Apparatus for integrality checking proportion of cryo-current comparator and the method thereof

A current comparator, low temperature technology, applied in the direction of instrument, reference value comparison, current/voltage measurement, etc., can solve problems such as difficult calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

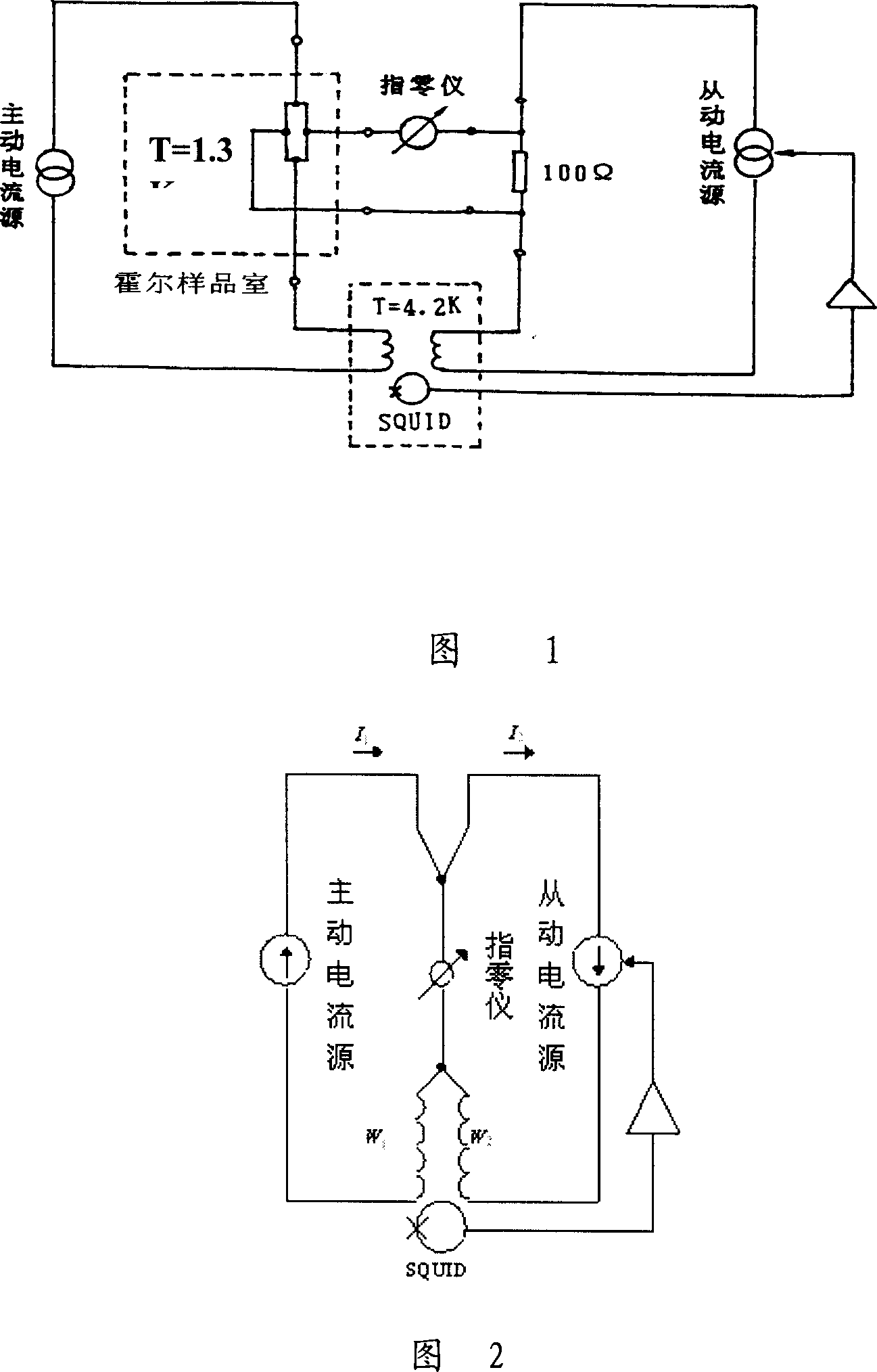

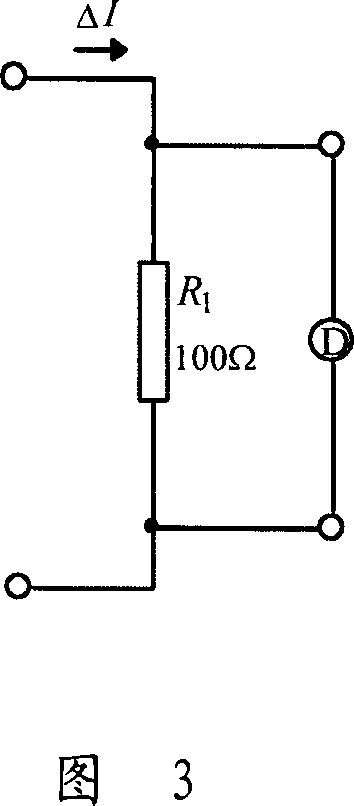

Method used

Image

Examples

Embodiment 1

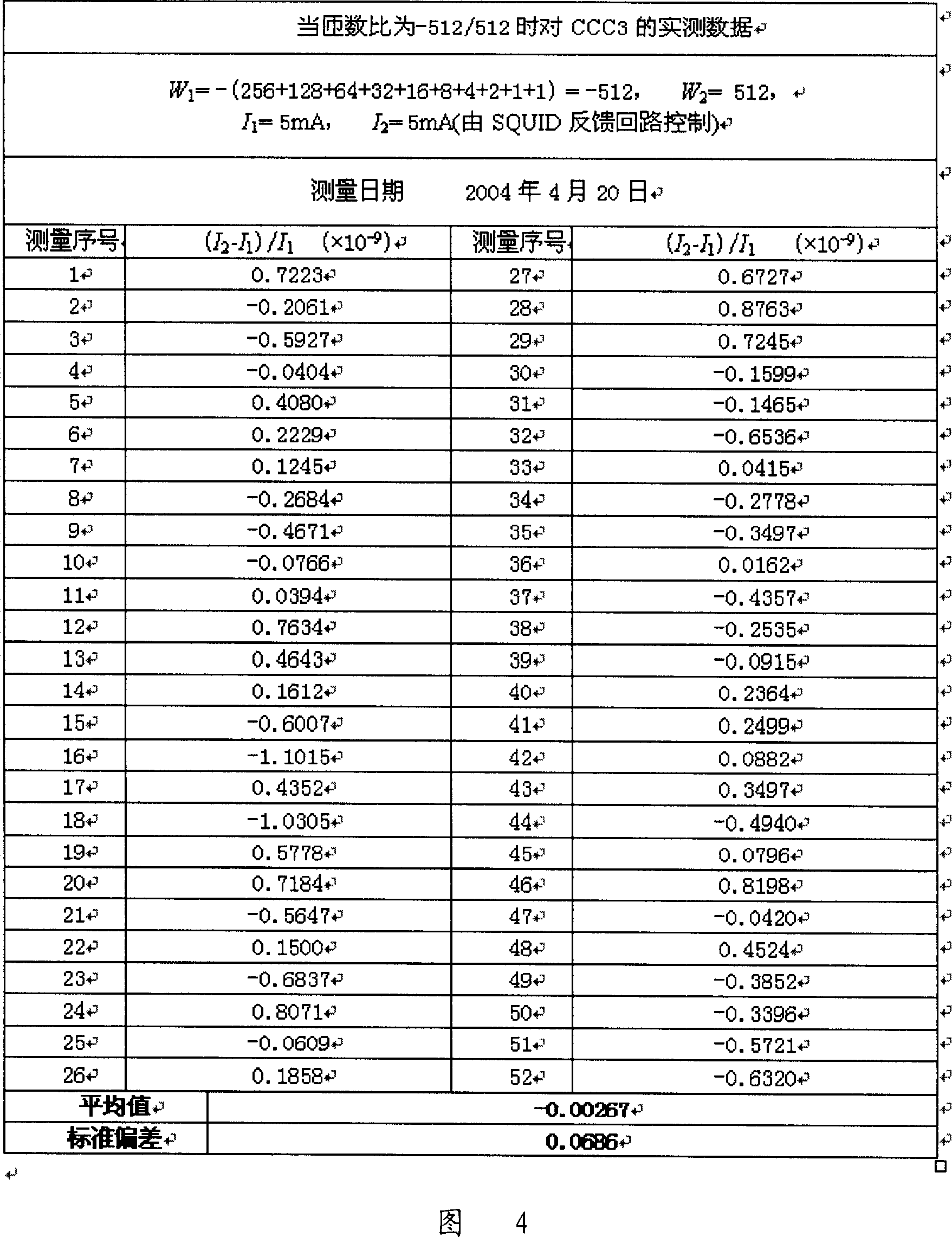

[0052] Figure 4 is the experimental data of the overall calibration of the low temperature current comparator CCC3 according to the method shown in Figure 2. The number of turns of the two proportional windings of the low temperature current comparator is 512. Since the current directions in the two windings are opposite, the actual ratio is -512 / 512. -512 / 512 is the limit situation that the inventor's research group can achieve when performing overall calibration. such as W 1 and W 2 Exceeding 512, the slave current source in Fig. 1 may appear current jump phenomenon. It should be noted that in articles published abroad, W 2 Generally only 16 turns, in some cases 31 turns are useful. W 2 No matter how big it is, the current jump phenomenon will appear. Since the inventor has better solved the difficulty that the operating current will jump when the number of ampere turns is large, the overall calibration is performed under the turns ratio of -512 / 512. It can be seen f...

Embodiment 2

[0054] 16133 / 125 is the turn ratio used by the inventor when comparing the quantized Hall resistance with 100Ω. The data in Figure 5 shows the actual measurement data for the overall calibration of CCC3 when the number of ampere turns is the same as this. The low temperature current The number of turns of the two proportional windings of the comparator is 125. The type A uncertainty of the 52 sets of data is 1.9×10 -10 (k=1), no systematic deviations were seen in the proportional values across the range of data scatter. Compared with the data in Figure 4, due to the smaller number of ampere-turns, the data dispersion is correspondingly larger.

Embodiment 3

[0056] When the inventor uses CCC3 to compare the quantized Hall resistance with 100Ω, sometimes he also adopts the turns ratio of -10067 / 78. The data in the accompanying drawing 6 shows the actual measurement data of the overall calibration when the number of ampere turns is the same. The number of turns of the two proportional windings of the cryogenic current comparator is 78. The type A uncertainty of the 52 sets of data is 3.3×10 -10 (k=1), no systematic deviations were seen in the proportional values across the range of data scatter. Compared with the data in Figure 5, because the ampere-turns are much smaller, the data dispersion becomes larger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com