Thread clip apparatus for sewing machine

A sewing thread and sewing machine technology, applied in the direction of sewing machine components, tension devices, sewing equipment, etc., can solve the problems of increasing parts, increasing production processes, increasing costs, etc., and achieve the effect of preventing the increase of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, specific embodiments of the thread clamping device of the sewing machine will be described in detail with reference to the drawings.

[0040]

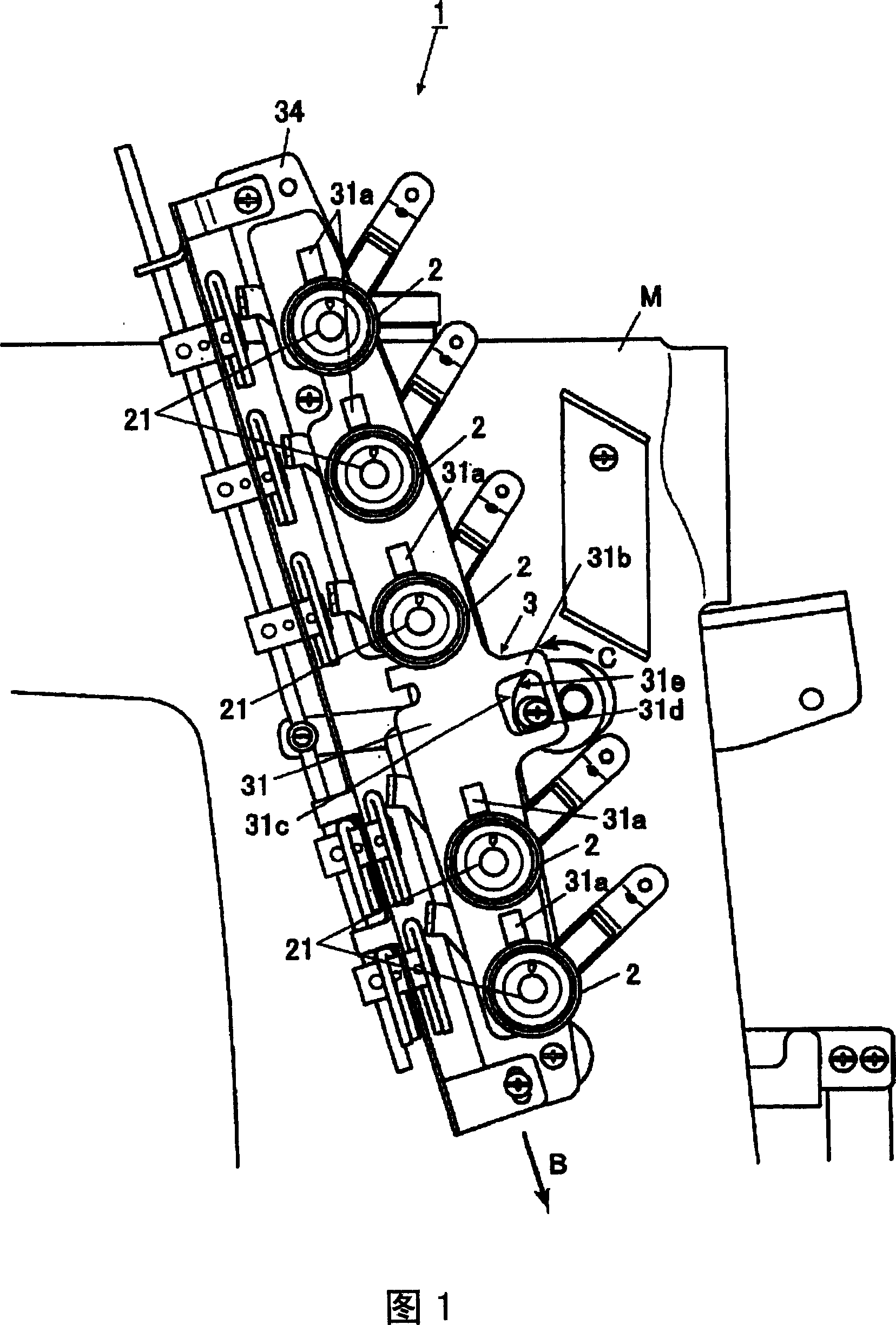

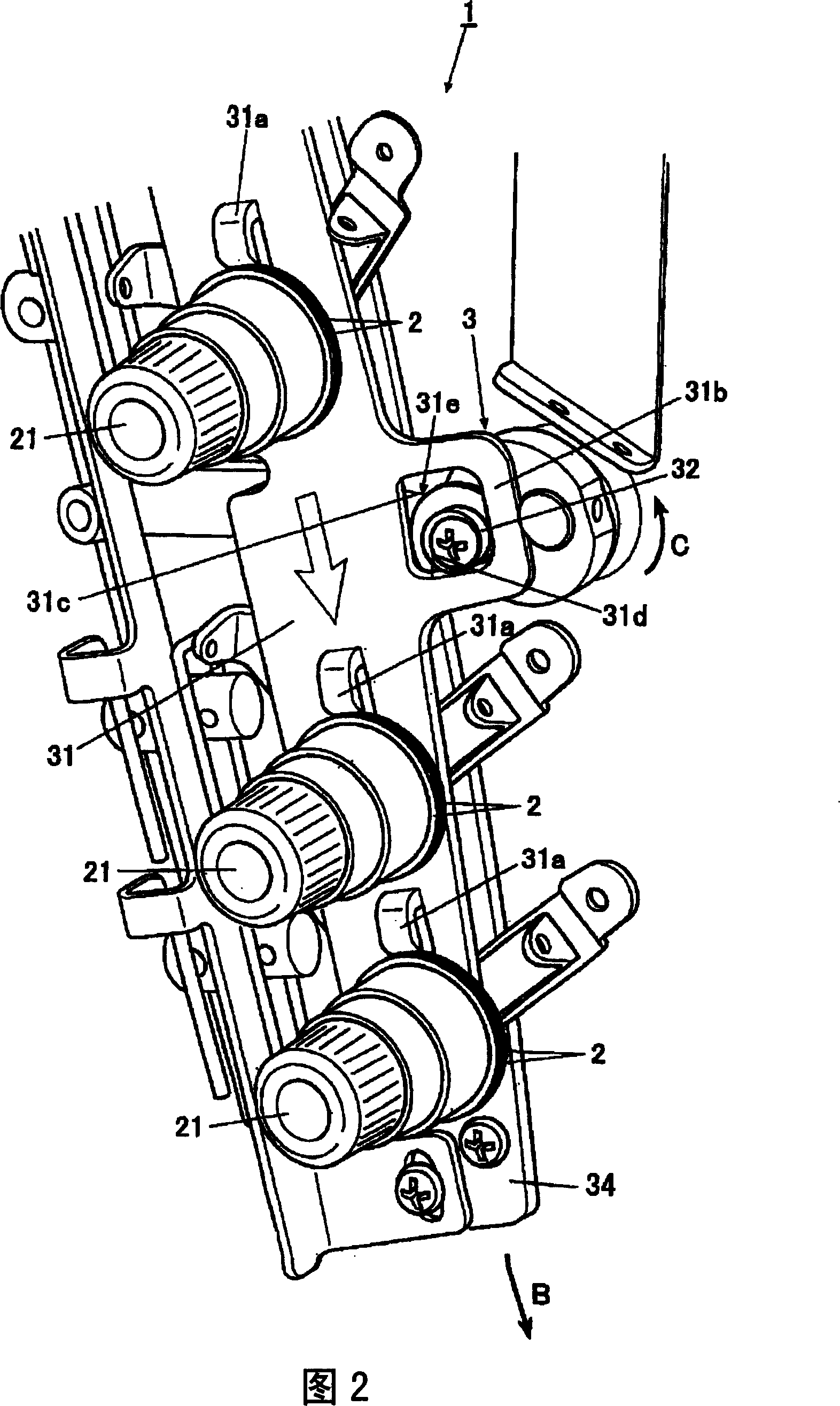

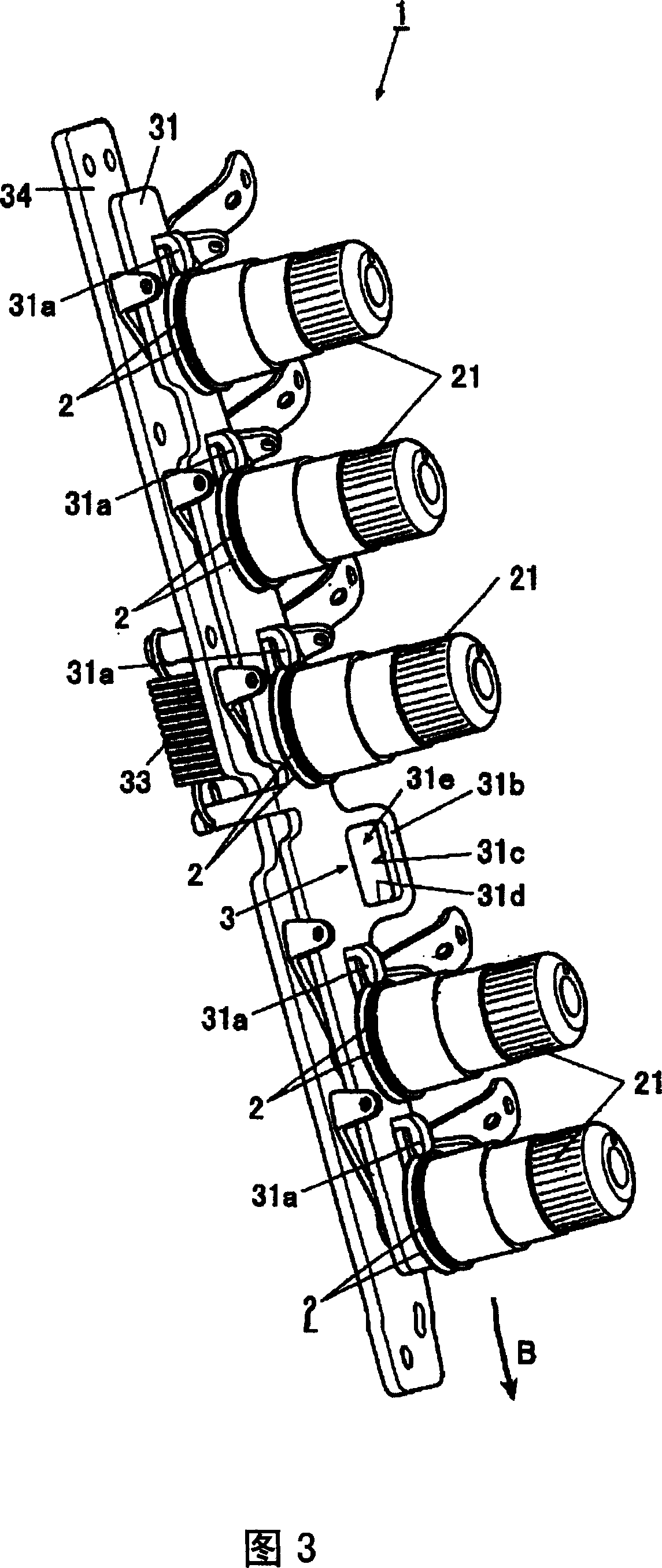

[0041] As shown in FIG. 1 , on the surface of the sewing machine frame M, the following thread clamping device 1 is provided: the tension is applied to the sewing thread inserted through the needle hole of the machine needle, and the operation of the thread cutting device (described later) that cuts the sewing thread is provided. Linked to release the tension applied to the sewing thread.

[0042] The thread clamping device 1 has: a pair of thread clamping plates 2 and 2 for sandwiching and holding the sewing thread; a tension release mechanism 3 which can be operated in conjunction with the action of the thread cutting device and can be operated independently of the action of the thread cutting device , Release the holding of the sewing thread by the pair of clamping plates 2 and 2 to release the tension given to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com