Cable conduit sounder

A cable duct and detector technology, which is used in optical device exploration, optical testing flaws/defects, etc., can solve problems such as hidden dangers left by cable laying, inability to inspect the laying condition, and inability to understand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

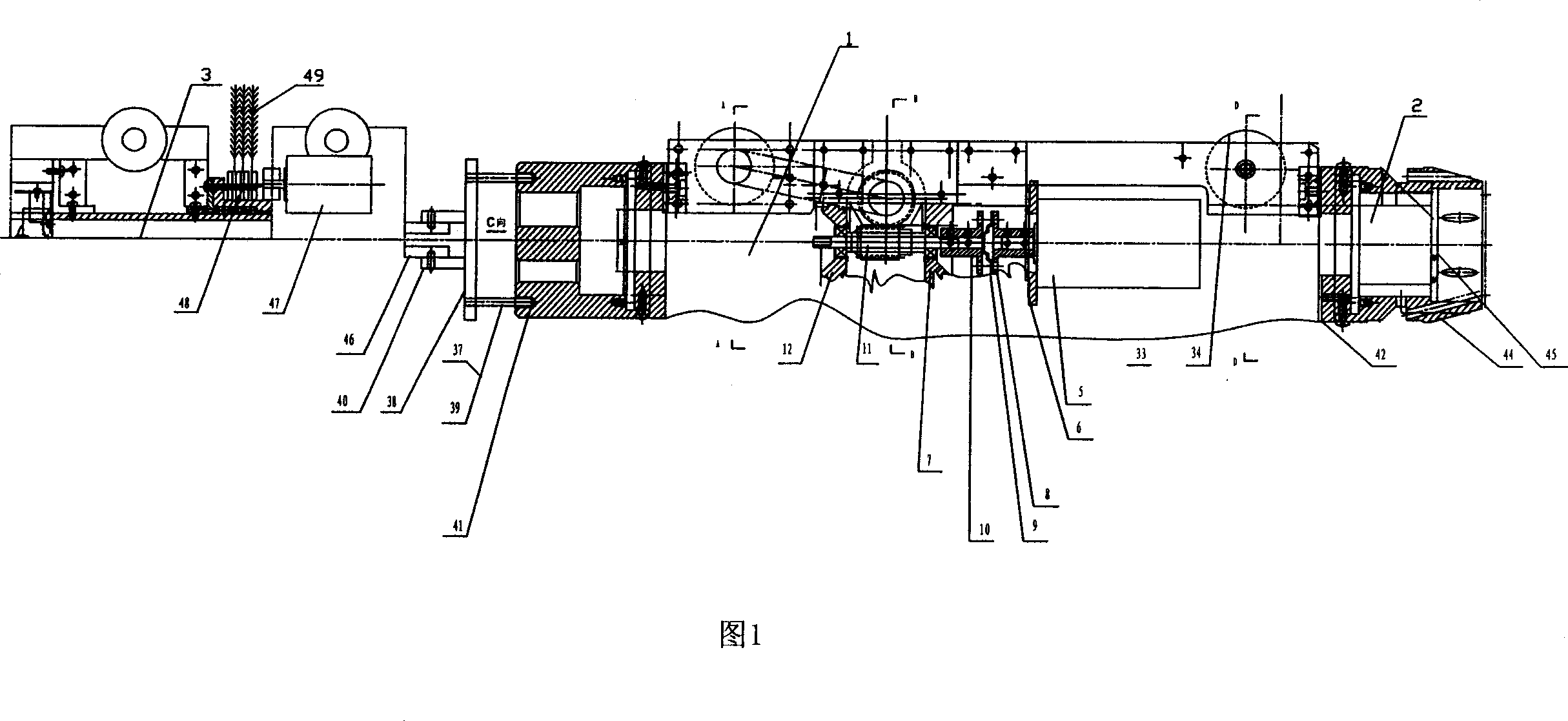

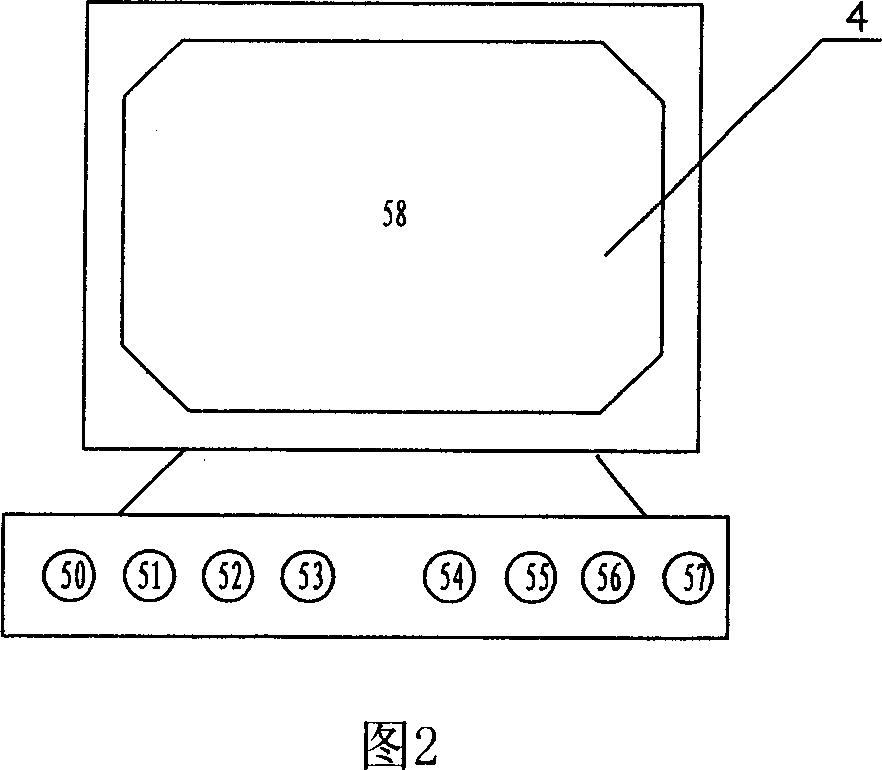

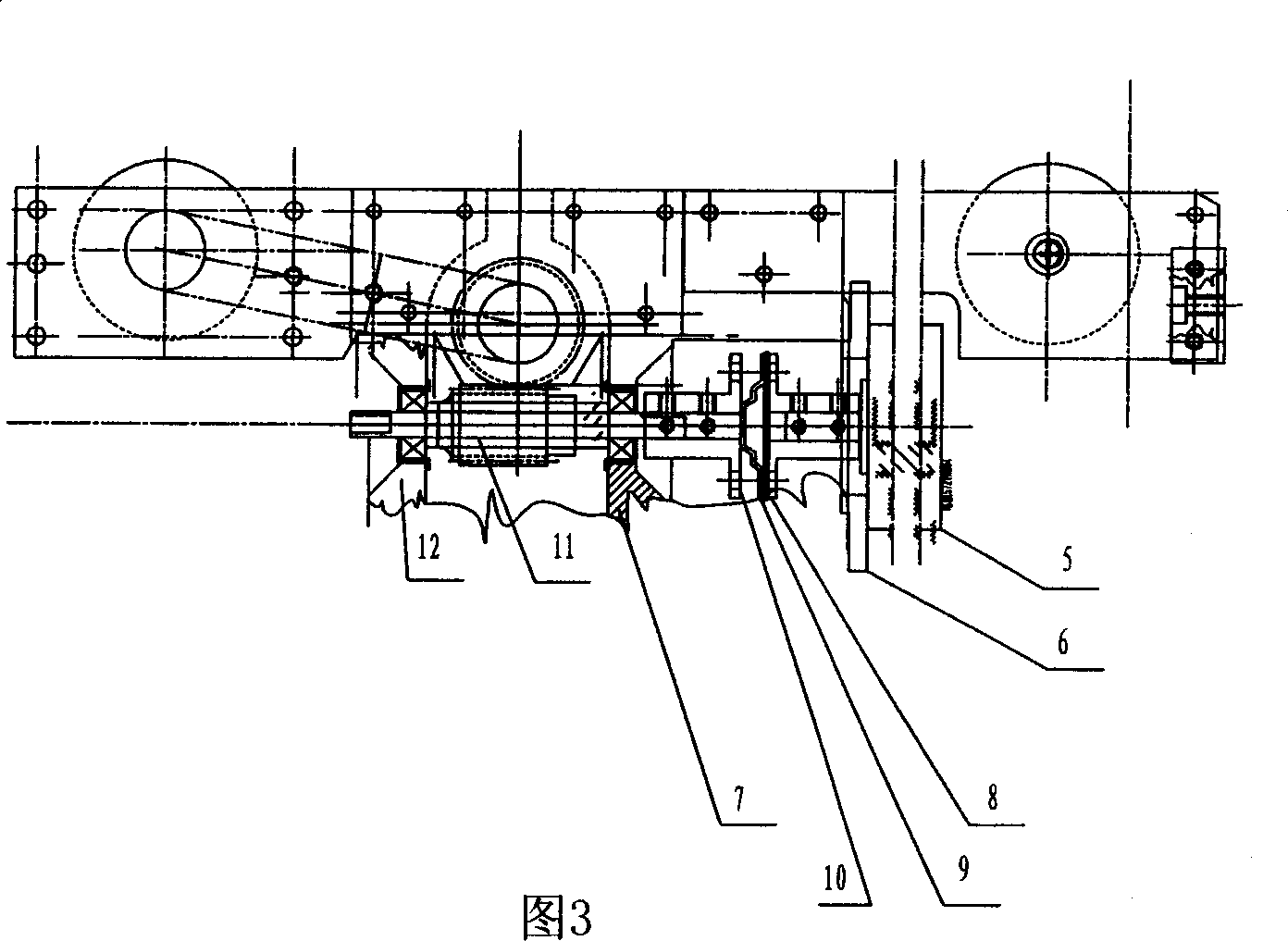

[0034] As shown in Fig. 1, Fig. 3, Fig. 4, Fig. 5: the present invention mainly is made up of power plant part 1, video device part 2, cleaning device part 3 and control device part 4. The video device part 2 is fixed in the positioning hole of the front cabin seat 42 of the power unit part 1 with screws. The cleaning device part 3 is fixed on the tail compartment nozzle 40 of the power unit part 1 with screws. The control device part 4 is placed near the work site, and is connected to the power supply seat 63 and the signal line seat 64 of the power device part 1 through power cables and signal cables to display the video image inside the pipeline and control the detector. Actions.

[0035] The power plant part 1 of the present invention is made up of body, power motor 5, worm screw 11, three worm gear assemblies, three main driving wheel assemblies...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com