Bar for a warp knitting machine and method of making same

A technology of knitting machine and bar, which is applied in the field of manufacturing knitting machine bar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

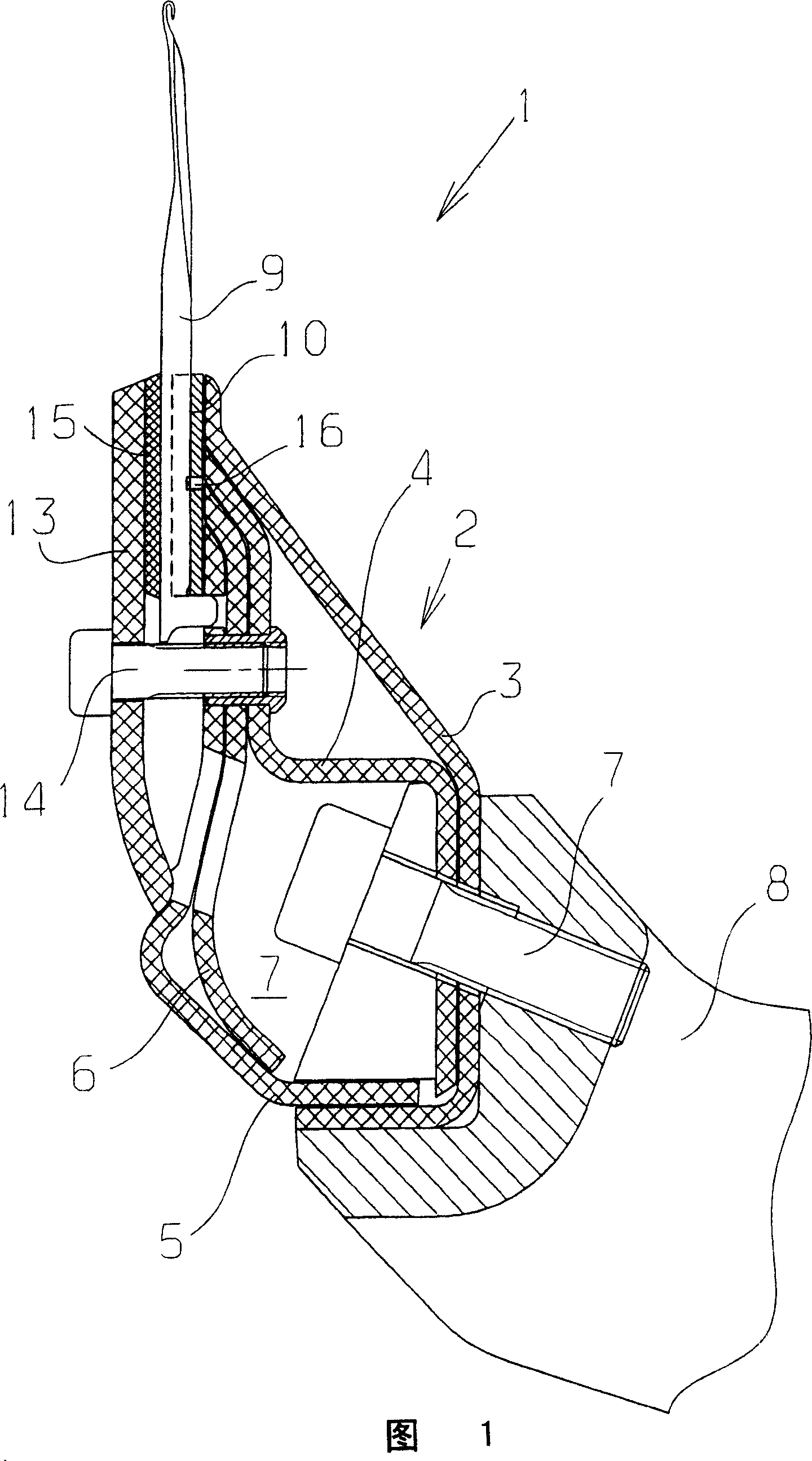

[0034] FIG. 1 shows a hub 1 with a carrier 2 . The support has several profiles 3 , 4 , 5 , 6 . The profiles are connected to one another and surround a cavity 7 . The profiles 3-6 are made of a plastic, in particular a carbon fiber reinforced plastic (CFK). Each profile 3-6 is open and can be made by extrusion.

[0035] The support 2 is fixed on a drive rod 8 of the knitting machine by means of a screw 7 .

[0036] The needle holder 1 supports a plurality of knitting needles 9, of which only one is visible, since the knitting needles 9 are arranged one behind the other perpendicular to the plane of the drawing.

