The valve body 3 , made to cooperate with the edge 20 of the opening, comprises a top plate 4 and two guide projections 5 arranged at the edge of the plate 3 and directed vertically downwards. The edge 20 of the opening has a rectangular shape with two short sides 21 and two long sides 22 . The top plate 4 accordingly has four straight sides 41 and 42 lying on a rectangle, wherein the side 41 is curved and the side 42 rests outside the edge 20 of the opening above the tray 10 . The guide extension 5 has barbs 6 by which the valve body 3 is anchored on the opening edge 20 so that the stroke is limited and the valve body 3 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com