Single-point mooring system suitable for hull type floating nuclear-powered plant

A single-point mooring and nuclear power plant technology, applied in the field of floating nuclear power plants, can solve the problems of increased engineering volume of peripheral breakwaters, increased total project cost, inconvenient promotion and application, etc., and achieve the effect of easy popularization and application, easy realization, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

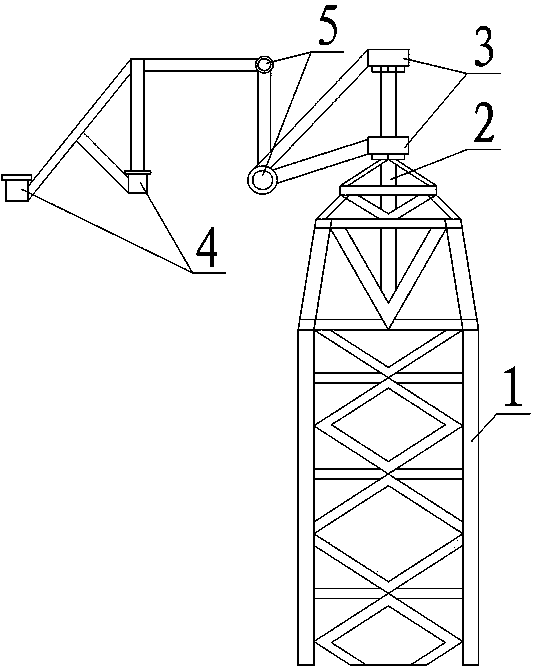

[0025] like figure 1 As shown, the single point mooring system suitable for hull-type floating nuclear power plants includes pile foundation 1, positioning column 2, rotating platform 3, positioning seat 4 and the connection mechanism connecting rotating platform 3 and positioning seat 4, wherein, in order to ensure that the pile To improve the structural strength of the foundation 1 and reduce the cost, the pile foundation 1 of this embodiment adopts steel pipe and concrete structure. The lower end of the pile foundation 1 is fixed on the seabed, the positioning column 2 is fixed on the pile foundation 1 and is located above the sea level, the rotary table 3 is arranged on the positioning column 2 and can rotate around the center line of the positioning column 2, the positioning seat 4 A common steel connecting seat is used, which is fixed on the hull of the floating nuclear power plant. In the specific setting of this embodiment, limit blocks fixed on the positioning column...

Embodiment 2

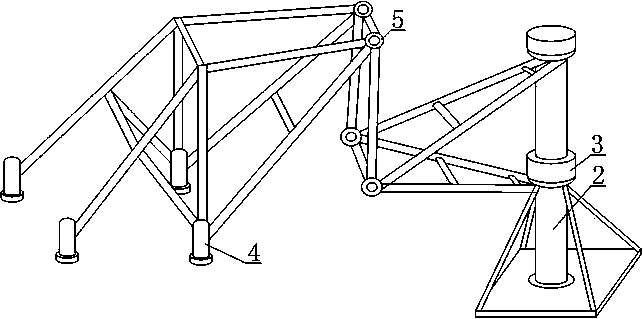

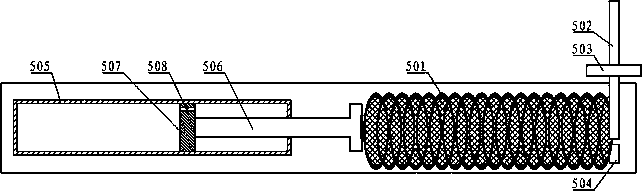

[0028] This embodiment makes the following further limitations on the basis of Embodiment 1: the connection mechanism of this embodiment includes a positioning seat connecting piece connected to the positioning seat 4, a rotating table connecting piece connected to the rotating table 3, and a connecting positioning seat The shock-absorbing damping device 5 of the connecting piece and the rotating table connecting piece, in order to ensure the structural strength of both the positioning seat connecting piece and the rotating table connecting piece, both the positioning seat connecting piece and the rotating table connecting piece are constructed of steel pipes.

[0029] When this embodiment is applied, the shock absorbing and damping device 5 can quickly attenuate the up and down, front and back, and left and right shaking of the floating nuclear power plant, which can further improve the stability of the floating nuclear power plant.

Embodiment 3

[0031]This embodiment makes the following further limitations on the basis of Embodiment 2: this embodiment also includes a vertical positioning frame. In order to ensure the structural strength of the positioning frame, the positioning frame adopts a steel pipe structure, wherein the upper and lower parts of the positioning frame are constructed of steel pipes. Both ends are fixed with shock-absorbing and damping devices 5 , the positioning seat connecting piece is connected with the shock-absorbing and damping device 5 fixed on the upper end of the positioning frame, and the rotary table connecting piece is connected with the shock-absorbing and damping device 5 fixed at the lower end of the positioning frame. In this way, when the present embodiment is applied, the shock absorption performance can be further improved through two-stage shock absorption, so that the floating nuclear power plant can quickly maintain stability when subjected to a load.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com