Method of determining the shape of a dental technology object and apparatus for per-forming the method

A dental technology and object technology, applied in this field, can solve the problems of speed determination, inaccurate spatial coordinates, inaccurate data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

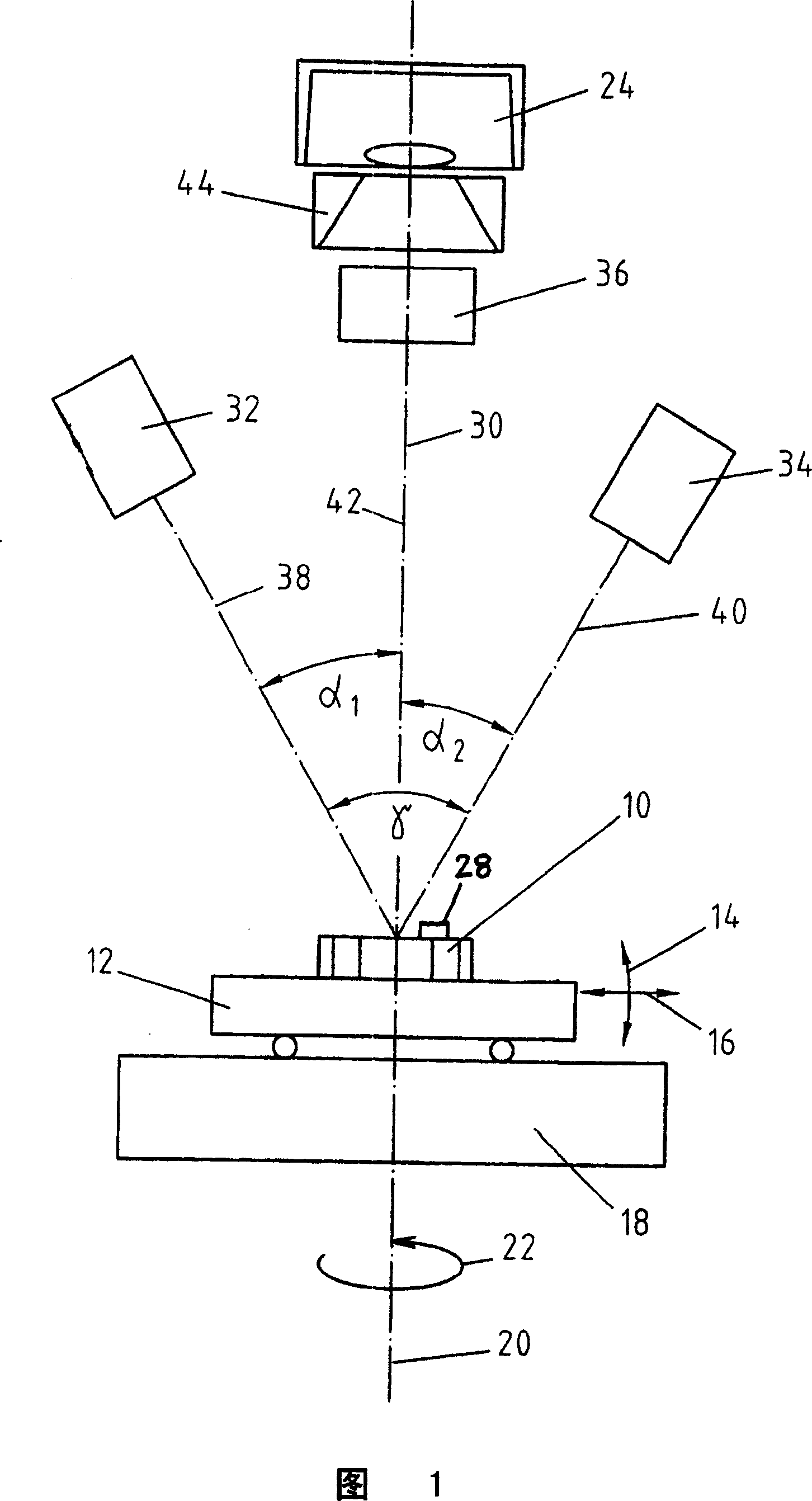

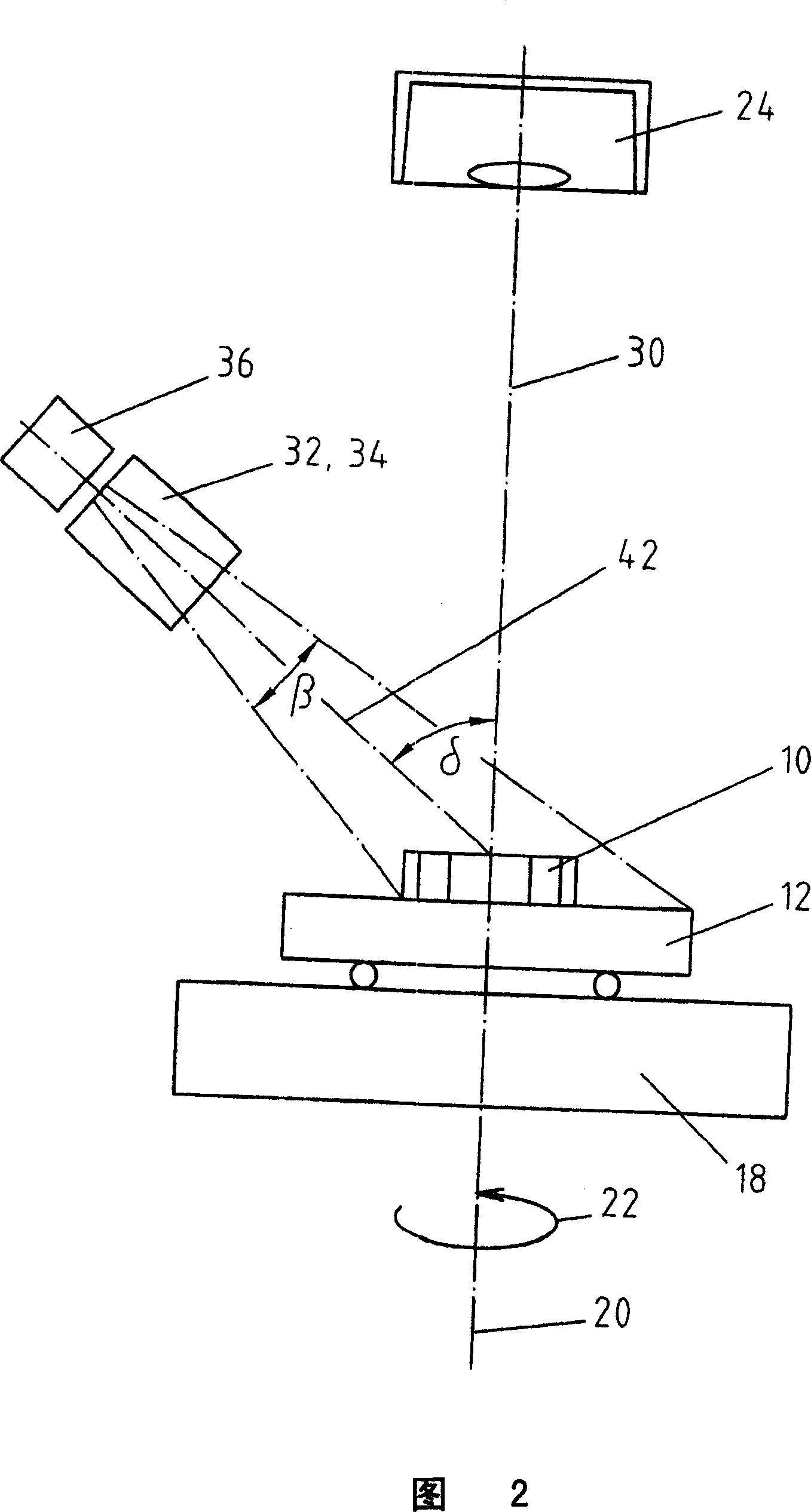

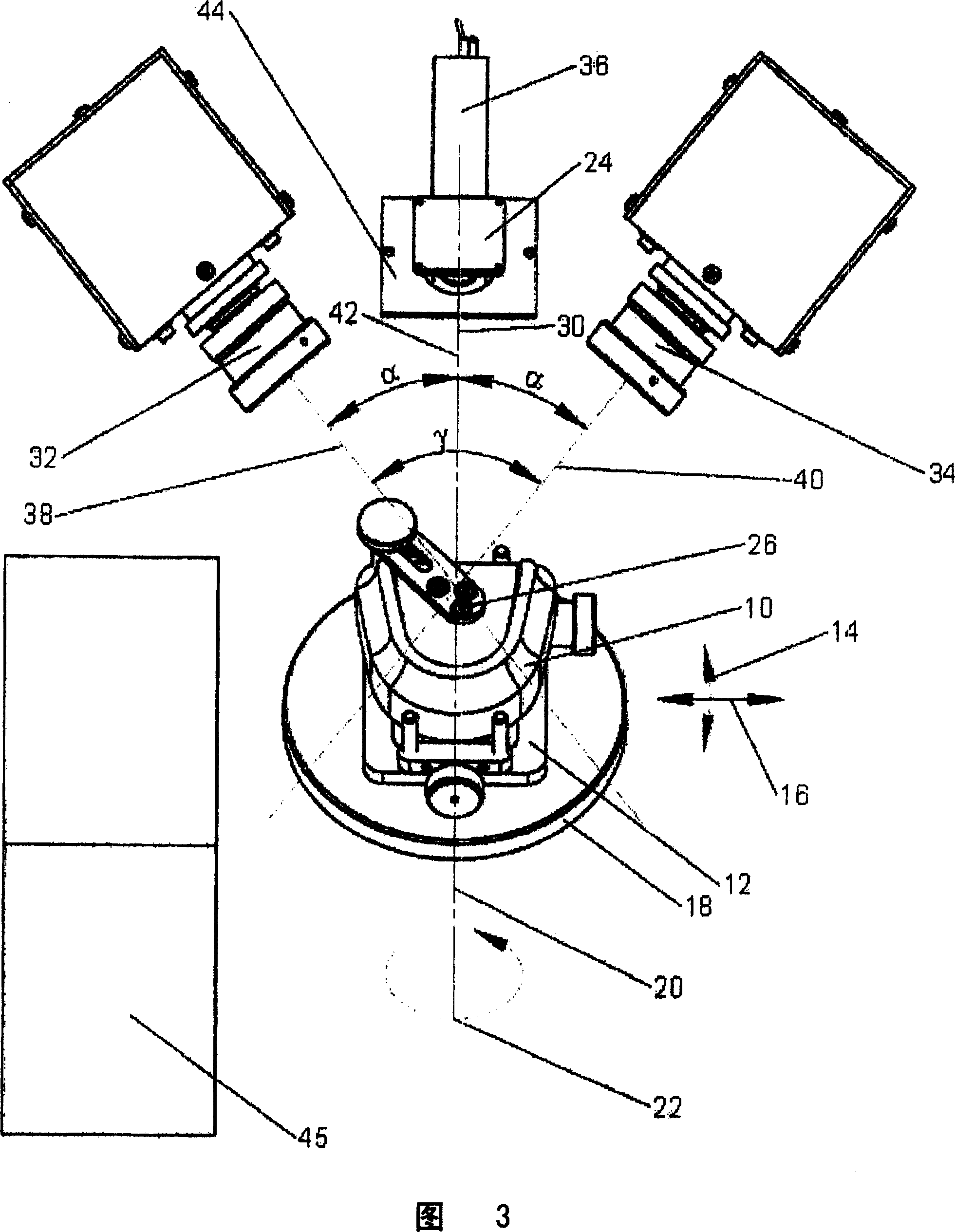

[0042] Schematic diagrams of a device for contactless shape detection of objects in dental technology, in various views and perspectives, in partial fragment form, can be extracted from these figures, where identical elements are designated by the same reference numerals, when elements Even when they are different from each other in terms of illustration but contain the same technical content, they are also denoted by the same reference numerals. In the exemplary embodiment, which can be seen from the figures, the dental technical object is a positive mold 10 , but the invention is not thereby restricted.

[0043] The plunger 10 is arranged on a holding device 12 , which can be adjusted, tilted and adjusted in height according to arrows 14 and 16 relative to a measuring table or swivel table 18 . The turntable 18 is itself rotatable about an axis 20 (arrow 22). A reference camera 24 is arranged above the rotary table 18, by means of which reference camera the rotary table 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com