Preparation process of rigid-flex board with laser blind holes

A soft-rigid combination board and preparation technology, which is applied in multi-layer circuit manufacturing, printed circuit manufacturing, electrical components, etc., can solve the problems of difficult production, many materials and manpower, and various production processes, so as to improve efficiency and precision, The effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation process of a rigid-flex board with laser blind holes provided by the present invention comprises the following steps:

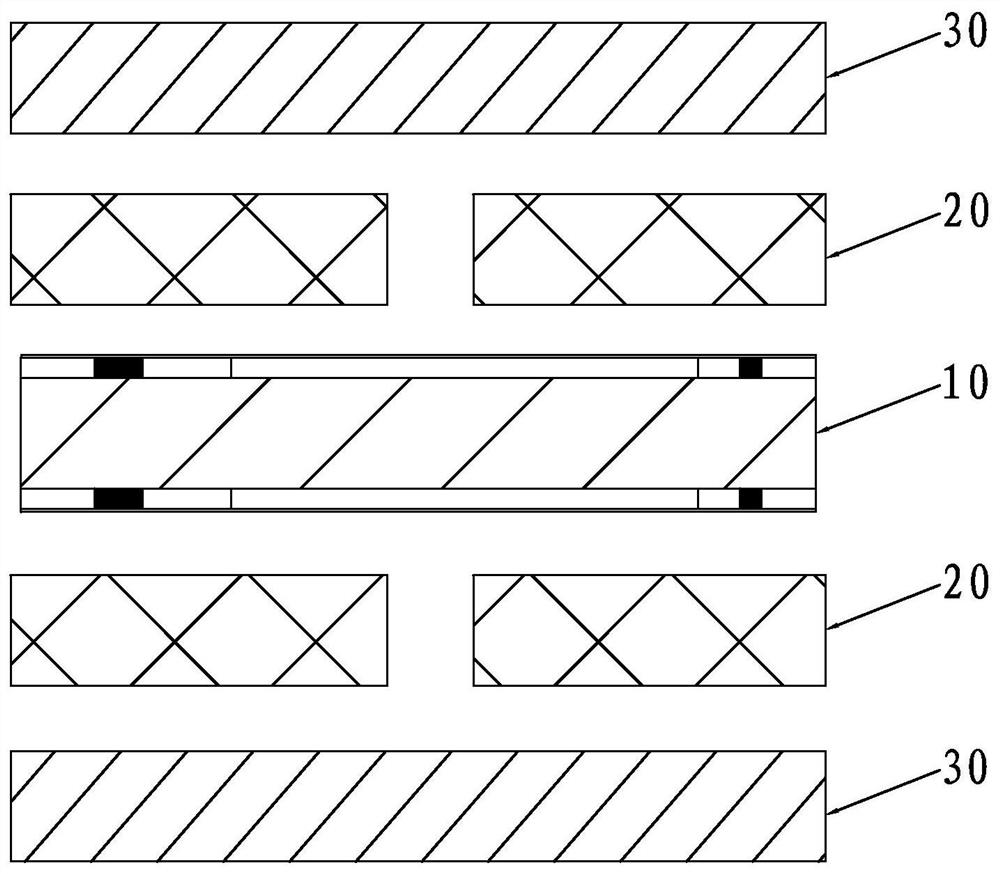

[0025] S1. Provide the flexible board 10 as the inner layer, and pre-make the circuit on the flexible board 10 and paste the cover film; provide the PP board 20 as the interlayer, and laser out the relief holes, openings and positioning holes on the PP board 20 , and, drilling and punching openings on the PP board 20; providing the copper foil 30 as the outer circuit, and drilling a relief hole and a positioning hole on the copper foil 30;

