Branch duct mixer

A technology of mixers and branch pipes, which is applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of influence, poor quality and yield of semi-coke and coal tar, and the inability to achieve uniform heating of coal, etc., to achieve heating The effect of gas uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

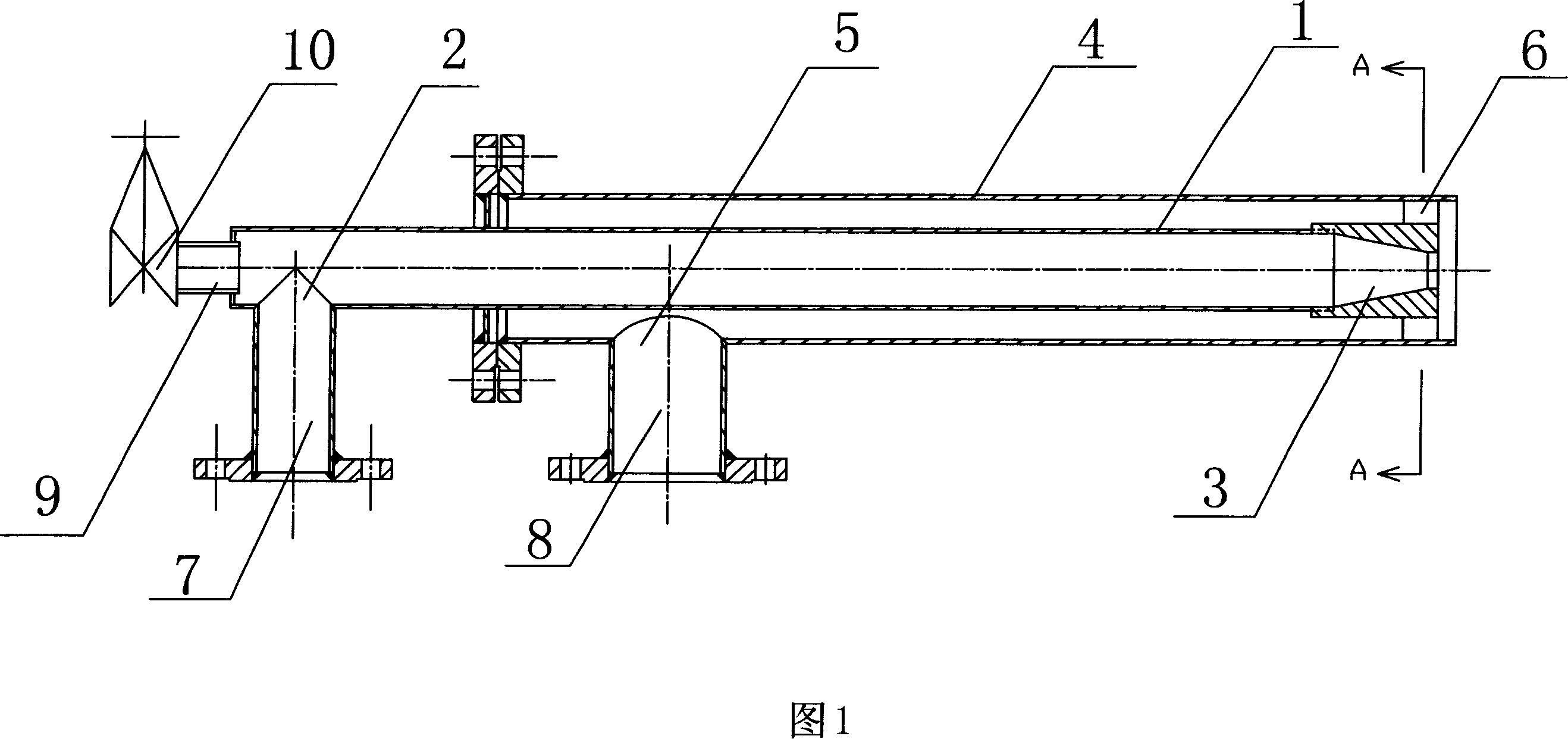

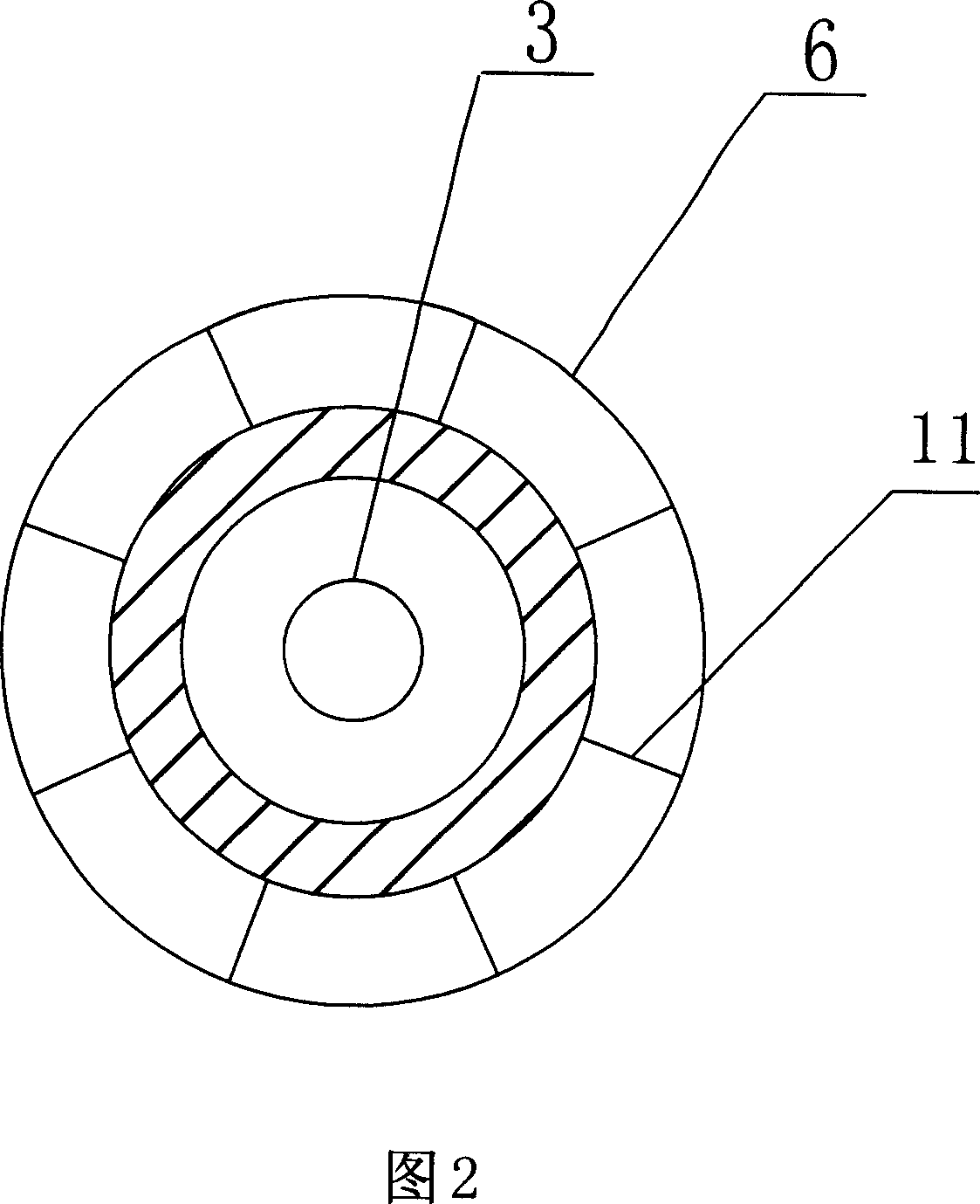

