Multi-cylinder rotary compressor

A technology of rotary compressor and compression mechanism, applied in the direction of pump combination, mechanical equipment, machine/engine, etc. for elastic fluid rotary piston type/oscillating piston type, which can solve the trouble of eccentric roller processing, poor reliability and performance Influence, poor assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

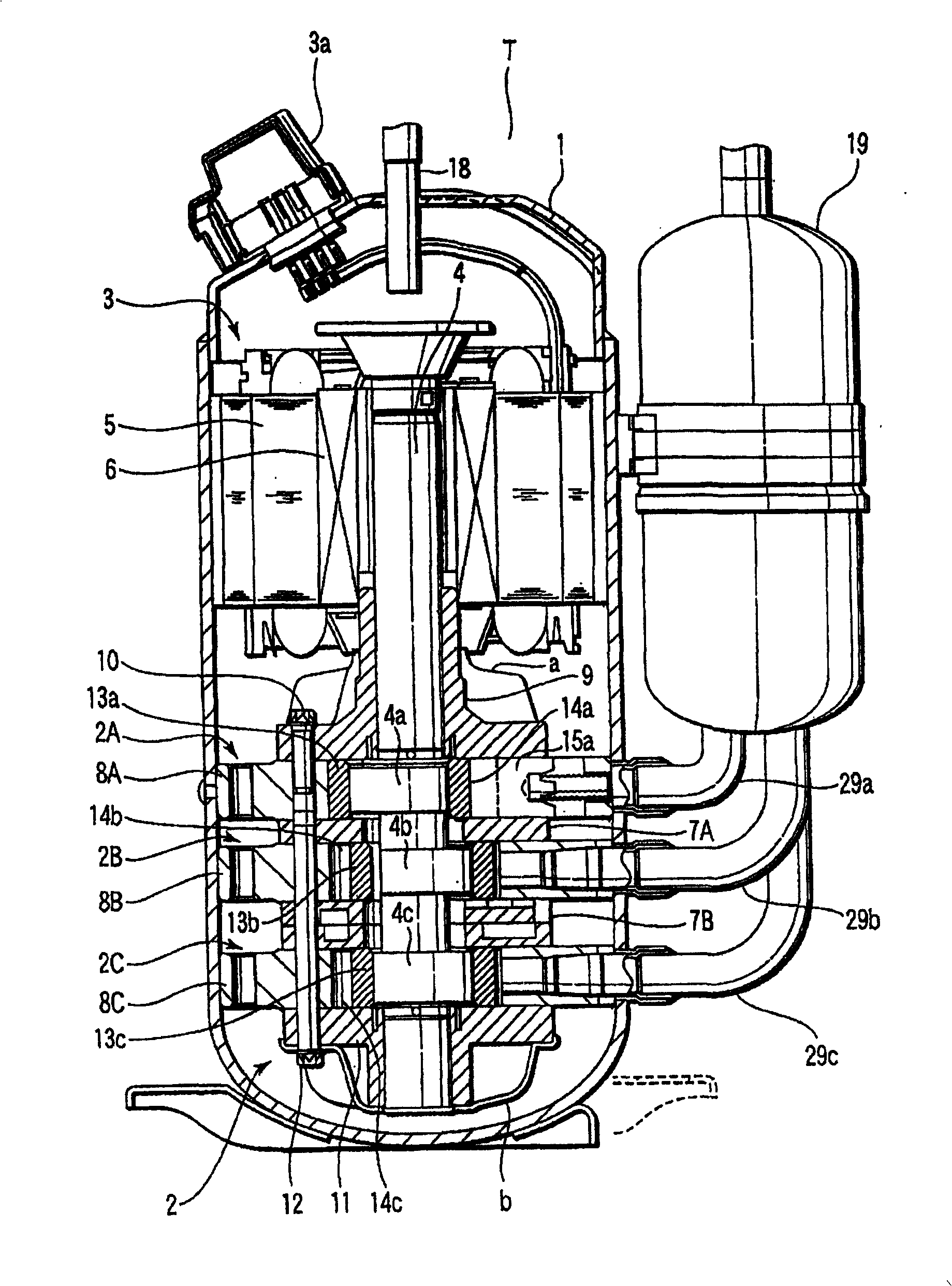

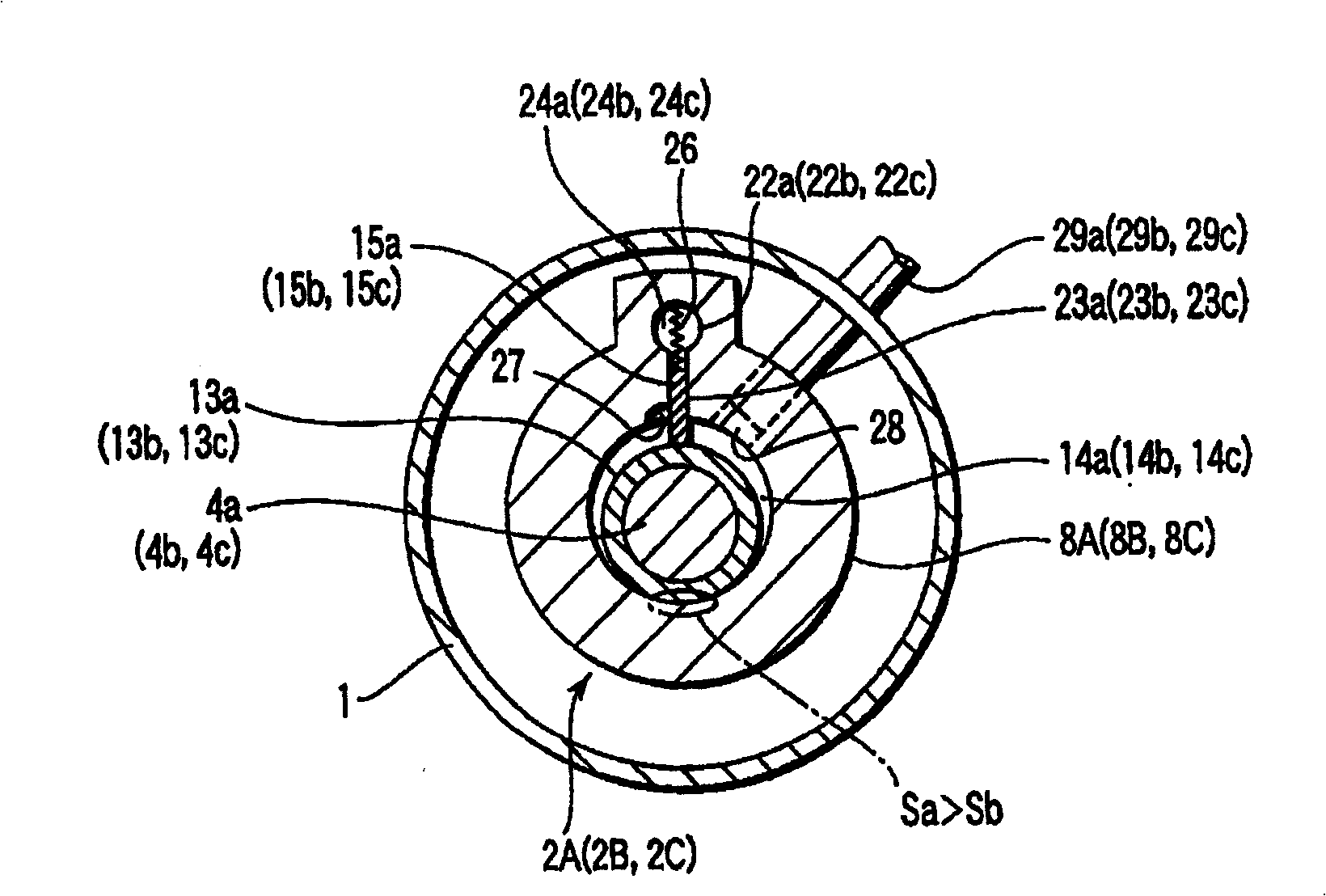

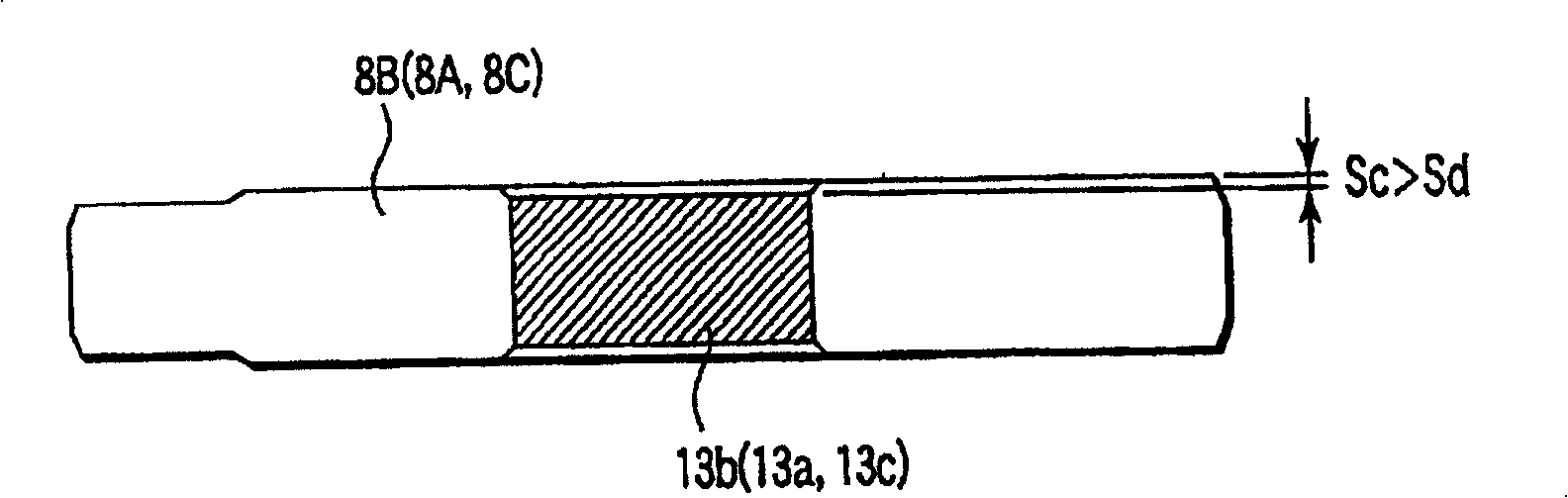

[0057] Next, one embodiment of the multi-cylinder rotary compressor of the present invention will be described with reference to the drawings. figure 1 It is a vertical cross-sectional view showing, for example, the internal structure of a multi-cylinder rotary compressor T constituting a refrigeration cycle of a refrigeration device.

[0058] figure 1 Among them, 1 is an airtight casing, and in the lower part of the airtight casing 1, a plurality of compression mechanism parts described later are provided, hereby the first compression mechanism part 2A, the second compression mechanism part 2B and the third compression mechanism Compression mechanism assembly 2 constituted by part 2C, motor part 3 is provided on the upper part of the compression mechanism assembly. These motor parts 3 and the first to third compression mechanism parts 2A to 2C constituting the compression mechanism assembly 2 are connected to each other by a rotary shaft 4 .

[0059] The motor unit 3 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com