Laser level meter

A laser level and leveling technology, which is applied in the field of laser level, can solve the problems of reduced adjustment stability, lower precision, and increased adjustment time, and achieve the effects of improved adjustment stability and accuracy, fast adjustment, and reduced adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

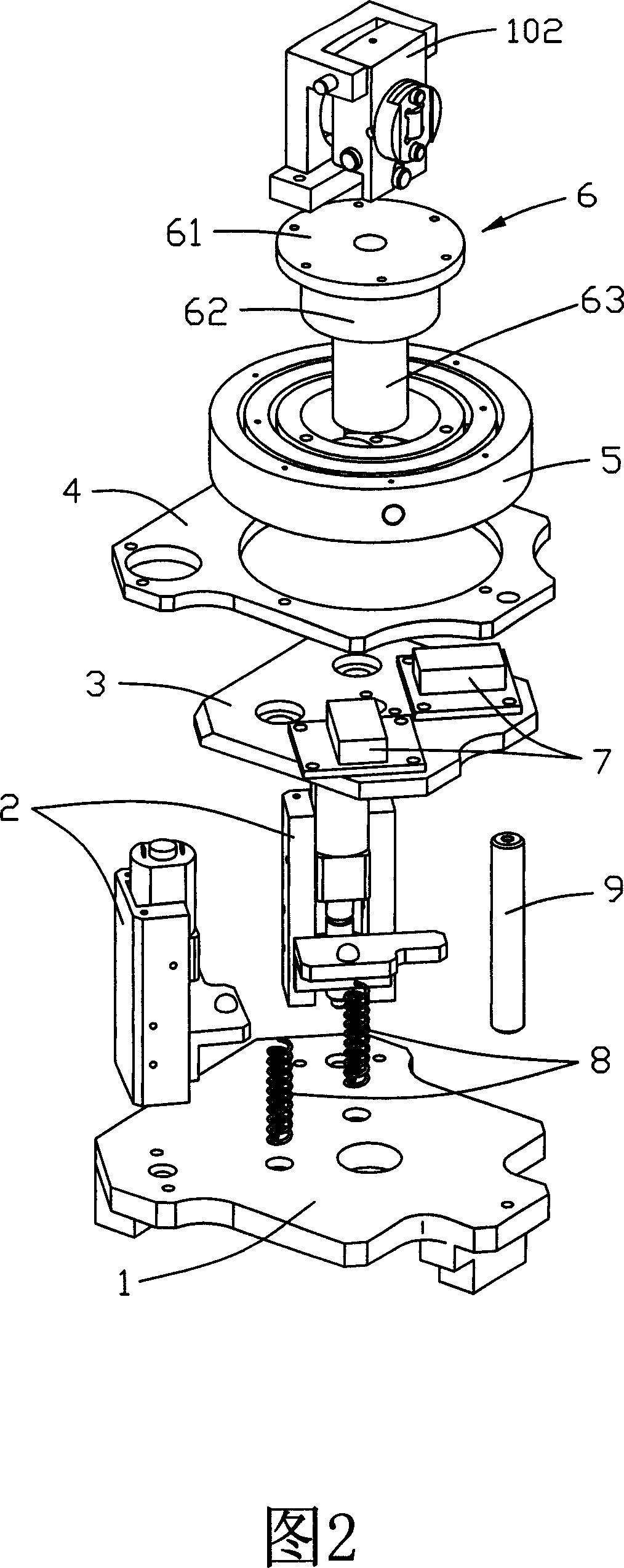

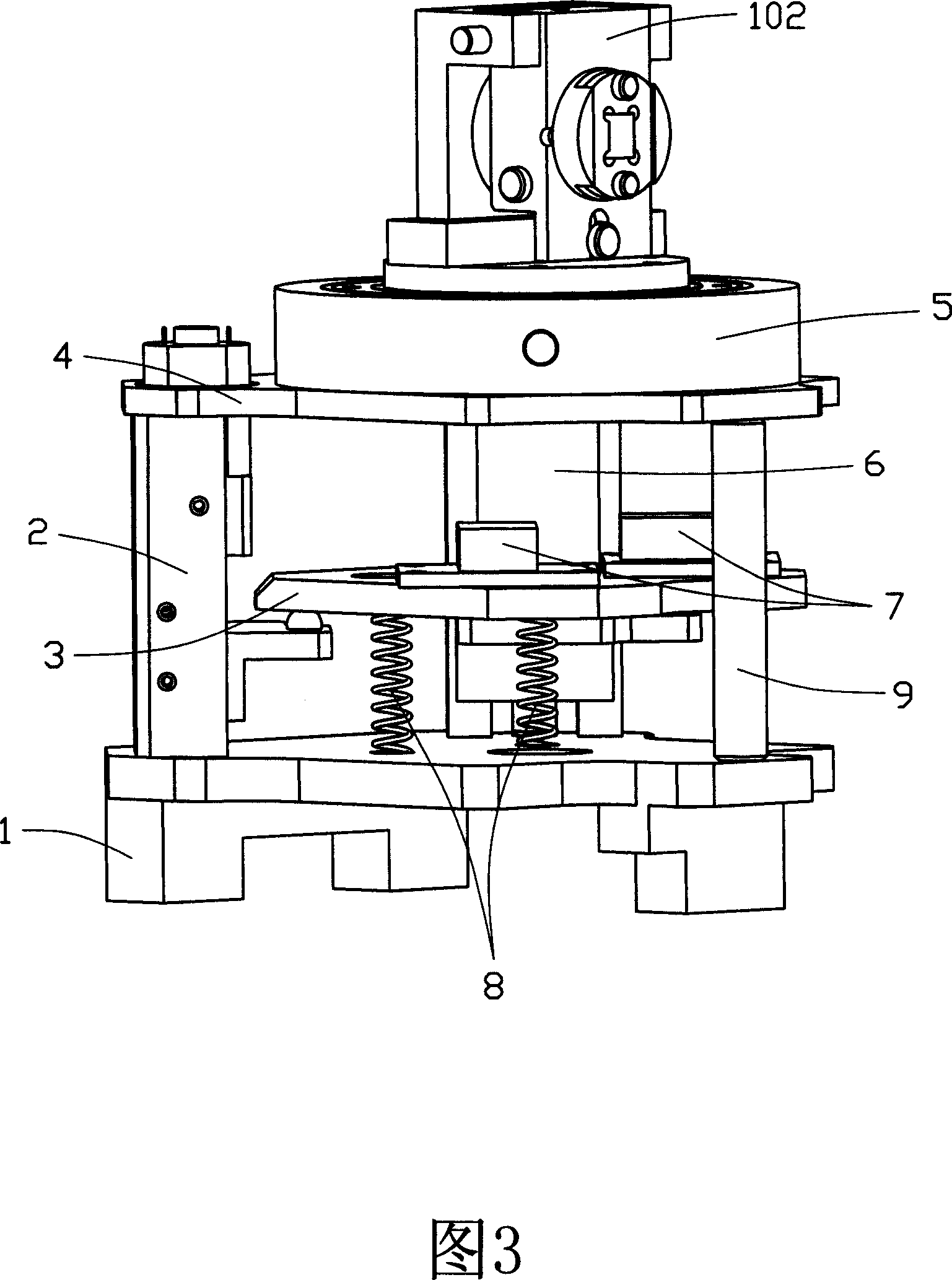

[0019] The detailed description and technical content of the plane adjustment mechanism of the level meter of the present invention are now described as follows in conjunction with the accompanying drawings:

