Braking device

A technology of braking device, transmission connection, applied in the direction of braking transmission device, brake, cooling brake, etc., can solve the problems of high cost and structure, no cooling cycle available, difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

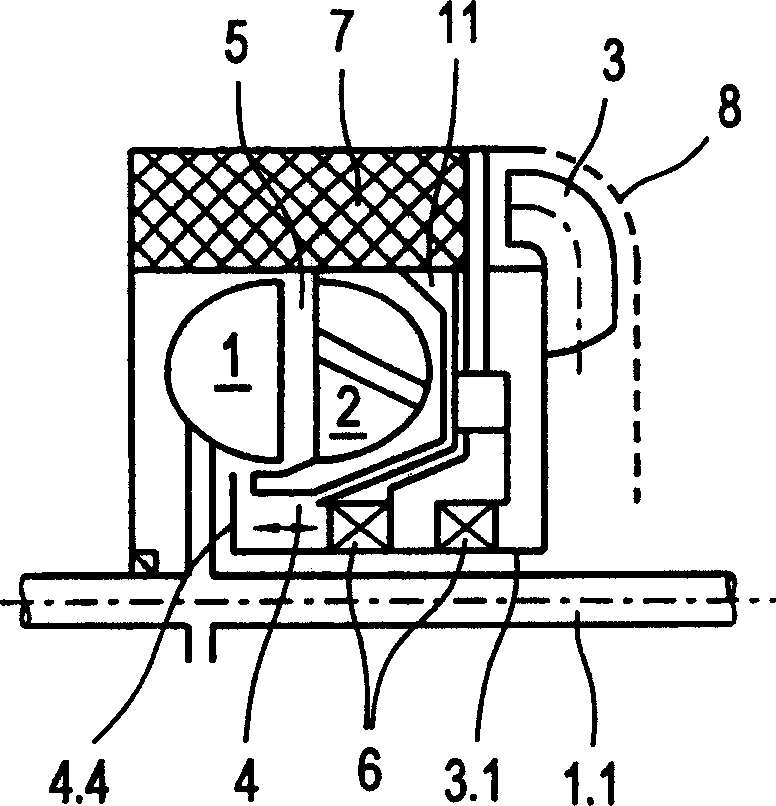

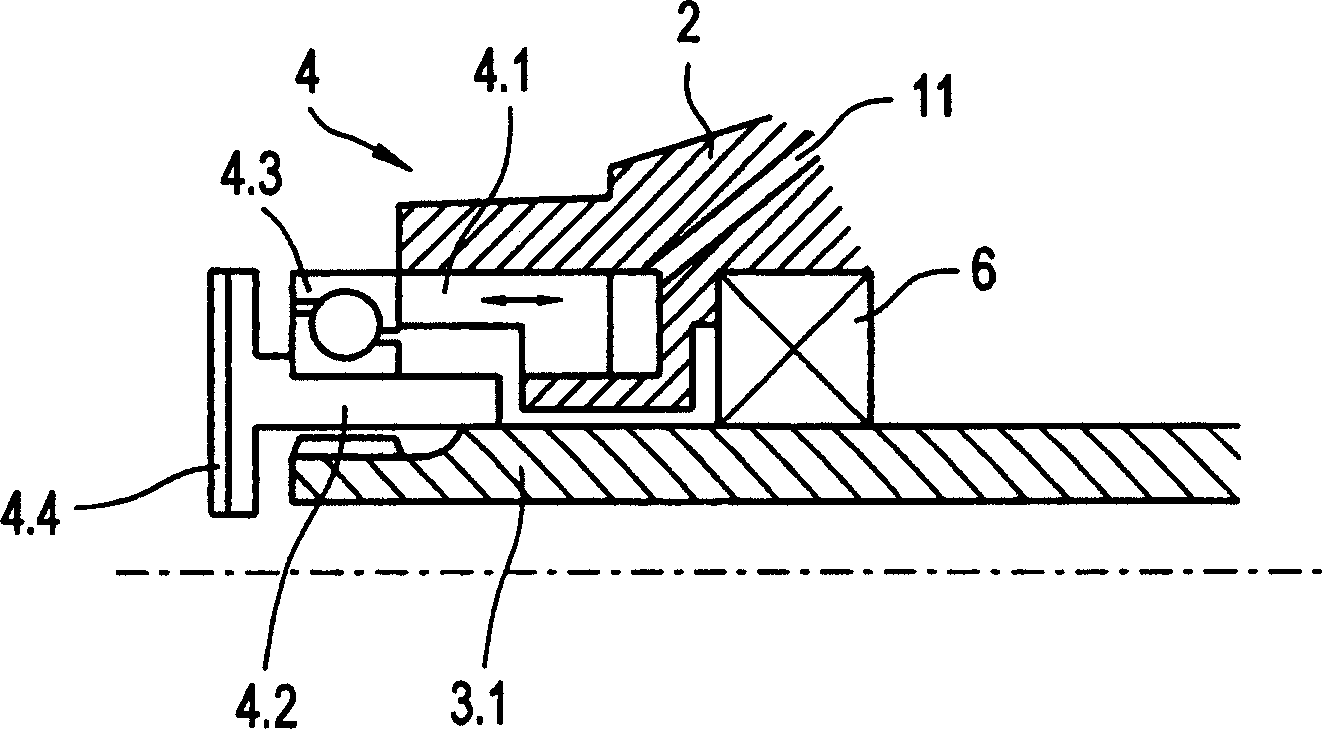

[0021] exist figure 1 The rotor 1 of the hydrodynamic retarder with the rotor shaft 1.1 by which it is rotatably arranged can be seen in FIG. The impellers of the rotor 1 together with the impellers of the stator 2 surrounding the rotor 1 delimit a torus-shaped working space 5 , in which a circulating flow is formed by the working fluid in the braking