Laser machining device, laser machining method, and thin sheet machined using same

A laser processing method and laser processing technology, applied to laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of laser beam blur, processing speed limit, and difficulty in forming through holes, etc., to achieve uniform power density and increase Processing speed, the effect of shortening the focal length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

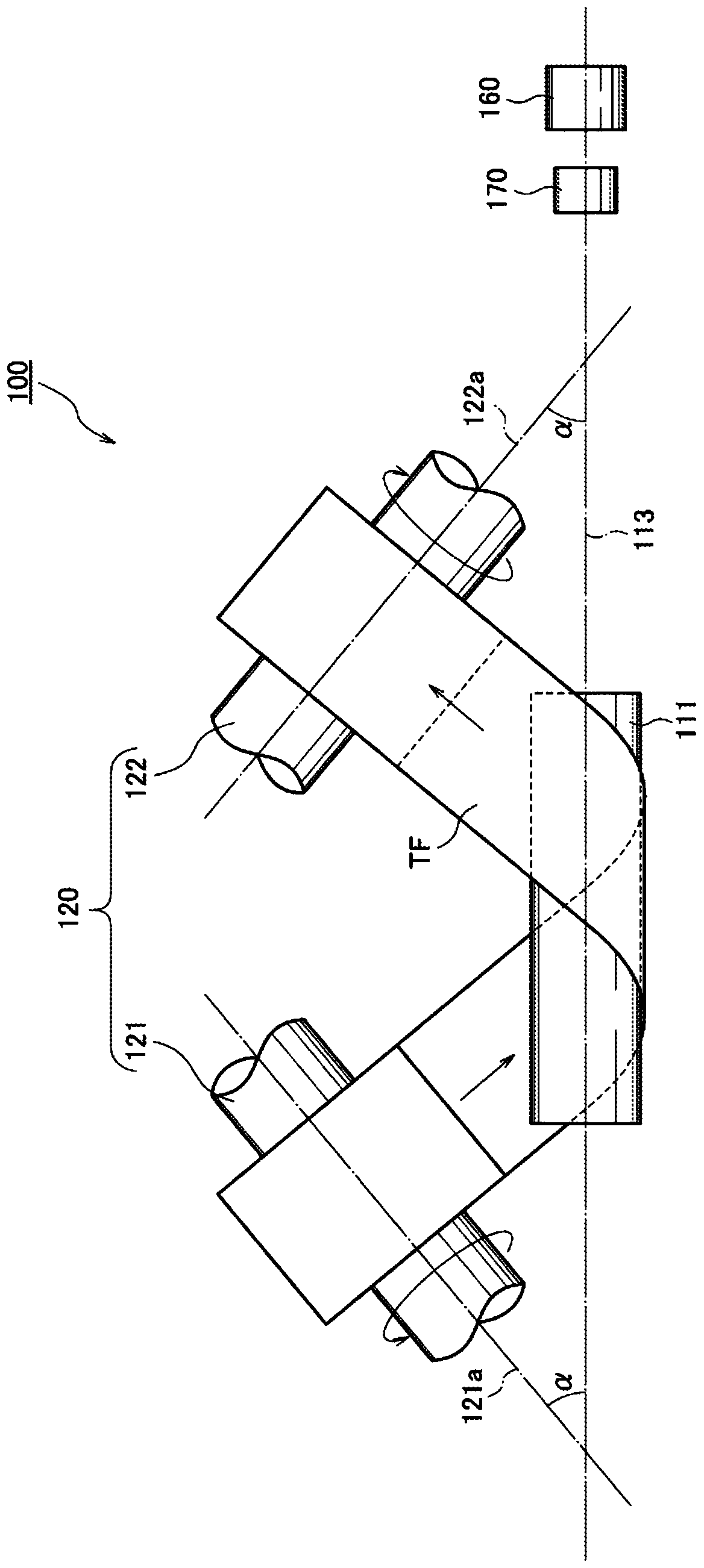

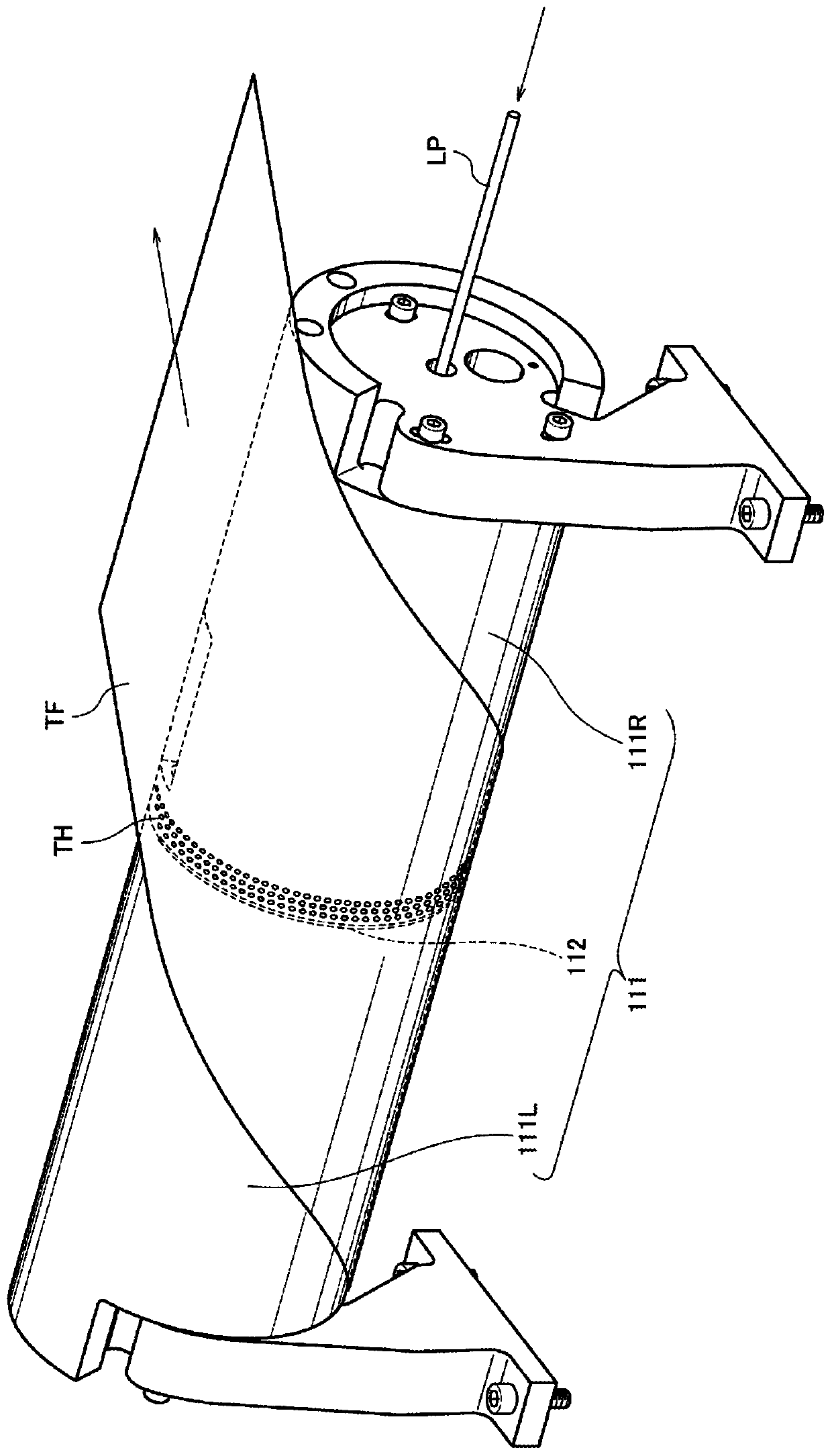

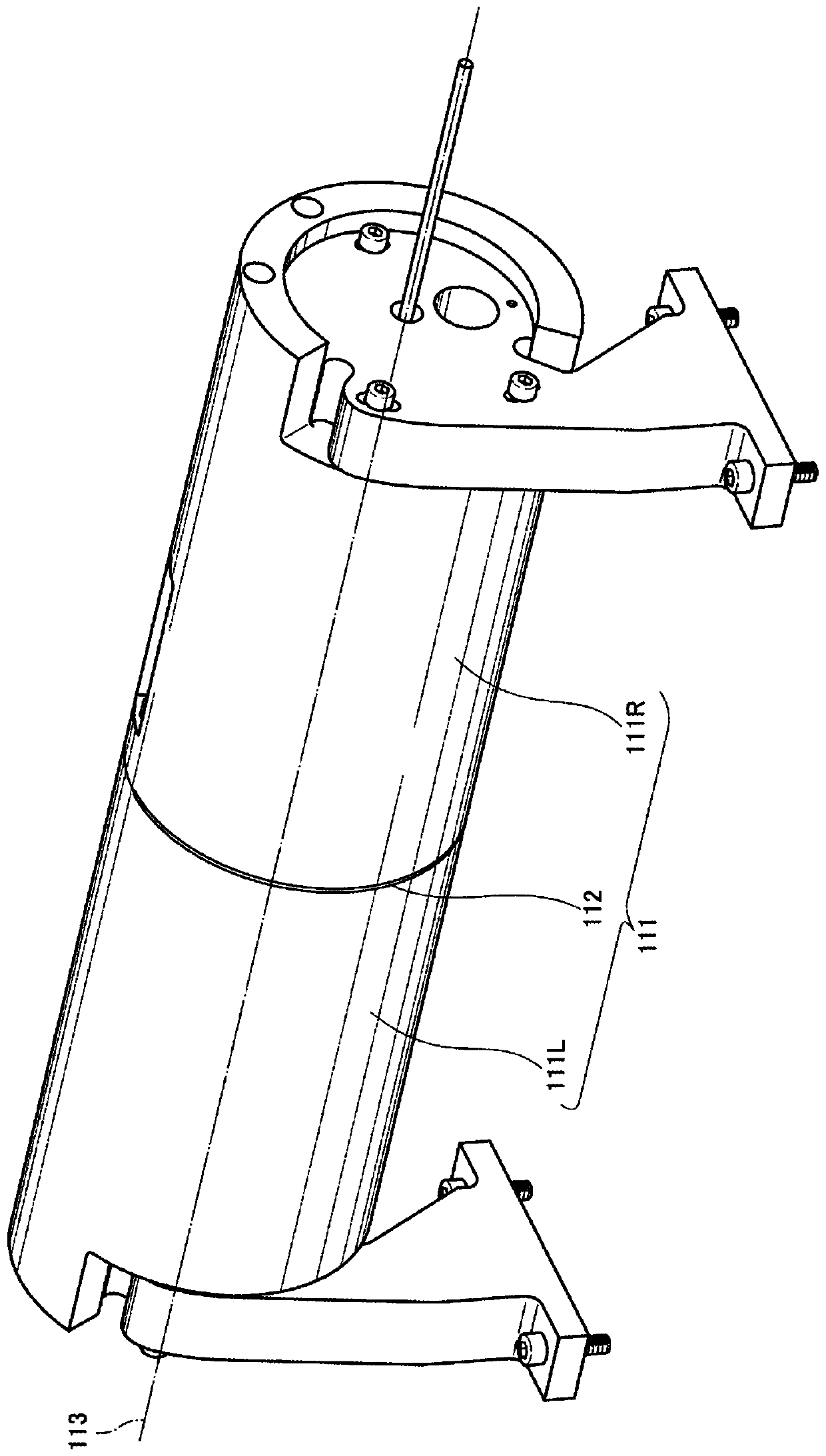

[0127] The laser processing device of the first embodiment of the present invention, together with the laser processing method and the long thin plate after laser processing, is based on Figure 1 to Figure 6 Be explained.

