Fastening means of bolt and or nut screw

A technology for fastening devices and bolts, applied to screwdrivers, wrenches, manufacturing tools, etc., which can solve the problems of reduced durability, difficulty in replenishing coloring liquid, and backflow of coloring liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

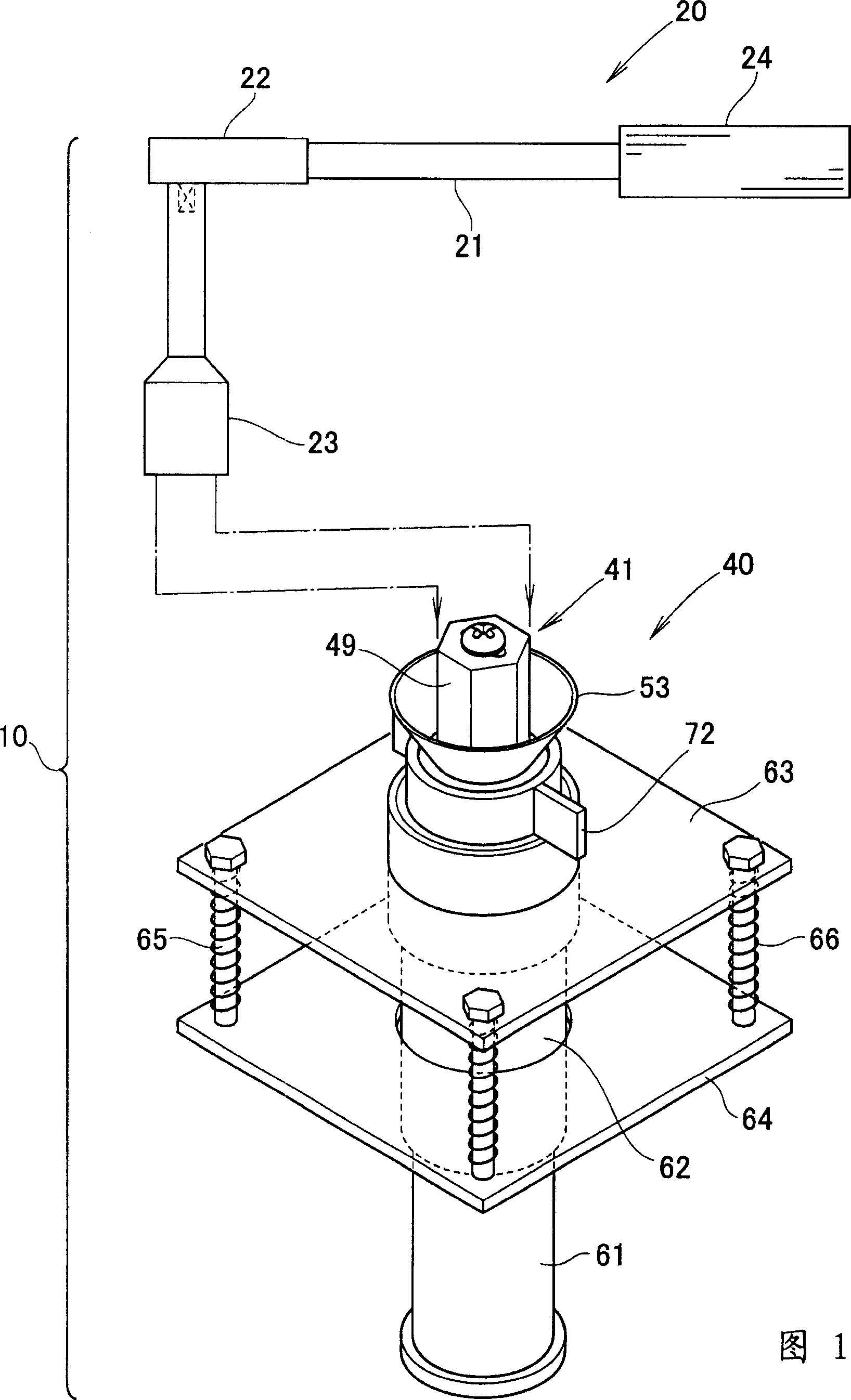

[0023] As shown in FIG. 1 , the bolt fastening device 10 is composed of a socket wrench 20 and a coloring solution supply mechanism 40 .

[0024] The socket wrench 20 is composed of a rod 21 , a torque meter 22 provided at one end of the rod 21 , a socket 23 provided on the torque meter 22 , and a handle 24 provided at the other end of the rod 21 . The coloring liquid supply mechanism 40 is provided with a valve mechanism 41 , and the sleeve 23 can be fitted into a hexagonal columnar liquid outlet pipe 49 provided on the valve mechanism 41 . That is, the discharge pipe 49 is formed in a shape similar to a head of a bolt or a nut.

[0025] The sleeve 23 and the coloring liquid supply mechanism 40 will be described in detail below.

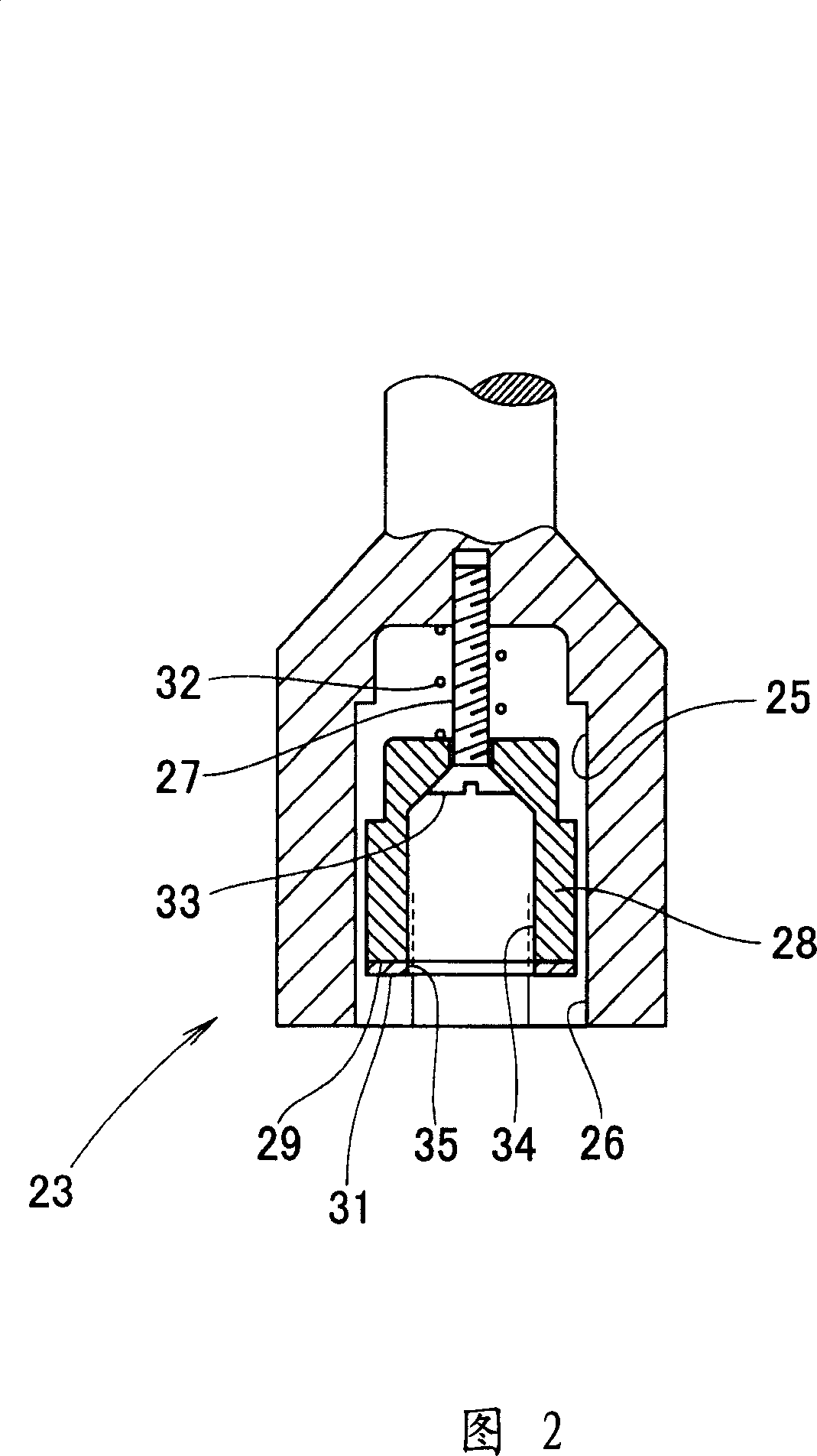

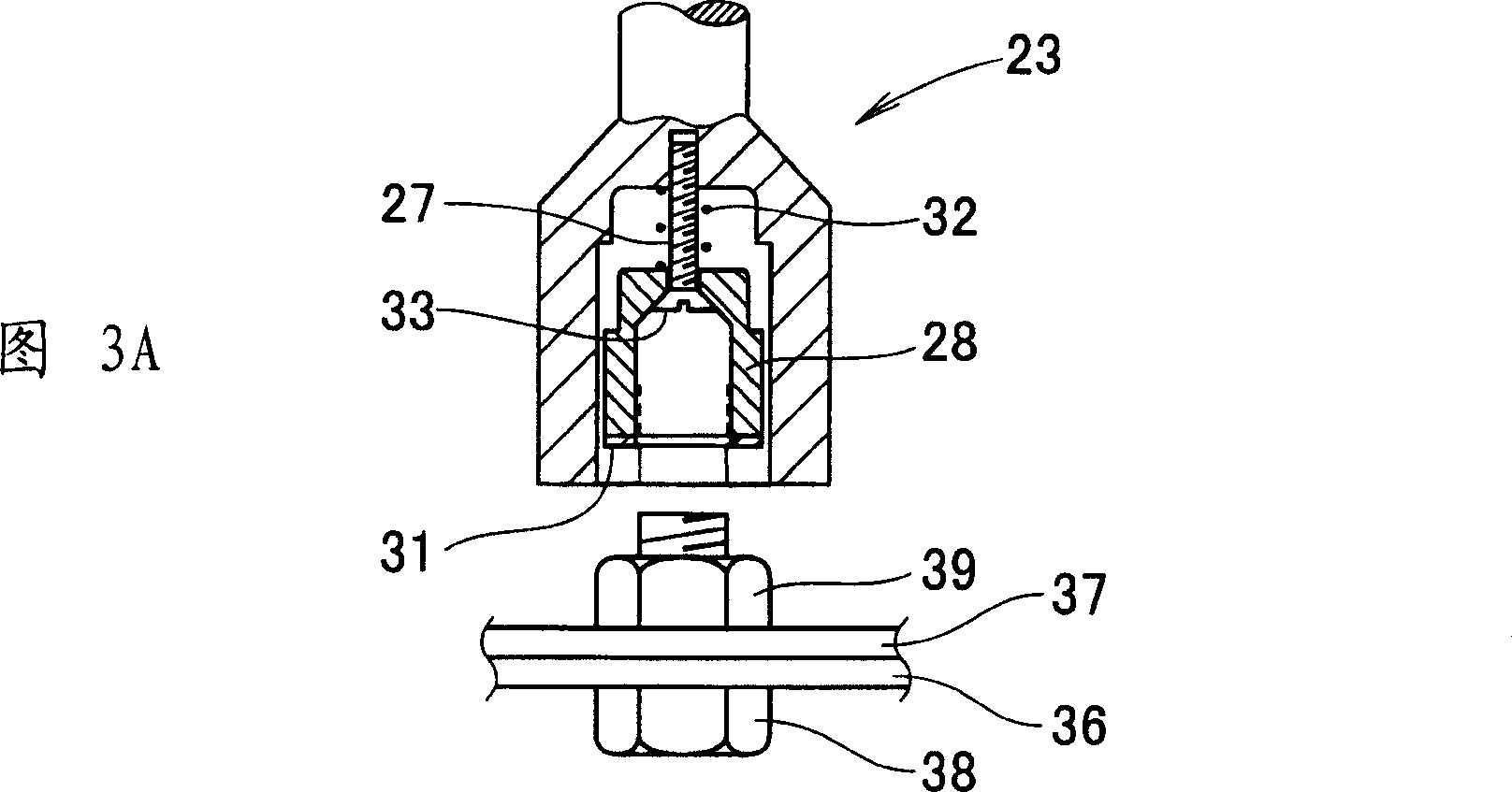

[0026] As shown in Figure 2, a large recess 25 is provided on the sleeve 23, and the inlet portion of the large recess 25 becomes the head of the bolt 38 (Figure 3A), the nut 39 (Figure 3A) or the outlet pipe 49 (Figure 1 ) into the fitting portio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap