Multi-cylinder rotary compressor

A technology of rotary compressor and compression mechanism, applied in the direction of elastic fluid rotary piston type/oscillating piston type pump combination, mechanical equipment, machine/engine, etc., which can solve the troublesome processing of eccentric rollers, poor assembly, and reliability and performance side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

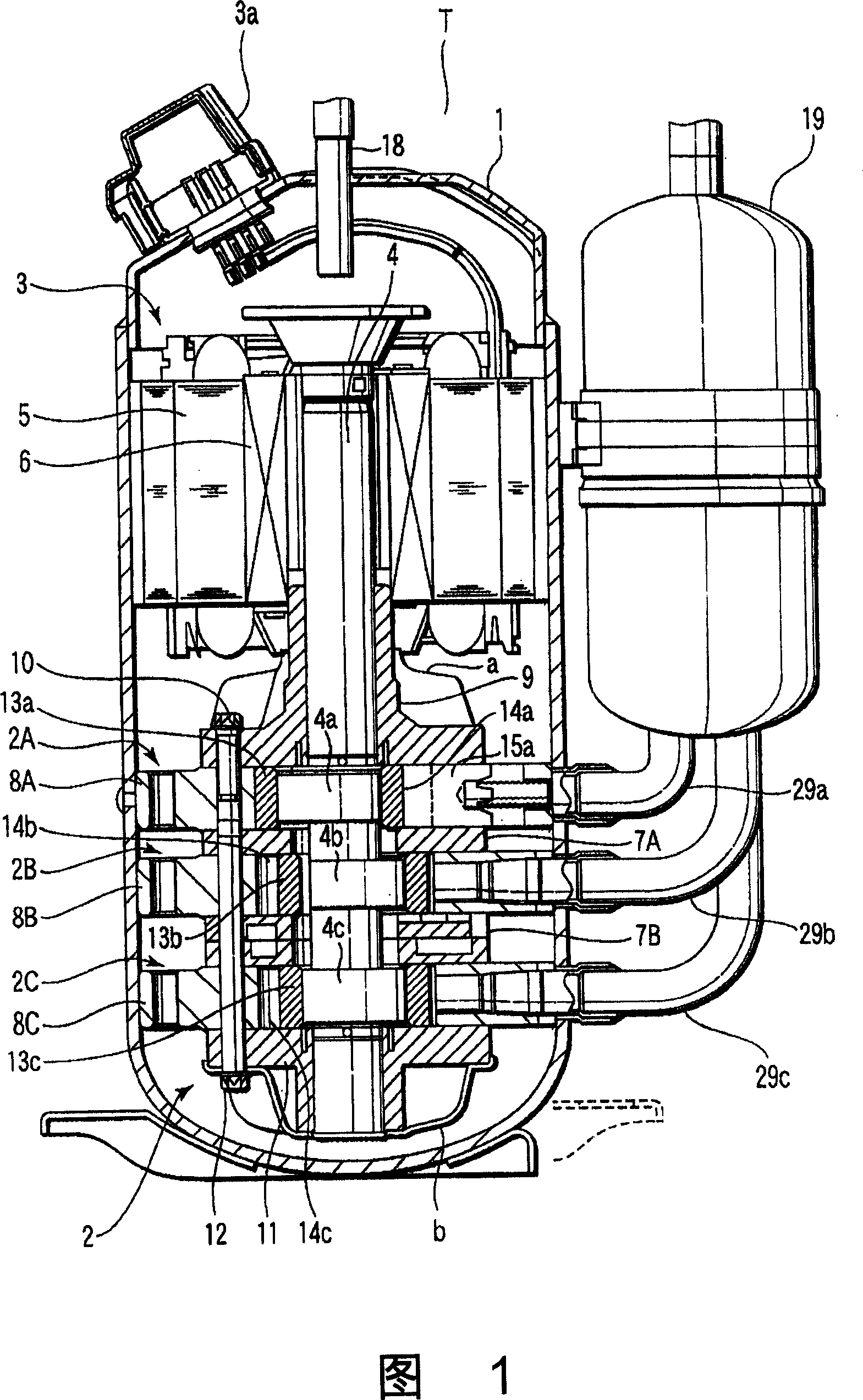

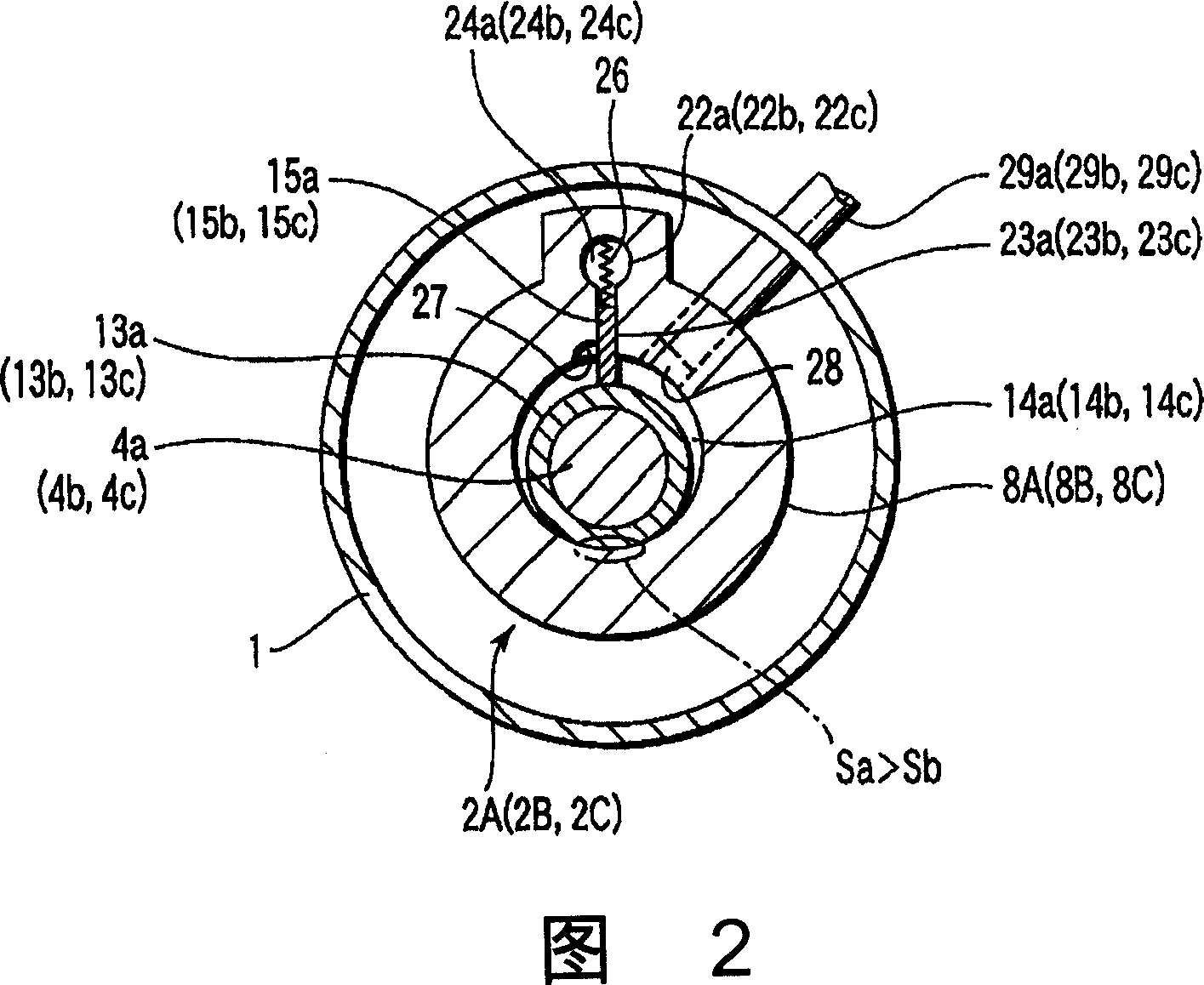

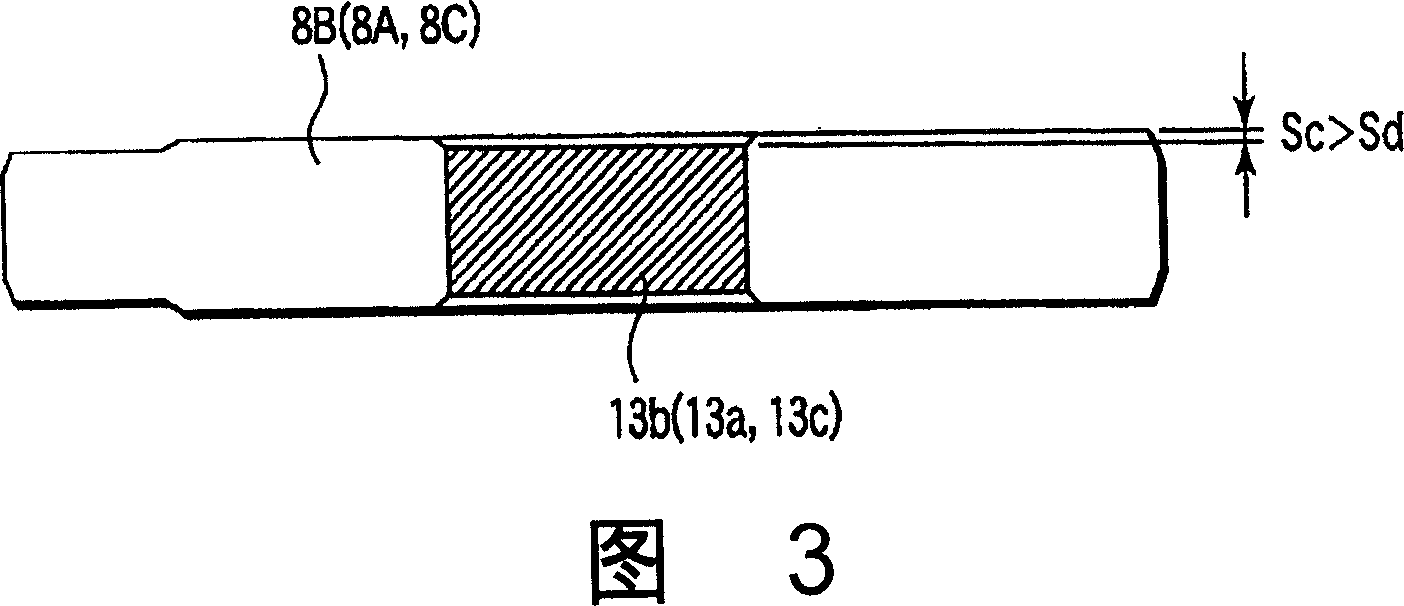

[0057] Next, one embodiment of the multi-cylinder rotary compressor of the present invention will be described with reference to the drawings. FIG. 1 is a longitudinal sectional view showing the internal structure of, for example, a multi-cylinder rotary compressor T constituting a refrigeration cycle of a refrigeration apparatus.

[0058] In Fig. 1, 1 is an airtight casing, and in the lower part of the airtight casing 1, a plurality of compression mechanism parts described later are provided, here by the first compression mechanism part 2A, the second compression mechanism part 2B and the third compression mechanism part. The compression mechanism assembly 2 constituted by the compression mechanism section 2C is provided with the motor section 3 on the upper portion of the compression mechanism assembly. These motor parts 3 and the first to third compression mechanism parts 2A to 2C constituting the compression mechanism assembly 2 are connected to each other by a rotary shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com