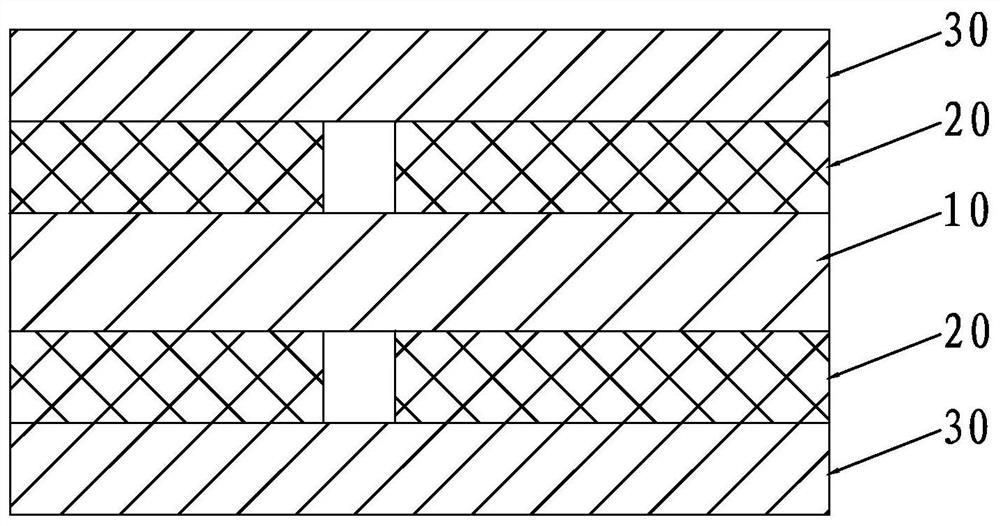

[0026] S2. Based on step S1, copper foil 30, PP board 20, soft board 10, PP board 20 and copper foil 30 are figure 1 The sequence shown is stacked sequentially and then pressure-transmitted and stacked, such as figure 2 shown;

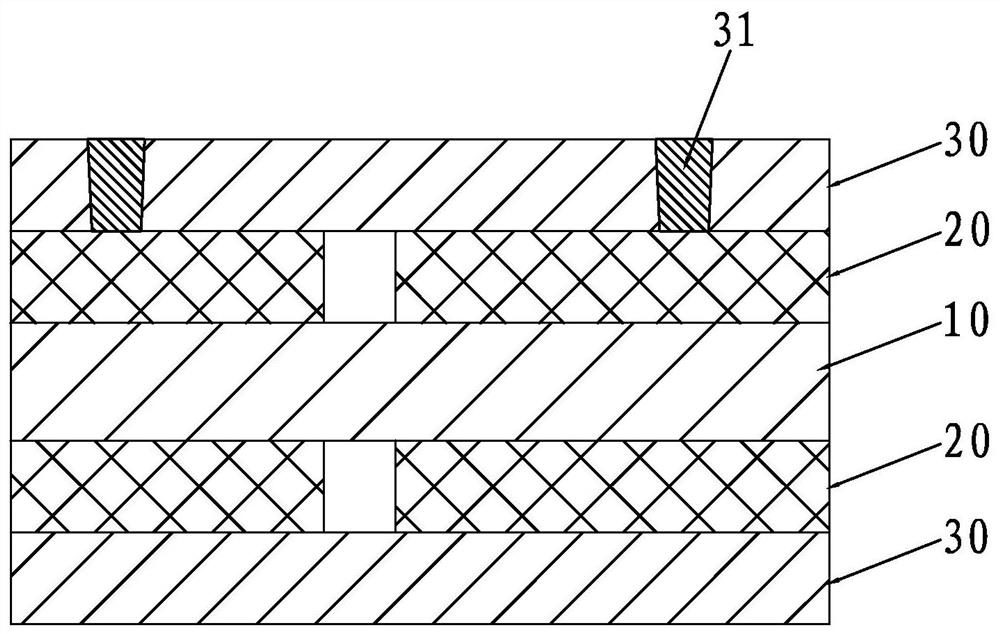

[0027] S3. Based on step S2, using the optical point of the inner flexible board 10 as a reference point, the pure copper laser is burned off by laser at the position whe...

Embodiment 2

[0031] Based on Example 1, in this Example 2, in step S3, the double-sided copper foil 30 is simultaneously laser-processed to form a primary blind hole 31; and in step S4, the double-sided PP board 20 is simultaneously laser-processed to form a secondary Blind hole 21.

[0032] The present invention uses a laser method to burn off the pure copper that needs laser blind holes to replace the traditional etching and window opening method in which copper is etched away at the blind holes. It has a short process flow, can effectively reduce costs and laser processing The advantages of high precision greatly improve the efficiency and precision of blind hole processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com