Filtration membrane cleaning method and apparatus using this method

A filter membrane and equipment technology, applied in the field of filter membrane cleaning, can solve problems such as the need to improve efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

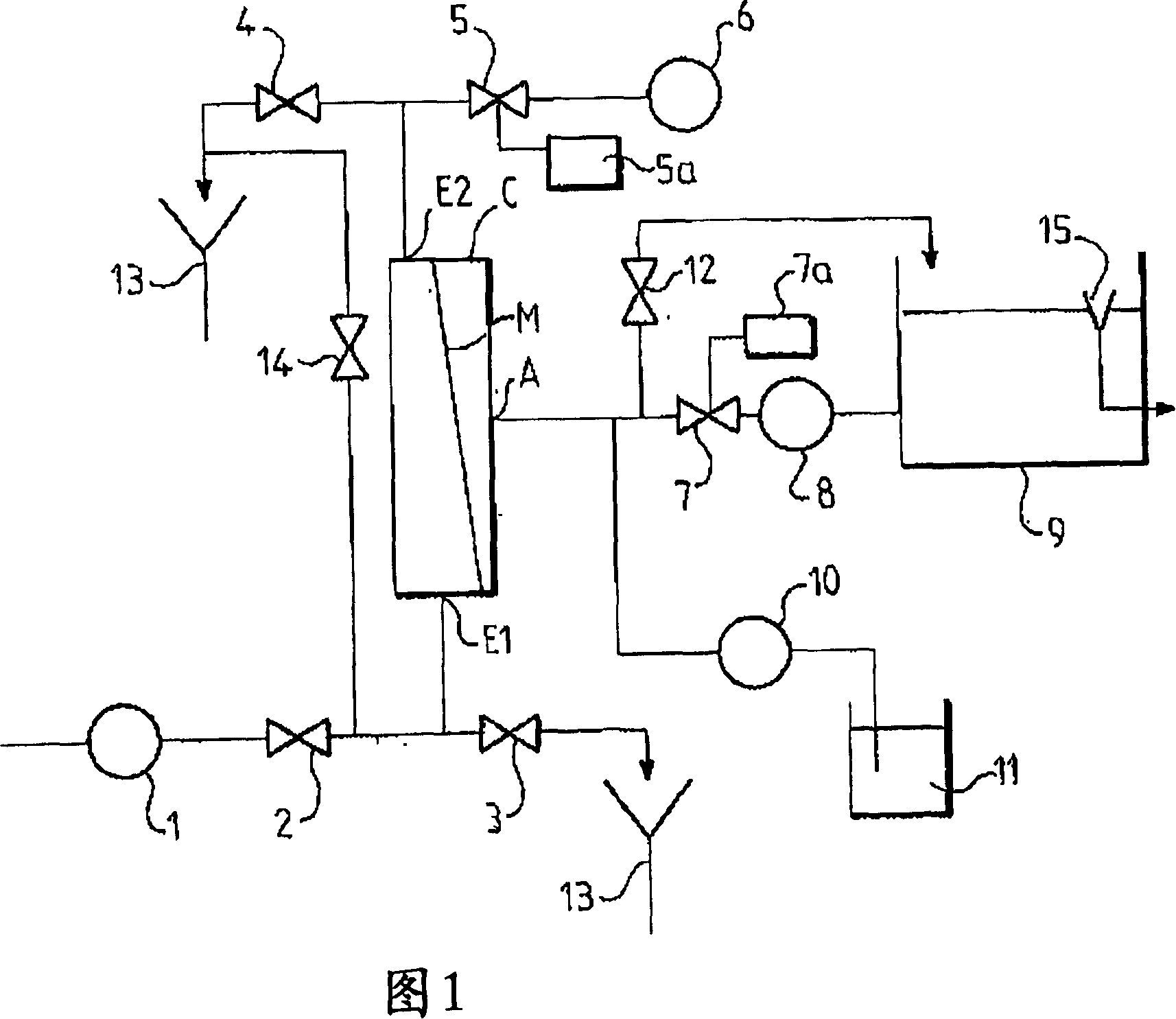

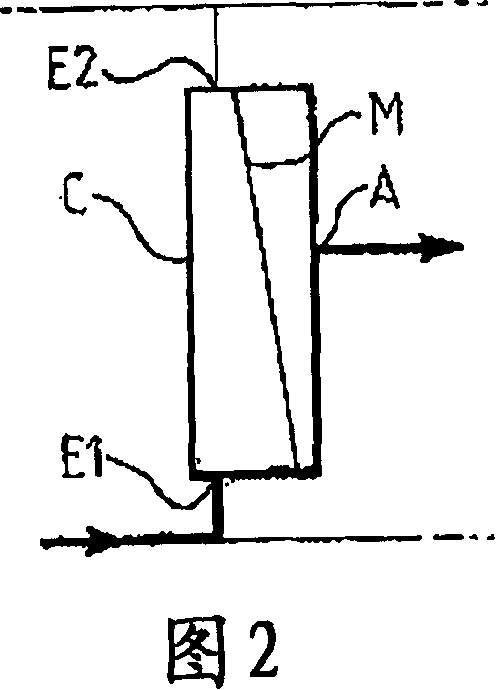

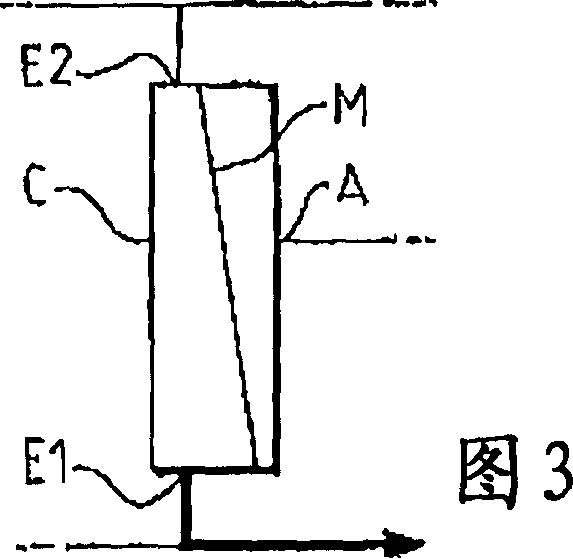

[0033] [33] The drawings, in particular FIG. 1 , show a device for deposit removal of filter membranes, ultrafiltration membranes, microfiltration membranes, ultrafiltration membranes or ultrafiltration membranes using the method according to the invention. The membrane module M shown in Fig. 1 has a tubular geometry and is used in a case C where a group of inner skin hollow fibers is arranged centrally. The box C is equipped with two holes E1, E2, which are respectively the lower hole and the upper hole, which can be used as outlet and / or inlet. The holes E1 , E2 are connected to a centralized compartment formed by the inner space of the hollow fibers. Inside the box, the space around and between the membranes forms the permeable compartment with a mid-position relative to the height of the module Exit A. In other embodiments, the outlet A may be axial relative to the diameter of the assembly.

[0034] [34] The membrane M is used for the filtration of liquids, usually wate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap