Scroll pump with load bearing synchronization device

A technology of synchronous devices and scrolls, which is applied to components of pumping devices for elastic fluids, rotary piston type/oscillating piston type pump components, pumps, etc., can solve the problem of not being able to rigidly support axial loads, lateral Problems such as high bending stress and failure to provide performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

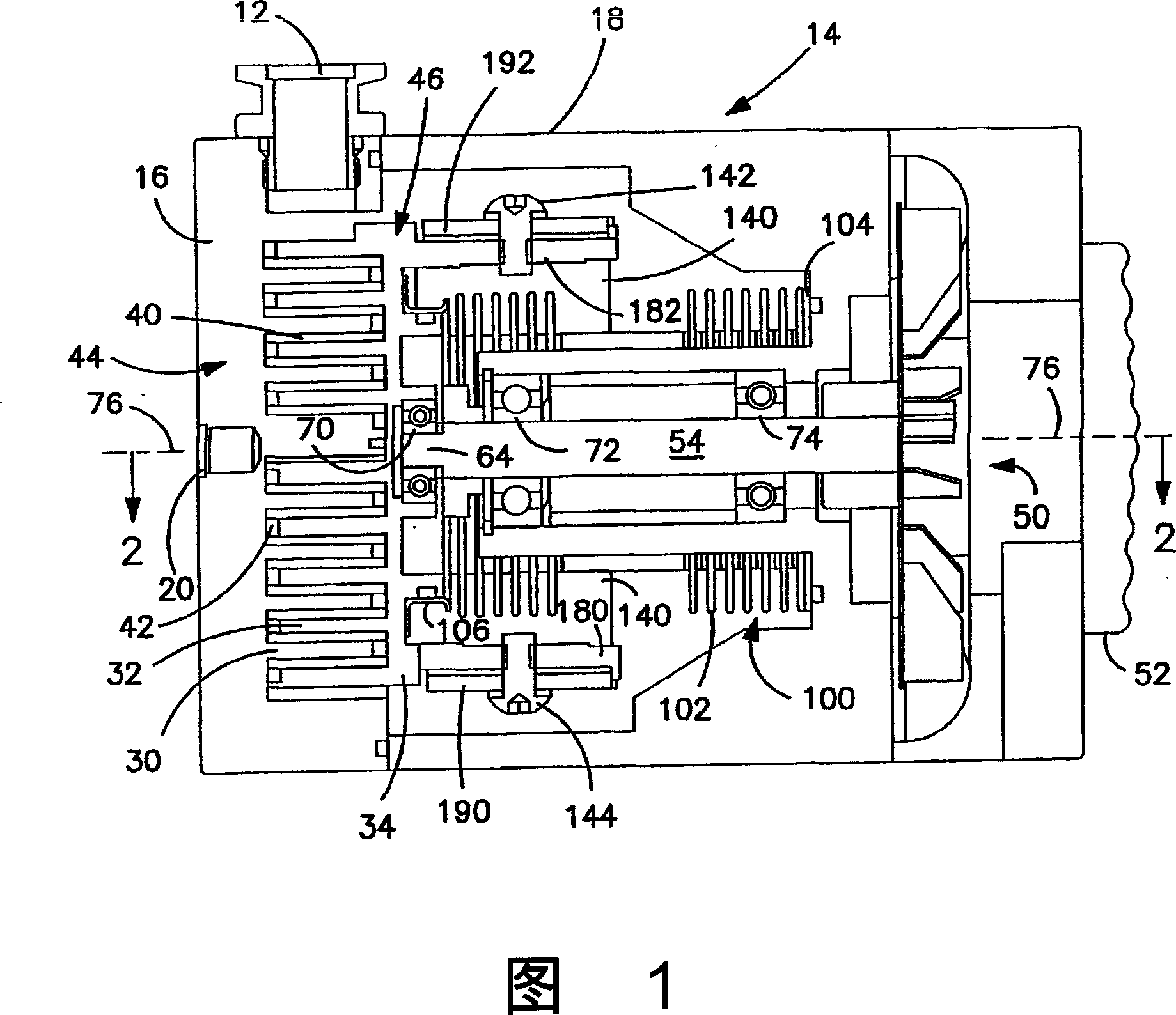

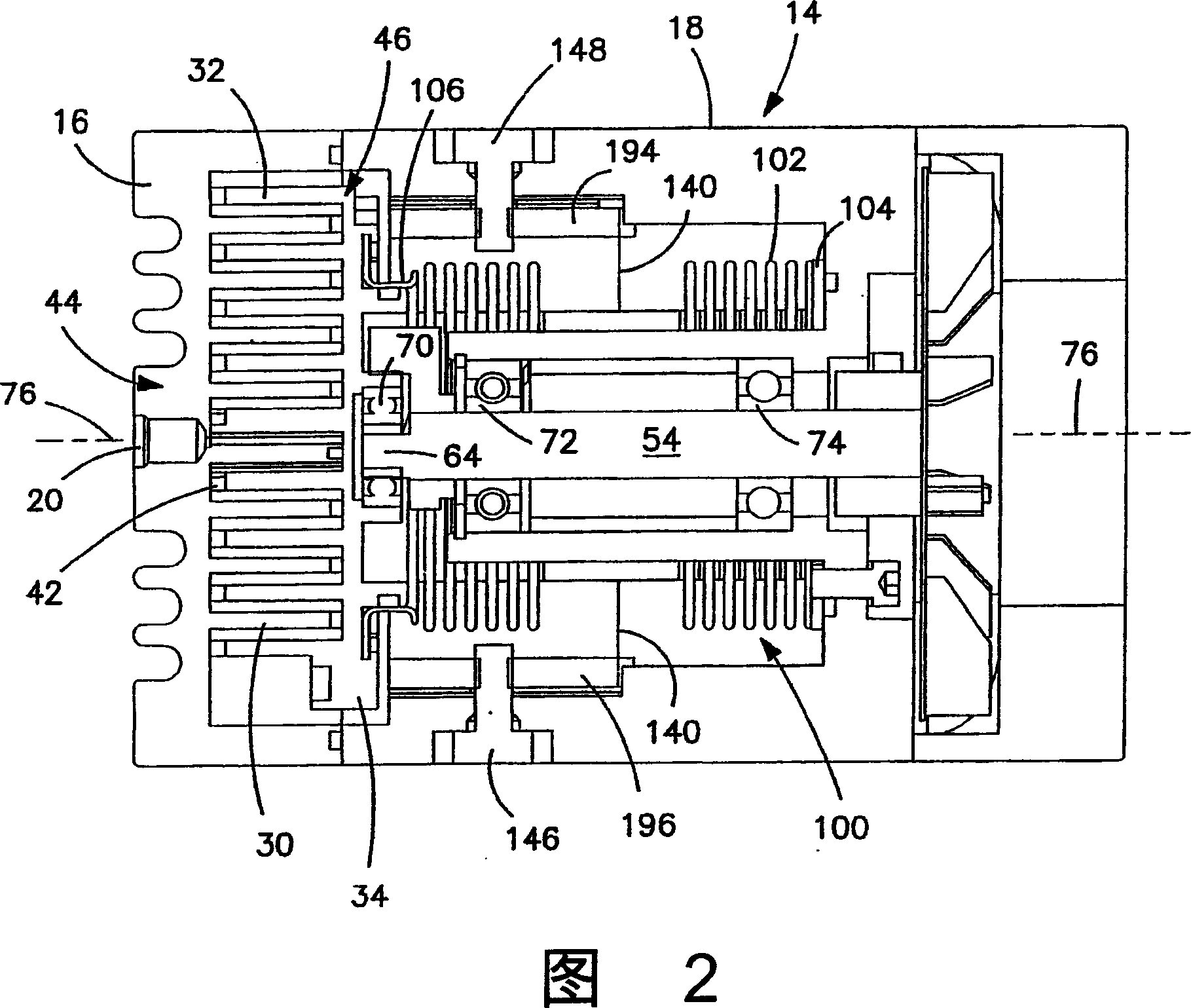

[0029] A scroll pump according to a first embodiment of the present invention is shown in FIGS. 1 and 2 . Gas, typically air, is drawn from a vacuum chamber or other device (not shown) connected to an inlet 12 of the pump. Pump casing 14 includes a fixed scroll plate 16 and a frame 18 . This pump also includes an outlet 12 for discharging the gas pumped by it.