state. In general, this construction is known in reducers to a person skilled in the art, so no further explanation is required.

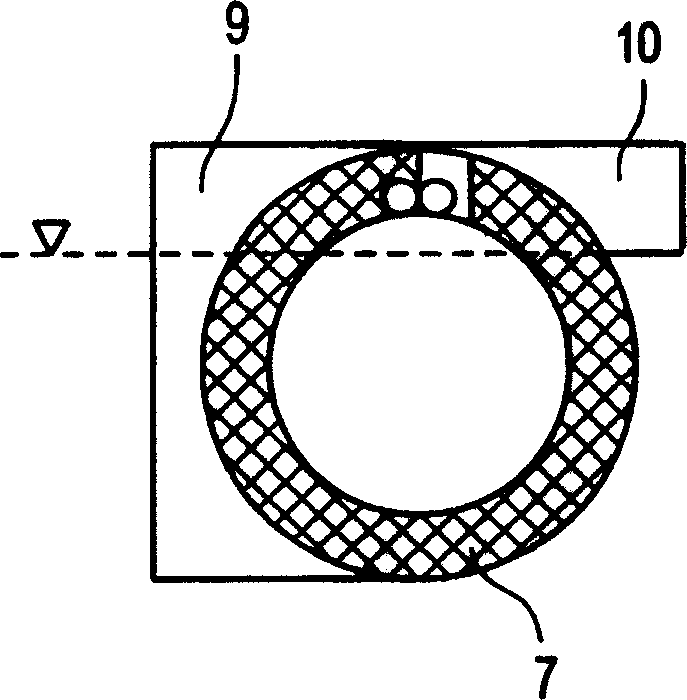

[0022] However, unlike the prior art, according to figure 1 The reducer has an annular heat exchanger 7 which is arranged along the outer circumference, ie radially outside the working space 5 . In the annular heat exchanger 5 , the working fluid is drawn out of the work space 5 , cooled there, and led back into the work space 5 . As a result, the annular heat exchanger 5 is acted upon on its inner side, ie on its heat absorption side, with working fluid as heat carrier.

[0023] To conduct heat f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com