Laser processing device, positioning device; observing device and observing method

An observation device and laser processing technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of unstable segmentation position determination accuracy and uneven transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0054]

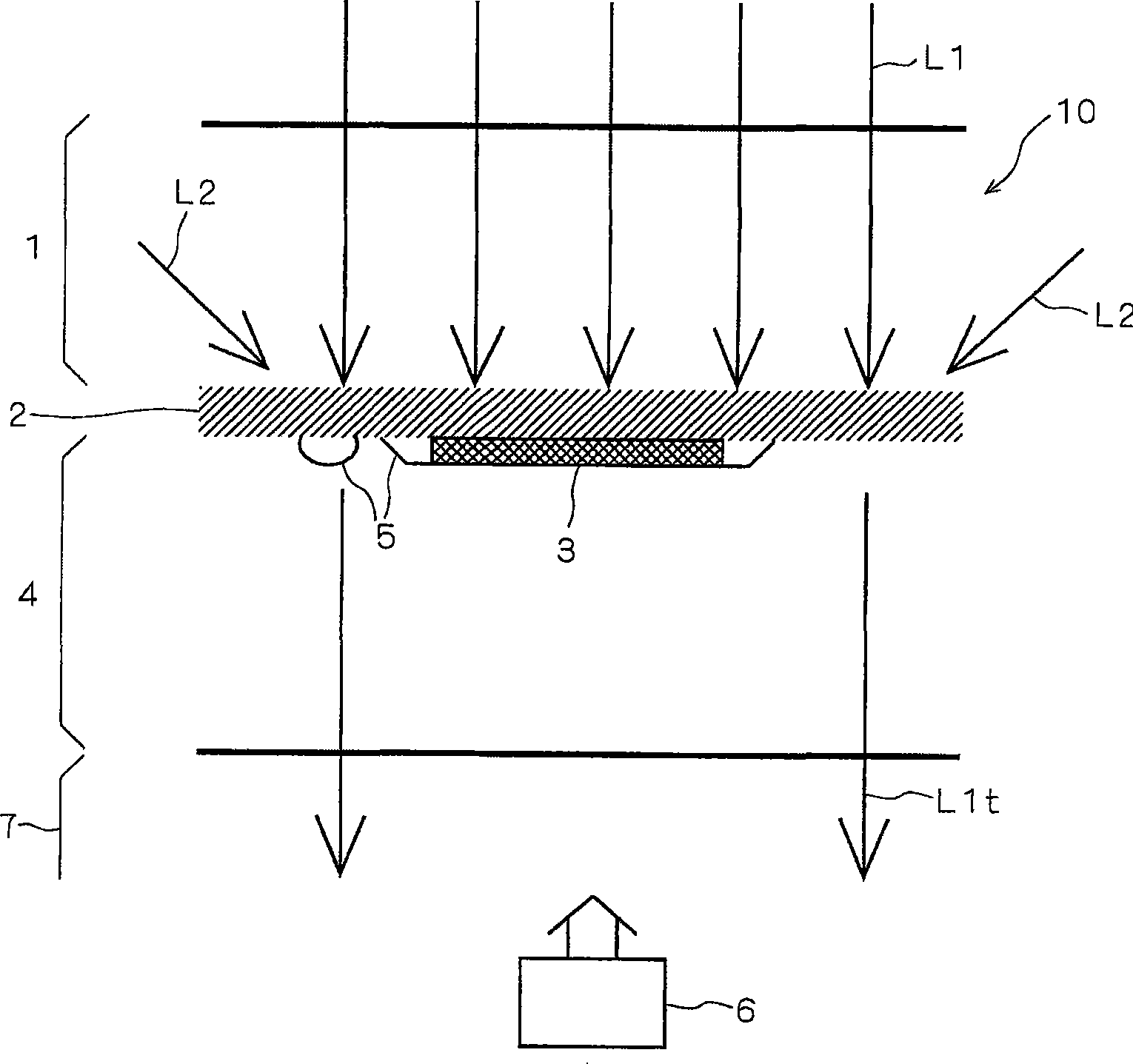

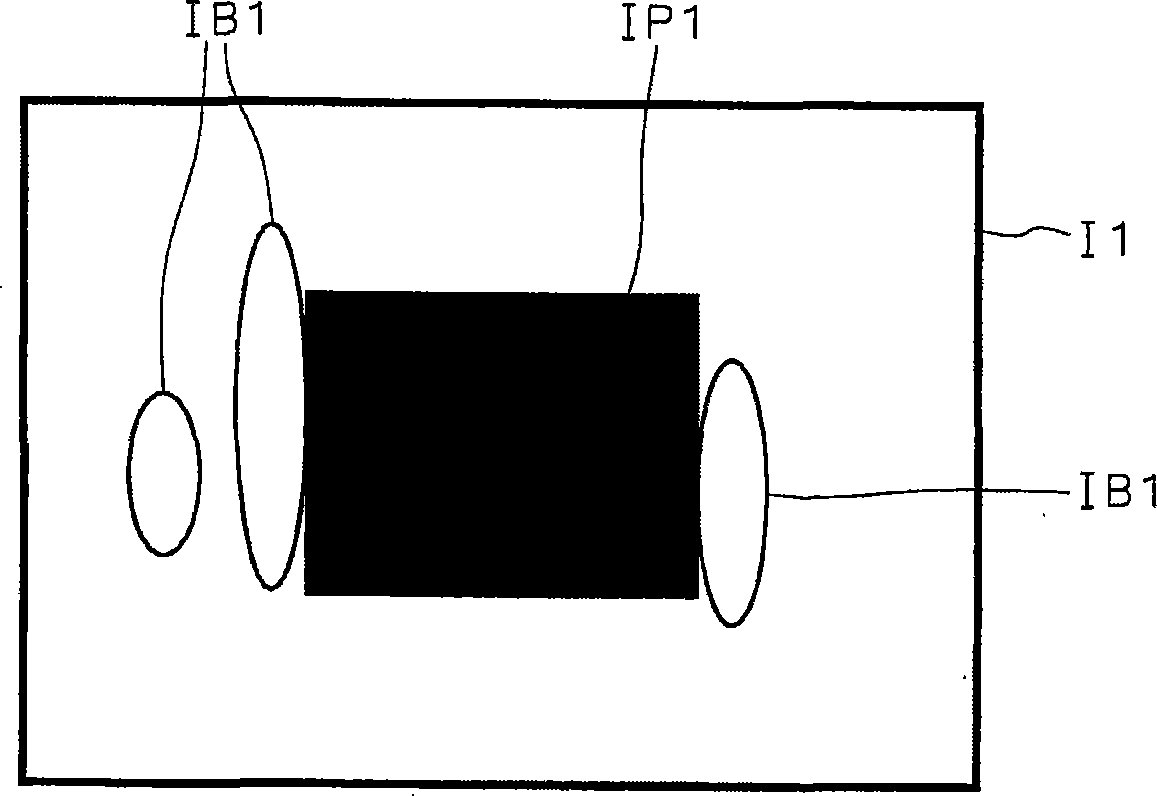

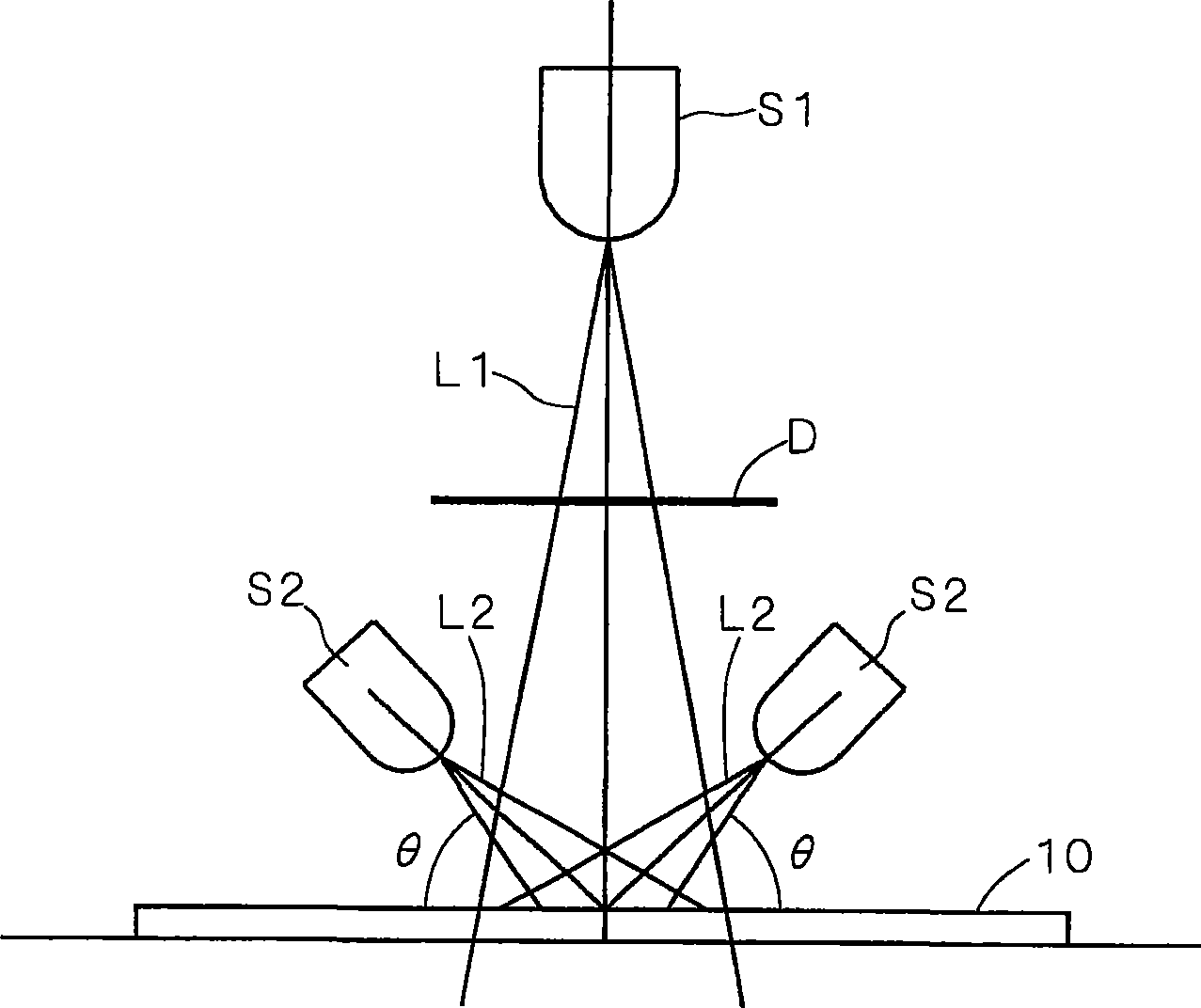

[0055] Figure 1A , Figure 1B It is used to describe the observation method of the first embodiment of the present invention. In this embodiment, the observation objects are as Figure 1A Shown is a laminate 10 in which a diffusion layer 2 for diffusing illumination light for observation is provided as a base layer on one main surface of a transparent substrate 1 such as sapphire, and an opaque device pattern 3 such as metal wiring and electrodes is formed. , as an example.

[0056] Alternatively, a transparent semiconductor layer made of a Group III nitride such as GaN (gallium nitride) may be provided between the transparent substrate 1 and the device pattern 3 .

[0057] In addition, in this embodiment, if Figure 1A As shown, an adhesive sheet 4 is pasted on the main surface of the laminated body 10 on which the device pattern 3 is formed, and the adhesive sheet 4 side is fixed to a transparent carrier 7 made of, for example, quartz to perform device patter...

no. 2 approach

[0088] In the above-mentioned embodiment, the case where the laminated body 10 is observed in a state where, for example, the back surface observation unit 50B of the laser processing apparatus 50 is simultaneously irradiated with the coaxial illumination light L1 having an incident angle of 90 degrees and the incident angle This is the case of oblique illumination light L2 at an acute angle, but of course the observation method is not limited to this.

[0089] FIG. 4 is a schematic configuration diagram schematically showing a laser processing apparatus 500 according to a second embodiment. In addition, the same reference numerals are assigned to the same configurations as those of the laser processing apparatus 50 of the first embodiment, and explanations thereof are appropriately omitted.

[0090] The laser processing apparatus 500 is equipped with the control part C comprised from an ordinary computer etc.. As shown in FIG. The control unit C is connected to each mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com