[0128] here, figure 1 is a schematic diagram of the laser processing device of the first embodiment of the present invention, figure 2 is a diagram showing the relationship between the cylindrical body and the thin plate in the first embodiment of the present invention, image 3 It is a figure which shows the appearance of the cylindrical body of the 1st Example of this invention, Figure 4 It is a figure which shows the structure of the opening part of the cylindrical body of the 1st Example of this invention, Figure 5 is a diagram showing the arrangement of reflective members according to the first embodiment of the present invention, Figure 6 It is a figure which shows the route and irradiation range of the pulsed light of the laser processing ap...

Embodiment 2

[0157] Next, with regard to the laser processing device of the second embodiment of the present invention, together with the laser processing method and the long thin plate after laser processing, based on Figure 7 ~ Figure 10 Be explained.

[0158] here, Figure 7 is a diagram showing the relationship between the cylindrical body and the thin plate in the second embodiment of the present invention, Figure 8 It is a figure which shows the appearance of the cylindrical body of the 2nd Example of this invention, Figure 9 It is a figure which shows the structure of the opening part of the cylindrical body of the 2nd Example of this invention, Figure 10 It is a figure which shows the other structure of the opening part of the cylindrical body of 2nd Example of this invention.

[0159] In addition, regarding the configuration of devices other than the slit fitting 214, the inner slit 215, the roller engaging bolt 216, the roller engaging pin 217, and the inspection window 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com