Method and apparatus for operating a fuel cell

A fuel cell, operating temperature technology, applied in the field of advanced equipment, can solve the problem of short battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

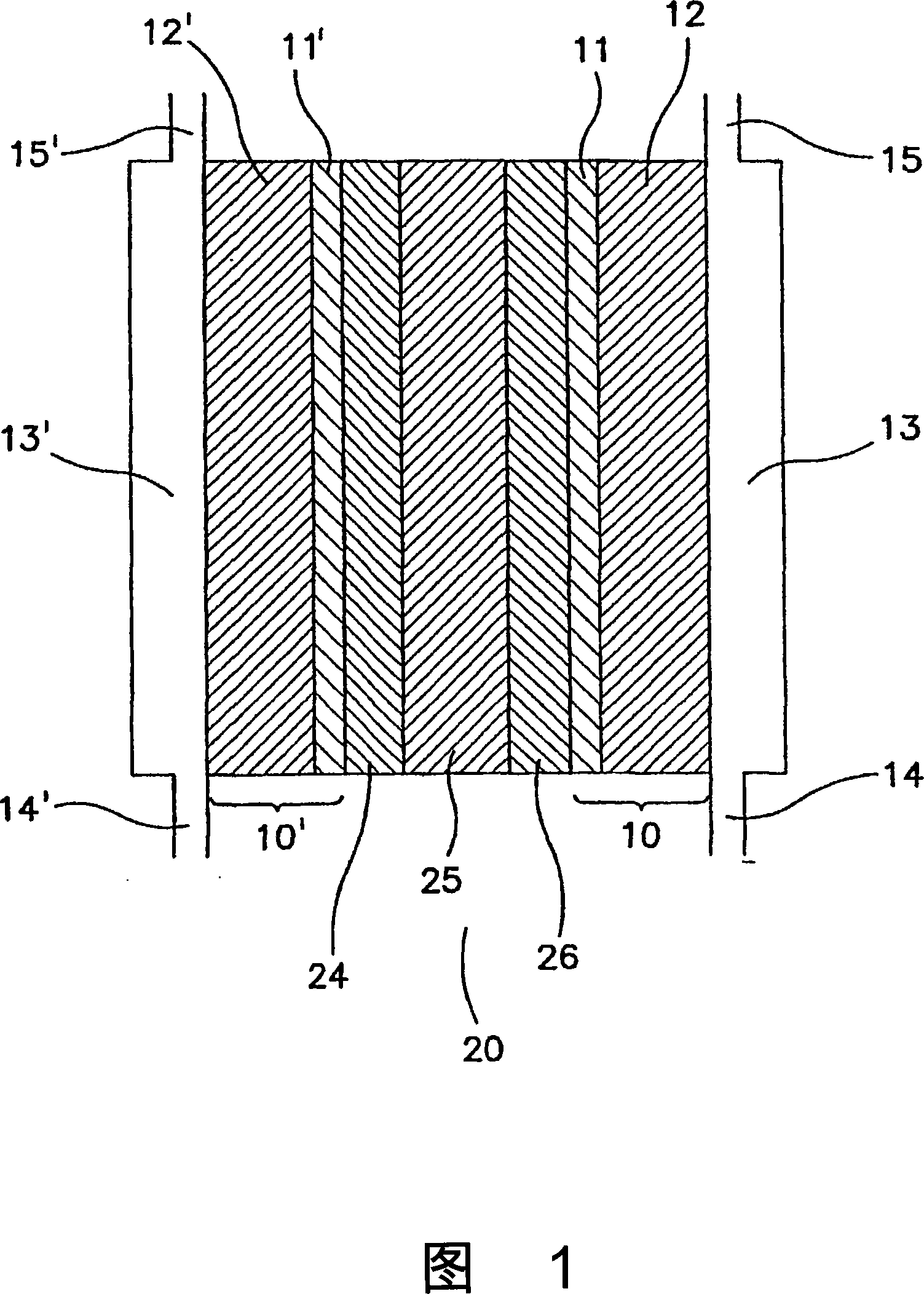

[0033] Description of Membrane Electrode Assembly (MEA)

[0034] Three types of MEAs labeled Type A, Type B and Type C were used in the tests. The Type A MEA was a PRIMEA(R) series 5510 membrane electrode assembly loaded with 0.4 mg / cm2 of Pt on both the anode and cathode sides, commercially available from W. L. Gore & Associates. These MEAs contain a composite diaphragm of GORE-SELECT's ePTFE-reinforced perfluorosulfonic acid ionomer. The Type B MEA is basically the same as the Type A MEA, except that the diaphragm of the Type B MEA is additionally treated before being assembled into the MEA, and the diaphragm is doped with about 550 ppm of Fe. Iron was chosen as a representative of a catalyst capable of enhancing the formation of free radicals from hydrogen peroxide that would accelerate membrane degradation. Specifically, iron was added to the diaphragm used in the preparation of Type A MEA by preparing a 5 PPM iron solution prepared by dissolving 0.034 grams of ferrous s...

Embodiment 1-10

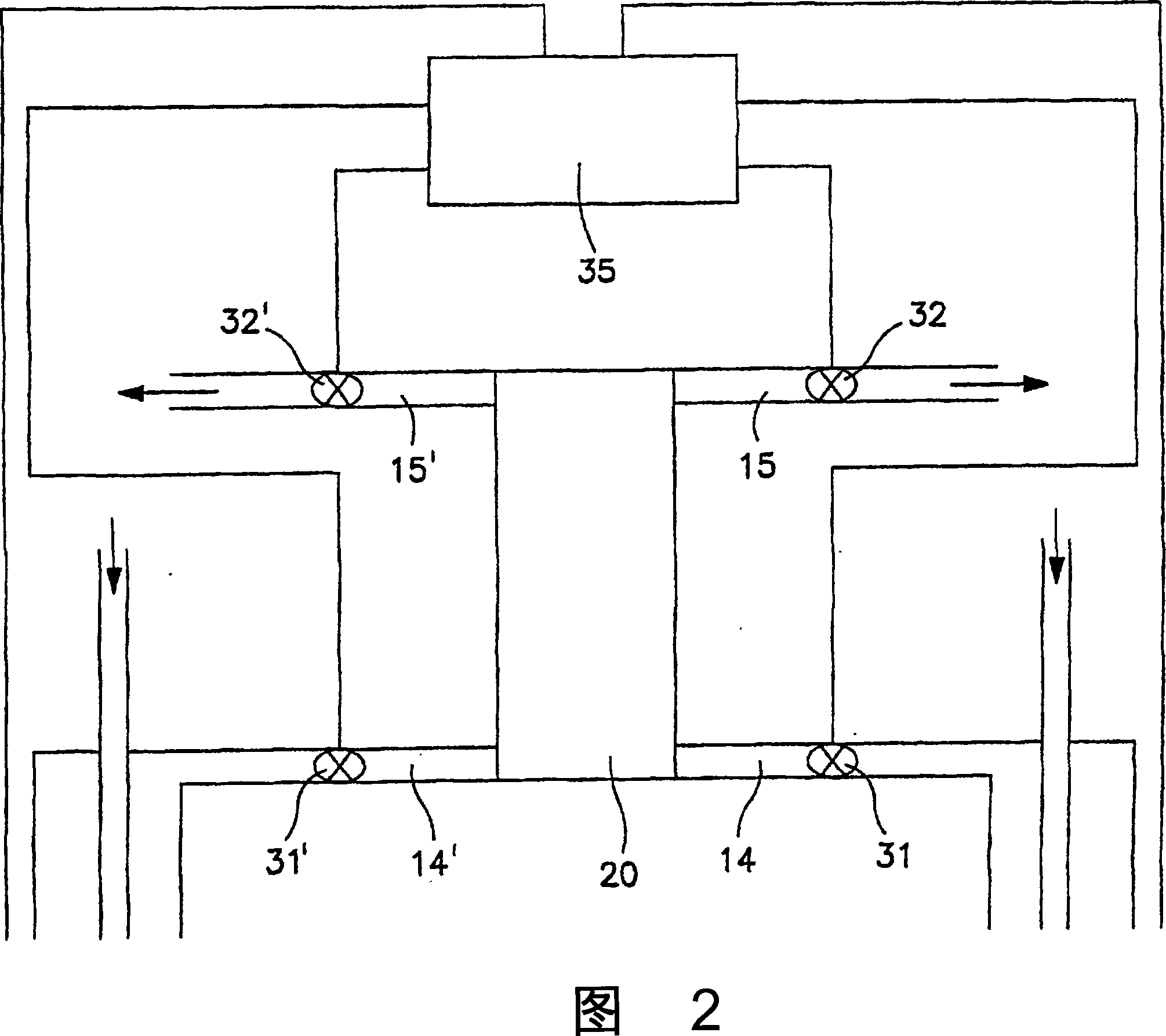

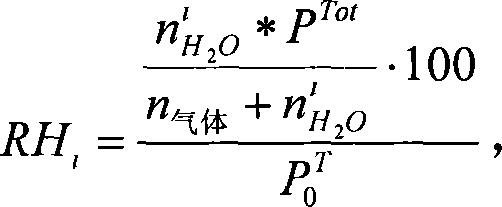

[0088]Assemble the cells and test with the conditions shown in Table 1, the average outlet relative humidity is not fully saturated. The temperature was varied between 80°C and 130°C as indicated in the table, the relative humidity at the anode and cathode inlets was varied and the pressure varied to ensure that the outlet conditions were not fully saturated. In some cases, the stoichiometry of the anode gas hydrogen was adjusted as shown in Table 1 to maintain stable cell performance. As shown in Table 1, tests were performed using three different types of MEAs and either bolt-loaded or spring-loaded batteries. The results of these tests are shown in Table 2. At a given temperature, compared with the comparative examples (Table 2, Examples 2-5 compared with C1-C2), the lifetime is longer, the average decay rate at two different currents is lower, and the fluoride release under the conditions of the present invention The rate is lower. Extended lifetime, low decay rate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com