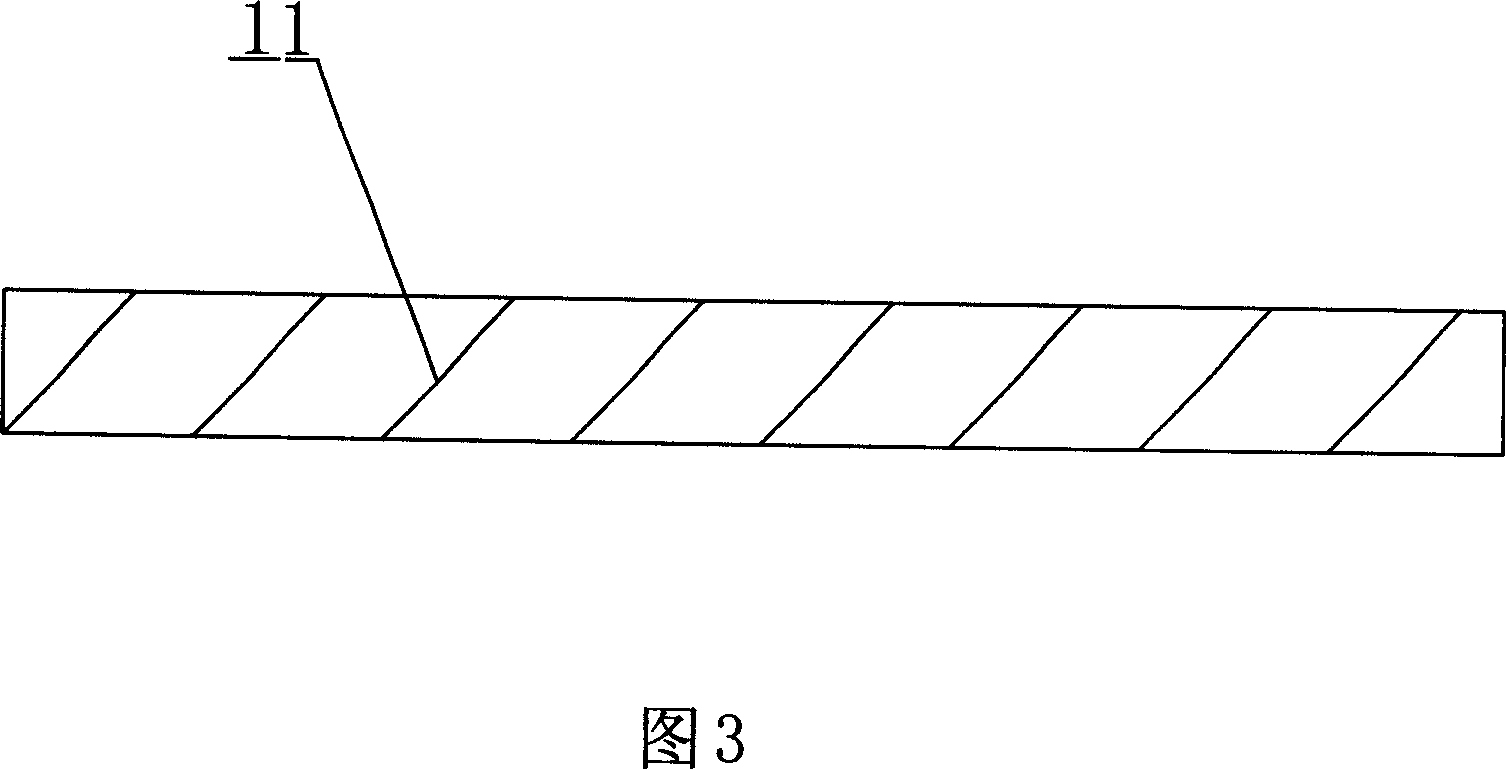

[0014] As shown in Figure 1, a branch pipe mixer includes an inner pipe 1, an inner pipe interface 2, an inner pipe nozzle 3, an outer pipe 4, an outer pipe interface 5, an outer pipe nozzle 6, an air main pipe interface pipe 7, and a gas main pipe interface Pipe 8, peephole 9 and ball valve 10, wherein the outer pipe 4 is set outside the inner pipe 1 to form a double-layer steel pipe structure, one end of the inner pipe 1 is the inner pipe nozzle 3, and the inner pipe nozzle 3 is a variable diameter structure welded to the inner pipe 1 front end, the caliber of the connection between the variable diameter structure and the inner tube 1 is larger than the caliber of the spout, and the other end is connected with a peep hole 9, and the end of the outer tube 4 corresponding to the inner t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com