Substrate test gear

A substrate inspection and substrate technology, which is used in measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of increasing the distance between the inspected substrate and the backlight, unable to obtain the observed brightness, and backlight lighting scattering, etc., to achieve high efficiency The effect of visual inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

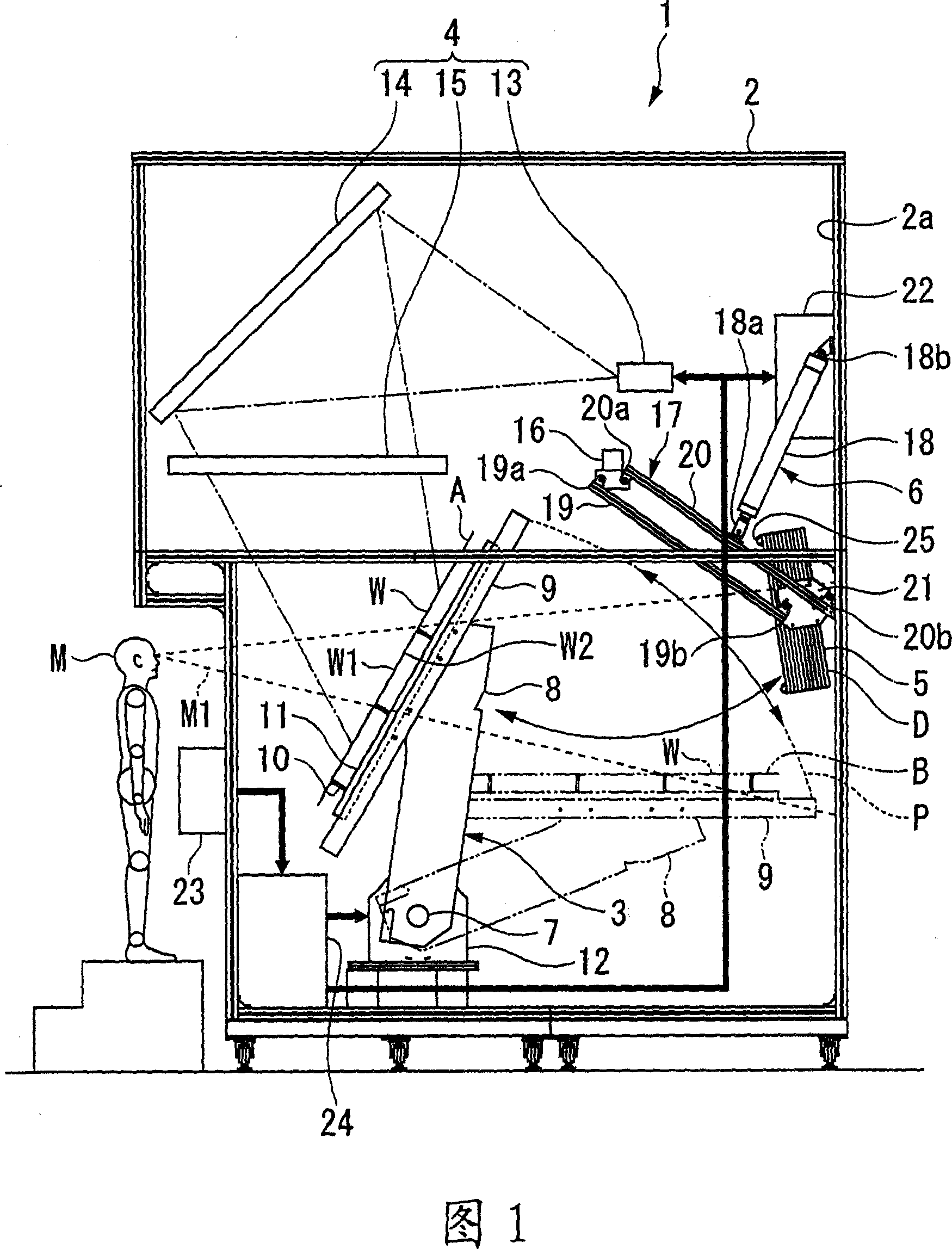

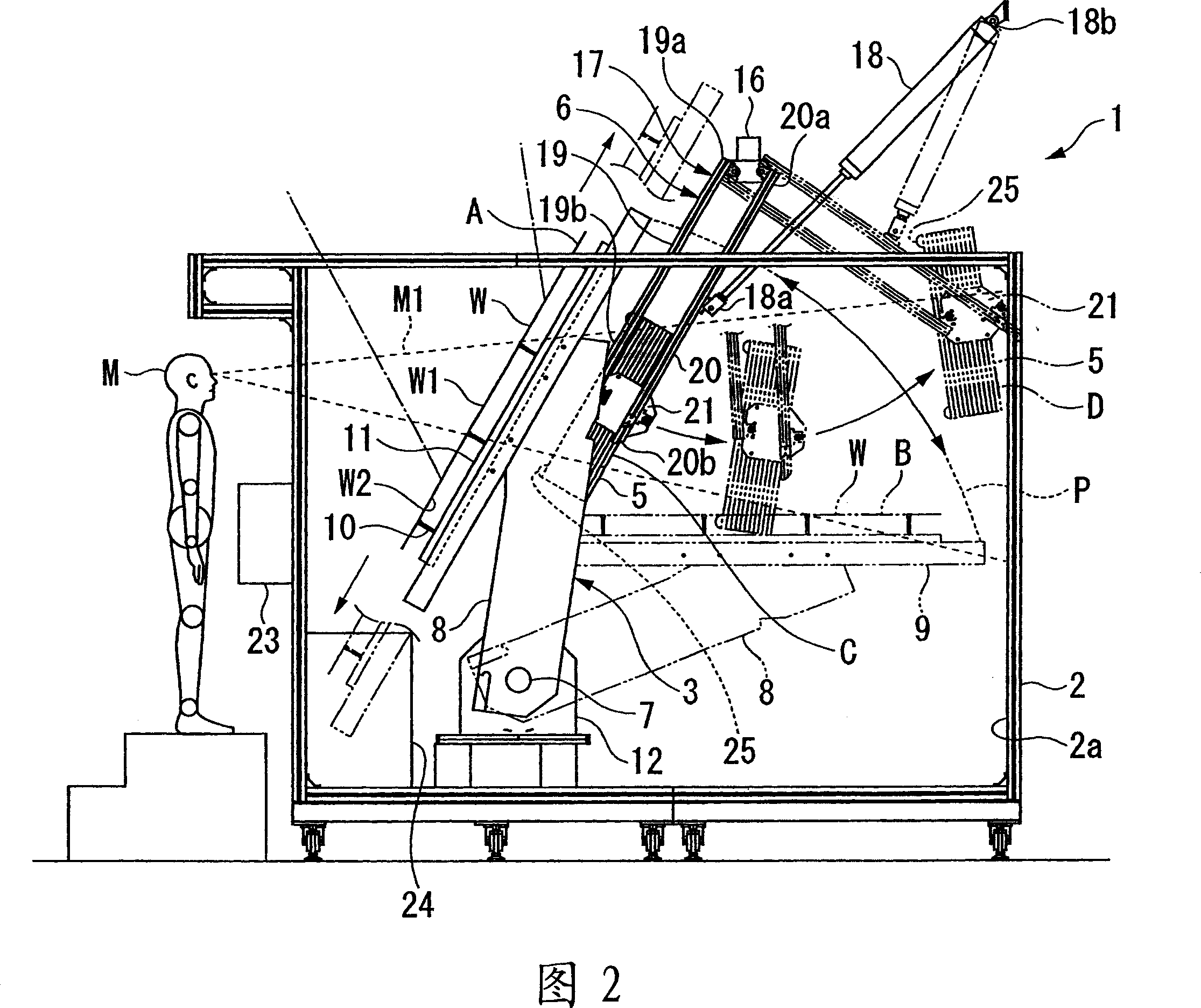

[0040] 1 and 2 show a first embodiment of the present invention. FIG. 1 shows an overall view of a substrate inspection device, and FIG. 2 shows an enlarged side view.

[0041] As shown in FIG. 1 , the substrate inspection apparatus 1 has: a housing 2 that forms an outer contour; a holder rotating mechanism 3 that rotates a substrate holder 11 holding a substrate W to be inspected; an epi-illumination unit 4 that illuminates the substrate W to be inspected. The surface W1 on which the pattern is formed is epi-illuminated; the backlight 5 illuminates the back surface W2 opposite to the surface W1 of the substrate W to be inspected; and the moving unit 6 of the backlight 5 . The inner wall surface 2a of the housing 2 is black so that light will not be diffusely reflected. In addition, the stand rotation mechanism 3 has: a turn shaft 7 provided at the turn center; a pair of turn arms 8 rotatably supported on the turn shaft 7 at base end portions of the arms; a pair of stand guid...

no. 2 Embodiment approach

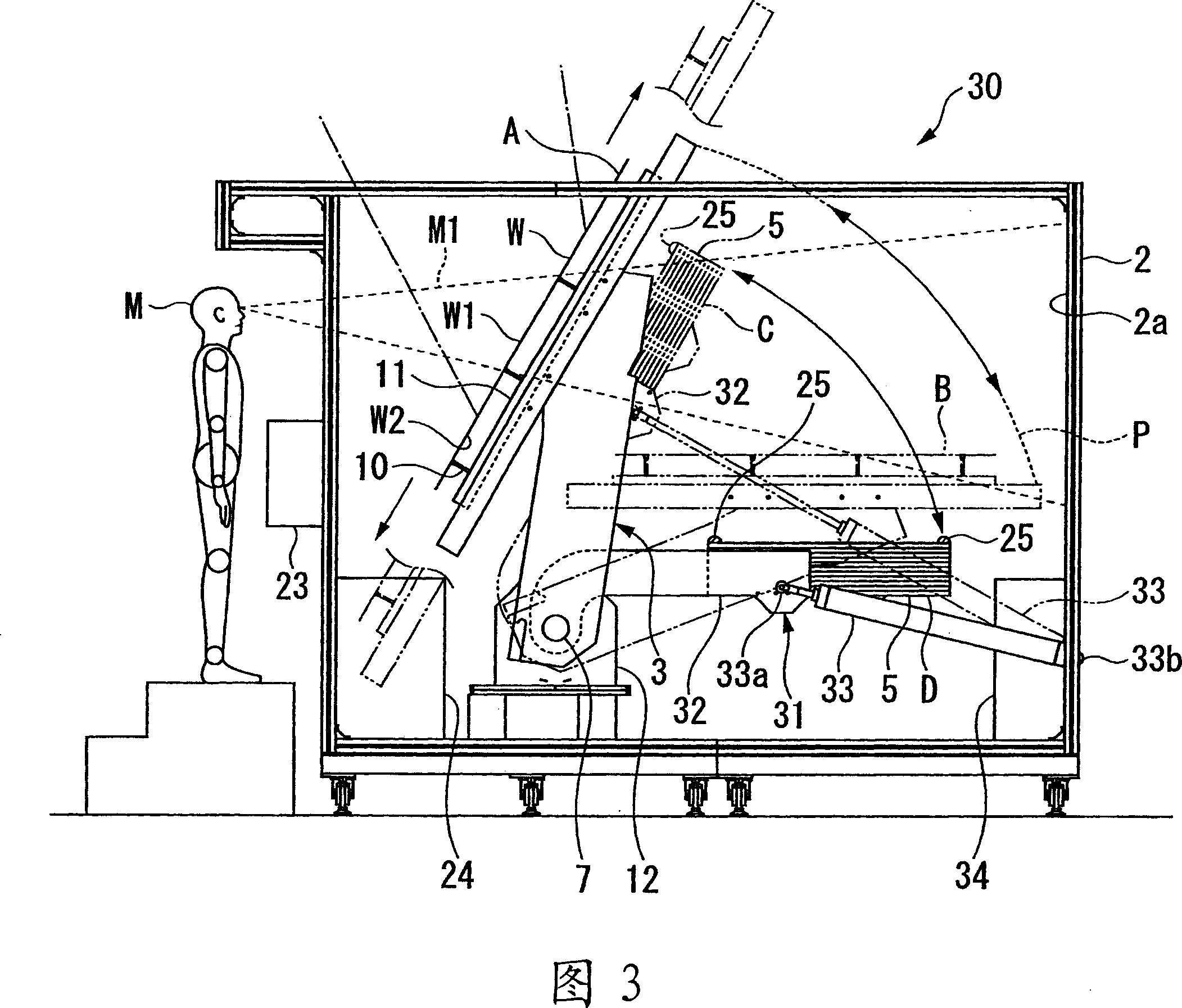

[0052] Fig. 3 shows a second embodiment of the present invention, and shows an enlarged side view of a substrate inspection device. In this embodiment, the same reference numerals are assigned to the same components as those used in the above-mentioned embodiment, and description thereof will be omitted.

[0053] As shown in FIG. 3 , in the substrate inspection apparatus 30 of this embodiment, the moving unit 31 that moves the backlight 5 is composed of a rotating arm 32 that is rotatably supported at the base end by a pair of rotating arms 8 . On the shaft that is coaxial with the rotating shaft 7; the actuator 33 rotates the rotating arm 32. The backlight 5 is fixed to the tip of the swivel arm 32 , and the backlight 5 is rotatable from a retracted position D below the substrate delivery position B of the holder guide 9 to an irradiation position C. As shown in FIG. In addition, one end 33a of the actuator 33 is connected to the rotating arm 32 with a pin, and the other end...

no. 3 Embodiment approach

[0056] Fig. 4 shows a third embodiment of the present invention, and shows an enlarged side view of a substrate inspection device. In this embodiment, the same reference numerals are assigned to the same components as those used in the above-mentioned embodiment, and description thereof will be omitted.

[0057] As shown in FIG. 4 , in the substrate inspection apparatus 40 of this embodiment, the moving unit 41 that moves the backlight 5 is composed of a rotating arm 42 that is rotatably supported at the base end of the frame rotating mechanism 3 . Above the swivel area P; the electric motor 43 which turns the swivel arm 42 . The backlight 5 is fixed to the front end portion of the rotating arm 42 and is set so as to be parallel to the substrate W to be inspected when located at the irradiation position C. As shown in FIG. In addition, the turning arm 42 can move the backlight 5 out of the turning area P of the stand turning mechanism 3 , and move to the retracted position D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com