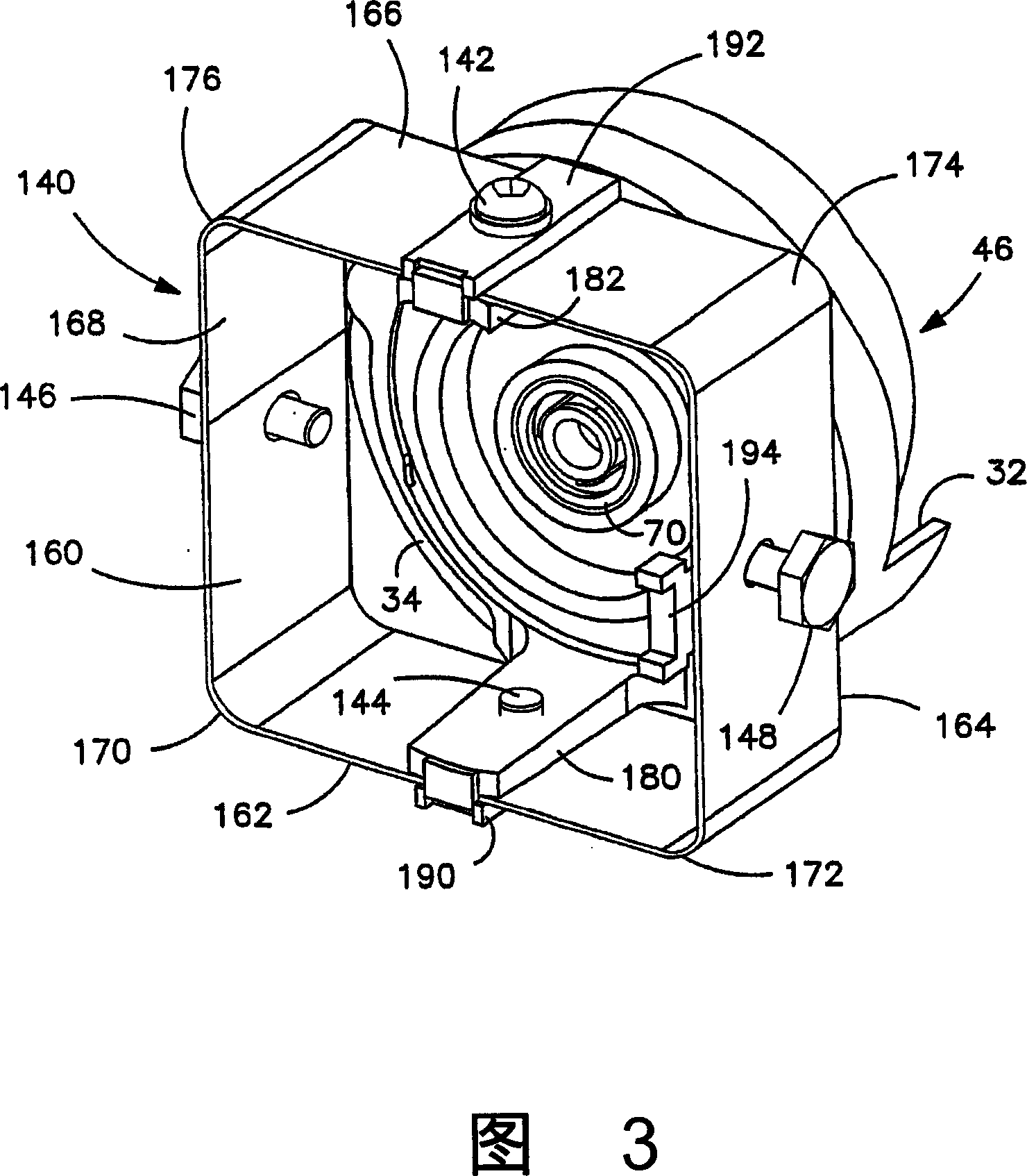

[0030] The scroll pump consists of a pair of interengaging helical scroll vanes. The scroll blade pair includes a fixed scroll blade 30 extending from the fixed scroll plate 16 and an orbiting scroll blade 32 extending from an orbiting scroll plate 34 . The scroll vanes 30 and 32 are preferably integrally formed with the scroll plates 16 and 34, respectively, to facilitate heat transfer and increase the mechanical rigidity and durability of the pump. The scroll blade 30 and the scroll plate 16 form a fixed scroll member 44 and the scroll blade 32 and the scroll plate 34 form an orbiting scroll member 46 . The respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com