Safety electric meat grinder

A meat grinder and electric technology, applied in the field of kitchen utensils, can solve problems such as the influence of children's wrong thinking, meat grinders swallowing people's hands, increasing limb crisis, etc., so as to improve safety protection performance, increase difficulty, and prevent safety accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

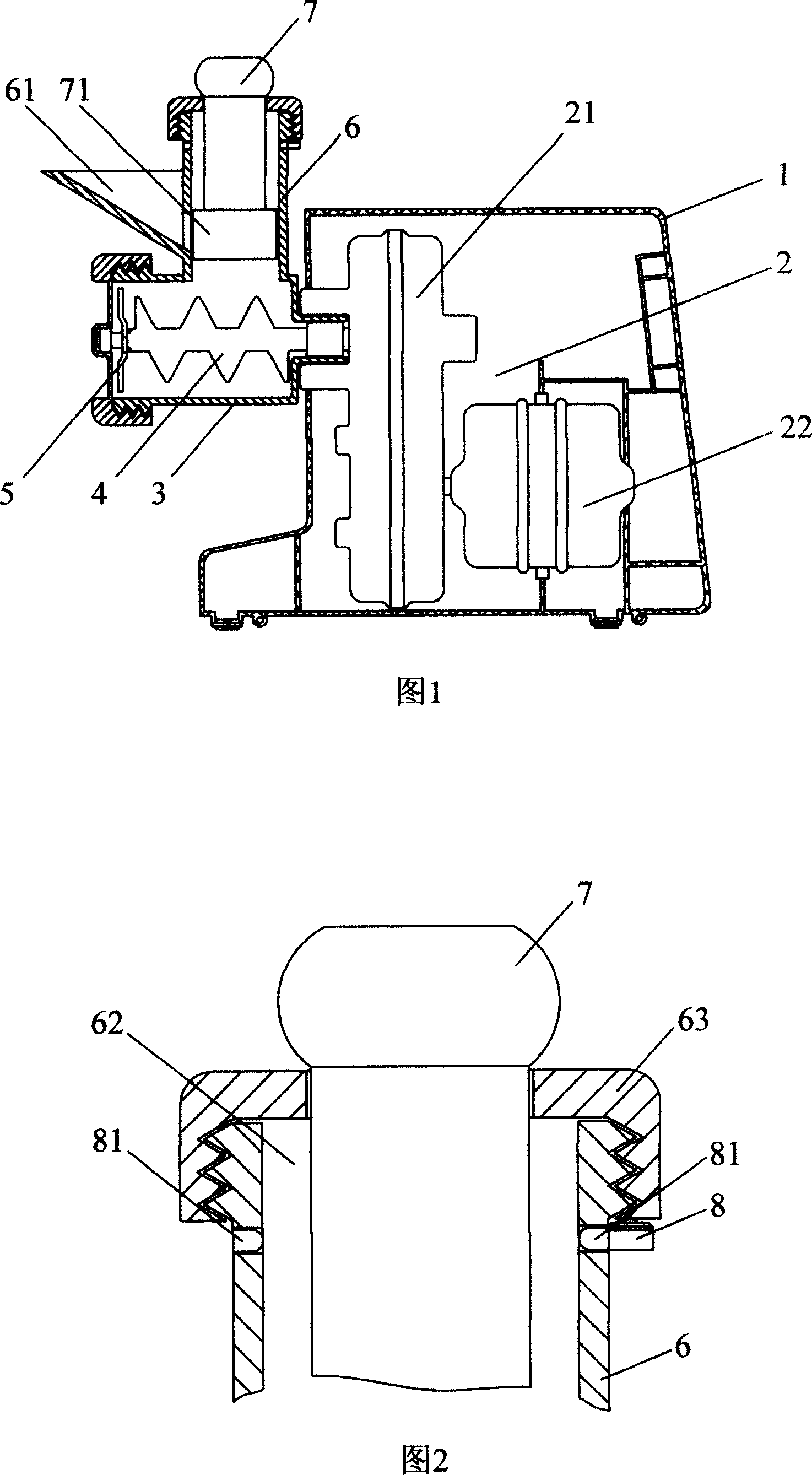

[0013] A safe electric meat grinder, as shown in Figure 1, includes a housing 1, a driving device 2 installed in the housing 1, a meat grinding cylinder 3, a conveying screw 4 and a blade 5 installed in the meat grinding cylinder 3, The meat grinding cylinder 3 is provided with a feeding cylinder 6, and the feeding cylinder 6 is provided with a feeding rod 7, wherein the side wall of the feeding cylinder 6 is provided with a feed inlet 61, and the feeding cylinder 6 is provided with a protection device that is electrically connected with the driving device 2. Switch 8, as shown in Figure 2. The feeding port 61 is located on the side wall of the feeding cylinder 6, which is conducive to increasing the difficulty for the user to touch the conveying screw 4, reducing the chance of the limbs being involved in the meat grinder, and once the meat grinder is abnormal, the protection switch 8 will Automatically cut off the power supply of the driving device 2 to prevent accidents.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap