Seal

A stamp and seal technology, applied in the field of stamps, can solve the problems of uneven stamp surface, uneven stamp image, unrecognized date, etc., and achieve a good effect of stamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

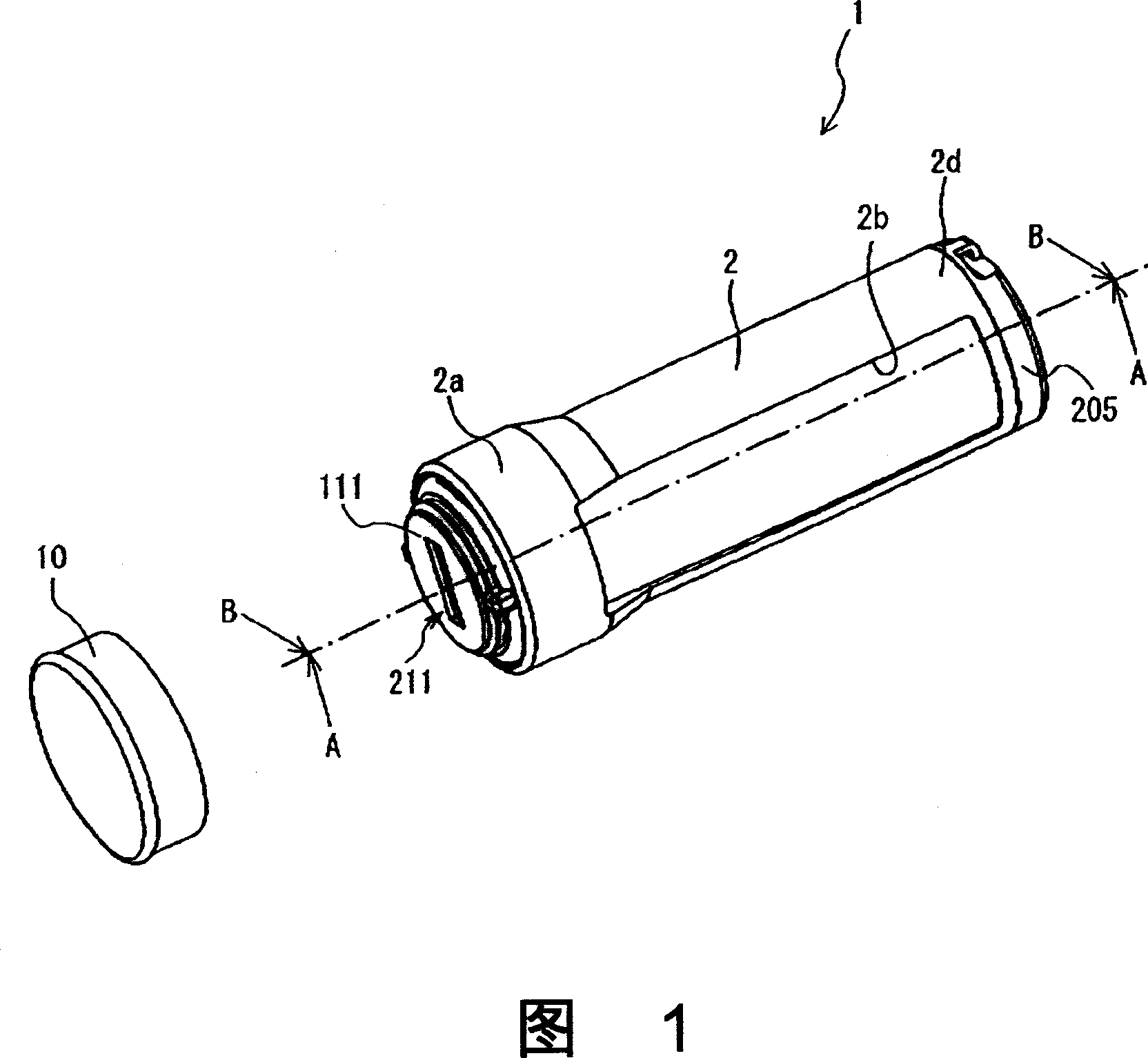

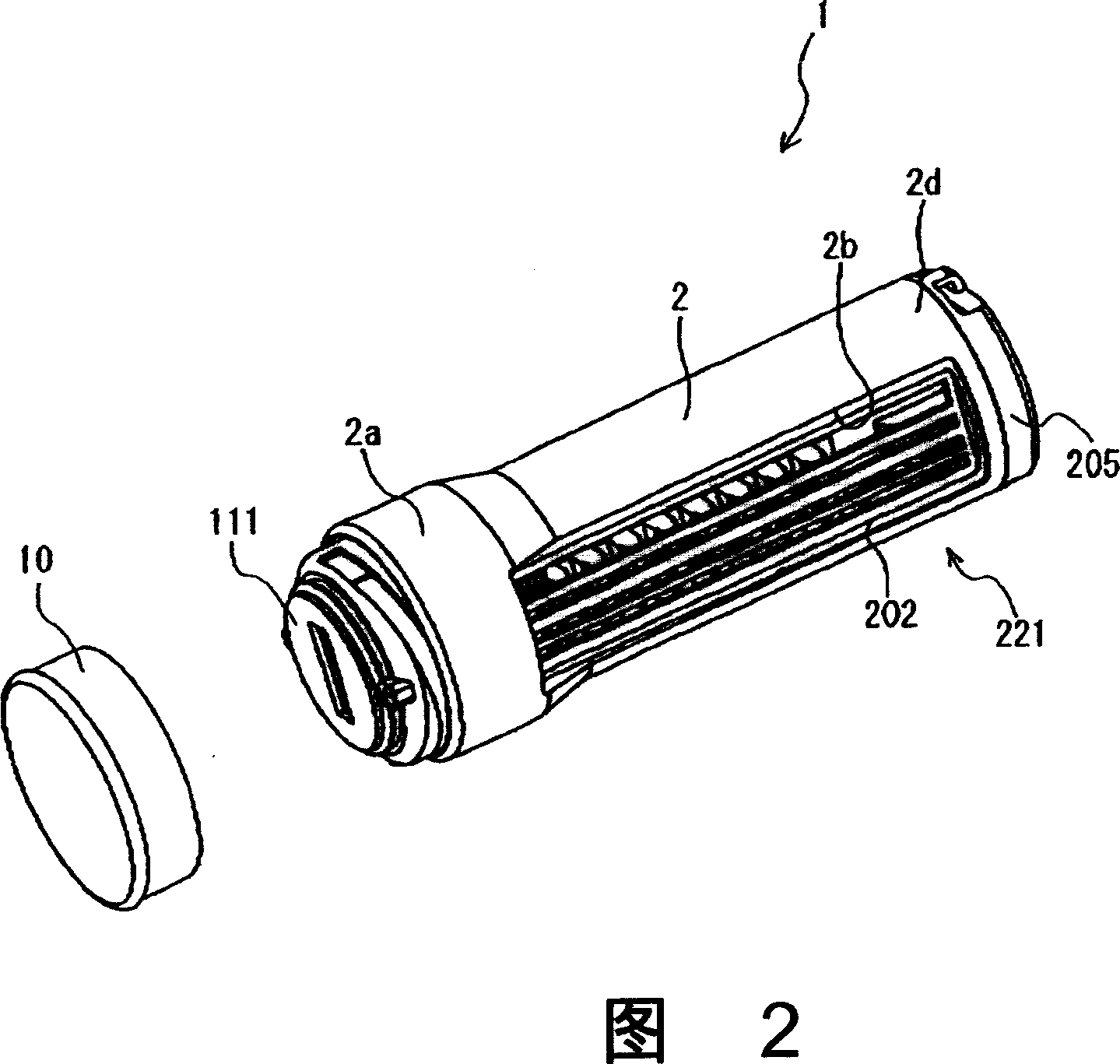

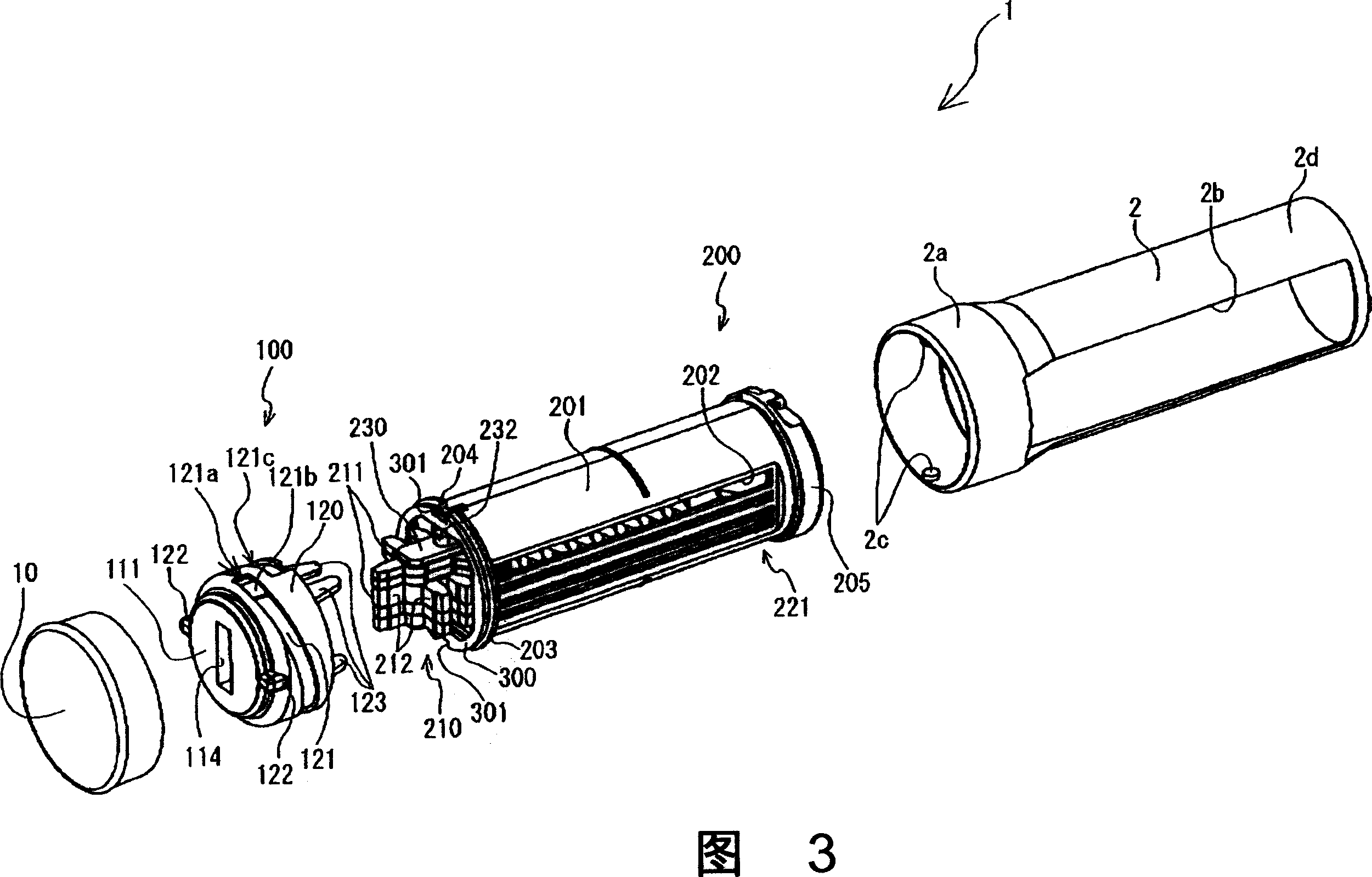

[0043] Next, an embodiment of the stamp of the present invention will be described with respect to a date stamp 1 . First, a first embodiment will be described with reference to FIGS. 1-6. FIG. 1 is a perspective view of a date stamp 1 in a state where stamping is permitted. Fig. 2 is a perspective view of the date stamp 1 in a state allowing its stamp face 211 to be changed. FIG. 3 is a disassembled perspective view of the date stamp 1 . FIG. 4 is a perspective view of a holding body 230 holding a movable stamp member 210 . FIG. 5 is a sectional view of the date stamp 1 viewed from the direction of arrow A with respect to the dotted line in FIG. 1 . Fig. 6 is a sectional view of the date stamp 1 when stamping.

[0044] As shown in FIGS. 1 and 2, the date stamp 1 has a substantially cylindrical main body case 2, and a cylindrical end portion 2a on one end of the main body case 2 has a hole made slightly larger than the body thereof. The cylindrical end portion 2a has a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com