Dust collector motor and motor

A technology of vacuum cleaners and brushes, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems affecting the service life of motors, and achieve the effects of optimizing iron core design, avoiding air leakage problems, reducing cross-sectional size and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention is described in detail below in conjunction with accompanying drawing:

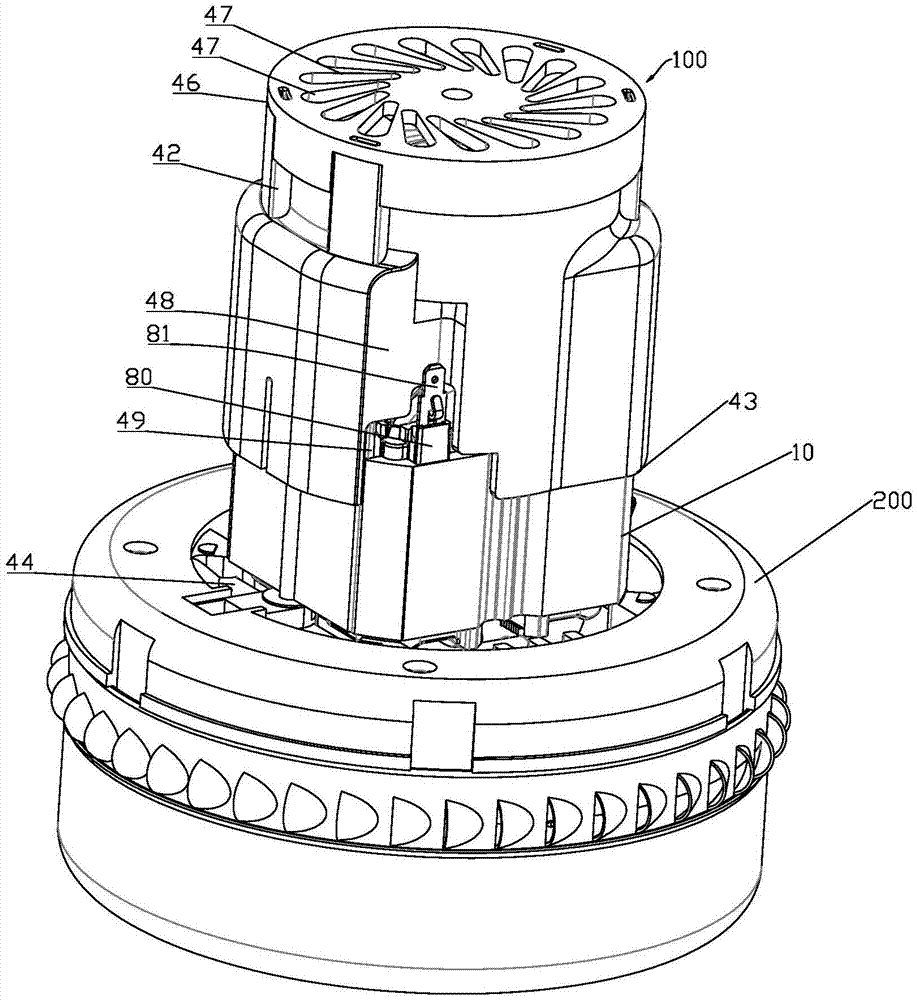

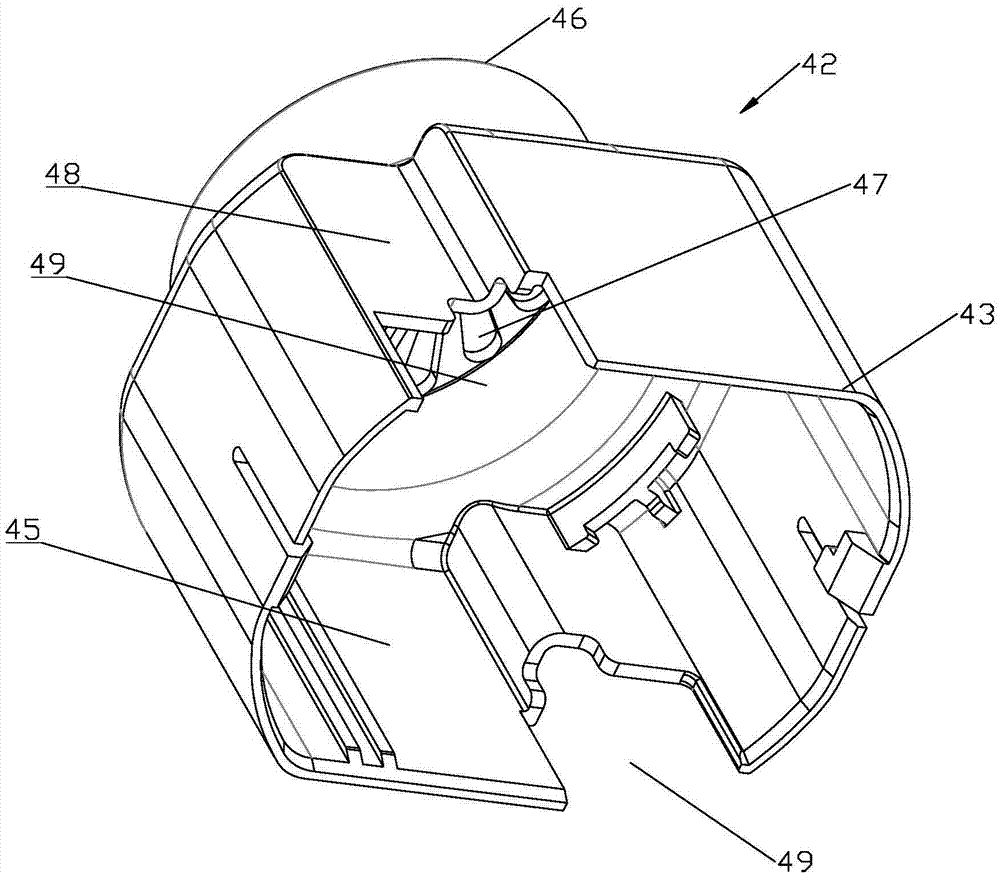

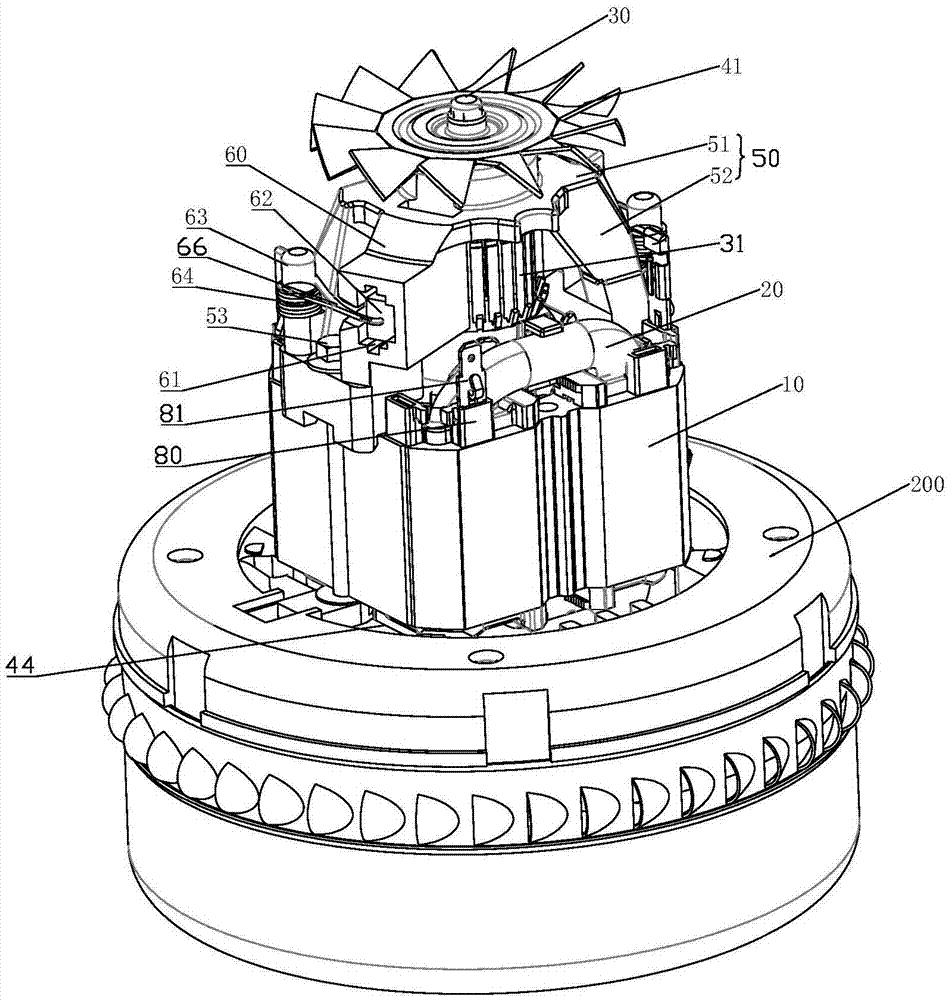

[0071] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the motor 100 includes a stator core 10, a stator core winding 20, a rotor core 30 and a fan. The stator core 10 is formed by stacking a plurality of silicon steel sheets in sequence. The stator core 10 has an upper surface 11 and a lower surface (not shown). The lower surface is a surface opposite to the upper surface 11 . Both the upper surface 11 and the lower surface are cross sections of the stator core 10 . The stator core 10 has a first through hole 13 . The rotor core 30 passes through the first through hole 13 of the stator core 10, and the rotor core 30 is rotatably disposed. The stator core winding 20 is disposed in the first through hole 13 of the stator core 10 . The stator core windings 20 are all located in the first through hole 13 , or partially protrude from the stator core 10 alo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Perimeter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com