Laser processing system and method

A technology of laser processing and laser beams, which is applied in the direction of lasers, laser welding equipment, laser parts, etc., can solve the problems of low processing accuracy, changes in focus spot size, and high processing accuracy requirements, and achieve the effect of high-precision laser processing

Inactive Publication Date: 2010-11-10

HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, 3C products such as computers, communications, and consumer electronics require high processing precision, and most of their shape and structure designs are relatively complicated. During the process of moving the workpiece horizontally for laser processing, the irregular shape structure on the surface of the workpiece For example, protrusions or depressions will change the distance between it and the lens. Since the focal length of the converging lens is fixed, it will cause the size of the focused spot irradiated on the workpiece to be processed to change, resulting in low processing accuracy.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

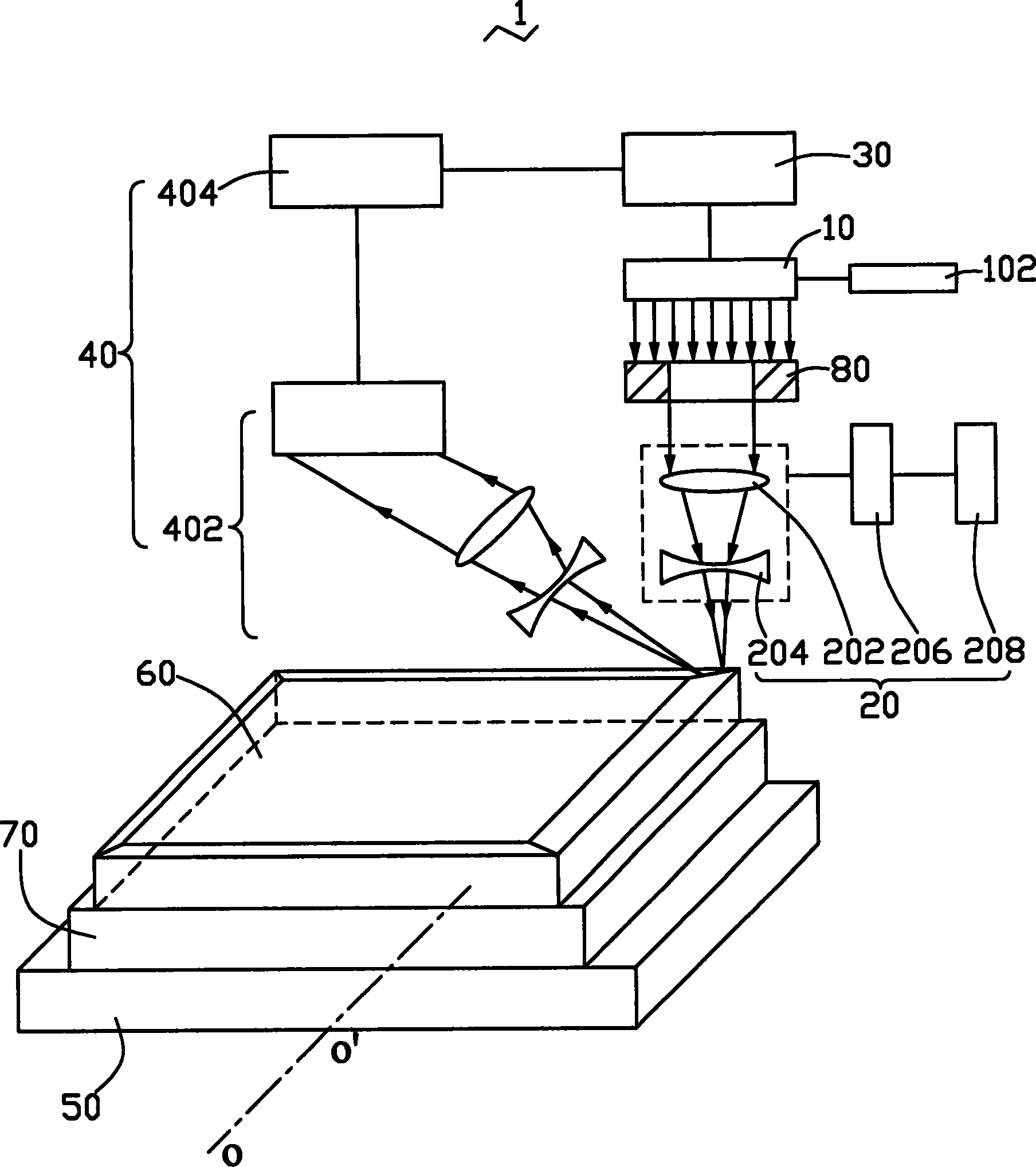

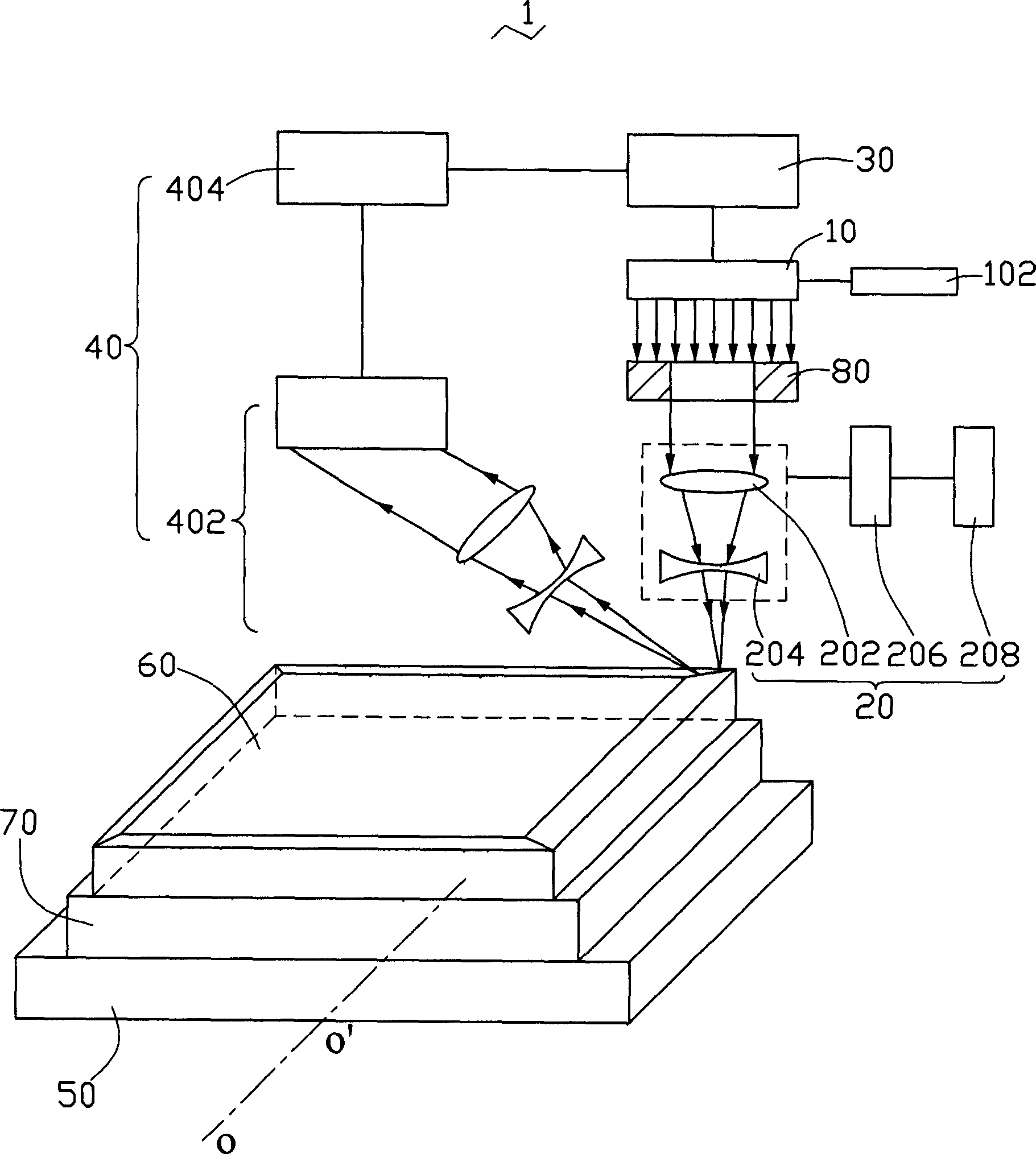

The invention relates to a laser processing system, which comprises a laser for generating laser beam, a variable-focus lens device for focusing said laser beam to the target part of work piece, a controller for controlling the working parameters of laser, and a feedback device for feeding back information which can detect and treat the information of target part and feedback said information to the lens device and controller, to adjust the focus and optimize the working parameters of laser. Said system can keep the light spot on the target part at preset size, to realize treatment accurately. And the invention also provides relative method.

Description

A laser processing system and processing method 【Technical field】 The invention relates to a material processing system and a processing method, in particular to a laser processing system and a processing method for high-precision processing of materials. 【Background technique】 With the continuous development of the 3C (computer, communication and consumer electronics) industry, it is becoming more and more important to realize high-precision processing of 3C products. At present, the frame parts of 3C products are often processed by stamping. Stamping, that is, to apply pressure or tension to the sheet through the die to form a shear force to remove the excess part of the sheet and shape the sheet to obtain a product with a certain size, shape and performance. However, since the excess part of the separated plate cannot be used again, it will become a waste material, thereby causing a waste of raw materials and resulting in higher processing costs. The laser processin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K26/00B23K26/04B23K26/06B23K26/42B23K26/08H01S3/10B23K26/046B23K26/064B23K26/70

Inventor 陈杰良

Owner HONG FU JIN PRECISION IND (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com