Writing tool provided with a valve feeding device

一种书写工具、阀门的技术,应用在书写器具、可连续调整的笔尖、印刷等方向,能够解决留下印记、书写工具正常操作有害、污迹等问题,达到有利于可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

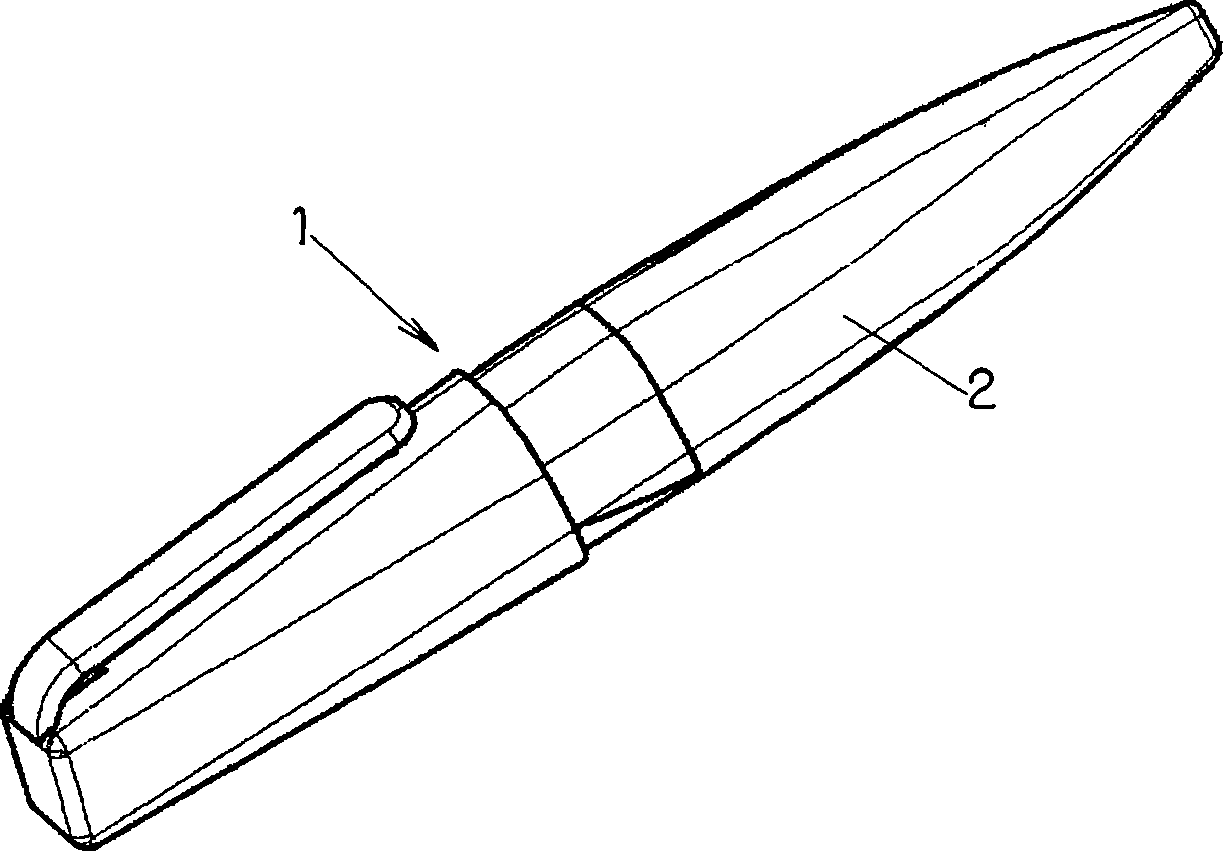

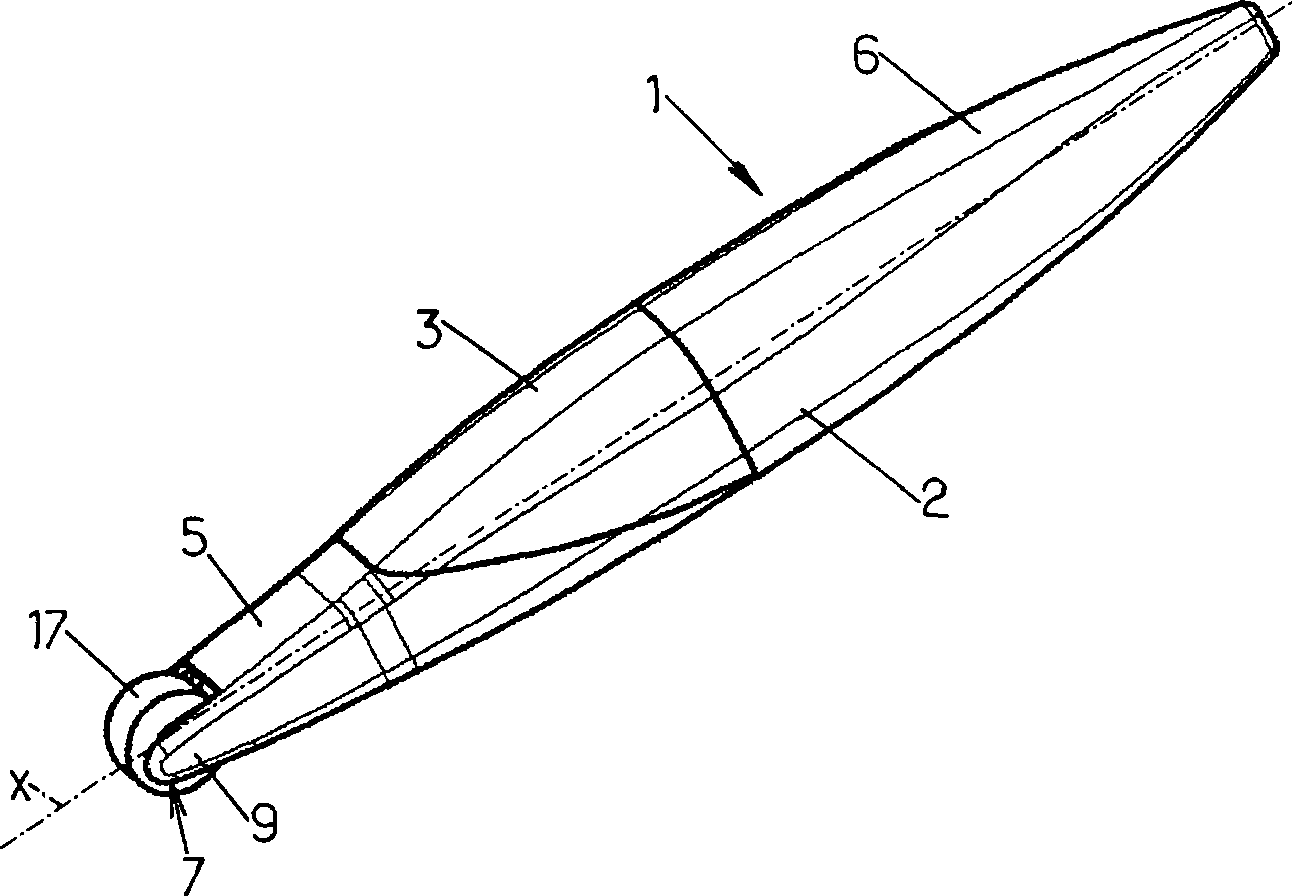

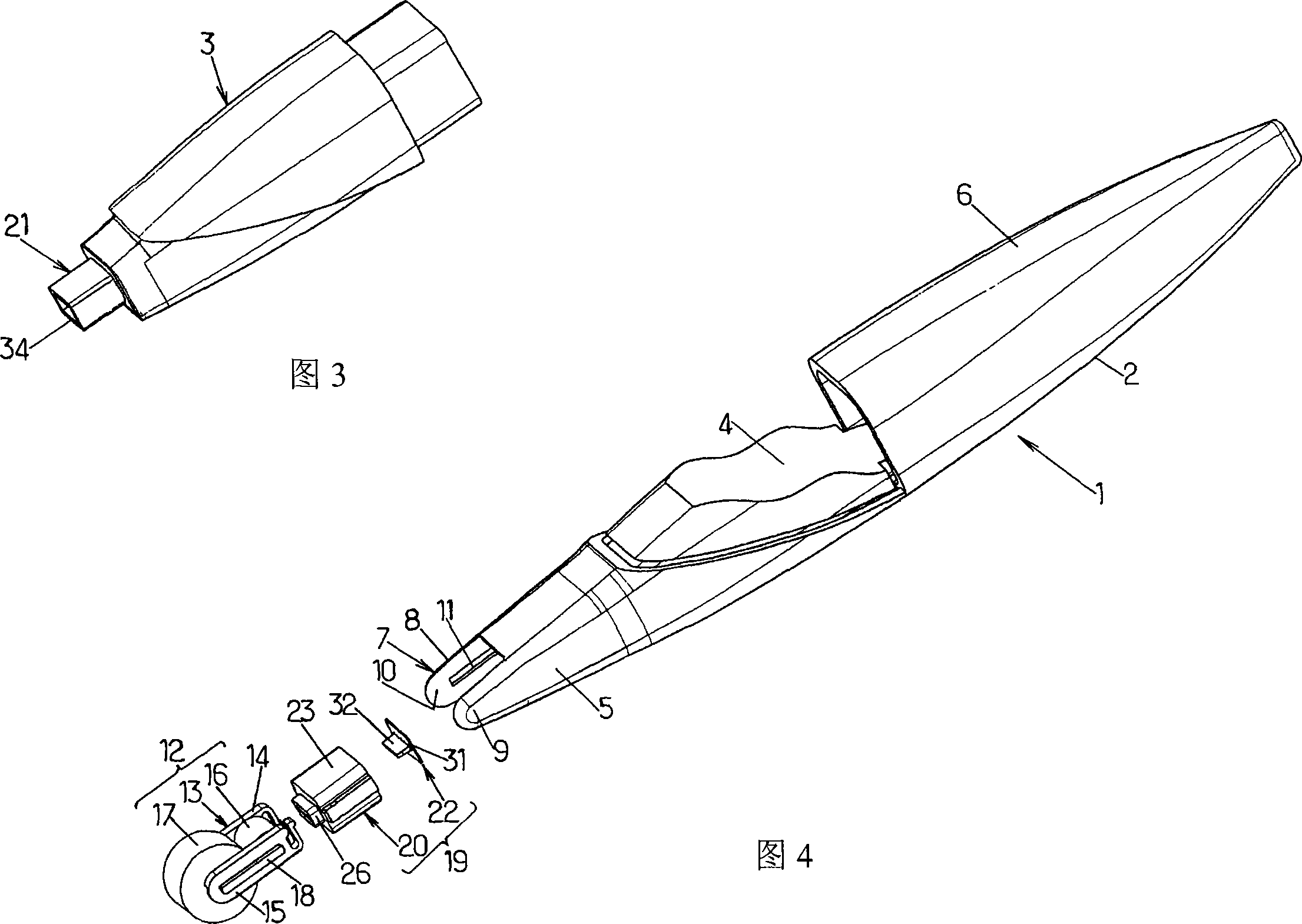

[0038] figure 1 The writing implement 1 in 4 has a tubular body 2 that is elongated along the main axis X, and this tubular body has an inner cavity 3 for liquid ink 4, especially referring to Fig. 4 , a part of the inner cavity is cut off in this figure 3.

[0039] As shown in Figures 3 to 5, the inner cavity 3 is a removable and replaceable modular barrel, which is just inserted between the front part 5 and the rear part 6 of the tube body 2. When the tube body 2 is assembled, the inner cavity 3 The surface is flush with the front 5 and the rear 6 ( figure 2 ).

[0040] As shown in particular in FIG. 4 , the front part 5 has at its end remote from the rear part 6 a fork-shaped front end 7 comprising two parallel arms 8 and 9 each having on its inner surface 10 an axis extending parallel to the main axis X. slot 11.

[0041] The tool 1 is preferably a marker pen or a line drawing pen, and also includes a writing device 12, which includes a support 13 with two bifurcation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com