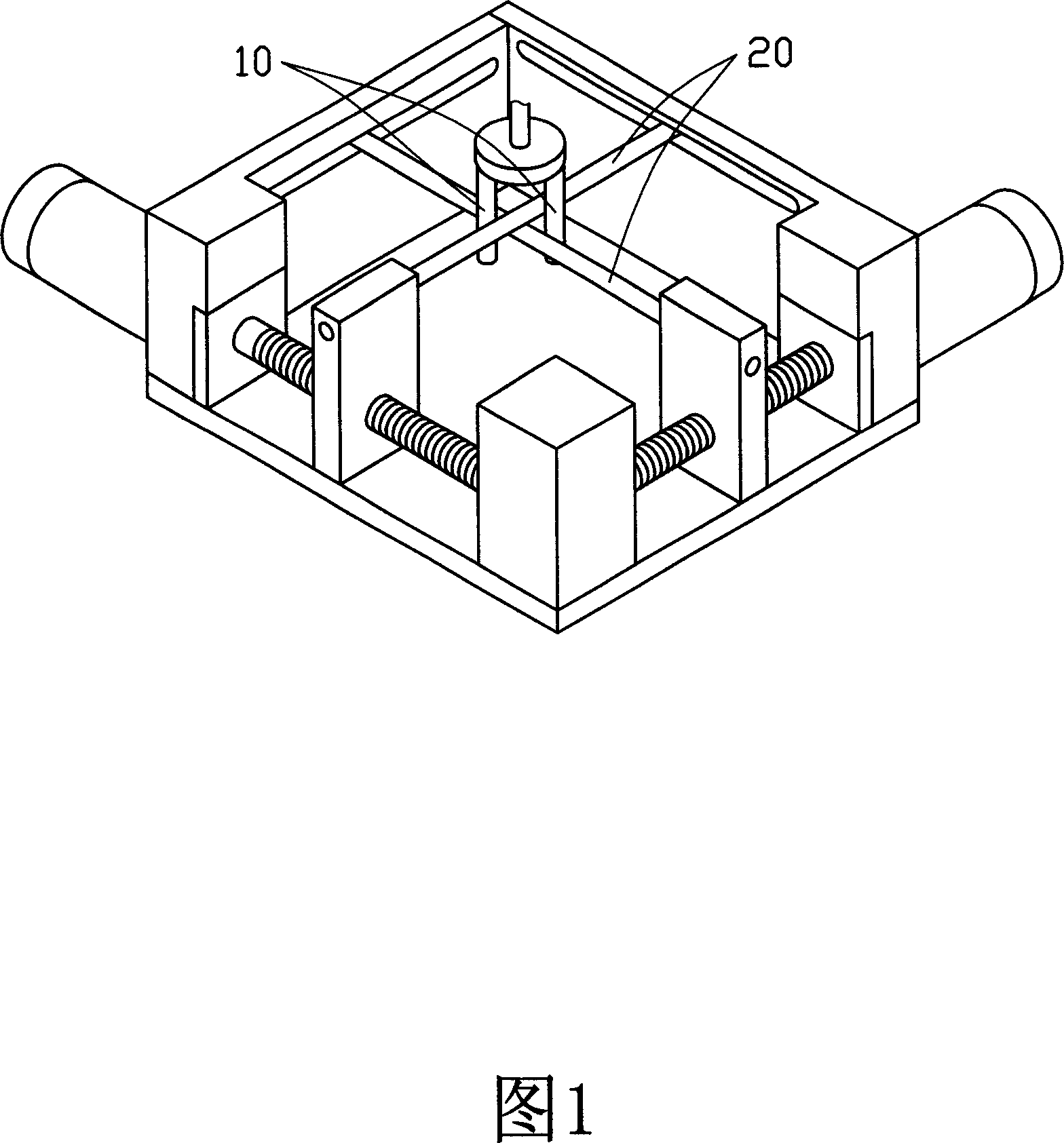

[0020] Please refer to FIG. 2 , the laser level 100 of the present invention includes a level adjustment mechanism 101 and a laser device 102 mounted on the level adjustment mechanism 101 .

[0021] The level adjustment mechanism 101 of the laser level 100 of the present invention includes a support base 1 , a motor module 2 , a spring 8 , a support column 9 , a level plate 3 , a level sensing module 7 , a bracket 4 , a cross rotating ring 5 and a connecting column 6 .

[0022] Please continue to refer to FIG. 2 , the connecting column 6 includes a cylindrical adjusting column 61 and a circular plate-shaped adjusting plate 62 perpendicular to the adjusting column 61 .

[0023] Please refer to shown in Fig. 4, motor module 2 comprises the column 21 of groove shape, is pro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap