Liquid container and liquid ejection device

A technology for liquid containers and container shells, which can be used in power transmission devices, printing, transfer materials, etc., and can solve problems such as increasing the amount of printing processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Hereinafter, a liquid container and a liquid ejection device according to preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

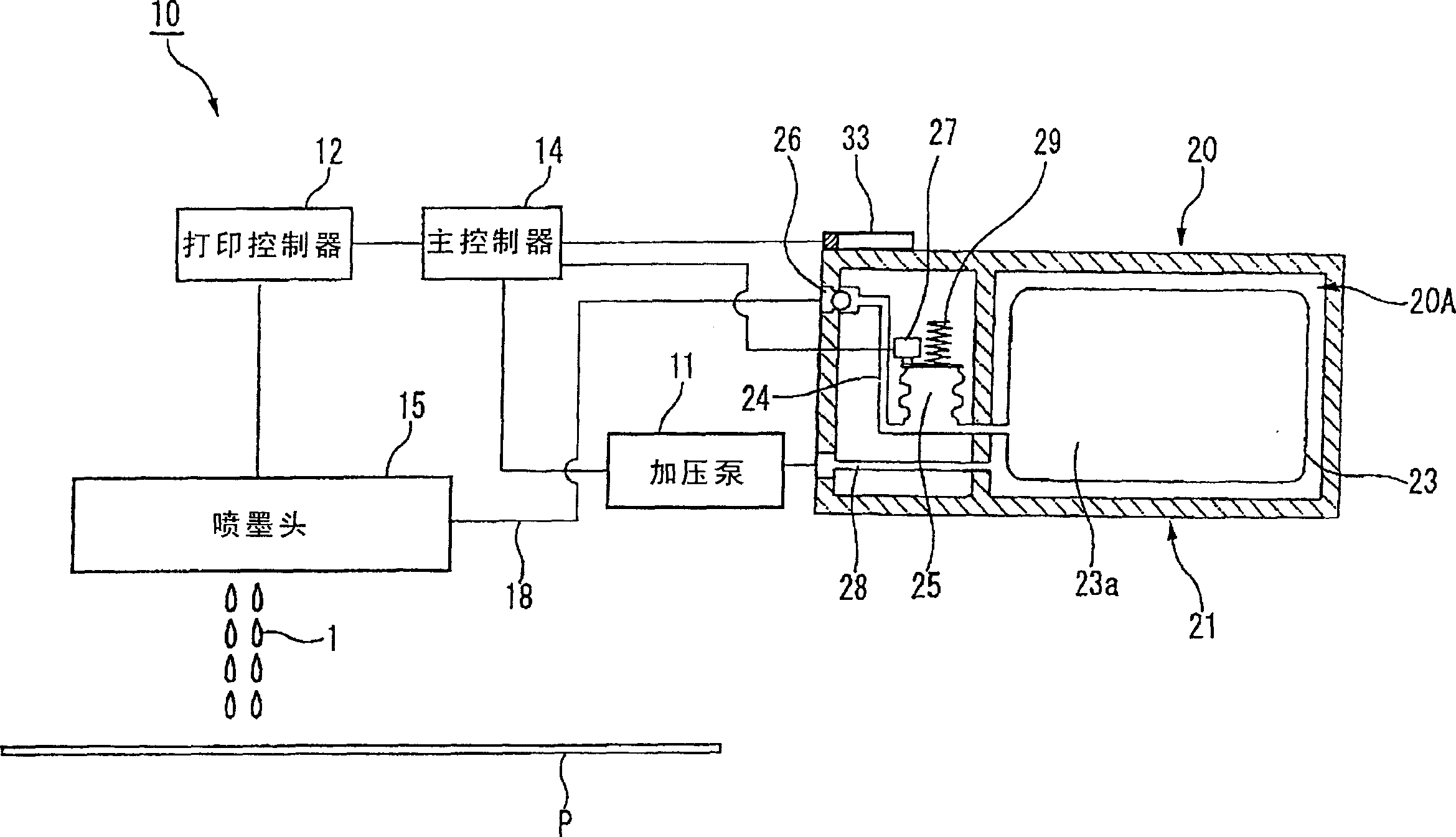

[0067] figure 1 is a schematic diagram showing a liquid container and a liquid ejection device according to a first embodiment of the present invention.

[0068] figure 1 The inkjet printer 10 shown in , corresponds to the liquid ejection apparatus of the present invention, and the ink cartridge 20 detachably mounted on the inkjet printer 10 corresponds to the liquid container of the present invention.

[0069] In the inkjet printer 10 according to the first embodiment of the present invention, if air is ejected into the inner space 20A of the ink cartridge 20 by the pressurizing pump 11 through the air inlet duct 28, the ink pack 23 arranged in the inner space 20A Pressurized by air so that its volume is compressed. Accordingly, the ink in the ink pack 23 is squeezed out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com