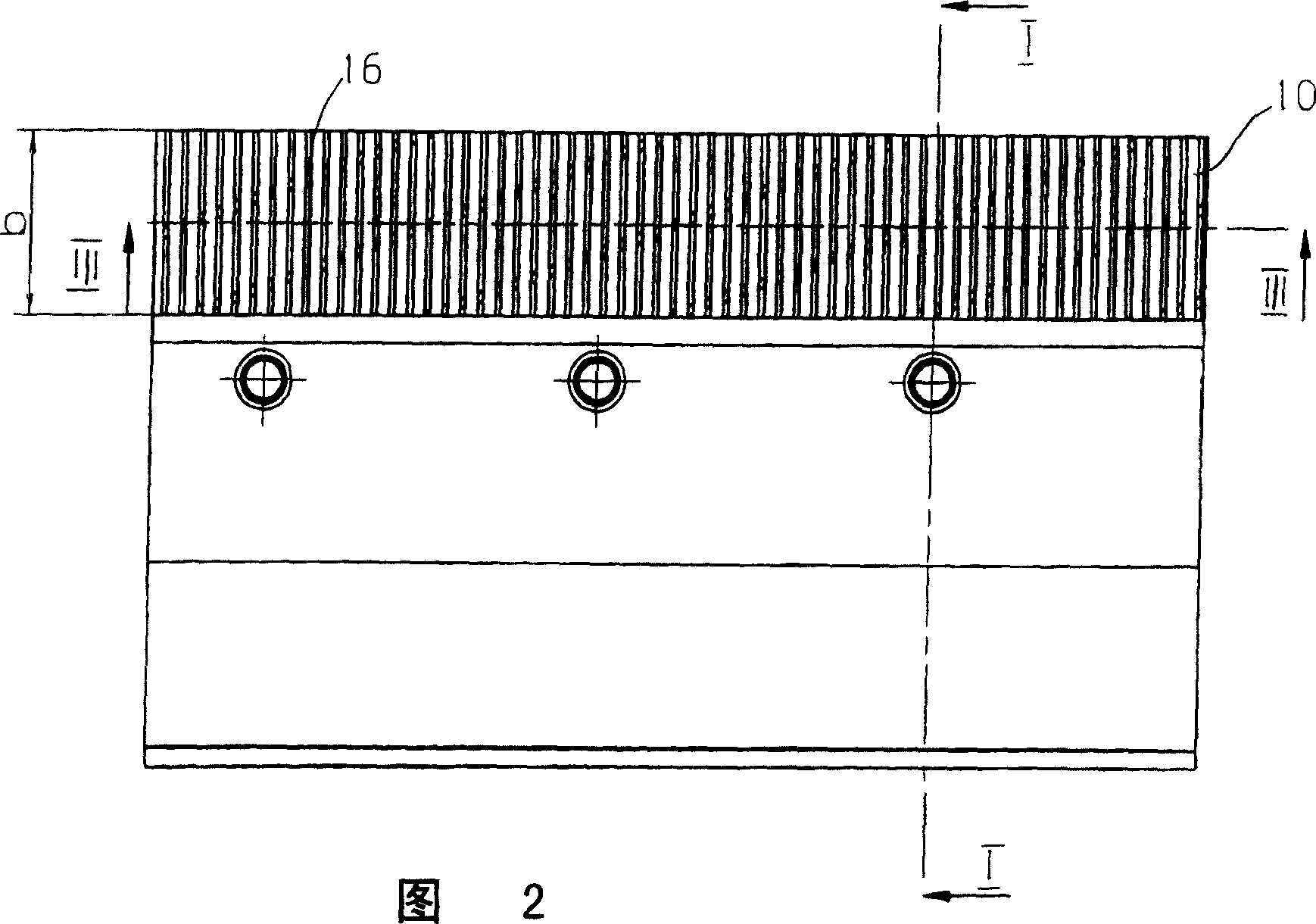

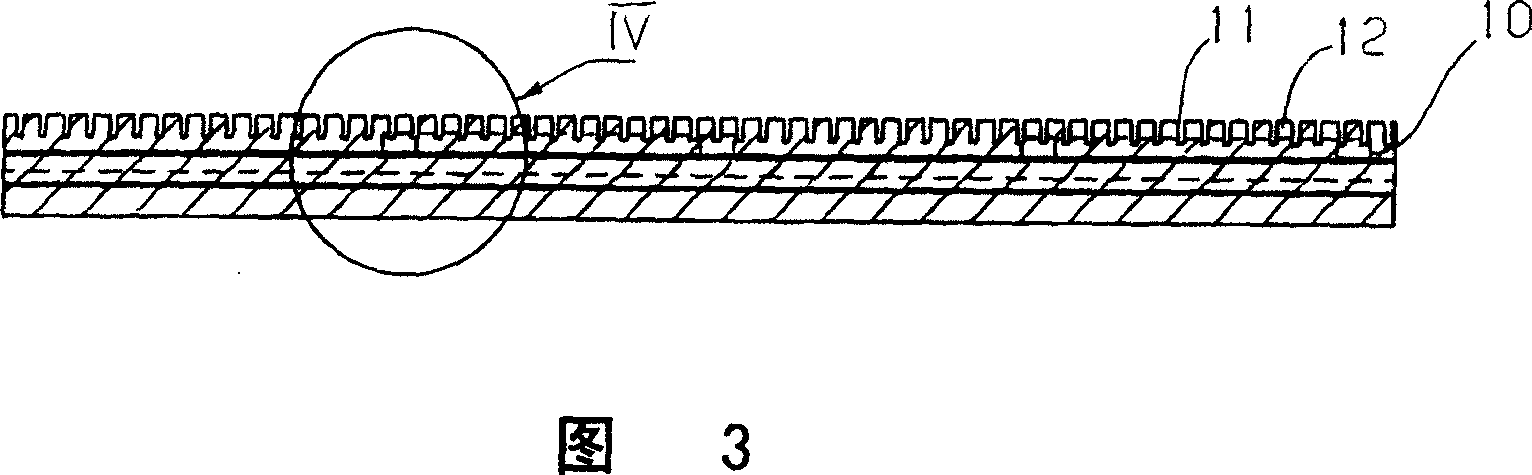

[0037] In this case, the knitting needles 9 are not fastened directly to the support 2 , but are arranged in an auxiliary part 10 which has a plurality of needle grooves 11 which are separated from one another by webs 12 . Each needle groove 11 is used to accommodate a knitting needle 9 . The auxiliary part bears against the support 2 with a fastening surface 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com